多功能沥青路面养护车的结构设计

多功能沥青路面养护车的液压系统设计【优秀】【word+9张CAD图纸全套】【液压系统类】【毕业设计】

【带任务书+鉴定意见+评阅表+外文翻译】【22页@正文13300字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

中期检查表 2.doc

任务书.doc

图纸

多功能沥青路面养护车的结构设计正文.docx

开题报告.doc

评阅表.doc

鉴定意见.doc

湘 潭 大 学

毕业论文(设计)任务书

论文(设计)题目: 多功能沥青路面养护车的结构设计

一、主要内容及基本要求

查阅相关文献资料,掌握多功能沥青路面养护车的国内外发展动态,完成多功能沥青路面养护车的结构和动力系统的相关设计。

要求:

1、查阅相关资料,掌握沥青路面综合养护车的结构和工作原理,以及相关知识和科学研究动态;

2、设计多功能沥青路面养护车液压控制系统

3、设计一款路面养护车的凿槽机构

3、2张A0图纸;

4、撰写毕业设计说明书。

5、相关外文文献翻译,字数3000字以上。

二、重点研究的问题

多功能沥青路面养护车的液压控制系统和凿槽机构的设计

三、进度安排

序号各阶段完成的内容完成时间

1查阅资料、调研第1-2周

2开题报告、制订设计方案第3周

3方案(设计)第4-5周

4设计多功能沥青路面养护车液压控制系统、凿槽机构第6-7周

5写出初稿,中期检查第8-9周

6修改,写出第二稿第10-11周

7写出正式稿第12-13周

8答辩第14周

四、应收集的资料及主要参考文献

LLY500型多功能沥青路面养护车[J].建筑机械(下半月),2011.

王宜登,林伟.浅谈我国公路养护设备的发展方向[C].//第八届河南省汽车工程科技学 术研讨会论文集.2012.

长安大学.一种高海拔低温地区沥青路面快速多功能养护车:中国.2013.

查官飞,于勇,邓久军等.新型沥青路面养护车的稳定性设计分析[J].专用汽车,2010.

目录

摘要3

第1章 绪论5

1项目研究的背景和意义5

2国内外研究现状7

第2章 任务特点9

第3章 方案设计10

3.1 机械手的设计要求10

3.2 机械手的整体设计方案10

3.3机械手的手臂结构方案设计11

3.4机械手的驱动方案设计11

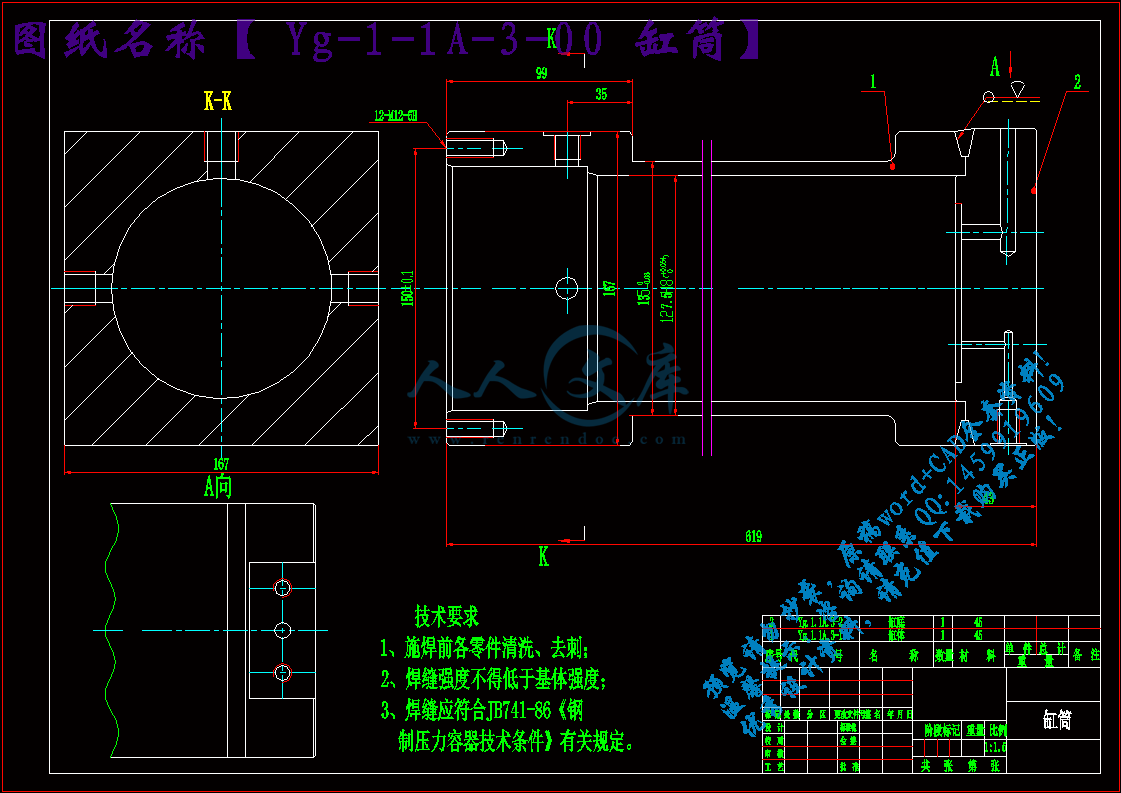

第4章 前后方向的液压缸设计12

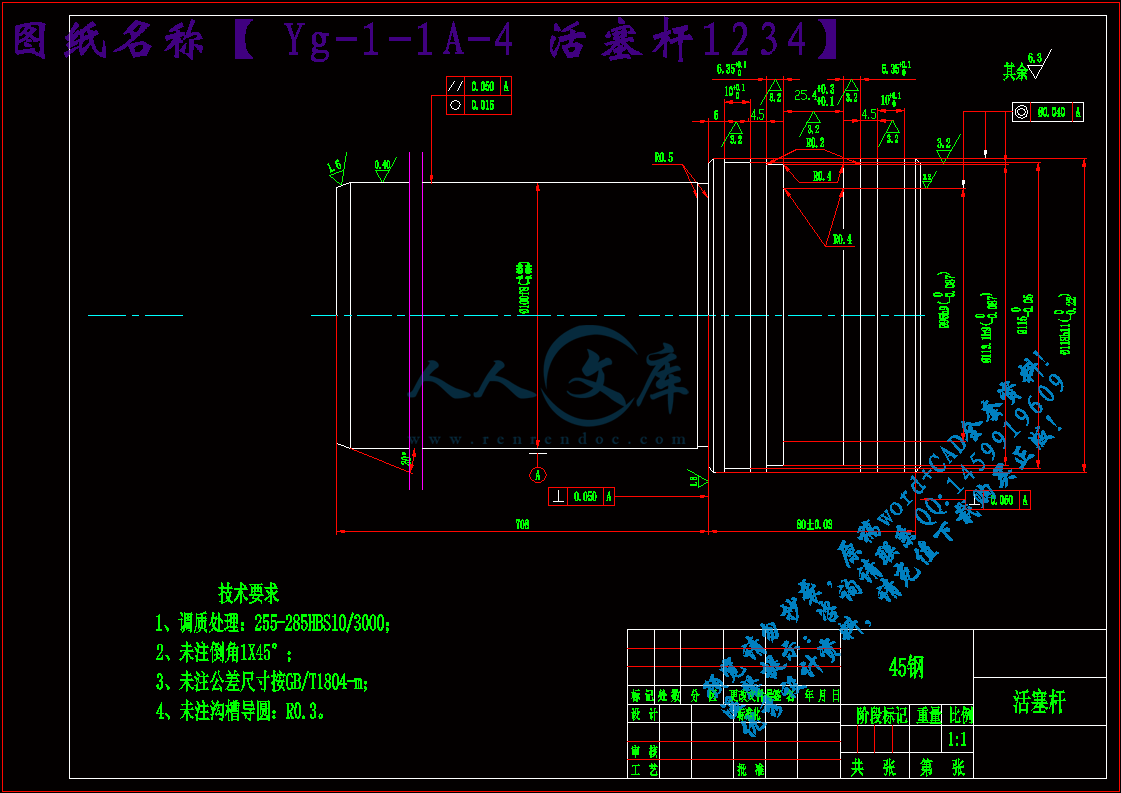

4.1手臂伸缩液压缸的尺寸设计与校核12

4.2 液压缸的密封设计14

4.3 支承导向的设计15

4.4 防尘圈的设计15

4.5 液压缸材料的选用16

第5章 左右方向液压缸设计17

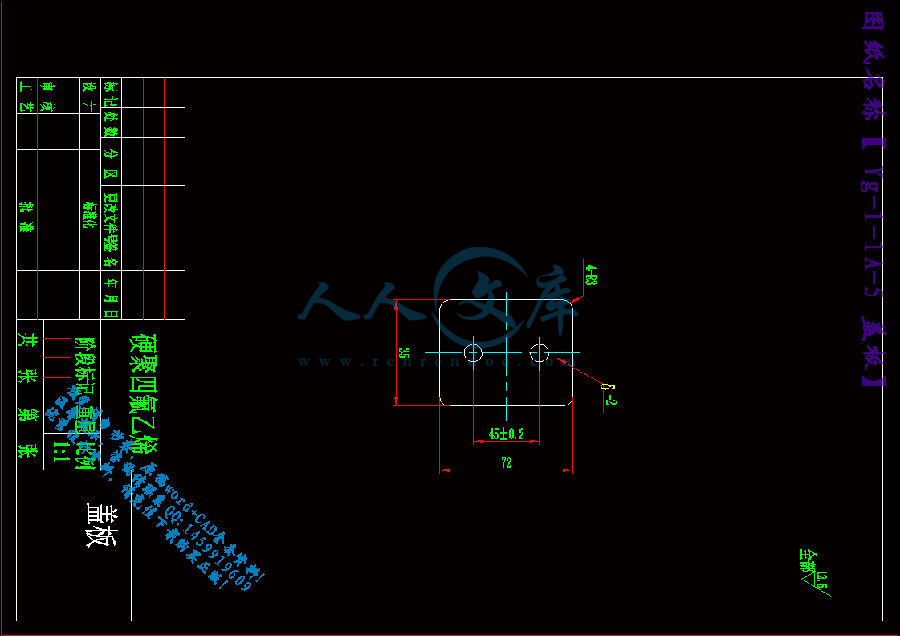

5.1 液压缸主要尺寸的确定17

5.2:液压缸的密封设计19

5.3、支承导向的设计20

5.4:防尘圈的设计20

5.5:液压缸材料的选用20

第6章 连接螺栓设计和校核21

6.1连接方式的选择21

6.2连接处的载荷及其强度校核与设计21

总结22

致谢22

参考文献23

多功能沥青路面养护车的结构设计

摘要:自改革开放以来, 我国主要发展经济, 加大了对公路等基础设施建设的投资的力度, 公路交通事业经过了20 多年的快速发展,国家“ 十二五” 规划预计的公路总里程将达450 万公里, 高速公路通车的总里程将达到了11万公里.近年来国家对公路养护的节能减排工作高相当重视, 国家对公路建养越来越重视, 在《公路水路交通中长期科技发展规划纲要2006 一2020)、《公路水路交通运输“ 十二五” 科技发展规划》、《产业结构调整指导目录(2011年本) 》中都做出了重要规划, 并制定了与之配套的大力的科技投入、税收鼓励、金融支持、研发能力及其他方面的政策支持。 在交通物流行业快速发展的今天, 为减少因公路养护维修造成交通的拥堵和不便, 给公路养护维修技术提出了更苛刻要求, 公路养护专用车因其快速、灵活机动的特性, 大量的广泛的应用在公路养护维修中。

公路的养护车是一种用在沥青公路路面的养护机械设备.该车的凿槽机构是用于将需要修复的路面进行破坏的结构。现在,无论国产还是进口养护车具有凿槽功能的绝大多采用的是人工手持风镐、液压镐或电镐,对操作工人来说重量重且冲击力大,很不利于广大工人的身心健康。并且,由于人工手持只能用小型冲击镐,凿槽的冲击力很不足且无法连续作业,效率很低,同时边线也不能凿直。

使用此凿槽机械手的优势有:此凿槽机构工作的时候比传统的人工手持风镐、液压镐或电镐要效率高。速度快、定位准确、边线整齐同时深度一致,并且是由液压系统和电控系统控制,大大的提高了工作效率,并为用电脑进行全自动控制留下了技术空间.

通过液压传动和电气控制的结合,用来驱动大功率液压镐,同时使其实现了5个自由度的手动和半自动的凿槽作业。

关键词:多功能沥青路面养护车 凿槽机构 机械手 液压传动

Structure design of multi function asphalt pavement maintenance truck

Abstract: Since the reform and opening up, China's economic development, the highway infrastructure construction investment, the highway after 20 years of rapid development, the national "Twelfth Five Year Plan" is expected to total highway mileage will reach 4500000 km, highway traffic mileage will reach 110000 km. In recent years, energy saving and emission reduction work to highway maintenance the state attaches great importance to the national construction and maintenance, more attention to the highway, waterway transportation in the "medium and long term science and technology development plan of highway 2006 a 2020)," highway and waterway transportation "1025" science and technology development plan "," adjustment of industrial structure to guide catalog (2011 version) "have made important planning, and to develop and supporting science and technology investment, tax incentives, financial support, research and development ability and other aspects of policy support. In the development of the transport and logistics industry growing today, in order to reduce the highway maintenance repair caused traffic congestion and inconvenience to road maintenance, repair technology demanding more, road maintenance vehicle based on the characteristics of fast, flexible, a widely used in highway maintenance and repair.

Chisel groove mechanism of the vehicle is used for structure will need to repair the pavement damage. At present, domestic or imported maintenance vehicle where a gouge function most artificial hand hammer, hydraulic pickaxe or hammer, for the operation of workers with heavy weight and large impact force, is not conducive to the health of workers. In addition, because the artificial hand can only use a small impact pickaxe, gouge impact power obviously insufficient and not continuous operation, low efficiency, also cannot cut straight edge.

Use this gouge manipulator has the advantages of: the work of the slotting mechanism than traditional artificial hand hammer, hydraulic pickaxe or hammer to higher efficiency. Faster, accurate positioning, edge neat and uniform depth, and is controlled by the electric control system of hydraulic system, improve work efficiency, and automatic control technology for the use of computer space left.

Through the combination of hydraulic and electric control, to drive high-power hydraulic pickaxe, and enable it to achieve 5 degree of freedom of the manual and semi automatic mortising slot assignment.

Keywords: multi function asphalt pavement maintenance truck Chisel groove mechanism Manipulator Hydraulic transmission

第1章 绪论

1项目研究的背景和意义

1.1路面养护再生技术与设备大力发展

近年以来国家对公路养护节能减排工作高度重视, 先后发布了国务院《节能减排综合性工作方案》、《交通部关于进一步加强交通行业节能减排工作的意见》(交体法发[2007]242 号) 、交通运输部《资源节约型环境友好型公路水路交通发展政策) (交科教发〔2009 〕80 号) 、2010年4 月19 日国家发改委同中国人民银行与银监会和证监会一起联合发布了《关于支持循环经济发展的投融资政策措施意见的通知》、交通运输部《交通运输“ 十二五” 发展规划》, 其中明确构架了“ 绿色交通” , 大力探索交通运输资源的循环利用的新发展模式, 完善了相关的标准规范和评价指标的体系。积极推广使用交通废弃物(废水)循环利用的新材料、新工艺以及新设备, 倡导标准化的设计及工厂化预制, 提高了资源的再利用水平。加强了港口、公路等的生产、生活污水循环利用效率, 大力开展路面材料、施工的废料、弃渣、港口疏浚土等资源再生和综合利用, 建设资源循环利用试点工程。以工程应用急需的高性能材料、工艺和装备为重点, 积极推广废旧路面材料冷再生、热再生等循环利用技术和施工工艺。

参考文献

[1] 王宜登,林伟.浅谈我国公路养护设备的发展方向[C].第八届河南省汽车工程科技学 术研讨会论文集.2012.

[2] 长安大学.一种高海拔低温地区沥青路面快速多功能养护车:中国.2013.

[3] 查官飞,于勇,邓久军等.新型沥青路面养护车的稳定性设计分析[J].专用汽车,2010

[4] 王忠生.公路养护车用凿槽机械手.工程机械2002,33(9)

[5] 陈金龙.一种新型的沥青路面养护车设计[J].专用汽车,2009(3):56-57.

[6] 徐达,蒋崇贤.专用汽车结构与设计[M].北京:北京理工大学出版社,l998.

[7] 冯晋祥.专用汽车设计[M].北京:人民交通出版社,2007.

[8] 苗永权.专用汽车改装稳定性设计[J].装备制造技术,2008(6):64-67.

[9] 2010年公路水路交通运输行业发展统计公报[R].交通运输部综合规划司

[10] 交通运输部“ 十二五” 规划[R]. 交通运输部

川公网安备: 51019002004831号

川公网安备: 51019002004831号