BJ4500越野车后驱动桥的设计

BJ4500越野车驱动车桥设计

越野车驱动桥设计

BJ4500越野车驱动桥设计【优秀汽车车辆类设计+3张CAD图纸】

【带外文翻译+52页@正文14100字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

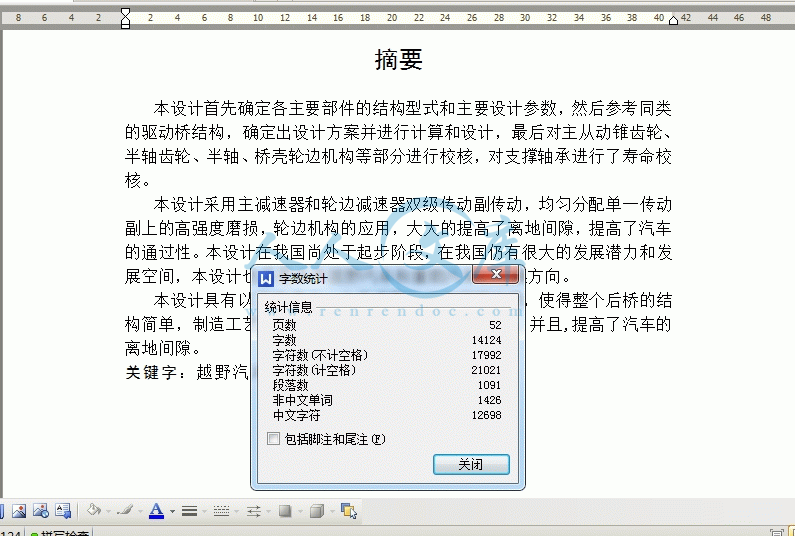

A0-轮边减速器装配图.dwg

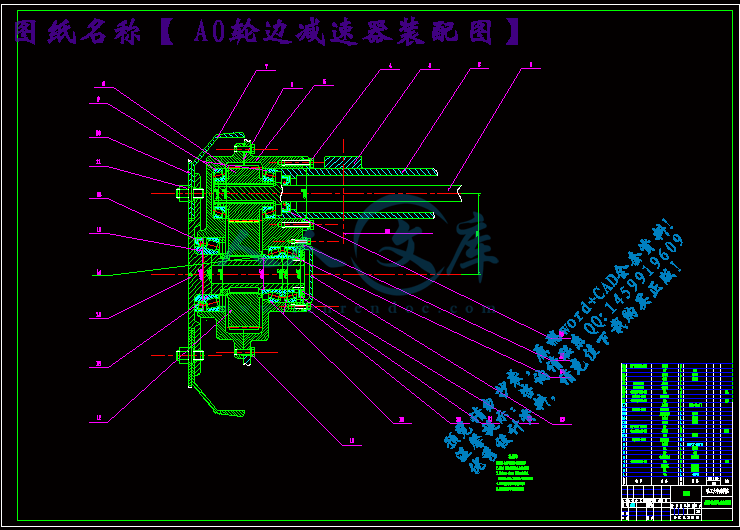

A0-驱动桥装配图1.dwg

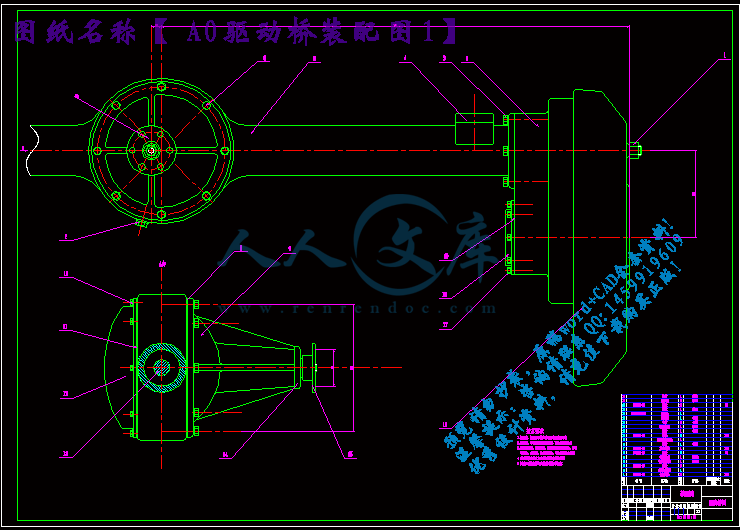

A1-驱动桥装配图2.dwg

任务书.doc

摘要目录.doc

说明书.doc

任务书

毕业设计(论文)题目: 越野车驱动桥设计

立题的目的和意义:

为了进一步提高越野性能,并且减少单一传动副上的受力和高强度磨损,采用轮边减速器和主减速器共同应用的二级减速,可以大大提高其最小离地间隙,并且延长该车驱动桥及其零部件的使用寿命。目前汽车轮边减速器在国外的应用相对较多,但在国内尚处于起步阶段,汽车轮边减速器在我国仍有很大的发展潜力和发展空间,并且,轮边减速器在汽车上的应用将是未来重载汽车和越野车的发展方向。因此,汽车轮边减速器的设计和研究对于我们来说具有十分重要的意义。

技术要求与主要内容:

1设计一个BJ4500越野车驱动车桥,提出一个完整的设计方案,画出装配图;

2.完成该车的驱动桥总体设计,或新增有关装置的选择与布置设计;

3.完成驱动桥的所有设计计算及校核;

4.独立完成A0图纸两张以上;

5.完成全面的设计论文。

摘要

本设计首先确定各主要部件的结构型式和主要设计参数,然后参考同类的驱动桥结构,确定出设计方案并进行计算和设计,最后对主从动锥齿轮、半轴齿轮、半轴、桥壳轮边机构等部分进行校核,对支撑轴承进行了寿命校核。

本设计采用主减速器和轮边减速器双级传动副传动,均匀分配单一传动副上的高强度磨损,轮边机构的应用,大大的提高了离地间隙,提高了汽车的通过性。本设计在我国尚处于起步阶段,在我国仍有很大的发展潜力和发展空间,本设计也将是未来越野汽车和重载汽车的发展方向。

本设计具有以下的优点:由于采用轮边双级驱动桥,使得整个后桥的结构简单,制造工艺简单,从而大大的降低了制造成本。并且,提高了汽车的离地间隙。

关键字:越野汽车;后桥;轮边双级;圆弧齿锥齿轮

Abstract

This design is to first identify major parts of the structure and main design parameters, then reference to similar axles structure, confirmed the design and calculation and design, final master-slave dynamic bevel gear and half axle gears, half axle, bridge housing wheel edges institutions, to test the part such as back-up bearing life respectively. This design USES the main reducer and wheel edges reducer doublestage transmission vice transmission, evenly distributed single transmission of high intensity vice wear, wheel edges institutions of applications, greatly improve the ground clearance is achieved, improved the car through sexual.

This design in our country is still at the beginning, in our country still has great potential for growth and development space, this design also will be the future off-road vehicle and heavy-load automobiledevelopment direction.

This design has the following advantages: due to the wheel edges doublestage axles, make the whole bridge structure is simple, make simple process, thus greatly reduce the production cost. And, improve the car from the ground clearance.

Key word: off-road vehicle, Rear axle, Wheel edges doublestage; Arc tooth wimble gear

目 录

摘要I

AbstractII

目 录III

第1章 绪论1

第2章 驱动桥总体结构方案分析2

第3章 主减速器设计4

3.1 主减速器的结构型式4

3.1.1 主减速器齿轮的类型4

3.1.2 主减速器主、从动锥齿的支承型式4

3.2 主减速器的基本参数与设计计算5

3.2.1 主减速比的确定5

3.2.2 主减速器齿轮计算载荷的确定5

3.2.3 主减速器齿轮基本参数的选择6

3.2.4 主减速器圆孤齿轮的几何参数计算7

3.2.5 主减速器圆弧锥齿轮的强度计算10

3.3 主减速器的材料选择及热处理方法12

3.4 主减速器轴承的计算12

3.4.1 锥齿轮齿面上的作用力12

3.4.2 主减速器轴承载荷的计算15

小结18

第4章 差速器设计19

4.1 差速器类型的选择19

4.2 差速器的设计和计算19

4.2.1 差速器齿轮的基本参数选择19

4.2.2 差速器齿轮的几何尺寸计算21

4.2.3 差速器齿轮的强度校核23

4.3 差速器齿轮的材料选择24

4.4 差速器壳体的材料选择24

小结24

第5章 驱动车轮的传动装置设计25

5.1 半轴的形式25

5.2 半轴的设计计算25

5.2.1 全浮式半轴的计算载荷确定25

5.2.2 全浮式半轴杆部直径初选26

5.2.3 半轴的强度计算26

5.2.4 半轴花键的强度计算27

5.3 半轴材料与热处理28

小结28

第6章 轮边部分的设计29

6.1 轮边减速器的结构型式29

6.1.1 轮边减速器的齿轮类型29

6.1.2 轮边减速器主、从动锥齿轮的支撑方式29

6.2 轮边减速器的基本参数与设计计算29

6.2.1 圆柱直齿轮主要参数的选择29

6.2.2 轮边减速器圆柱直齿轮的几何参考数计算30

6.2.3 轮边减速器圆柱齿轮的强度计算31

6.3 轮边减速器齿轮材料的选择及热处理方法34

6.4 轮边减速器壳的材料选择34

6.5 轮边减速器圆柱轴承的计算34

6.5.1 圆柱齿轮齿面上的作用力34

6.5.2 轮边减速器轴承载荷的计算36

小结38

第7章 驱动桥壳设计39

7.1 桥壳的结构型式39

7.2 桥壳的受力分析与强度计算39

7.2.1 桥壳的静弯曲应力计算39

7.2.2 在不平路面冲击载荷作用下的桥壳强度计算40

7.2.3 汽车以最大牵引力行驶时的桥壳强度计算41

7.2.4 汽车紧急制动时的桥壳强度计算43

7.2.5 汽车受最大侧向力时的桥壳强度计算43

7.3 桥壳的材料选择44

小结44

结论45

致谢46

参考文献47

附录48

第1章 绪论

汽车驱动桥位于传动系的未端。其基本功用首先是增扭、降速,改变转矩的传递方向,即增大由传动轴直接从变速器传来的转矩,并将转矩合理的分配给左右驱动车轮;其次,驱动桥还要承受作用于路在或车身之间的重直力,纵向力和横向力,以及制动力和反作用力等。驱动桥一般由主减速器,差速器,车轮传动装置和桥壳组成。

汽车的使用性能对传动系统有较高的要求,而驱动桥在传统中起着举足轻的作用。汽车的特点和优越性对于生产商来说提高其产品市场竞争力的一个法宝。对于越野汽车驱动桥的离地间隙来说,绝大多数汽车企业只是单纯的提高悬架和钢板弹簧的高度,这样做很大程度上降低了汽车的可靠性和安全性,然而轮边减速器驱动桥就可以解决这些问题,而且其优越性是无可比拟得,所以设计新型的驱动桥成为新的课题。

目前国外掌握轮边减速器技术核心的企业屈指可数,在国内更是聊聊无几,所以轮边减速器驱动桥的研究对于我们来说有举足轻重的意义。

设计后桥时应当满足如下基本要求:

1.选择适当的主减速比,以保证汽车具有最佳的动力性和燃油经济性。

2.外廓尺寸小,保证汽车具有足够的离地间隙,以满足通过性的要求。

3.齿轮及其他传动件工作平稳,噪声小。

4.在各种载荷和转速工况下有较高的传动效率。

5.具有足够的强度和刚度,减少不平路面的冲击载荷,提高汽车的平顺性。

6.制造容易,维修,调整方便。

第2章 驱动桥总体结构方案分析

本设计的课题是BJ4500后驱动桥,要设计这样的越野车驱动桥,一般选用非断开式结构,该种型式的驱动桥的桥壳是一根支承在左右驱动车轮的刚性空心梁,一般是铸造或钢板冲压而成,主减速器,差速器和半轴等所有传动件都装在其中,外接轮边部分。此时驱动桥,驱动车轮都属于簧下质量

驱动桥的结构形式有多种,基本形式有三种:

1.中央单级减速驱动桥。

2.中央双级驱动桥。

3.中央单级、轮边减速驱动桥。轮边减速驱动桥较为广泛地用于油田、建筑工地、矿山等非公路车与军用车上。当前轮边减速桥可分为3类:一类为圆锥行星齿轮式轮边减速桥;一类为圆柱行星齿轮式轮边减速驱动桥;另一类是普通圆柱齿轮式轮边减速器。

(1)圆锥行星齿轮式轮边减速桥。由圆锥行星齿轮式传动构成的轮边减速器,轮边减速比为固定值2,它一般均与中央单级桥组成为一系列。在该系列中,中央单级桥仍具有独立性,可单独使用,需要增大桥的输出转矩,使牵引力增大或速比增大时,可不改变中央主减速器而在两轴端加上圆锥行星齿轮式减速器即可变成双级桥。这类桥与中央双级减速桥的区别在于:降低半轴传递的转矩,把增大的转矩直接增加到两轴端的轮边减速器上 ,其“三化”程度较高。但这类桥因轮边减速比为固定值2,因此,中央主减速器的尺寸仍较大,一般用于公路、非公路军用车。

(2)圆柱行星齿轮式轮边减速桥。单排、齿圈固定式圆柱行星齿轮减速桥,一般减速比在3至4.2之间。由于轮边减速比大,因此,中央主减速器的速比一般均小于3,这样大锥齿轮就可取较小的直径,以保证重型卡车对离地问隙的要求。这类桥比单级减速器的质量大,价格也要贵些,而且轮穀内具有齿轮传动,长时间在公路上行驶会产生大量的热量而引起过热;因此,作为公路车用驱动桥,它不如中央单级减速桥。

(3)普通圆柱齿轮式轮边减速器。在双级主减速器中,通常把两级减速齿轮放在一个主减速器壳内,也可将第二级减速齿轮移向驱动车轮并靠近轮毂,作为轮边减速器。对于越野汽车来说,为了提高汽车驱动桥的离地间隙,可将普通的由一对圆柱齿轮构成的轮边减速器的主动齿轮置于其从动齿轮的垂直上方,这种布置方式的优点是结构紧凑、强度高、成本低,故广泛用于越野汽车上。

参考文献

1 刘惟信. 汽车车桥设计.北京:清华大学出版社,2004.

2 王望予. 汽车设计. 北京: 机械工业出版社,2004.

3 郭新华. 汽车构造. 2版. 北京: 高等教育出版社,2008.

4 朱孝录. 齿轮传动设计手册. 北京:化学工业出版社,2005.

5 廖念钊. 互换性与技术测量. 北京:中国计量出版社,2000.

6 戴少度. 材料力学. 北京:国防工业出版社,2002.

7 刘惟信. 汽车设计. 北京: 清华大学出版社, 2001.

8 陈家瑞. 汽车构造. 5版 北京:机械工业出版社,2006.

9 王黎钦. 机械设计. 4版 哈尔滨:哈尔滨工业大学出版社,2008.

10 王望予. 汽车设计. 4版 北京:机械工业出版社,2004.

11 王丽洁. 画法几何. 哈尔滨:哈尔滨工业大学出版社, 1998

12 汽车工程手册编辑委员会.汽车工程手册:设计篇.北京:人民交通出版

社,2001.

13 汽车工程手册编辑委员会.汽车工程手册:基础篇.北京:人民交通出版

社,2001.

14 Ford Motor Company Arup Gangopadhyay, Sam Asaro, Michael

Schroder,Ron Jensen and Jagadish Sorab. Fuel Economy

Improvement Through Frictional Loss Reduction in Light Duty

Truck Rear Axle.SAE,2002.

15 Dirk Spindler Georg von Petery INA-Schaeffler KG. Angular

Contact Ball Bearings for a Rear Axle Differential.SAE ,2003.

川公网安备: 51019002004831号

川公网安备: 51019002004831号