饺子机设计【含全套17张CAD图纸】【答辩毕业资料】

收藏

资源目录

压缩包内文档预览:

编号:347122

类型:共享资源

大小:4.94MB

格式:RAR

上传时间:2014-10-24

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

45

积分

- 关 键 词:

-

饺子机

设计

全套

cad

图纸

答辩

毕业

资料

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

1绪论 2

1.1 包馅(夹馅)食品机械的应用前景和发展现状 2

1.2 饺子机的相关介绍、研制意义和目标、未来的发展方向 2

1.2.1 饺子机的介绍 2

1.2.2 饺子机的研制意义和目标及未来的发展方向 3

2机械系统总体方案的拟定 4

2.1动力系统的拟定 4

2.2传动系统的拟定 4

2.3执行机构的拟定 4

3工作机构运动需求分析及初步设计 6

3.1饺子模型的建立与分析 6

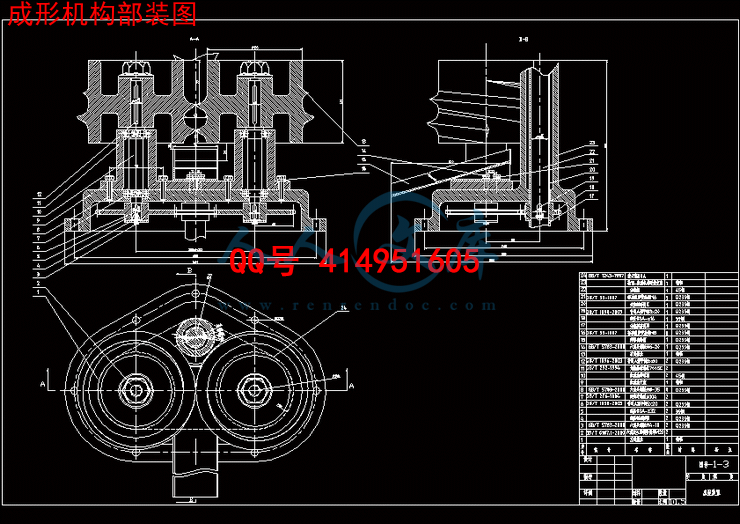

3.2 生产效率与成型盘的设计 7

3.3 横、竖蛟龙的设计计算 8

3.3.1 竖绞龙的设计计算 8

3.3.2 横绞龙的设计计算 8

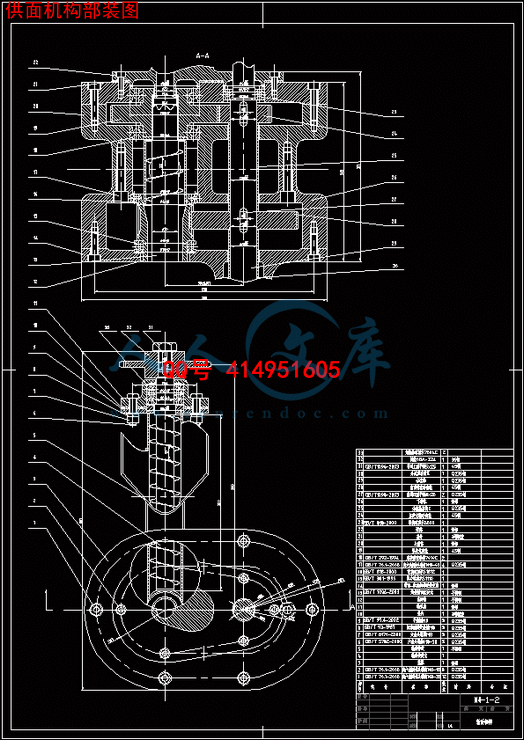

3.4 供馅泵的设计 9

3.4.1供馅装置局部装配图 9

3.5 出面嘴的设计 10

4传动系统的设计计算 11

4.1 传动比的分配 11

4.1.1 电动机转速的确定 11

4.1.2 传动比的总体分配及各轴转速的确定 11

4.1.3 确定各个执行部件所需的功率 11

4.2 蜗轮蜗杆传动副的设计 11

4.2.1 设计要求 11

4.2.2 初选参数及材料 12

4.2.3 初步计算 12

4.2.4 根据齿面接触疲劳强度条件设计蜗轮蜗杆副 13

4.2.5 校核蜗轮齿根弯曲疲劳强度和热平衡 14

4.2.6 蜗轮蜗杆受力计算 14

4.3 直齿圆锥齿轮传动副的传动设计 15

4.3.1 设计要求 15

4.3.3 初步计算 16

4.3.4 根据齿面接触疲劳强度条件设计直齿圆锥齿轮传动副 16

4.3.5 校核齿根弯曲疲劳强度 16

4.3.6 圆锥齿轮受力计算 17

4.4 链传动设计 17

4.4.1 横绞龙链传动设计 17

4.4.2 成形机构链传动设计 17

4.5 出面嘴直齿圆柱齿轮设计及校核 18

4.5.1 设计要求 18

4.5.2 模数、齿数及分度圆直径的计算 19

4.5.3 选择参数与材料并进行初步计算 19

4.5.4 校核齿轮强度条件 19

4.5.5 受力计算 21

4.6 竖绞龙直齿圆柱齿轮设计及校核 21

4.6.1 设计要求 21

4.6.2 模数、齿数及分度圆直径的计算 21

4.6.3 选择参数与材料并进行初步计算 21

4.6.4 校核齿轮强度条件 22

4.6.5 受力计算 23

5分流轴及其附件的设计计算 23

5.1 分流轴的设计与校核 23

5.1.1 设计要求 23

5.1.2 分流轴受力情况分析 23

5.1.3 计算初选轴径 25

5.1.4 分流轴各段轴径的确定 25

5.1.5 轴的受力分析 25

5.1.6 轴的校核 31

5.2 轴承的设计与校核 32

5.2.1 轴承的选择 32

5.2.2 1位置轴承的校核 32

5.2.3 3位置轴承的校核 33

5.2.4 7位置轴承的校核 33

5.3 键联接的设计与校核 34

5.3.1 键的选型 34

5.3.2 键的校核 34

5.4 花键连接的设计与校核 35

6 结论 36

7部分外购件清单 37

8参考文献 39

1 普通图书 39

2 期刊中析出的文献 39

3专利 40

饺子机设计

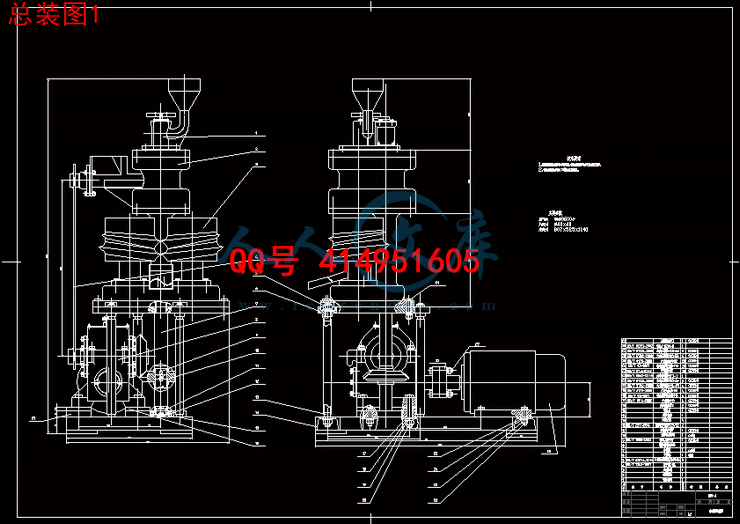

摘 要:本毕业设计完成了“饺子机设计”,设计目的是实现将饺子生产从手工劳动到机械化生产的转变。通过观察饺子手工生产过程以及借鉴国内外相关食品成型机械的结构特点,采用成型盘为成型元件、螺旋机构为面料输送元件、滑片泵为输馅元件的灌肠式滚切成型原理设计饺子机。该种成型原理生产效率高,可以实现连续式生产,因此在食品机械中得到广泛应用。本次设计动力源使用电动机、主要变速机构使用蜗轮蜗杆减速器、动力分配机构使用分流轴的传动方式,并对传动系统中大部分的传动部件进行了设计和校核,同时绘制了饺子机的主要零部件图纸及总体装配图纸。

关键词: 饺子;食品机械;成型盘;螺旋机构

The Design of dumpling Machine

Abstract

This graduation design accomplished “the design of dumpling producing machine”. The purpose of this designing is to realize the improvement of the dumpling production method from manual labor to machine manufacturing. Based on the observation of the manual labor process of the dumpling production and the reference of the analogous food shaping machinery’s configuration in home and abroad, with which the shaping principle to design the dumpling producing machine and also with the shaping wheel for shaper, screw mechanism for dough transporter and vane pump for stuff transporter. Greater production efficiency and continuous production can be realized by this shaping principle, therefore, it can be widely applied in food machinery industry.

This design adapt the electric motor for power, worm reducer for main speed change transmission and shunt shaft for power allocation mechanism as well as to make design and check on most of the driver units in driver system. Besides, both the main parts and the assembly drawing have been rendering.

Keywords:dumpling, food machinery, shaping wheel, screw mechanism

1绪论

1.1 包馅(夹馅)食品机械的应用前景和发展现状

包馅(夹馅)食品在我国历史悠久,伴随着几千年的文明的发展已经成为我国食品文化中的代表,如饺子、包子、馄沌是主食的一部分;汤圆、月饼、粽子是传统节日中必不可缺的食物。如今,经济的迅速增长、人民生活水平的提高和生活节奏的加快,对食品行业提出了新的要求。而本人认为这些要求可以归纳为两大类:

- 内容简介:

-

重 庆 理 工 大 学毕业设计(论文)任务书 题目 饺子机设计 (任务起止日期2013年2月28日2012年6月13日) 重庆汽车学院 学院 机械设计制造及其自动化 专业 09424 班学生姓名 彭小刚 学 号 10904020416 指导教师 王黎明 系 主 任 冯文杰 二级学院院长 课题内容本课题的内容是关于包饺子机的设计,主要包括饺子机的输面、送馅儿机构和成型模块的设计。课题任务要求1. 完成文献资料的搜集和整理,至少查阅四篇中文专利和一篇外文专利。2. 在现有资料和专利的基础上提出自己设计方案,画出机构简图3. 完成必要的设计计算和零件的结构设计和标准件和外购件的选择4. 完成工程装配图和零件图5. 完成毕业设计论文主要参考文献(由指导教师选定)【1】葛文杰机械原理,高等教育出版社【2】濮良贵、纪名刚 机械设计,高等教育出版社【3】李兴国 食品机械学四川教育出版社【4】科学计算器,计算机,三维建模软件(CATIA、Solidworks、AutoCAD等)【5】吕志昆,张立,王艳秋“新型饺子机的设计”【6】朱景超 多功能全自动饺子机 CN 102726671A【7】林登财 饺子机 93203845.X【8】孙桓、陈作模、葛文杰 西北工业大学机械原理 高等教育出版社【9】濮良贵 纪名刚 西北工业大学机械原理 高等教育出版社【10】机械设计 课程设计指导书 袭湘义 罗圣国 高等教育出版社 【11】吕志昆,赵国平,等“互逆转动输出管状制品装置” 专利说明书【P】【12】无锡轻工学院,天津轻工学院编食品工厂机械与设备【M】北京:轻工业出版社,1991同组设计者 无注:1、任务书由指导教师填写;2、任务书在第七学期第15周前下达给学生。学生完成毕业设计(论文)工作进度计划表序号毕业设计(论文)工作任务工 作 进 度 日 程 安 排周次1234567891011121314151617181查找整理课题相关资料文献等2撰写开题报告、文献综述、任务书3阅读英文文献并翻译一篇英文文献4前期工作的汇总整理5确定具体方案以及整理思路6理论计算7结构设计8绘制工程图9完成课题论文的撰写注:1、此表由指导教师填写;2、此表每个学生一份,作为毕业设计(论文)检查工作进度之依据;3、进度安排用“”在相应位置画出。毕业设计(论文)阶段工作情况检查表时间第 一 阶 段(撰写开题报告、外文翻译、文献综述)第 二 阶 段(论文初稿撰写或方案设计)第 三 阶 段(论文终稿或图纸绘制)内容组织纪律完 成 任 务 情 况组织纪律完 成 任 务 情 况组织纪律完 成 任 务 情 况检查情况教师签字签字 日期 签字 日期签字 日期注:1、此表由指导教师认真填写;2、“组织纪律”一栏根据学生具体执行情况如实填写;3、“完成任务情况”一栏按学生是否按进度保质保量完成任务的情况填写;4、对违纪和不能按时完成任务者,指导教师可根据情节轻重对该生提出警告或不能参加答辩的建议。第二篇Dumpling makerAbstractA cooking utensil includes an all-in-one device that incorporates a partially perforated pan, circular in shape, with a permanent and continuous circumferential holder with one or more supports that provide stability and safety during the extrusion process of the soft batter. At the same time, this cooking utensil fits easily on top of commonly used cooking vessels regardless of lip configuration or vessel diameter. This cooking utensil also includes versions for removable type holders in kit form that can be used interchangeably with several pans with different hole sizes while providing multiple support and stability over commonly used cooking vessels. Claims claim: 1. An all-in-one cooking utensil comprising: a pan having a bottom, sides that extend from said bottom to a continuous circumferential rim, a width of said continuous circumferential rim being in an inclusive range of 1 inch through 6 inches, at least one extended support that extends radially from said rim, and a handle formed integrally with said rim, wherein said bottom includes two side-by-side sections including a first section having holes formed therethrough and a second section that is devoid of said holes and is configured to hold batter thereon as a staging area for being extruded through said holes in said first section, wherein said handle and said at least one extended support are configured to rest on a cooking pot so as to position an entirety of said bottom of said pan over an interior portion of said cooking pot. 2. The all-in-one cooking utensil of claim 1, wherein: said holes including circular-shaped holes arranged in a pattern. 3. The all-in-one cooking utensil of claim 1, wherein: said holes including non-round shaped holes. 4. The all-in-one cooking utensil of claim 1, wherein: said handle is longer than said at least one extended support. 5. A cooking utensil comprising: a pan; a continuous circumferential pan holder having a frame having an inner diameter sized to accommodate the pan, the pan being a partially perforated pan having a diameter in an inclusive range of 7.5 inches through 12 inches in diameter, and an outer diameter up to 19 inches, a handle that extends from said outer diameter of said frame up to 7 inches in length; and at least one extension connected to said frame that extends, radially outward from said outer diameter by a distance and displaced along said outer diameter from said handle by another distance, wherein a bottom of said partially perforated pan includes two side-by-side sections including a first section having holes formed therethrough and a second section that is devoid of said holes and is configured to hold batter thereon as a staging area for being extruded through said holes in said first section, and when resting on a cooking pot said pan holder is configured to hold an entirety of the bottom of the pan over an interior portion of the cooking pot. 6. The cooking utensil of claim 5, wherein: same frame having a substantially flat upper and lower surface. 7. The cooking utensil of claim 6, wherein: said frame being formed of sheet metal. 8. The cooking utensil of claim 6, wherein: said frame being formed of heat resistant plastic. 9. The cooking utensil of claim 6, wherein: a difference between said inner diameter and said outer diameter being in an inclusive range of 1 inch to 3 inches, and said outer diameter being not more than 15 inches. 10. The cooking utensil of claim 5, wherein: said frame being formed from a rod with a circular cross-section. 11. The cooking utensil of claim 10, wherein: said handle being formed from said rod. 12. The cooking utensil of claim 11, wherein: said at least one extension being formed from said rod. 13. The cooking utensil of claim 12, wherein: said at least one extension includes a first extended support ear at a 10:00 oclock position a second extended support ear at a 2:00 oclock position, and said handle being at a 6:00 oclock position. 14. The cooking utensil of claim 5, wherein: said handle is longer than said at least one extension. 15. A cooking kit, comprising: a first substantially circular cooking pan having a substantially circular bottom having a diameter in an inclusive range of 7 through 12 inches; a frame configured to hold an entirety of said bottom of said cooking pan within an inner diameter of a cooking pot on which said frame is configured to be disposed; a side that extends from said bottom to a continuous circumferential lip that is configured to contact and be supported by the frame, said side includes a detent formed therein such that said frame is held in place between said lip and said detent when said pan is placed on said frame, and said bottom includes two side-by-side sections including a first section having holes formed therethrough and a second section that is devoid of said holes and is configured to hold batter thereon as a staging area for being extruded through said holes in said first section. 16. The kit of claim 15, further comprising: a second pan including different shaped holes as said first pan. 17. The kit of claim 15, further comprising: a second pan including a different pattern of holes than said first pan. 18. The kit of claim 15, further comprising: a second pan including more holes than said holes in said first pan. DescriptionBACKGROUND OF THE INVENTION 1. Field of Invention The present invention relates to food preparation devices. More particularly, the present invention relates to machines and apparatuses for preparing cooked foods, especially dumplings. 2. Discussion of the Background People have been making dumplings for years. In a typical process, the cook uses various cooking utensils to extrude soft batter and the like into a pot of hot liquid, such as water or oil. These conventional utensils generally include a partially perforated (e.g., holes distributed over half a surface) or totally perforated (holes distributed over an entire surface) pan or a die through which a cook extrudes pre-prepared through the perforated plates, or surfaces, by applying a force to the batter, perhaps using a tool to assist in applying the force. For example, U.S. Pat. No. 3,452,688 describes a dough extruding apparatus having an extrusion die mounted directly above a cooking vessel. The dough is extruded through the die by a force exerted on a pressure plate by manually pushing handle downwardly. U.S. Pat. No. 1,461,504 describes a macaroni die that includes a plurality of plates secured together. The die is adapted for producing food products with irregular shapes. U.S. Pat. No. 4,452,581 describes a cooking utensil having a pan with a food holding area and an array of holes making up the extrusion area for batter that is pressed therethrough. The pan is removably mounted on a cooking vessel by way of a single removable clamp that holds the pan in place during the batter extrusion process. The present inventor identified a number of limitations with this convention device. For example, the use of a single clamp provides insufficient stability for a pan, thus creating a safety hazard because the device is used over boiling water. Furthermore, the device cannot be universally used over a wide variety of cooking vessels because the clamp is not adapted for use with cooking vessels having, for example, a curved lip. The utility of this device is also limited because the single clamp mounting arrangement of the pan on top of cooking vessel leaves excessive exposed surface area of the boiling water, and thus creating a steam scolding hazard for the cook. The present inventor also recognized that this conventional device offers no provision for a handle, making the pan awkward to manage. Lastly, certain batter mixtures are very sticky and can easily lift up the whole cooking utensil and force it to fall into the boiling water, thus creating another safety hazard. BRIEF SUMMARY OF THE INVENTION An object of the present invention is to overcome the above-identified and other deficiencies with conventional cooking apparatuses. As recognized by the present inventor, it would be advantageous to provide a one-piece cooking utensil that would have a radially-extended, continuous circumferential rim with one or more extended supports and a handle over the cooking vessel to provide safety and speed to facilitate dumpling making. It would also be advantageous to provide a two-piece cooking utensil having a detachable holder and a partially or completely perforated pan that can be universally placed on top of any commonly used cooking vessel regardless of lip configurations that are commonly available. It would also be advantageous if the cooking utensil could be supported at multiple points on top of the cooking vessel to provide stability and safety for the utensil during operation. It would also be advantageous to cover or significantly reduce the exposed surface area of the boiling water around the cooking utensil to protect the cook from steam scolding during the extrusion process. It would also be advantageous to have a handle for the holding device to provide additional support, quick and safe removal of the cooking utensil from the cooking vessel. It would also be advantageous to provide a holding device for the perforated pan that would be removable and easily adaptable to different size perforated pans and at the same time provide a handle and one or more supports for safety and speed to the dumpling making process. It would also be advantageous to provide a removable holding device that would tightly snap around the perforated pan that would prevent the pan from coming loose during dumpling making. It would also be advantageous to provide a two piece cooking utensil having a detachable holder and a partially or completely perforated pan that can be universally placed on top of any commonly used cooking vessel regardless of lip configuration. The present invention addresses these, and other, needs by providing a continuous circumferential pan holder for the partially perforated pan, preferably circular but it can be of rectangular or other geometric shape, on top of the cooking vessel and thereby provide total support all the way around the pan, stability and safety during the extrusion process. Another object is to provide a universal pan holder that can be used on all common cooking vessels typically ranging from 7.5 inches to 19 inches in diameter, or any pot diameter by matching an appropriate size holder for the pan. Another object is to provide a pan holder with one or more support points that can be easily attached to other perforated pans having different hole sizes and patterns to facilitate smaller or larger dumpling production. Another object is to provide a handle for the pan holder outside of the cooking vessel surface area to prevent the homemaker from steam burns and to provide additional stability and mobility during dumpling making. In addition, the handle would provide a way to lift the perforated pan from the cooking vessel and help with the occasional stirring of the dumplings in the boiling water or soup. In a first embodiment, an all-in-one piece, or integrated, stamped or molded cooking utensil includes a partially perforated pan having a narrow rim, radially extended outward continuously and circumferentially. The device also has one or more supports and a handle that protrudes beyond the outermost diameter of the rim. The resultant cooking utensil is a one piece stamped (forged, molded or cast) assembly, whereby the extended rim and outer supports are flat and become an integral part of the perforated pan. The cooking utensil is made to conveniently rest on top of most common cooking vessels. A second embodiment provides a universal and removable-type one piece stamped, forged or molded flat holder, of sufficient structural strength to hold, a perforated pan. This holder, has a void in its center (or other interior portion) to accommodate the perforated pan, has a continuous and circumferential wide rim and has one or more supports and a handle as an integral part of the assembly. This universal pan holder can be made from sheet metal such as aluminum or stainless steel, heat resistant plastic or any other suitable food-grade material. A flat holder fits directly underneath the pan rim and provides continuous circumferential support as well as one or more extended support points over a cooking vessel similar to all-in-one utensil described above. This embodiment of the invention is suitable to be packaged as part of a kit to facilitate the interchangeability of several pans with different perforated hole sizes, shapes and layouts to accommodate a partially perforated pan having a refill area and an extrusion area. A third embodiment of the invention provides a separate removable and universal wire-type pan holder made from round stainless stock and bent into an appropriate pattern to provide one or more support points. This embodiment may also be packaged as a part of a kit to facilitate the interchangeability of several pans with different hole sizes, shapes and layouts having a refill area and an extrusion area. In conjunction with the use of this wire-type holder, the vertical sides of the perforated pan are fitted with multiple detents whereby the holder is slipped over them and is locked between the detents and the rim of the pan. The resultant holder assembly provides multiple support points with handle to operate cooking utensil safely and quickly. A fourth embodiment provides a separate removable and universal vertical metal band-type pan holder made from flat stainless steel stock, preferably 1/16 in.times.3/8 in, bent vertically into an appropriate pattern to provide one or more support points. This embodiment may also be packaged as part of a kit to facilitate the interchangeability of several pans with different hole sizes and layouts having a refill area and an extrusion area. BRIEF DESCRIPTION OF THE DRAWINGS FIG. 1-Plan view of all-in-one cooking utensil-(Dumpling maker) FIG. 2-Profile view of all-in-one cooking utensil FIG. 3-Plan view of universal flat-type pan holder FIG. 4-Plan view of circular partially perforated pan FIG. 5-Side view of circular partially perforated pan FIG. 6-Plan view of assembled cooking utensil with flat-type pan holder FIG. 7-Side view of assembled cooking utensil with flat-type pan holder FIG. 8-Plan view of wire/rod-type universal pan holder FIG. 9-Plan view of partially perforated pan modified with detents FIG. 10-Side view of partially perforated pan modified with detents FIG. 11-Side view of assembled cooking utensil with wire/rod-type holder with detents FIG. 12-Plan view of vertical metal band-type holder FIG. 13-Side view of vertical metal band-type holder DETAILED DESCRIPTION OF THE INVENTION The present invention is an all-in-one piece cooking utensil comprising a pan with a partially perforated flat bottom 7, and vertical side 8. The pan has a narrow rim 2 that radially extends outward up to 6 inches continuously and circumferentially and one or more extended supports 3. The lengths of the supports 3 are configured to suit the cooking vessel diameter, and can either be of fixed length, or variable length. The variability may be accomplished with extension rods. The pan also includes a handle, 1, up to 7 inches in length, for example, that further protrudes passed the outermost diameter of the rim, as illustrated in FIG. 1. The resultant cooking utensil is one piece stamped, cast or molded whereby the extended rim, 2, and outer supports, 3, is generally flat and becomes an integral part of the partially perforated pan. The outer supports extend between one to six inches from the outermost diameter of the circumferential support, (rim), 2, at 10:00 oclock and 2:00 oclock positions; however, the support locations can be at any point around the circumference. The new cooking utensil, FIG. 1, will conveniently rest on top of most common cooking vessels up to 19 inches in diameter. In a preferred embodiment a universal, removable type, flat holder is provided as a one piece, stamped or molded part, 11, with sufficient structural strength to hold a perforated pan, FIG. 5. This flat holder, 11, with its center cut out (or formed with a void in the center), 7.5 inches to 12 inches in diameter, to accommodate the perforated pan, would be continuous and circumferential with wide rim, 2, with extended supports, 3, and a handle, 1, as an integral part of the assembly. This universal pan holder is made from metal such as stainless steel (sheet metal) or aluminum, plastic or any other suitable food-grade material. This flat rim holder, 11, as illustrated in FIG. 3 fits directly underneath the pan rim and provides continuous circumferential support, 2, as well as one or more extended support points, 3, over the cooking vessel similar to the all-in-one utensil described above. One attribute of this invention is that it can be arranged as a kit to facilitate the interchangeability of several pans with different hole sizes and layouts to accommodate a partially perforated pan having a refill area, 5, and an extrusion area, 4. In a preferred embodiment a separate removable and universal wire/rod-type pan holder is made from round stainless steel stock, preferably 1/8 inch diameter, and bent into an appropriate pattern as illustrated in FIG. 8 to provide one our more support points. This embodiment of the invention is optionally packaged as a part of a kit to hold and facilitate the interchangeability of several pans with different diameter hole sizes and layouts having a refill area, 5, and an extrusion area, 4. In conjunction with the use of this wire/rod-type holder, the vertical side of the perforated pan, 9, is fitted with multiple detents, 13, whereby the wire holder is slipped over them and is locked between the detents, 13, and the rim of the pan, 10. The resultant holder assembly provides multiple extended support points with a handle to operate the cooking utensil safely and quickly. Typically, three detents, but it can be any number, are punched on the vertical side of the pan, 9, that protrude 1/16 inch from the side of the pan and located on its circumference 1/4 inch below the rim of the pan. In a preferred embodiment a separate, removable and universal vertical metal band-type pan holder is provided. The holder is made from flat stainless steel stock, preferably 14 to 20 gauge in thickness by 1/4 inch to 1 inch in width, bent vertically into an appropriate pattern shown in FIG. 13 to provide one or more support points. The inner diameter of the bent holder would accommodate circular pans from 7.5 inches to 12 inches in diameter. This invention would be a part of a kit to facilitate the interchangeability of several pans with different hole sizes and layouts having a refill area, 5, and an extrusion area, 4. Although the present invention has been particularly shown and described with reference to specific embodiments, it will be understood by those skilled in the art that various other changes in the form and details may be made therein without departing from the spirit and scope of the invention.第三篇Pastry and dumpling makerAbstractA pastry and dumpling maker for shaping and forming filled pastries, such as dumplings and the like, including a pair of cooperating mold sections which define therebetween a particular pastry shape to be formed. The mold sections are relatively moved into cooperative engagement with each other after the pastry is formed. A flexible strap is suspended above the mold sections and supports a dough skin with a filling placed thereon. As the mold sections are brought into cooperative engagement, a center portion of the flexible strap, together with the dough skin and filling, move downwardly between the mold sections, whereupon the dough skin is folded over the filling and sealed by the mold sections into the particular pastry shape. The shaped pastry is then removable upon separation of the mold sections. ClaimsWhat is claimed is:1. A pastry and dumpling maker comprising: a pair of cooperating first and second mold sections defining therebetween a particular shape of a pastry to be formed; first means for relatively moving said mold sections into cooperative engagement with each other to form the pastry, and for subsequently separating said mold sections after a shaped pastry is formed; a flexible strip of material defining a strap for supporting a dough skin with a filling of food ingredients thereon; second means for suspending said flexible strap above said mold sections, and for lowering a center portion of said flexible strap with the dough skin and filling supported thereon between said mold sections as said mold sections are moved into cooperative engagement, whereby the dough skin is folded over the filling and sealed into the particular pastry shape, the shaped pastry being removable upon separation of said mold sections. 2. A pastry and dumpling maker as in claim 1, and comprising means for removing said flexible strap from said suspending second means, whereby said flexible strap can be replaced. 3. A pastry and dumpling maker as in claim 1, wherein said mold sections define a cavity therebetween having an open bottom. 4. A pastry and dumpling maker as in claim 3, wherein said cavity has a semi-oval configuration. 5. A pastry and dumpling maker as in claim 1, wherein said first means for moving includes retaining means for fixedly retaining said first mold section, and operating means for moving said second mold section relative to said first mold section. 6. A pastry and dumpling maker as in claim 5, wherein said operating means includes support means, guide rails supported by said support means and yoke means slidable along said guide rails, said yoke means supporting said second mold section, said retaining means retaining said first mold section along a sliding path of said yoke means. 7. A pastry and dumpling maker as in claim 6, and comprising a base plate, said support means being upstanding from said base plate, said first mold section being retained by said retaining means above said base plate, and said second mold section depending from said yoke means and being confrontingly aligned with said first mold section. 8. A pastry and dumpling maker as in claim 7, wherein said flexible strap is a length of fabric material. 9. A pastry and dumpling maker as in claim 6, wherein said second means for suspending includes first engagement means for coupling one end of said strap to said support means and second engagement means for coupling an opposite end of said strap to said yoke means, whereby a center portion of said strap moves downwardly between said mold section as said yoke means slides towards said first mold section. 10. A pastry and dumpling maker as in claim 9, wherein said support means includes a fixed support platform, said guide rails being cantilevered outwardly from said support platform, a sliding limit of said yoke along said guide rails being limited by a longitudinal extent of said strap during operation of said pastry and dumpling maker. 11. A pastry and dumpling maker as in claim 10, wherein said first and second engagement means are respectively removable from said support platform and said yoke means. 12. A pastry and dumpling maker as in claim 11, wherein said first engagement means includes a U-shaped clip having a pair of legs interconnected by a bight portion, said support platform containing a pair of spaced apertures for removably receiving said legs of said clip, and a loop provided at said one end of said strap for removably receiving said bight portion of said clip therethrough. 13. A pastry and dumpling maker as in claim 7, including a recess provided in said yoke means for receiving said strap therein and defining a pair of side leg sections on opposite sides of said yoke means, bores extending through said side leg sections coaxial with said guide rails for receiving said guide rails therethrough, aligned apertures provided through said side leg sections coplanar with and perpendicular to said bores, said aligned apertures communicating with said bores, a pin received in said aligned apertures and extending between said guide rails, and a loop provided at said opposite end of said strap for receiving said pin therethrough, whereby said pin is retained in place by said guide rails when said yoke means is mounted on said guide rails, and said strap is removed by removing said U-shaped clip from said support platform, sliding said yoke means off said guide rails, and removing said pin from said aligned apertures. 14. A pastry and dumpling maker as in claim 12, wherein one leg of said U-shaped clip is shorter than the other leg. DescriptionBACKGROUND OF THE INVENTION This invention relates to a food processing device, and more particularly to a device for forming shaped pastries, dumplings and the like. Various types of pastries and dumpling require specific shapes. For example, one type utilizes a skin dough which encloses a filling. The dough is semicircularly shaped and seals around the filling. Ethnic-type pastries are particularly known for this type of structure. For example, the oriental dumpling is formed in this manner with the skin dough surrounding a chopped meat filling. Likewise, the Jewish pastry kreplech has a similar construction. Although it is well known to use particular shaped molds, such as cookie cutters and the like, for forming particular shapes of pastries, these are generally limited in use. In one type, the pastry is poured into the mold. In another type, the mold cuts directly into the pastry dough. However, when the dough must be folded around a particular filling and then sealed, molds are not used to form this shape, but rather the operation is done manually. Normally, in making such types of pastries, the dough is cut into sections, the filling is placed into the dough and, by hand, the dough is folded about the filling and then the open edges are sealed together by pressing the makers fingers into the dough. As a result, the prior art process requires skilled labor and is time consuming, thus increasing the cost per unit of these types of pastries. SUMMARY OF THE INVENTION It is accordingly an object of the present invention to provide a food processing device which can form a filled type of pastry. A further object of the present invention is to provide a pastry maker which can form and shape particular filled types of pastries, such as dumplings. Yet another object of the present invention is to provide a pastry maker which can fold a dough skin over a filling and thus seal the open edges of the dough skin around the filling. Another object of the present invention is to provide a pastry maker for forming filled dumplings and the like, which can be easily utilized, and which will decrease the time of processing and eliminate the use of skilled labor. Still another object of the present invention is to provide a pastry maker for forming filled dumplings and the like, which only utilizes a single replaceable strip of material in contact with the food, to thereby maintain sanitary conditions in the formulation of these food items. Briefly, in accordance with the present invention, there is provided a pastry and dumpling maker including a pair of cooperating mold sections which define therebetween the particular form and shape of the filled dumpling being made. The mold sections are mounted on a mechanism which can relatively move the mold sections together into cooperative engagement with each other, and can subsequently separate the mold sections. A flexible strip of material is suspended above the mold sections, and supports a dough skin and a particular filling placed on the dough skin. The flexible strip of material is lowered downwardly between the mold sections as the mold sections are moved into cooperative engagement. Together with the strip of material, the dough skin is positioned between the mold sections to fold over the filling therein, and thus the open edges of the dough skin become sealed as the mold sections engage with each other. The shaped pastry can then be removed upon separation of the mold sections. In an embodiment of the present invention, the flexible strip of material can be removed and replaced for easy maintenance thereof and to maintain sanitary conditions. The only part of the device that comes in contact with the food is the flexible strip of material, which can be easily cleaned and maintained in a sanitary condition by the removal and repositioning thereof, or by the entire replacement thereof. No other part of the device has any direct contact with the food and, therefore, the device is not contaminated after usage, and can be maintained in a sanitary manner with only minimum effort. The aforementioned objects, features and advantages of the present invention will, in part, be pointed out with particularity, and will, in part, become obvious from the following more detailed description of the present invention, taken in conjunction with the accompanying drawings, which form an integral part thereof. BRIEF DESCRIPTION OF THE DRAWINGS In the drawings: FIG. 1 is an exploded perspective view of the various parts of the pastry and dumpling maker, in accordance with the present invention; FIG. 2 is a top view of the pastry and dumpling maker, showing a dough skin and filling positioned in place on the flexible strip of material, ready to be shaped and formed; FIG. 3 is a side elevational view similar to that shown in FIG. 3, showing a later stage in the formation of the pastry in which the mold sections are brought together for folding and sealing the dough skin therebetween; FIG. 5 is a cross sectional view taken through the mold sections shown in FIG. 4, and showing the shaping and forming of the pastries therein; and FIG. 6 is a side elevational view similar to that shown in FIG. 3 with the mold sections being separated, showing the completed pastry now available for removal from the flexible strip of material. In the various figures of the drawing, like reference characters designate like parts. DESCRIPTION OF THE PREFERRED EMBODIMENT Referring now to the drawings, the pastry and dumpling maker of the present invention is shown generally at 10 and includes a base plate 12 having an upper surface 14, on one end of which is mounted a support block 16. On top of the support block 16 is placed a support platform 18 which extends laterally outwardly from the support block 16 on both sides thereof to provide a T-shaped construction. Semicircular channels 20, 22 are formed into the opposing side edges of the support platform 18. The channels 20, 22 receive elongated guide rails 24, 26 which are secured within the respective channels 20, 22 by means of an adhesive, or the like, the guide rails 24, 26 being cantilevered from the support platform 18. A yoke 28 is provided in the form of a substantially rectangular block member. A forward face 30 of yoke 28 is positioned towards the support platform 18. A central recess 32 is formed into the forward face 30 and defines, on opposite sides thereof, a pair of opposing leg section 34, 36 laterally extending outwardly from both sides of the yoke member 28 to provide a C-shaped construction. Respective bores 38, 40 are formed completely through the leg section 34, 36, being aligned with the guide rails 24, 26 respectively, so that each bore 38, 40 receives a respective guide rail 24, 26 therethrough. In this way, the yoke member 28 can be positioned on and slide along the cantilevered guide rails 24, 26 which are secured to the support platform 18. Aligned apertures 42, 44 are respectively formed through the leg sections 34, 36 so as to lie in the same plane as the bores 38, 40, being perpendicular thereto. In this way, the apertures 42, 44 extend through to intersect the bores 38, 40 at the axes thereof. A flexible strap 46 is provided in the form on an elongated strip of material, preferably fabric. Each end is hemmed over to define respective loops 48, 50. The loops 48, 50 are held in place by means of respective stitching 52, 54 at the hemmed over sections. The flexible strip of material or strip 46 is retained in place at one end by means of a U-shaped clip 56 having opposing legs 58, 60 interconnected by a bight section 62. The legs 58, 60 are respectfully received in apertures 64, 66 formed through the support platform 18, the apertures 64, 66 being inwardly positioned from the guide rails 26, 24 and laterally outwardly spaced from the support block 16. For convenience of insertion and removal of the clip 56, one leg 58 is made longer than the other leg 60, so that the leg 58 extends beneath the support platform 18, as shown in FIGS. 3, 4 and 6. This construction permits the user to push upward on the longer leg 58 to release the clip 56 from the support platform 18. Likewise, when inserting the clip 56 into the support platform 18, the longer leg 58 can be first inserted into its corresponding receiving aperture 64 to facilitate alignment of the clip 56 and insertion of the other leg 60 into the other aperture 66 of support platform 18. First, however, the bight portion 62 of the clip 56 is passed through the loop 50 of the strap 46 to hold that end of the flexible strip of material 46 secured to the fixed support platform 18, as shown in FIG. 2. A pin 68 is provided at the other end of the flexible strap 46 and passes through within the loop 48. The pin 68 has a length approximately equal to or slightly less than the spacing between the guide rails 24, 26, as best shown in FIG. 2. The flexible strap 46 is retained at one end by the U-shaped clip 56 passing through the loop 50 being inserted into the apertures 64, 66 in the support platform 18, and at the other end by means of the pin 68 passing through the loop 48 and being retained within the aligned aperture 42, 44 of the yoke 28. In this manner, the yoke 28 can slide along the guide rails 24, 26 and move toward the support platform 18. As it does so, the center portion of the flexible strap 46 will move downwardly between the guide rails 24, 26. The yoke 28 can then be moved away from the support platform 18, at which time the flexible strap 46 will again resume its raised horizontal position. The limit of movement of the yoke 28 away from the support platform 18 is restricted by the longitudinal extent of the flexible strap 46. In order to remove the flexible strap 46 to clean it and/or replace it, initially the clip 56 is pulled upwardly out of the support platform 18, in the manner set forth above. This will remove one end of the flexible strap 46. The clip 56 can then be passed through the loop 50 and be entirely removed from that end of the flexible strap 46. Without any restriction, the yoke 28 can then be completely slid off the cantilevered ends of the guide rails 24, 26. While the guide rails 24, 26 were in position within their respective bores 38, 40, the pin 68 was prevented from being removed by means of the blocking position of the guide rails 24, 26, as can best be seen in FIG. 2. However, with the yoke 28 slid off the guide rails 24, 26, the pin 68 can now be extracted through either of the aligned apertures 42, 44, and can be completely removed from the yoke 28. This will free the other end of the strap 46 for cleaning and/or replacement of the strap 46. After the strap 46 has been cleaned and/or replaced, it is then reinserted by placing it into the recess 32 formed at the front end of the yoke 28. The pin 68 is then passed through the aligned apertures 42, 44 of the yoke 28 so that it passes through the loop 48 of the strap 46, the pin 68 being positioned between the bores 38, 40 of the yoke 28. The yoke 28 is then slid onto the guide rails 26, 24 and moved towards the support platform 18. The U-shaped clip 56 is then placed through the loop 50 of the strap 46, into the receiving apertures 64, 66 in the support platform 18. The opposite ends of the strap 46 are now secured to the device. Depending from the movable yoke 28 is a mold section 70 for movement therewith, which mates with a corresponding fixed mold section 72. The movable mold section 70 is supported by means of a Z-shaped bracket 74 having a lower leg 77 supporting the bottom of the mold section 70, and interconnecting leg 79 secured into the back of the movable mold section 70 by me

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号