【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

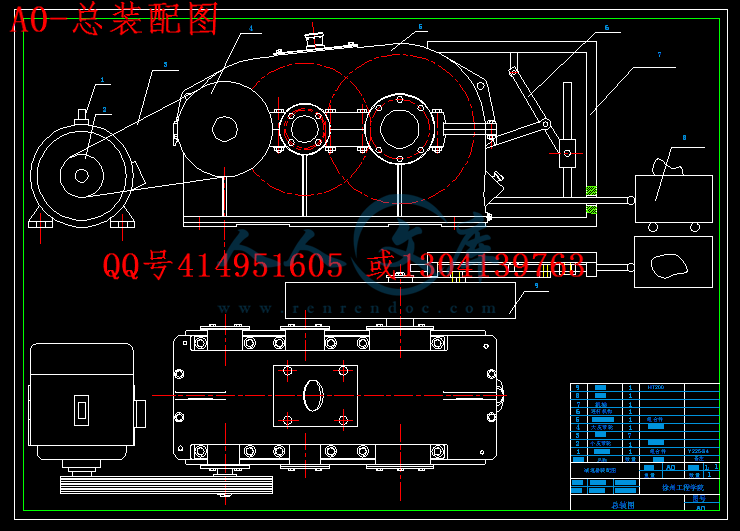

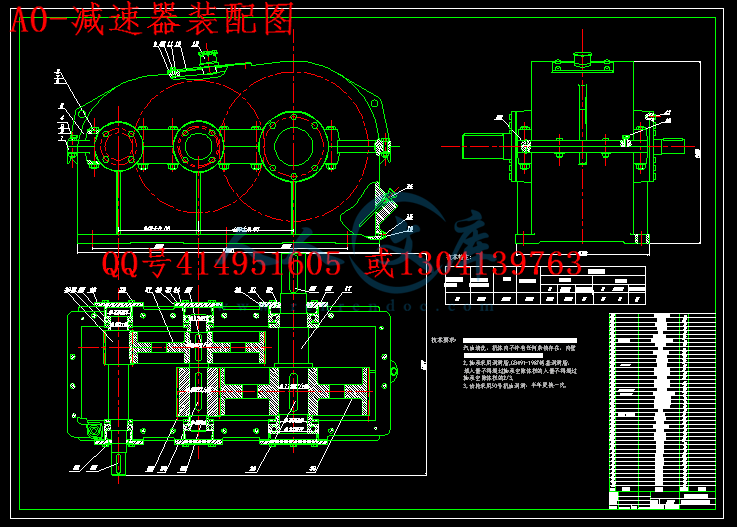

当今社会,随着科技的发展,矿山摇摆式输送机的应用越来越广泛,人们对输送机的研究从来没有停止过,为了满足不同的需求,出现了各式各样的输送机,有摇摆式输送机和带式输送机,平板式输送机等为了把自己所学的专业知识理论更好的应用于实际,以摇摆式输送机为目标,该输送机主要有三部分组成:连杆机构,电动机,还有个减速器,它的设计是在连杆机构运动分析的基础上,进行电动机的选择,减速器零件的设计,其中包含有:轴,齿轮,轴承的设计和校核,材料的选择和附件的设计,最后完成减速器装配,从而构建了矿山摇摆式输送机,相比其他几类传输机而言,该减速器结构简单,装拆使用都很方便,适用范围也比较广,一般可应用于煤矿运输,也可用于矿山一类的材料运输。

关键词 减速器;传输机;摇摆

Abstract

Today's society, along with the development of technology, mining sway conveyor application of more and more extensive. People on the conveyor of the study have never stopped. In order to meet different requirements for a wide range of conveyor. A swing-and conveyor belt, such as concrete mixers. With the progress of mankind, more and more and more good swing-conveyor will be manufactured to meet the needs of production development. Through this study and research the subject so that students learn knowledge on a systematic grasp and understanding. They found that training and problem-solving abilities. In order to study their expertise in theory better applied to practical, to sway for the transmission of goals. The design of transmission linkage is in motion analysis on the basis of the choice of motors, parts of the design reducer (shaft, gear, bearing the design and verification), the complete reducer assembly, which built a swing-transfer machine.

Keywords Reduction gear Transmission machine Swing

目 录

1绪论……………………………………………………………………………………………. 1

1.1毕业设计的目的,内容和进行形式………………………………………………………1

1.2机械设计的一般过程……………………………………………………………………. 1

1.2.1选定设计的课题……………………………………………………………………… 1

2机构简介和设计数据………………………………………………………………………… 2

2.1机构简介………………………………………………………………………………… 2

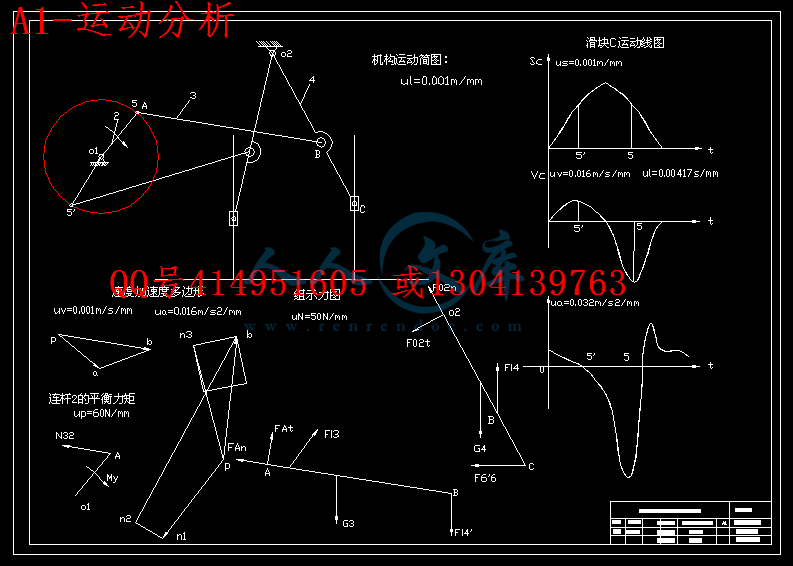

3连杆机构与物料的运动分析………………………………………………………………… 3

3.1机构进行速度分析………………………………………………………………………. 3

3.2对机构进行速度加速度分析………………………………………………………………4

3.3连杆机构与物料的动态静力分析………………………………………………………. 5

4传动装置的总体设计………………………………………………………………………… 9

4.1动力机的机械特性………………………………………………………………………. 9

4.2电动机的选择……………………………………………………………………………. 9

4.2.1 确定电动机的转速…………………………………………………………………. 9

4.3总传动比的计算与分配………………………………………………………………… 11

4.3.1总传动比的计算……………………………………………………………………. 11

4.3.2传动比的分配………………………………………………………………………. 11

5传动零件的设计计算………………………………………………………………………… 13

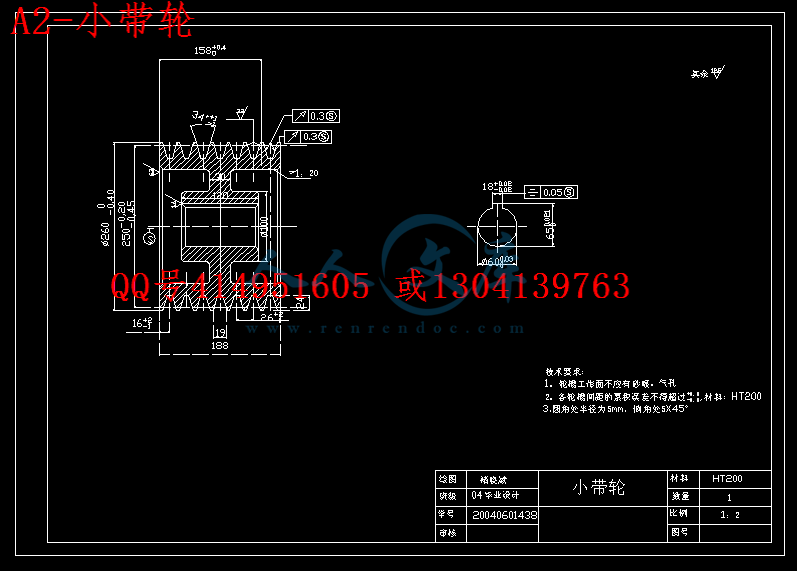

5.1带传动的设计…………………………………………………………………………… 13

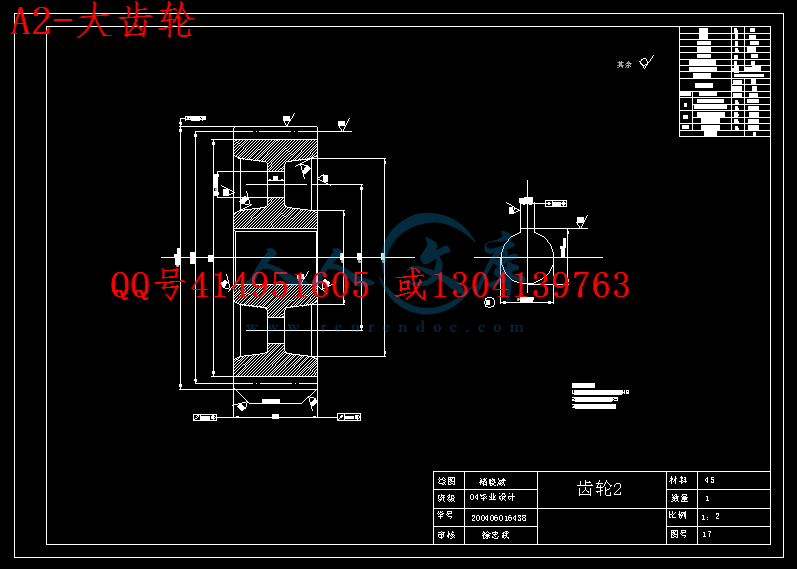

5.2齿轮的设计……………………………………………………………………………… 15

5.2.1对高速级齿轮的参数计算…………………………………………………………. 15

5.2.2对低速级齿轮的参数计算…………………………………………………………. 18

6轴和轴承的设计……………………………………………………………………………. 22

6.1绘制装配图前的准备工作……………………………………………………………… 22

6.2对轴的设计……………………………………………………………………………… 22

6.2.1概述…………………………………………………………………………………. 23

6.2.2初步设计……………………………………………………………………………. 23

6.3轴的校核………………………………………………………………………………… 24

6.4轴承的设计……………………………………………………………………………… 26

7减速器的附件和机体………………………………………………………………………… 29

7.1附件概述………………………………………………………………………………… 29

7.1.1附件…………………………………………………………………………………. 29

7.1.2轴承端盖设计………………………………………………………………………. 30

7.1.3轴承的润滑与密封…………………………………………………………………. 30

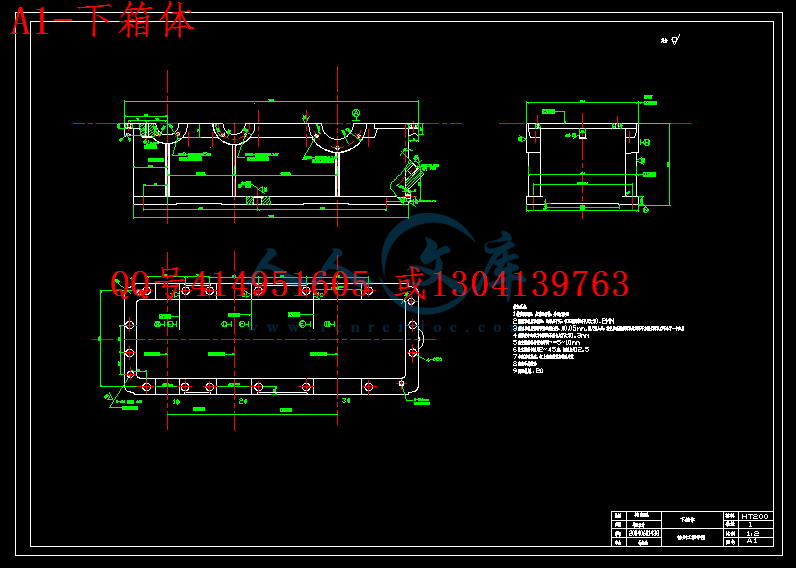

7.2箱体的设计……………………………………………………………………………. 30

7.2.1箱体的结构…………………………………………………………………………. 30

7.2.2箱体的结构尺寸……………………………………………………………………. 31

7.2.3箱体设计时应满足的要求…………………………………………………………. 32

7.3承盖、套杯、调整垫片组设计与选择………………………………………………… 32

7.3.1轴承盖………………………………………………………………………………. 32

7.4速器的润滑与密封……………………………………………………………………… 33

7.4.1齿轮油的选择………………………………………………………………………. 33

7.4.2润滑济的选择………………………………………………………………………. 33

7.4.3减速器的密封………………………………………………………………………. 34

8机架的设计………………………………………………………………………………….. 35

结论…………………………………………………………………………………………… 37

致谢……………………………………………………………………………………………. 38

附录……………………………………………………………………………………………. 39

英文原文:……………………………………………………………………………………. 39

中文翻译:……………………………………………………………………………………. 50

1绪论

1.1毕业设计的目的,内容和进行形式

培养理论联系实际的设计思想,训练综合运用机械设计和有关先修课程的理论,结合生产实际分析和解决工程实际问题的能力,巩固,加深和扩展有关机械设计方面的知识;通过制定设计方案合理选择传动机构和零件类型,正确计算零件工作能力,确定尺寸和选择材料,以及较全面的考虑加工制造工艺,使用和维护等要求,之后进行结构设计,达到了解和掌握机械零件,机械传动装置或简单机械的设计过程和方法; 进行设计基本技能的训练。例如计算,绘图,熟悉和运用资料(手册,图册,标准和规范等)以及使用经验数据,进行经验估算和处理数据的能力。

1.2机械设计的一般过程

任何一部新机器都要经过设计,研制,生产和使用等四个阶段。其中设计阶段通常没有固定的程序,典型的顺序:

(1)明确设计任务,制定设计任务书

(2)提供方案并进行评价

(3)按照选顶的方案进行各零部件的总体布置,运动学,动力学和零件工作能力计算,结构设计和绘制总体设计图

(4)施工设计:根据总体设计的结果,考虑结构工艺性等要求,绘出零件工作图

(5)审核图纸

(6)整理设计文件,包括:编写计算书,使用说明书等。

1.2.1选定设计的课题

摇摆式传输机一般在矿山采煤,或者用于矿山运输,整个机器的工作过程就包括了运动学,动力学和零件工作能力,通过对摇摆式传输机的设计可以让我们了解整个机器的设计过程,也能够加深和巩固运动学,动力学,还有零件设计的能力,更加熟悉机械设计的计算机设计工具(auto-cad)和资料。

明确设计的目的和设计的一般过程。

2机构简介和设计数据

川公网安备: 51019002004831号

川公网安备: 51019002004831号