【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

全部文件包含以下内容

摘 要

中厚板(厚度为的钢板)是我们日常工业加工中经常用到的一种基础材料,它在工业生产中需求量非常大,起着中流砥柱的作用。所以我们对中厚板的质量要求有了很高的标准,其中包括对它进行尺寸测量如:长度,宽度和平坦度等。长度是中厚板轧制产品的一项关键的质量指标,对轧制生产线、产品的应用都有很大的影响。近年来,随着我国现代化的不断发展,我们对钢材的需求量以及品质感也提出了更高的要求。长度检测系统为后续一系列钢板检测系统提供关键的数据支撑,将会直接影响到后期产品的质量。由于冷轧中厚板在辊道上的输送速度是轮廓检测过程中的一个非常关键的数据,因此对速度的测量精度直接关系到轮廓检测的准确程度。本论文研究的是采用一种新型的非接触式测速方法与传统的测量方法有很大不同。钢板长度是通过多普勒激光测速仪得到速度,依据一段时间内测量的速度来计算钢板的长度。求得各个纬度的长度,平均长度,最大长度和最小长度。由于条件所限,实验主要采用Labview软件构建整个系统的检测程序。随着系统的运行能立即得出所需要的关键数据以便用来分析。以下是论文的详细内容:

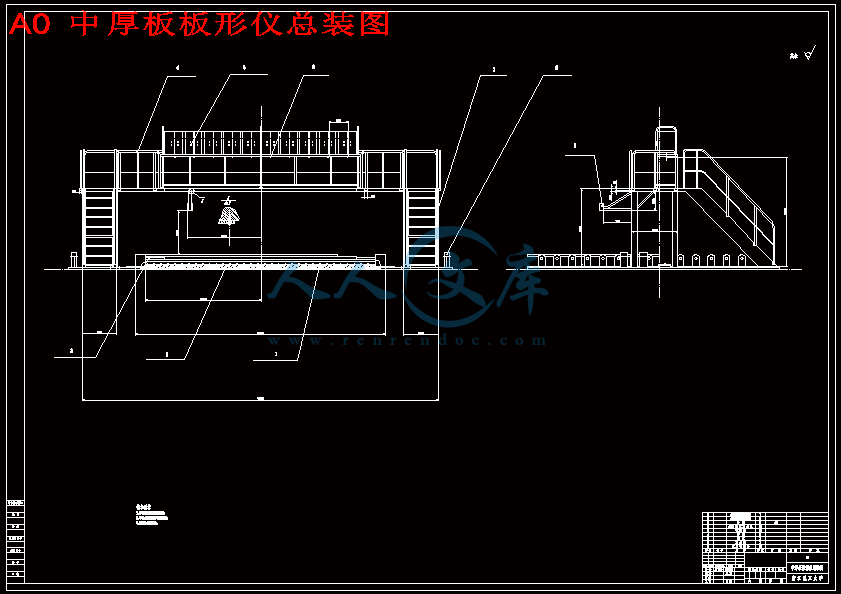

第1章本章主要是介绍中厚板及板形仪的定义。国内外中厚板板形仪的研究现状和发展趋势,以及中厚板长度检测的研究意义和价值。根据其发展现状和研究的重要性,设计一套完整的长度检测系统。

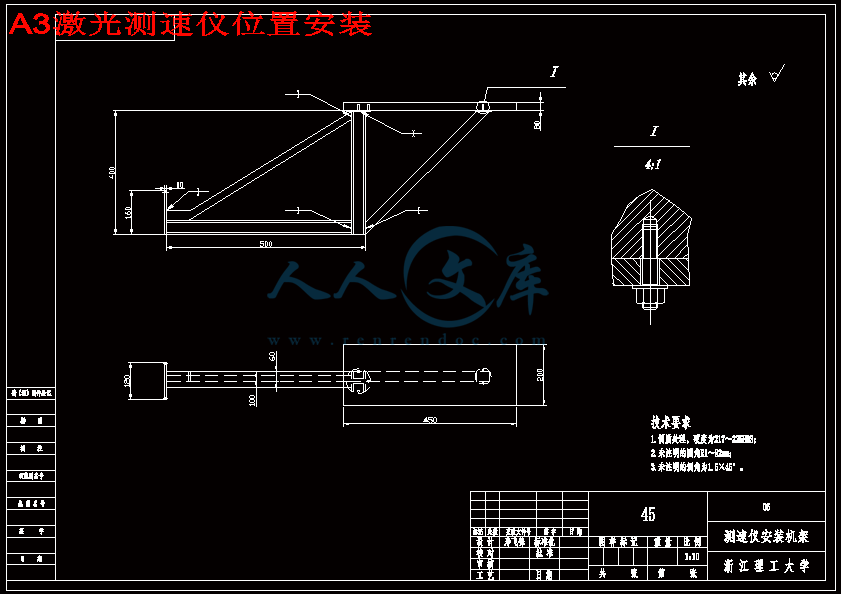

第2章本章根据研究所需设计检测仪系统的整体构架,其中包括传感器,多普勒测速仪的位置安装定位。重点介绍长度检测系统的工作原理。

第3章本章论述检测系统的组成和相关参数,着重介绍多普勒激光测速仪工作原理。

第4章本章主要介绍运用Labview构建程序框图和前面板。通过运行虚拟程序得到相应数据,并对数据进行分析。

第5章使用Matlab软件编写程序用来处理测量所得数据。

第6章本章主要是总结研究过程中所遇到的问题和对构建的程序框图所产生的一些不足,提出解决之道和展望未来研究方向。

关键词:长度检测 多普勒测速 程序框图 总结

Abstract

Steel plate is often used as a base material in our industrial process .We need a great quantity numbers. It plays a very important role. So we want have the quality of steel plate by a very high standard. Include its size measurement such as length, width and flatness, etc. The length is a key quality indicator, has a significant impact in production lines and product application. In recent years, with the continuous development of China's modernization, Demand for steel plate and a sense of quality we also put forward higher requirements. Length detection system give the follow-up series of steel plate detection system provides key data support will directly affect the latter part of the quality for the product. Cold-rolled plate in the conveying speed of the rollers is a very critical detection process data, the accuracy of speed measurement is directly affects the accuracy of the contour detection. This study is the use of a new type of non-contact speed is very different from the traditional measurement methods. It is measure speed by Doppler velocimetry and Multiplied by the measurement time that can have the measuring length. At the same time, determines all latitude length and an average length, maximum length and minimum length. Due to limited conditions, experiment using Labview software to build the entire system testing procedures. With the operation of the system can immediately draw the critical data needed to be used. Here are the details:

Chapter 1, Introduced the steel plate and Shapemeter definition. Home and abroad the steel plate Shapemeter the research status and development trends, as well as the length of steel plate detection significance and value. According to the development status and the importance of research, design a complete set of the detection system.

Chapter 2, According to the research required to design the overall architecture of the detector system, including the positioning of sensors, Doppler velocimetry location of installation. Focus on the working principle of the length of the detection system.

Chapter 3, Make an introduction of system components and related parameters.

Focus on the working principle of the laser Doppler anemometer.

Chapter 4, Use Labview builds the block diagram and front panel, runs the virtual program to get the appropriate data, analyze the data.

Chapter 5, According to the measured data use Matlab software to write programs to analyze the data.

Chapter 6, Summary and Outlook.

Key words:Length Detection, Doppler velocimetry, The block diagram, Summing

目 录

摘 要

Abstract

第1章 绪论 1

1.1 前言 1

1.2 课题研究现状和发展趋势 1

1.2.1 中厚板及板型仪的定义 1

1.2.2 国内外研究背景及现状 2

1.2.3 研究趋势 3

1.3 论文研究意义和主要内容 4

1.4 论文的结构安排 5

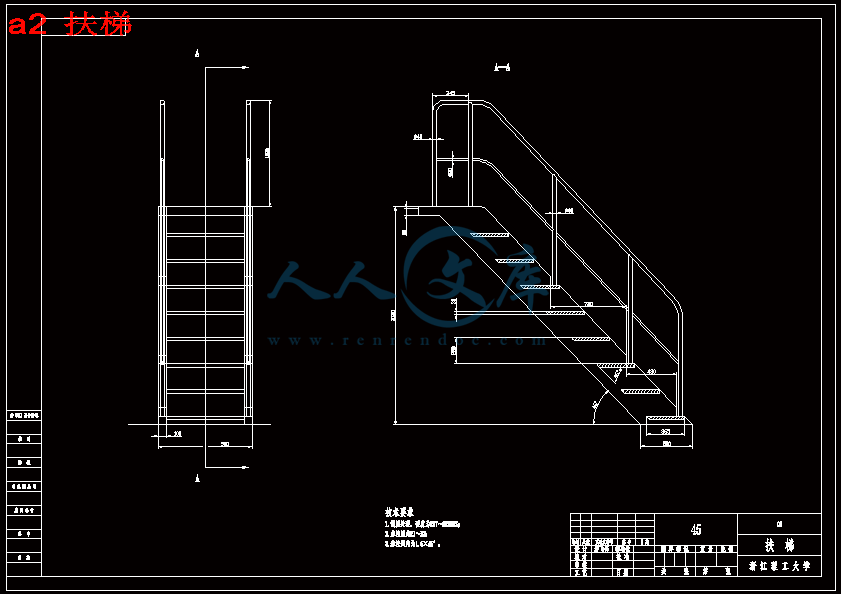

第2章 中厚板板型仪长度检测系统整体框架的设计 6

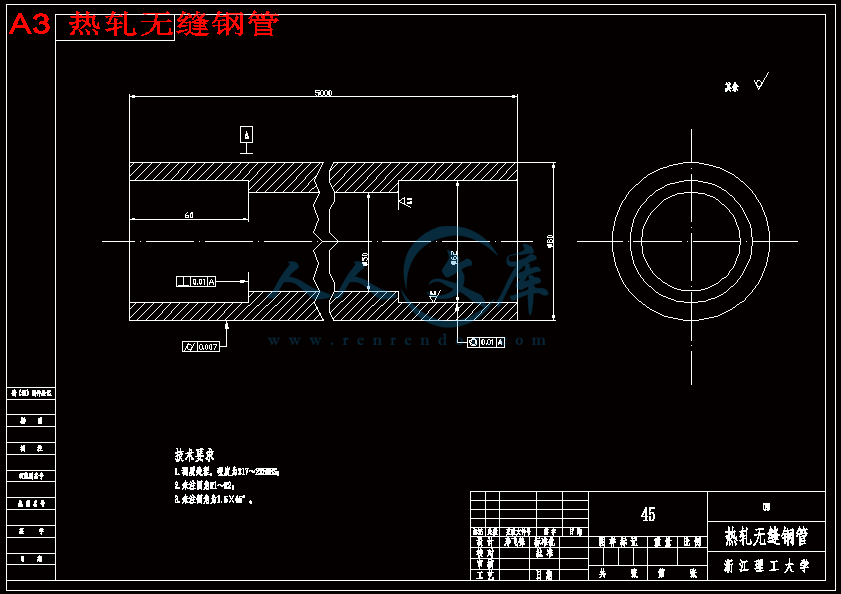

2.1 安装布局 工作环境及仪器选择 6

2.2 冷轧中厚板轮廓检测仪各个子系统的功能 9

2.3 结构的受力分析 12

2.4 仪器的安装定位 16

2.5 长度检测原理和方案 17

第3章 系统组成和多普勒激光测速仪 20

3.1 长度检测系统的组成 20

3.2 多普勒激光测速仪及测量原理 20

3.3 钢板长度测量过程中需要探讨的问题 23

第4章 基于Labview的长度检测系统的设计 25

4.1 Labview程序图主界面的设计 25

4.2 速度测量程序框图和前面板的设计 26

4.3 长度测量程序框图和前面板的设计 27

4.4 数值显示与分析 29

4.5 小结 30

第5章 MATLAB编程 31

5.1 程序编写 31

5.2 小结 33

第6章 总结与展望 34

6.1 总结 34

6.2 展望 34

参考文献 36

致 谢 38

附录 1 39

附录 2 40

第1章 绪论

1.1 前言

钢铁行业作为重工业和基础原材料行业,其发展状况直接影响到国民经济的稳固发展[1]。目前,我国已经成为全球最大的钢铁生产国,然而我国钢铁行业与国外相比仍存在很大的差距,其主要原因是我国钢铁行业的总体技术装备和生产集中化程度不高,因此生产的钢铁产品的品质、质量、附加值等都还远不如发达国家,导致我国钢铁产品在国际市场上缺乏竞争力[2-5]。所以如何由钢铁大国发展成为钢铁强国,其关键在于提高我国钢铁行业的生产专业化的集中程度和自动化检测技术。

川公网安备: 51019002004831号

川公网安备: 51019002004831号