多功能封口机的设计

多功能封口机的结构设计【优秀】【word+15张CAD图纸】【毕业设计】

【带任务书+开题报告+文献综述+外文翻译】【28页@正文7900字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

任务书.doc

填料斗.dwg

多功能包装机装配图.dwg

多功能封口机结构设计参考.docx

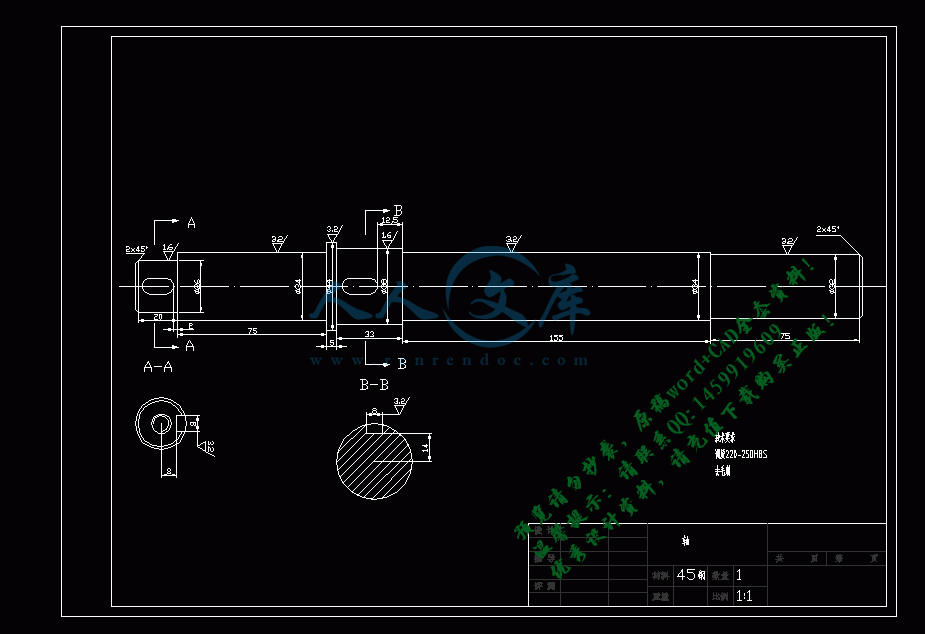

导辊心轴.dwg

开题报告.doc

摘要+目录.doc

文献综述.docx

文献翻译.doc

模板

横封辊.dwg

正文.docx

直齿圆柱齿轮齿轮.dwg

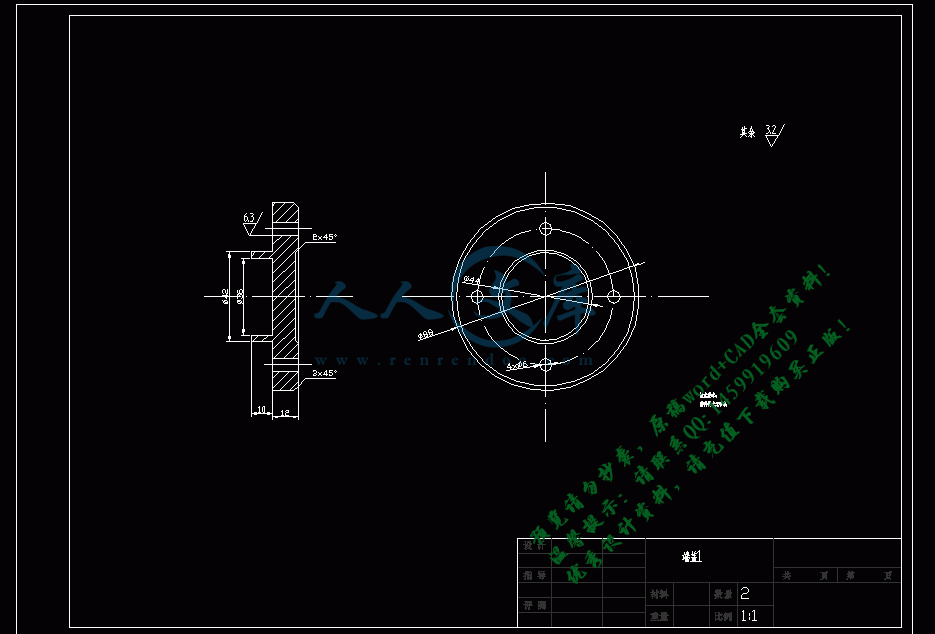

端盖1.dwg

端盖2.dwg

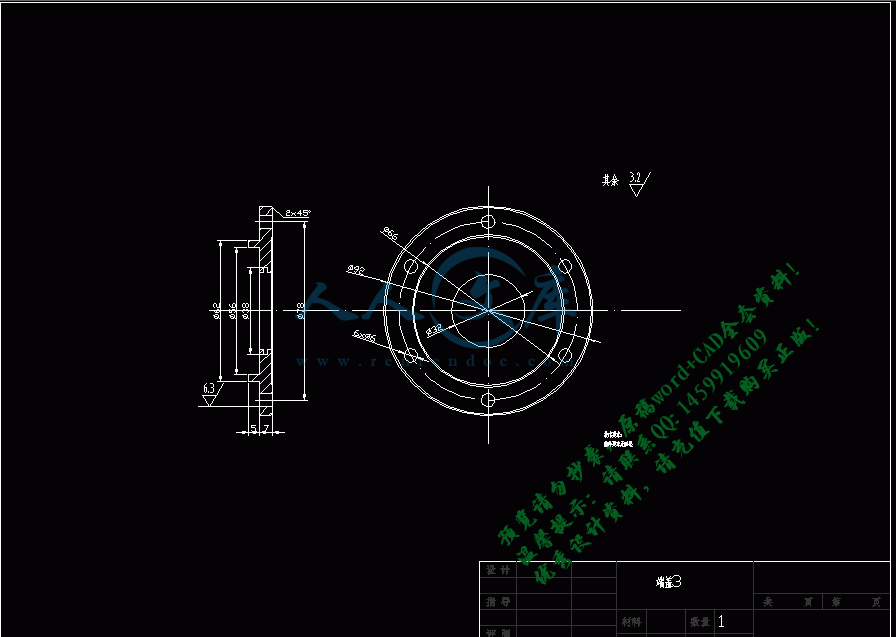

端盖3.dwg

草稿

资料

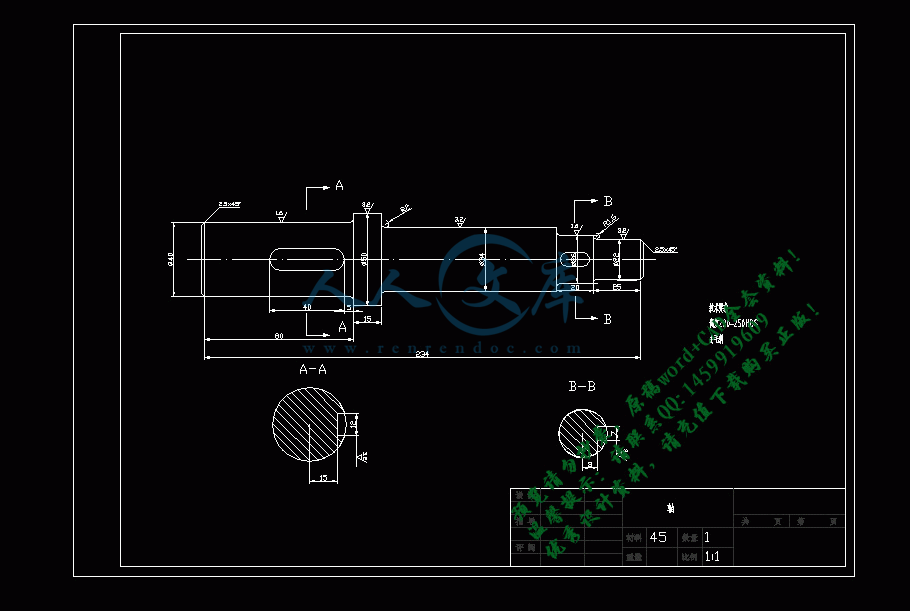

轴1.dwg

轴2.dwg

轴3.dwg

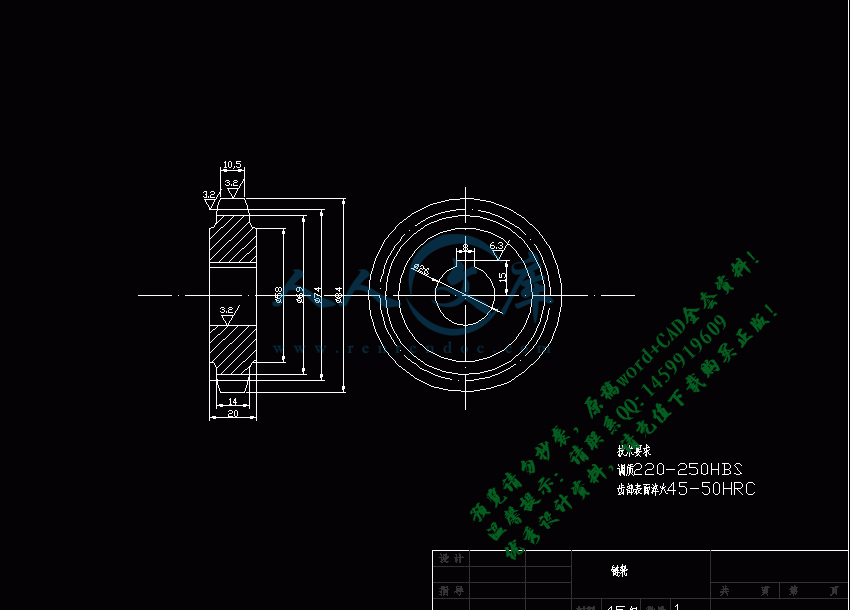

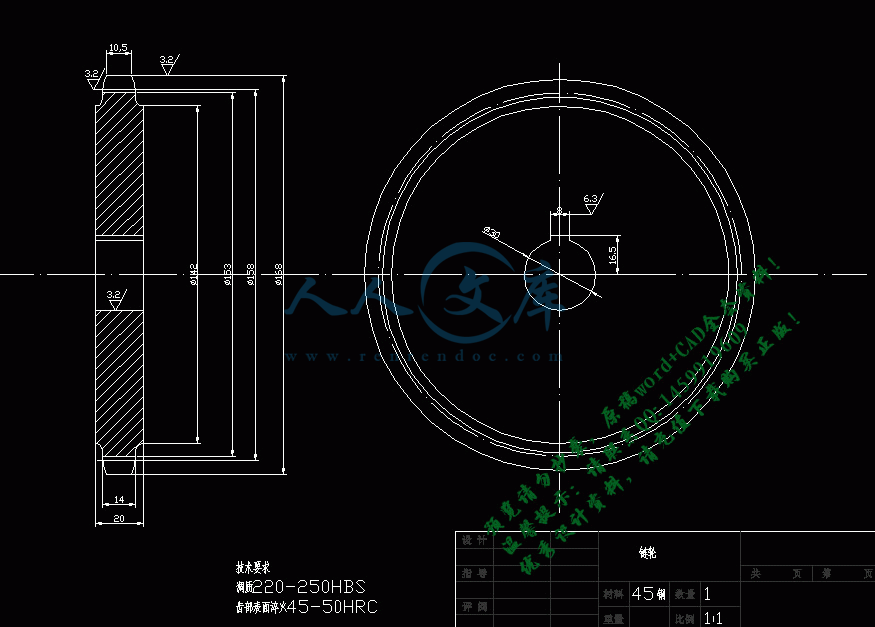

链轮1.dwg

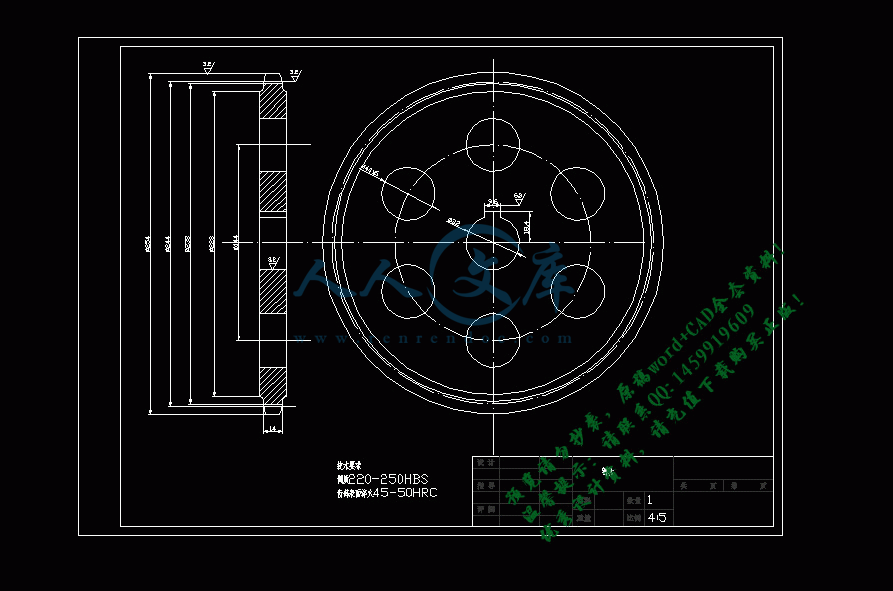

链轮2.dwg

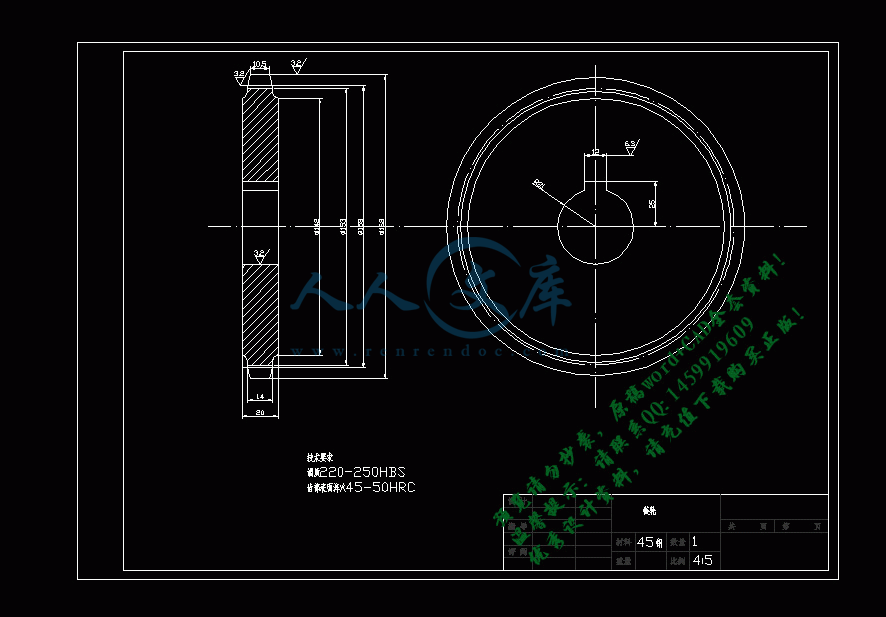

链轮3.dwg

链轮4.dwg

任务书

课题内容

本课题的内容是关于多功能封口机的设计,主要包括多功能封口机的结构设计以及对现有产品的结构优化和创新。能够实现较高的自动化程度和生产效率,如1)设计封口机的多功能化,实现其从填料到封口一体化;2)优化结构计算填料与封口之间的运动时间关系,提高工作效率;3)设计简易的填料和封口装置,减少设备耗材与复杂程度,提高设备工作质量与工作效率。主要研究对象是多功能封口机的结构设计,通过Solidworks等三维建模软件对设计的封口机进行三维造型与仿真,利用有限元分析等计算填料和封口部分的疲劳强度等。将三维造型图转化为工程图,计算并确定结构参数,完成零件图的绘制与标注,最后完成对论文的撰写。

课题任务要求

1.查阅多功能封口机相关文献并进行收集和整理,完成毕业设计前期工作:任务书、文献综述、开题报告、外文翻译;

2.查阅大量关于封口机结构设计的资料、封口机填料资料、封口机封口相关资料。整理后确定多功能封口机的具体设计方案;

3.进行必要的设计计算和结构设计,填料与封口运动之间的时间关系、装置中使用的机构尺寸设计等。保证其具备良好的机械性能;

4.运用CAD软件,对设计的多功能封口机进行三维建模,绘制装配图及零件图析;

5.利用三维建模完成工程图的转换,工程图要体现出结构上的尺寸参数等部分;

设计出的多功能封口机要求在现有同类产品上有所改良,同时保证生产效率不低于现有同类产品。

主要参考文献(由指导教师选定)

[1] 孙桓 陈作模 葛文杰 机械原理 第七版[M].高等教育出版社,2006

[2] 刘鸿文 材料力学 第四版[M].高等教育出版社,2004

[3] 濮良贵 纪名刚 机械设计 第八版[M] 高等教育出版社,2006

[4] 辛文彤 李志尊 Solidworks2012中文版从入门到精通[M] 人民邮电出版社,2012

[5] 赵美宁 王闯 王佳 塑料封口机自动控制系统设计[J]包装工程,2007,第10期

[6] 哈尔滨工业大学理论力学教研室 理论力学I 第七版[M] 高等教育出版社,2004

[7] 闻邦椿 机械设计手册 第五版[S] 机械工业出版社 2010

[8] 丰日美 机械扣式电池封口机毕业论文[D] 天津工业大学机械工程学院,2007

[9] 周林辉 软包装自动充填封口机的结构设计探讨[J]包装与食品机械 2005,第2期

[10]作者不详 塑料袋热压式封口机[J]包装与食品机械 2009,第1期

[11]孙建锋 桌上型全自动塑杯封口机的设计[J]包装与食品机械 2000,第6期

目 录

摘 要I

Abstract II

1绪论1

1.1多功能封口机设计背景1

1.2设计目的与意义1

1.3设计内容2

2方案设计5

2.1方案设计方法5

2.2任务要求键入章标题(第 2 级)5

2.3多功能封口机工作原理5

2.4方案选择6

2.5 总体布置7

3结构设计 8

3.1成形器 8

3.1.1袋形选择 8

3.1.2成形器种类及选择 8

3.1.3成形器相关计算 9

3.2总体方案设计 11

3.2.1电机的选择 11

3.2.2运动参数计算12

3.2.3各传动轴参数计算12

3.2.4主轴最小直径 13

3.2.5功率分配14

3.3链轮设计 14

3.4纵封辊 17

3.5横封辊 17

3.6齿轮设计18

3.7切断装置20

3.8导辊21

4 结论 22

致谢 23

参考文献 24

文献综述 25

文献翻译 31

摘 要

本文是针对多功能封口机的设计以及说明。

多功能封口机,即多功能包装机,因为在一台机器上完成两个或两个以上的包装工序故称之为多功能包装机。其主要由引导成型部分、填料部分、封制部分以及切断部分组成。包装材料被安置在卷桶上,经由导辊引导至成型器处,在成型器作用下完成包装袋的基本成型,同时完成填料,此时由横封装置以及纵封装置完成对袋的封口工作,之后由切断装置切断,使之分离为完整的包装袋个体。

本文对多功能包装机的工作原理、结构等做了分析及说明,并在现有多功能封口机的基础上进行设计,设计出一套可行的方案并进行相关计算,使用制图软件画出其相应工程图。

本文使用Autocad2010对其进行绘图,Autocad2010是比较基础的工程制图软件,能够使机械的平面结构简单、清晰地表现出来,是当下十分常见与实用的制图软件之一。

关键词:多功能封口机 包装 Autocad

Abstract

This paper is aimed at the multifunctional sealing machine design and description.

Multifunctional sealing machine, the multifunction packing machine, because the completion of two or more than two of the packaging process is called multifunction packing machine in a machine. It is mainly composed of lead forming part, filling, sealing and cutting part part part. Packaging materials are placed in the roll barrel, through the guide roller guide to forming device, the completion of the basic molding packing bag in the shaper, at the same time, filler, this time by the sealing device and longitudinal sealing device to complete sealing of the bag, then cut by the cutting device, so that the separation for the complete package bag of individual.

This paper makes analysis and description of the working principle, multi function packaging machine structure, and machine design based on the existing multifunctional sealing, designed for the relevant calculation a set of feasible solutions and, using the mapping software to draw the corresponding engineering drawings.

In this paper, Autocad2010 drawing of engineering drawing software, Autocad2010 is the basis of comparison, can make the plane mechanical structure simple, clearly demonstrated, is now very common and practical drawing software.

Keywords: Multifunctional sealing machine sealing Autocad

绪 论

1.1多功能封口机设计背景

封口机是典型的包装机械,包装机械在世界上已有一段历史。可以说,正因为有中国的造纸技术,才给纸包装技术的产生以及发展提供了必要条件,之后才得以由此发展出各种材料的包装机械。

从1850年始,世界的纸价格大幅跌落,纸张开始应用于食品包装。在这之后的1852年,美国的沃利发明出了纸袋制造机,由此正式出现了纸制品机械。1861年,德国人建立了世界上第一个包装机械工厂,并且在50年后也就是1911年成功生产出全自动成形充填封口机,这应该是有历史记载的最早的多功能封口机。

而中国在此方面由于各种原因起步晚于欧美各国,但经过了二十多年的发展,中国的包装机械已经成为国内机械工业十大行业之一,为中国的包装工业作出了重大贡献,满足了国内市场的基本需求,填补国内在此方面的空白,甚至出口国外。但是总体上看,中国包装机械的进出口额与发达国家相比仍然相去甚远,品种少,配套数量少,缺乏高精度以及大型化产品仍然是国内市场不可忽视的问题。而且国内此类产品主要以针对国外产品的仿制为主而缺少自主创新类产品,元器件的整体质量也不如国外,这就导致了包装产品的质量不如国外。

1.2设计目的与意义

本此设计的目的,在于对于多功能封口机的原理分析与结构设计,加深对于包装类机械的了解,能够在现有机械的基础上作出自己的一些设计,增强自我设计方面的能力,锻炼自身的相关能力。

由上文可知我国当前在包装机械上的成果并不如国外,因此,就更加需要我们对其产生重视,藉由对于多功能封口机的设计,进一步了解机械包装产业。

参考文献

[1] 卢立新 包装机械概论[M]中国轻工业出版社.2011

[2] 陈镜波 世界包装机生产与贸易概况[J]包装与食品机械.1995,第4期

[3] 孙恒 陈作模 葛文杰 机械原理第七版[M]高等教育出版社.2006

[4] 杨裕根 诸世敏 现代工程图学[M]北京邮电大学出版社.2008

[5] 濮良贵 纪名刚 机械设计第八版[M]高等教育出版社.2006

[6] 周林辉 软包装自动充填封口机的结构设计探讨[J]包装与食品机械 2005,第2期

[7] 杨军良 刘云霞 多功能忱型包装机横封传动机构设计探讨[J]包装与食品机械1999,第6期

[8] 张西良 式包装机工艺过程及其控制系统研究[J]轻工机械2003,第3期

[9] 戴远敬 袋成型包装机中常用拉膜机构分析[J]包装与食品机械 1999,第1期

[10] 孙建锋 桌上型全自动塑杯封口机的设计[J]包装与食品机械 2000,第6期

川公网安备: 51019002004831号

川公网安备: 51019002004831号