饺子机设计【含全套17张CAD图纸】【答辩毕业资料】

收藏

资源目录

压缩包内文档预览:(预览前20页/共24页)

编号:347122

类型:共享资源

大小:4.94MB

格式:RAR

上传时间:2014-10-24

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

45

积分

- 关 键 词:

-

饺子机

设计

全套

cad

图纸

答辩

毕业

资料

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

1绪论 2

1.1 包馅(夹馅)食品机械的应用前景和发展现状 2

1.2 饺子机的相关介绍、研制意义和目标、未来的发展方向 2

1.2.1 饺子机的介绍 2

1.2.2 饺子机的研制意义和目标及未来的发展方向 3

2机械系统总体方案的拟定 4

2.1动力系统的拟定 4

2.2传动系统的拟定 4

2.3执行机构的拟定 4

3工作机构运动需求分析及初步设计 6

3.1饺子模型的建立与分析 6

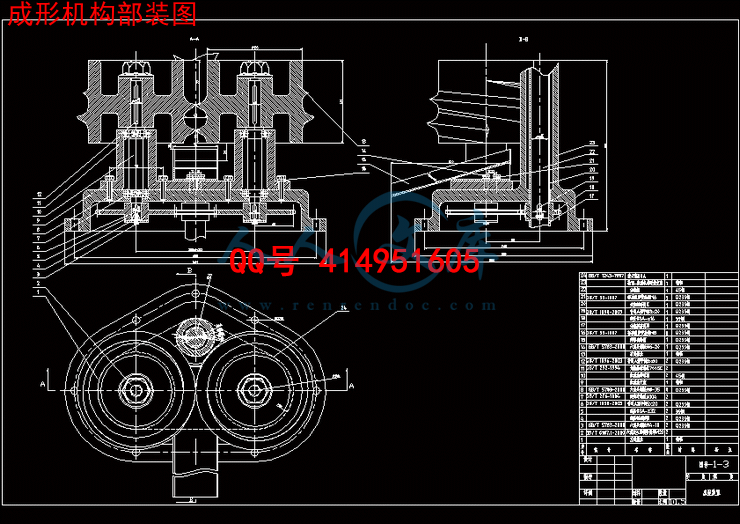

3.2 生产效率与成型盘的设计 7

3.3 横、竖蛟龙的设计计算 8

3.3.1 竖绞龙的设计计算 8

3.3.2 横绞龙的设计计算 8

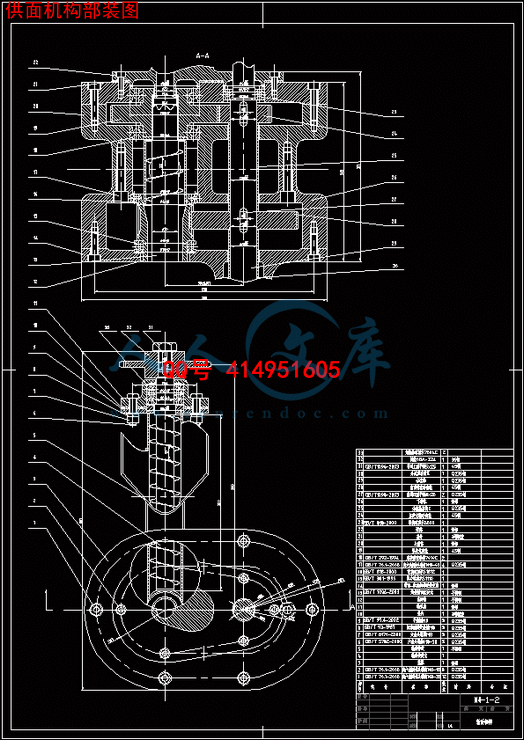

3.4 供馅泵的设计 9

3.4.1供馅装置局部装配图 9

3.5 出面嘴的设计 10

4传动系统的设计计算 11

4.1 传动比的分配 11

4.1.1 电动机转速的确定 11

4.1.2 传动比的总体分配及各轴转速的确定 11

4.1.3 确定各个执行部件所需的功率 11

4.2 蜗轮蜗杆传动副的设计 11

4.2.1 设计要求 11

4.2.2 初选参数及材料 12

4.2.3 初步计算 12

4.2.4 根据齿面接触疲劳强度条件设计蜗轮蜗杆副 13

4.2.5 校核蜗轮齿根弯曲疲劳强度和热平衡 14

4.2.6 蜗轮蜗杆受力计算 14

4.3 直齿圆锥齿轮传动副的传动设计 15

4.3.1 设计要求 15

4.3.3 初步计算 16

4.3.4 根据齿面接触疲劳强度条件设计直齿圆锥齿轮传动副 16

4.3.5 校核齿根弯曲疲劳强度 16

4.3.6 圆锥齿轮受力计算 17

4.4 链传动设计 17

4.4.1 横绞龙链传动设计 17

4.4.2 成形机构链传动设计 17

4.5 出面嘴直齿圆柱齿轮设计及校核 18

4.5.1 设计要求 18

4.5.2 模数、齿数及分度圆直径的计算 19

4.5.3 选择参数与材料并进行初步计算 19

4.5.4 校核齿轮强度条件 19

4.5.5 受力计算 21

4.6 竖绞龙直齿圆柱齿轮设计及校核 21

4.6.1 设计要求 21

4.6.2 模数、齿数及分度圆直径的计算 21

4.6.3 选择参数与材料并进行初步计算 21

4.6.4 校核齿轮强度条件 22

4.6.5 受力计算 23

5分流轴及其附件的设计计算 23

5.1 分流轴的设计与校核 23

5.1.1 设计要求 23

5.1.2 分流轴受力情况分析 23

5.1.3 计算初选轴径 25

5.1.4 分流轴各段轴径的确定 25

5.1.5 轴的受力分析 25

5.1.6 轴的校核 31

5.2 轴承的设计与校核 32

5.2.1 轴承的选择 32

5.2.2 1位置轴承的校核 32

5.2.3 3位置轴承的校核 33

5.2.4 7位置轴承的校核 33

5.3 键联接的设计与校核 34

5.3.1 键的选型 34

5.3.2 键的校核 34

5.4 花键连接的设计与校核 35

6 结论 36

7部分外购件清单 37

8参考文献 39

1 普通图书 39

2 期刊中析出的文献 39

3专利 40

饺子机设计

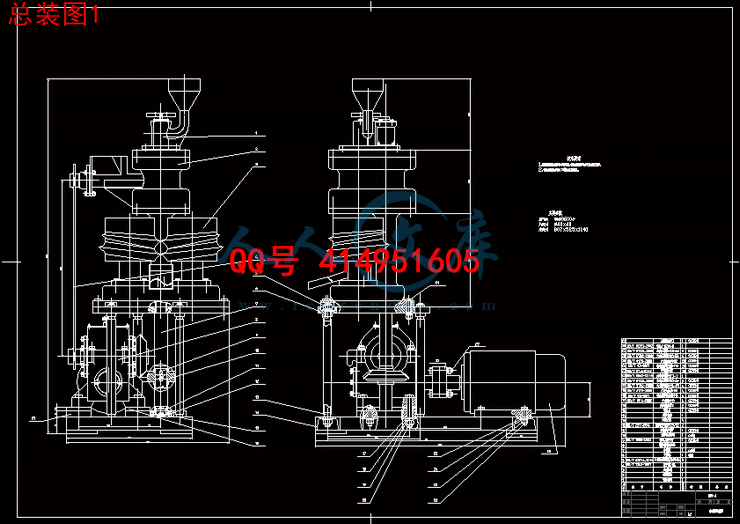

摘 要:本毕业设计完成了“饺子机设计”,设计目的是实现将饺子生产从手工劳动到机械化生产的转变。通过观察饺子手工生产过程以及借鉴国内外相关食品成型机械的结构特点,采用成型盘为成型元件、螺旋机构为面料输送元件、滑片泵为输馅元件的灌肠式滚切成型原理设计饺子机。该种成型原理生产效率高,可以实现连续式生产,因此在食品机械中得到广泛应用。本次设计动力源使用电动机、主要变速机构使用蜗轮蜗杆减速器、动力分配机构使用分流轴的传动方式,并对传动系统中大部分的传动部件进行了设计和校核,同时绘制了饺子机的主要零部件图纸及总体装配图纸。

关键词: 饺子;食品机械;成型盘;螺旋机构

The Design of dumpling Machine

Abstract

This graduation design accomplished “the design of dumpling producing machine”. The purpose of this designing is to realize the improvement of the dumpling production method from manual labor to machine manufacturing. Based on the observation of the manual labor process of the dumpling production and the reference of the analogous food shaping machinery’s configuration in home and abroad, with which the shaping principle to design the dumpling producing machine and also with the shaping wheel for shaper, screw mechanism for dough transporter and vane pump for stuff transporter. Greater production efficiency and continuous production can be realized by this shaping principle, therefore, it can be widely applied in food machinery industry.

This design adapt the electric motor for power, worm reducer for main speed change transmission and shunt shaft for power allocation mechanism as well as to make design and check on most of the driver units in driver system. Besides, both the main parts and the assembly drawing have been rendering.

Keywords:dumpling, food machinery, shaping wheel, screw mechanism

1绪论

1.1 包馅(夹馅)食品机械的应用前景和发展现状

包馅(夹馅)食品在我国历史悠久,伴随着几千年的文明的发展已经成为我国食品文化中的代表,如饺子、包子、馄沌是主食的一部分;汤圆、月饼、粽子是传统节日中必不可缺的食物。如今,经济的迅速增长、人民生活水平的提高和生活节奏的加快,对食品行业提出了新的要求。而本人认为这些要求可以归纳为两大类:

- 内容简介:

-

重 庆 理 工 大 学文 献 翻 译二级学院 重庆汽车学院 班 级 109040204 学生姓名 彭小刚 学 号 10904020416 自动饺子成型机摘要:一个自动饺子成型机实质上由传输机控制饺皮厚度并负责传送,面粉容器盛放面粉用于做饺皮。控制器负责向每块饺皮输送固定量的馅。多数饺子成型设备安装在两个多边形旋转轮的外围表面,便于将装满馅的饺皮包起来形成饺子。一个推杆将做好的饺子推出设备,放入饺子收集器。注意事项注意的内容是:1、一个自动饺子成型机实质上包含以下几部分:一个固定面团所使用的面团固定器、一个传送面团的传输装置; 一个制作饺皮所需的面粉容器、一个存储馅料的馅料料斗、一个控制放入饺子皮中馅料数量的填料控制装置、一个把馅料填入饺子皮中的填料装置、一个通过压饺皮的中间部分以形成一个凹痕包裹馅料的挤压装置、两个多边形形状的旋转轮子; 多个安装在上述两多边形形状的旋转轮的外围表面以便折叠饺子皮形成一个饺子成型装置; 一个推动完成的饺子出饺子成型机的推杆; 一个清洁饺子成型机的固定刷和活动刷; 一个分别收集完成的饺子和剩下的饺子皮的饺子收集器和饺子皮收集器。其中每个饺子皮是通过传输装置传输到饺子成型装置中,在该装置处挤压装置压饺皮形成中央凹痕,把馅料从馅料料斗通过填料控制装置填入该凹痕中,饺子成型装置然后折叠起来饺皮并且削减成形状相同、大小一样。上述活动刷由刷毛和刷柄两部分部分组成,其一端形成一个环形槽用于接收一叉子的一端,叉子的另一端被固定在一个座位上, 叉子安装有叉臂与车轮以便与具有一个凸角的凸轮配合,因此,当所述凸轮的凸角接触到车轮后,叉子被强制与固定叉子的一端一起旋转,然后向后拉动刷子,刷子被弹簧弹起从而再次向前推进。2、根据第一条的说明,自动饺子成型机的特征在于,所述传送面团的传输装置包括两个相对地布置的轮子,使得输出的饺皮厚度保持恒定。3、根据第一条的说明,自动饺子成型机中的旋转轮具有锯齿表面。而且面粉容器中有搅拌器,用于搅拌其内的面粉和积累在上述旋转轮锯齿表面的面粉。这样当积累在锯齿表面的面粉随着齿轮旋转后就给面团施加了一层面粉。4、根据第一条的说明,自动饺子成型机中的填料控制器包括两个相向的相互啮合的滚轴,把填料控制器分成上下两部分,因此当两个滚轴相对彼此旋转时,定量的馅料就从控制器的上部进入到控制器的下部。 5、根据第一条的说明,自动饺子成型机中的填料装置包含有接馅料的导管和可垂直移动的供料杆,所述导管与一个固定的支撑物相连接,供料杆与垂直滑动板相连接,由此以垂直方向运动的方式把馅料放入饺皮中。6、在对第五条填料装置的描述中,与供料杆接触的有爪形除料剂,与供料杆相关的垂直运动能进一步完全去除粘附在供料杆上的馅料。7、根据第一条的说明自动饺子成型机中的饺子成型设备由一个固定的下模和一个可转动的上模组成,该下模和上模沿一侧锁定在一起,上模相对于另一侧上的轴转动180度。这就使得自动饺子机一个凸起的下模可以紧密地夹进到相应的凹槽,以便把面团折叠和切割到理想的形状 8、根据第一条说明,自动饺子成型机中的两个多边形形状的旋转轮基本上是由两个同步的八角形轮与保护套筒安装在两者之间以便用于防止面粉落入旋转轮的轴上,一组八个饺子成型设备安装在八角形轮的外围。9、根据第一条说明,自动饺子成型机中的推杆连接到楔形块上,并且由其驱动垂直滑落到多边形旋转轮固定轴上的楔形槽内。10、一个自动饺子成型机实质上由一个面团筒控制面团使用;一个传动装置传输面团;一个面粉容器盛放面粉用于做面团;一个馅料斗用于存储馅料;填料控制装置控制放入饺皮的馅的量;填料供给装置负责把馅放入饺皮;,一个敲打装置用来敲打饺皮的中央部分,形成一个凹痕,接收馅料;两个多边形旋转轮子;多数饺子成型设备安装在上述两个多边形旋转轮外围表面,便于把饺皮包起来形成饺子;一个推杆把做好的饺子推出成型装置;一个固定和可移动的电刷用来清洁饺子成型装置;一个饺子收集器和面团收集器分别负责收集做好的饺子和剩下的面团,其中传动装置传送每个面团到其中一个饺子成型器,敲打装置敲打饺皮形成一个中间的凹痕,通过馅料控制器,馅料从馅料斗进入凹痕,接着成型设备把饺皮折起来,裁剪成理想的相同大小和形状,上述装料装置包括一个填料导管,其中送料装置包括一个填料导管接收填料,和一个垂直可动进料杆,上述导管连接到一个固定的支撑,进料杆连接一个垂直可滑动的板,随其传送形成一个垂直运动,把馅放入面团,可滑动板的垂直滑块运动受到一个半圆形滚筒和一个半圆形槽的影响,半圆形滚筒从有个轮的板那里产生一个销,从那里产生一个半圆形槽,当栓与槽齿合在一起时,转动的滚筒接触到刚脱离板影响的轮子,当栓与槽分离时,板继续传送随其进入垂直运动。 说明该项发明的背景本发明涉及一种全自动饺子机。饺子是一种非常受欢迎的中国食物。包饺子的传统方式是首先用手把适量的馅放在一块面团上,再把面团捏到合适的大小或形状,最后把面团包起来形成一个饺子。用这种方法做成的饺子可能会不尽如人意,要么变得太大要么太小,因为很难控制放入的馅的量,饺皮的厚度也不是固定的。此外,传统的手工包饺子是不卫生的,效率也不高。比如,它可能需要半个小时左右才能包好两份饺子。随着饺子需求量的快速增长,的确非常需要一个自动饺子成型机。总结该发明本发明的主要目的是提供一个自动饺子成型机,自动执行做好一个饺子必须完成的一系列操作,如传送面团,填充馅料,切割及折叠饺皮,以及饺子成品输送等。本发明的另一个目的是提供一个易于控制饺皮厚度和放入馅的量的自动饺子成型机。本发明还有一个目的,即提供一个紧凑的自动饺子成型机,高效,卫生,耗能少。本发明的其他目的和优势将在以下详细描述本发明的参照图纸中变得明显。图纸的简要描述图一是自动饺子成型机的立体图图二是自动饺子成型机的前视图图三是填料装置的分解透视图图四是饺子成型装置的分解透视图图五是饺子成型设备活动刷的分解透视图图六是饺子成型设备旋转轮控制栓的分解透视图图七是饺子成型机滑板传输装置的分解透视图图八是图七中传输装置的垂直视图图九是展示一套饺子成型设备所需的两个八角轮的分解透视图图十是图九中旋转轮的垂直剖面图详细说明 图一和图二根据本发明分别展示了自动饺子成型机的前视图。自动饺子成型机大体上包含以下几部分:一个固定饺皮的饺皮固定器一个传输饺皮的传输装置一个把面粉施加在饺子皮上的面粉容器一个储存馅料之后通过馅料控制器分送到填料装置的馅料料斗一个把饺子皮切割成理想的形状和大小的切割装置一个通过压饺皮的中央部分形成凹痕以包裹馅料的挤压装置一个在馅料包裹在饺皮内后推动饺子成型装置折叠饺皮形成一个饺子的压轮一个连接到饺子成型装置推动包好的饺子出该设备进入饺子收集器的推杆每个饺子完成后就清扫一次饺子成型设备的固定刷和活动刷一个收集剩下饺皮的饺皮收集器。 参考图二展示了自动饺子成型机制作饺子的过程。存储在饺皮固定器中的饺皮通过传输装置的两个轮子和围板传输到面粉容器,两个轮子相对的布置,使得饺皮的厚度保持恒定。面粉容器中有一个搅拌器搅拌容器中的面粉。轮子表面呈锯齿状,轮子与其相对布置。当饺皮经过旋转轮和之间的空隙时,该设备就会在饺皮的背面施加定量的面粉以防止之后输送过来的饺皮粘附在饺子成型装置上。饺皮从面粉容器中出来之后就被输送到了饺子成型装置,然后挤压装置用其扩展出的一端压饺皮的中间部分形成凹痕来包裹馅料,同时切割装置把饺皮切割成理想的形状。馅料控制器把定量的馅料从馅料料斗中填入饺皮的凹痕处,然后压轮使得饺子成型装置折叠饺皮形成一个饺子。然后饺子通过推杆出饺子成型装置进入到饺子收集器中。两个刷子清扫饺子成型装置,然后该装置就开始接收下一个饺皮。这样的一个过程一直重复,直到所有的饺皮固定器上的饺皮完尽。就目前的发明情况来看,现有一套含八个相同饺子成型装置的设备,该设备今后会把包饺子的过程做的更为细致。图二中,馅料料斗中的螺旋给料机能持续的把馅料推到料斗的下方。如图二所示,馅料控制器中装有两个滚轴,因此当两个滚轴以预定的角度旋转时,聚集在馅料控制器上面的馅料就被挤压到馅料控制器的下方,然后馅料通过导管进入到填料装置。图三展示了本发明填料装置的分解透视图。填料装置通过第一个支撑与饺子成型装置紧密相连,支撑物的一端有一个铁环以便填料导管和供料杆插入。供料杆通过环形螺母与第二个支撑物的一端相连,第二个支撑物的另外一端固定在垂直滑板上(图一所示),因此可以形成垂直运动。以这种方式供料杆能够上下运动即推动定量的馅料通过填料导管从馅料料斗中进入到饺皮的凹痕处。为了完全去除粘附在供料杆上的馅料,在供料装置中装有桶形馅料去除器,把其细长的爪形臂装在铁环外围预先制定的凹槽内。臂的一端弯曲度落在滑板上靠螺丝钉与第二个支撑物连在一起。通过这种方式,活动金属板带动金属板与桶形馅料去除器一起做垂直运动。弹簧装置能够进一步加速馅料去除器向下运动的速度。图四是饺子成型装置的分解透视图。饺子成型装置有两个模具,一个固定的下模和一个可旋转的上模。上模通过滚柱轴承与饺子成型装置的侧面相连,绕着轴的一侧旋转。上模和下模通过螺丝钉紧密的连在一侧,上模和下模整体与两个八角转动轮相连,这将在图九和图十中具体说明。上模的一个轴由带臂的传动装置带动。通过这种方式,上模绕着轴做180度旋转,这样下模凸出的地方就恰当的夹进到旋转上模的凹陷处。这个过程相当于折叠饺子皮的操作,同时由于凸起的快进入凹陷处,饺子皮被切割成理想的形状和大小。一个饺子包好后下个饺子进入饺子成型装置前,该装置就会被清洁一次。像前面图二提到的那样,固定刷用于清洁饺子成型装置的表面,活动刷用于进一步清洁凹痕和凸起的块。图五描述了活动刷的分解透视图。其中刷毛与一端插在两个金属板之间的环形槽中的柄相连。叉子的一端固定在座位上,另一端插入环形槽用于驱动活动刷。叉安装有臂和一个轮子,轮与轴上的凸轮一起运动,这样当凸轮的凸起部触碰到,叉就会被迫转动到一端,从而推动柄退向另一端。通过这种方式活动刷可以反复旋转与饺子成型装置的旋转轮相互配合一起转动来清洁凸起的地方和凹痕。弹簧连接在叉的两个螺旋体和之间,叉上的螺旋体与轴分别驱动活动刷向前。图六是旋转轮控制栓的分解透视图。旋转轮控制栓安装在饺子成型装置上由带螺旋体的杆驱动,该操作过程是通过杆的支点实现的。旋转轮控制栓的前端呈叉状,其由连接在杆上端的推杆驱动。杆的下端弯曲呈臂状.,并装有一个轮。图五所示的轮与凸轮相互配合这样当凸轮的凸起部分触碰到轮,就会推动杆向逆时针方向旋转,由此推动控制栓通过推杆做横向运动。弹簧的作用在于使杆回归到最初的位置。垂直滑板通过本发明所涉及的特殊传输装置实现垂直滑动。图七和图八分别展示了传输装置的分解视图和垂直剖面图。呈半圆状的滚筒装有栓,该栓位于半圆形滚筒的外围和凸起部的中间,栓与金属板上的半圆形槽衔接。齿轮通过另一个栓固定在滚筒轴的一端。金属板上还装有一个小的轮,该轮围绕着自身的周旋转。图一所示的金属板上安装的相连的杆,用于在金属板垂直滑动时带动垂直滑板从而做垂直运动。金属板的垂直滑动可以通过滚筒和半圆形槽的相互配合得以实现。在滚筒上的栓衔接到半圆形槽时,轮就会触碰到滚的表面。因此,尽管滚筒在转动但是金属板依旧不会动。在栓到达半圆形槽的左端之后,栓随着滚筒的旋转持续向下迫使金属板向下,在达到最低位置后栓和金属板然后被一起抬上去,最后再次与半圆形槽衔接,在达到最高点时金属板会被控制停留一端时间。之后不断重复这样的一个过程。特别强调的是金属板停留的时间相当于从一个旋转轮上的成型装置到另一个装置的时间。上述整个过程所需的时间能够通过调整齿轮的旋转速度来控制。切割装置和填料杆的操作也能够很容易的得到控制。图九和图十详细描述了饺子成型装置的八角旋转轮即旋转轮和旋转轮的轴与轴承的一端相连,滚轴和轴上的传输装置通过螺母相连。在饺子成型机后面的齿轮外壳都配有上述装置,也就是说上述装置位于齿轮防护外壳的后方。轴和齿轮防护外壳的前方安装有两个通过螺丝钉和连在一起的凸轮,还有八角轮和轮。螺丝钉用于把轮固定在轴的一端。八角轮与八角轮同时运行,两者都安装在饺子成型装置的前方。在下方打开的水平保护套管连接在两个轮和之间,这样是为了防止饺皮上的面粉落入两个旋转轮的轴上,装有固定轴的八角轮的表面有楔形槽。一套饺子成型装置镶嵌在八个八角轮和的外围表面。垂直滑动的楔块嵌在固定轴的楔形槽内。当轮转动时楔形块水平杆槽内的栓滑动,从而导致槽中楔形块垂直滑动。楔形块垂直滑动是为了推动完成的饺子出饺子成型装置进入到饺子收集器中,这个过程是依靠推杆(图二所示)与臂的连接实现的。需要明白的是旋转轮的八角形状只是目前发明的最好的体现,而且基本上相当数量的饺子成型装置所装有的任何多边形旋转轮都能够被改装。根据目前的自动包饺子机来看,这种发明是很高效的,因为操作这台机器的能量大约只需要1HP,并且比起工人来,机器可以更卫生更快的包饺子。机器体积很小巧,可以把它很容易地移动到任何方便的地方。文章来源:/netacgi/nph-Parser?Sect1=PTO2&Sect2=HITOFF&p=1&u=%2Fnetahtml%2FPTO%2Fsearch-bool.html&r=1&f=G&l=50&co1=AND&d=PTXT&s1=%22dumpling+machine%22&OS=外文原文:United States Patent 4,160,634Automatic dumpling making machine AbstractAn automatic dumpling making machine substantially comprising a transmission mechanism for dough sheets thickness control and delivery, a flour container for containing flour to be applied over the dough sheets, stuffing control and feeding devices for feeding a fixed amount of stuffings into each of the dough sheets, a plurality of dumpling forming devices mounted on the peripheral surfaces of two polygon-shaped rotating wheels for folding up the dough sheets after stuffings have been fed in to form a dumpling, and a pushing rod for pushing the finished dumplings out of the forming devices into a dumpling collector. ClaimsWhat is claimed is:1. An automatic dumpling making machine substantially comprising a dough sheet holder for holding dough sheets to be used; a transmission mechanism for transmitting the dough sheets; a flour container for containing flour to be applied over the sheets; a stuffing hopper for storing stuffings; a stuffing control device for controlling the amount of stuffings to be fed into a sheet; a stuffing feeding device for feeding stuffings into a sheet; a hitting device for hitting the central part of the sheet to form a dent for receiving stuffings; two polygon-shaped rotating wheels; a plurality of dumpling forming devices mounted on the peripheral surfaces of said two polygon-shaped rotating wheels for folding up the dough sheet to form a dumpling; a pushing rod for pushing the finished dumplings out of the forming device; a fixed and a movable brush means for cleaning the dumpling forming device; and a dumpling collector and a dough sheet collector for collecting the finished dumplings and remaining dough sheets respectively, wherein each dough sheet is transmitted by the transmission mechanism to one of the dumpling forming devices where the sheet is hit by the hitting device to form a central dent and stuffings are fed into the dent from the hopper through the stuffing controller, and the forming device then folds up the dough sheet and cuts the same into a desirable shape and size, said movable brush comprising a brush part and a handle whose one end is formed into a ring groove for receiving one head of a fork, and the other end of the fork being secured to a seat, the fork having an arm with a wheel mounted thereon for engaging with a cam having a lobe so that when said cam lobe comes into contact with the wheel the fork is forced to rotate with respect to the fixed fork head and pull the brush backward, the brush being thereafter spring means pushed forward again. 2. The automatic dumpling making machine according to claim 1, wherein the transmission mechanism for dough sheets comprises two wheels oppositely arranged so that the thickness of the dough sheets passing therethrough is maintained constant. 3. The automatic dumpling making machine according to claim 1 wherein a wheel having a zig zagged surface and a stirrer means are provided in the flour container for stirring the flour contained therein and accumulating the flour on said zig zagged surface of said wheel so that when the latter is in rotation a layer of flour will be applied over the surface of the dough sheet. 4. The automatic dumpling making machine according to claim 1, wherein the stuffing controller comprises two intermeshing rollers oppositely arranged to form an upper and a lower part of the stuffing controller so that when the two rollers rotate with respect to each other a fixed amount of stuffings will be forced from the upper part into the lower part of the controller. 5. The automatic dumpling making machine according to claim 1, wherein the feeding device comprises a stuffing guide pipe for receiving stuffings and a vertically movable feed rod, said guide pipe being connected to a fixed support and said feed rod being connected to a vertically slidable plate and carried therewith to form a vertical motion for feeding the stuffings into the dough sheets. 6. The stuffing feeding device according to claim 5, wherein a stuffing remover having a claw portion in contact with the feed rod and capable of a vertical motion relative to the feed rod is further provided for completely removing the sticky stuffings from the feed rod. 7. The automatic dumpling making machine according to claim 1 wherein the dumpling forming device comprises a fixed lower die and a rotatable upper die locked together along one side, and the upper die is 180 degree rotatable with respect to the axes on the other side thereof so that a raised block on the lower die may be tightly clamped into a corresponding recess formed on the upper die for folding and cutting the dough sheet placed therein into a desirable shape. 8. The automatic dumpling making machine according to claim 1, wherein the polygon-shaped rotating wheels are substantially two synchronous octagon wheels with a protection sleeve mounted in between for preventing flour from falling into the shafts of the rotating wheels, and a set of eight dumpling forming devices is mounted on the eight peripheral surfaces of the octagon wheels. 9. The automatic dumpling making machine according to claim 1, wherein the pushing rod is connected to and drivable by a wedge block vertically slidable in a wedge-shaped slot on a fixed axis of one of the two polygon-shaped rotating wheels. 10. An automatic dumpling making machine substantially comprising a dough sheet holder for holding dough sheets to be used; a transmission mechanism for transmitting the dough sheets; a flour container for containing flour to be applied over the sheets; a stuffing hopper for storing stuffings; a stuffing control device for controlling the amount of stuffings to be fed into a sheet; a stuffing feeding device for feeding stuffings into a sheet; a hitting device for hitting the central part of the sheet to form a dent for receiving stuffings; two polygon-shaped rotating wheels; a plurality of dumpling forming devices mounted on the peripheral surfaces of said two polygon-shaped rotating wheels for folding up the dough sheet to form a dumpling; a pushing rod for pushing the finished dumplings out of the forming device; a fixed and a movable brush means for cleaning the dumpling forming device; and a dumpling collector and a dough sheet collector for collecting the finished dumplings and remaining dough sheets respectively, wherein each dough sheet is transmitted by the transmission mechanism to one of dumpling forming devices where the sheet is hit by the hitting device to form a central dent and stuffings are fed into the dent from the hopper through the stuffing controller, and the forming device then folds up the dough sheet and cuts the same into a desirable shape and size, said feeding device comprising a stuffing guide pipe wherein the feeding device comprises a stuffing guide pipe for receiving stuffings and a vertically movable feed rod, said guide pipe being connected to a fixed support and said feed rod being connected to a vertically slidable plate and carried therewith to form a vertical motion for feeding the stuffings into the dough sheets, the vertical slide motion of said slidable plate being effected by the cooperation of a semi-circular roller having a pin protruding therefrom with a plate having a wheel and a semi-circular slot provided therein so that when said pin is engaged in said slot the rotating roller will be in contact with the wheel while leaving the plate unaffected and when the pin is disengaged from the slot the plate will be carried therewith into a vertical motion. DescriptionBACKGROUND OF THE INVENTION The present invention relates to an automatic dumpling making machine. Dumpling is a very popular Chinese food. Traditional way of making dumplings is to first manually put a proper amount of stuffings on a piece of dough sheet, then cut the sheet into a suitable size or shape, and finally fold the sheet up to form a dumpling. Dumplings produced in this way may undesirably become too large or too small because the amount of stuffings to be put in is difficult to control, and the thickness of the dough sheets is not constant. Furthermore, the traditional way of making dumplings by hands is unsanitary and inefficient. It may take, for instance, half an hour or so to complete dumplings for a serving of two. With the fast growing demand for dumplings, an automatic dumpling making machine is indeed in great need. SUMMARY OF THE INVENTION The primary object of the present invention is to provide an automatic dumpling making machine wherein a series of operations required to complete a dumpling such as dough sheets delivery, stuffings feeding, dough sheets cutting and folding, and dumpling product removing etc. are performed automatically. Another object of the present invention is to provide an automatic dumpling making machine wherein the thickness of dough sheets and the amount of stuffings to be fed in can be readily controlled. Still another object of the present invention is to provide a compact automatic dumpling making machine which is efficient and sanitary in making dumplings and consumes very little power. Other objects and advantages will become apparant from the following detailed description of the present invention with reference to the accompanying drawings. BRIEF DESCRIPTION OF THE DRAWING FIG. 1 is a perspective view of the automatic dumpling making machine according to the present invention; FIG. 2 is a front view of the automatic dumpling making machine according to the present invention; FIG. 3 is an exploded perspective view of a stuffing feeding device according to the present invention; FIG. 4 is an exploded perspective view of a dumpling forming device according to the present invention; FIG. 5 is an exploded perspective view of a movable brush in the dumpling forming device; FIG. 6 is an exploded perspective view of a rotating wheels control pin in the dumpling forming device; FIG. 7 is an exploded perspective view of the transmission mechanisms for a slidable plate in the dumpling making machine; FIG. 8 is a vertical view of the transmission mechanisms in FIG. 7; FIG. 9 is an exploded perspective view showing two octagon rotating wheels upon which a set of eight forming devices can be mounted; and FIG. 10 is a vertical sectional view of the rotating wheels in FIG. 9. DESCRIPTION OF PREFERRED EMBODIMENT FIGS. 1 and 2 show respectively the perspective and the front views of the automatic dumpling making machine according to the present invention. The automatic dumpling making machine 10 substantially comprises a dough sheets holder 11 for holding dough sheets to be used; a transmission mechanism 12 for transmitting dough sheets; a flour container 13 for containing flour to be applied over the dough sheets; a stuffing hopper 14 for storing stuffings and later dispensing them through a stuffing controller 15 to a stuffing feeding device 16; a cutting device 17 for cutting the dough sheets into a proper shape and size; a hitting device 18 for hitting the central part of the dough sheet to form a dent for receiving stuffings; a pressing wheel 19 for forcing a dumpling forming device 20 to fold up the dough sheet after stuffings have been fed into the sheet to form a dumpling; a pushing rod 21 connected to the forming device 20 for pushing the finished dumplings out of the forming device into a dumpling collector 24; a fixed brush 22 and a movable brush 23 for cleaning the forming device 20 everytime after a dumpling is completed; and a dough sheet collector 25 for collecting the remaining dough sheets. The process of making dumplings by means of the automatic dumpling making machine 10 is described below with reference to FIG. 2. The dough sheets stored in the holder 11 are transmitted through a pair of wheels 121 and 122 of the transmission mechanism 12 and a confining plate 26 into the flour container 13. The wheels 121 and 122 are oppositely arranged so that the thickness of the dough sheets passing therethrough is made constant. Provided in the flour container 13 are a stirrer 131 for stirring the flour in the container, a wheel 132 having a zigzagged outer surface, and a wheel 133 located opposite to the wheel 132. When a dough sheet passes through the space between the two wheels 132 and 133, a proper amount of flour will be applied over the back surface of the dough sheet for preventing the same from sticking to the dumpling forming device 20 later. After exiting from the flour container 13, the dough sheet is placed on the forming device 20. The hitting device 18 then hits with its one enlarged end 181 the central part of the sheet to form a dent for filling in stuffings. In the meantime, the cutting device 17 cuts the dough sheet into a proper shape. A fixed amount of stuffings is fed from the hopper 14 through the amount controller 15 into the dent on the sheet. The pressing wheel 19 then forced the forming device 20 to fold up the dough sheet to form a dumpling. The dumpling is then pushed by the pushing rod 21 out of the forming device into the dumpling collector 24. The forming device 20 is cleaned by brushes 22 and 23, and is then ready for receiving the next sheet. This process repeats until all the dough sheets in the holder 11 are used up. According to the present invention, there is a set of eight identical forming devices which are to be detailed later. Referring to FIG. 2, a screw feeder 141 is provided in the stuffing hopper 14 for constantly driving the stuffings downward. Two rollers 151 and 152 shaped as illustrated in FIG. 2 are provided in the stuffing controller 15 so that when the two rollers rotate through a predetermined angle the stuffings accumulated in the upper part 153 of the controller are squeezed into the lower part 154 of the same and then enter the feeding device 16 through a guide tube 155. FIG. 3 shows an exploded perspective view of the feeding device 16 according to the present invention. The feeding device 16 is secured through a first support 161 to the outer surface of the forming device 20. One end of the support 161 is formed into a ring 162 for receiving a stuffing guide pipe 164 which in turn receives a feed rod 165. The feed rod 165 is connected to one end of a second support 166 by means of a ring nut 167. The other end of the second support 166 is fixed to a vertically slidable plate 27 (shown in FIG. 1) and is therefore allowed a vertical movement. In this manner, the feed rod 165 is capable of an up and down motion whereby driving a fixed amount of stuffings from the hpper 14 through the piep 164 into the dent on the dough sheet. In order to be able to completely remove the sticky stuffings from the feed rod 165, a ladle-shaped stuffing remover 168 having a claw portion is also provided in the feeding device with an elongated handle thereof received in a recess preformed on the peripheral wall of the ring 162. The upper end of the handle 170 is bent 90 degree and rested on a plate 169 screw connected to the second support 166. In this way, the plate 169 together with the ladle-shaped stuffing remover may be carried by the slidable plate 27 to perform a vertical motion. A spring device 171 is further provided to accelerate the downward movement of the stuffing remover 168. FIG. 4 shows an exploded perspective view of one of the set of eight forming devices 20 according to the present invention. The forming device 20 comprises a set of two dies, a fixed lower die 201 and a rotatable upper die 202. The upper die 202 can rotate about axes 203 located on one side thereof, and is connected to the side walls 205 of the forming device through roller bearings 204. The upper and lower dies are locked together at one side by means of screws 206, and the entire assembly is connected to two octagon rotating wheels to be detailed in FIGS. 9 and 10. One of the axes 203 of the upper die 202 is drivable by a driving device 207 having an arm 208. In this manner, the upper die 202 is 180 degree rotatable with respect to the axes 203 whereby a raised block 209 on the lower die 201 is clamped into a conformable recess 210 formed on the rotatable die 202. This corresponds to the operation of folding up the dough sheet. In the meantime, the dough sheet is cut into proper shape and size because of the tight engagement of the block 209 into the recess 210. The forming device according to the present invention has to be cleaned everytime a dumpling is formed before it is ready for the next. Referring to FIG. 2, as mentioned before, a fixed brush 22 is used to clean the surface of the forming device, and a movable brush 23 is further provided for cleaning the recess 210 and the block 209. An exploded perspective view of the movable brush 23 is illustrated in FIG. 5. Brush part 231 is attached to a handle 232 whose one end is formed into a ring groove 233 between two metal plates. A fork 234 whose one head 235 is secured to a seat 236 and another head 237 is received in the groove 233 is adopted for driving the movable brush 23. The fork 234 has an arm 238 with a wheel 239 mounted thereon. The wheel 239 is engaged with a cam 241 on a shaft 240 so that when the cam lobe of the cam 241 is in contact with the wheel 239 the fork 234 will be forced to rotate with respect to one end 235 thereof and whereby pull the handle 232 backward by its another end 237. In this manner, the movable brush can both rotate and reciprocate to cooperate with the motion of the forming device on the rotating wheels, and to clean the space between the raised block 209 and the recess 210. A spring 242 is connected between two screws 243 and 244 provided on the fork 234 and 244 provided on the fork 234 and the shaft 240 respectively for driving the movable brush 23 forward again. FIG. 6 is an exploded perspective view of a rotating wheels control pin. The control pin 280 is mounted on the forming device and operated by a lever 282 having a screw 281 as the lever fulcrum. The front end 286 of the control pin is in the form of a fork drivable by a pushing bar 285 connected at the upper end of the lever 282. The lower end of the lever 282 is bent into an arm 283 with a wheel 284 mounted thereon. The wheel 284 is engaged with a cam 245 shown in FIG. 5 so that when the cam lobe of the cam 245 is in contact with the wheel 284 the lever 282 can be rotated counterclockwise, whereby pushing the control pin 280 by means of the pushing bar 285 into a lateral motion. A spring 287 is used to restore the lever 282 to its original position. The vertical slide motion of the slidable plate 27 mentioned before is achieved by means of a special transmission mechanism according to present invention. An exploded perspective view and a vertical sectional view of the transmission mechanism is shown in FIGS. 7 and 8 respectively. A roller 301 in the form of a semi-circle is provided with a pin 302 located in the middle of the semi-circular periphery and protruding therefrom. The pin 302 is engageable with a semi-circular slot 307 formed on a plate 306. A gear 304 is fixed by another pin 305 to one end of the axis 303 of the roller 301. A small wheel 308 is further provided on the plate 306 and is rotatable with respect to its own axis 309. A connecting rod 310 is formed integrally with the plate 306 for vertically carrying the slidable plate 27 shown in FIG. 1 when the plate 306 performs a vertical slide motion. The vertical slide motion of the plate 306 is enabled through the cooperation of the roller 301 with the semi-circular slot 307 on the plate 306. During the period in which the pin 302 on the roller 301 is engaged in the slot 307, the wheel 308 is in contact with the surface of the roller 301. As a result, though the roller 301 is rotating, the plate 306 stands still. After the pin 302 reaches the left end of the slot 307, the pin 302 keeps going down with the rotation of the roller 301 forcing the plate 306 downward. Later, the pin 302 together with the plate 306 is carried up again after having passed its lowest position, and finally enters the slot 307 again. The plate 306 is then held still for another period of time at this highest position. The entire process repeat

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号