【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

经过十几年的发展,我国工业化进程不断推进,起重行业的需求进一步增大。桥式起重机是桥架型起重机中最主要的型式,它具有场地利用率高、作业范围大、适应面广、通用性强等特点。桥式起重机一般由桥架,起升机构和小车运行机构,大车运行机构,操纵室,小车导电装置,起重机总电源导电装置等组成。本设计采用10吨位电动双梁桥式起重机进行研究。

全文分五部分内容来完成本次设计课题内容:

第一部分为绪论部分,简要介绍了起重机械的作用、国内外起重机械的发展状况及存在的问题、我国起重机械的发展方向。

第二部分为总体结构布置的确定,该部分主要分析了起重机的工作特点,主要参数及组成部分包括起升机构、大小车机构的布置方案,轮压的计算。

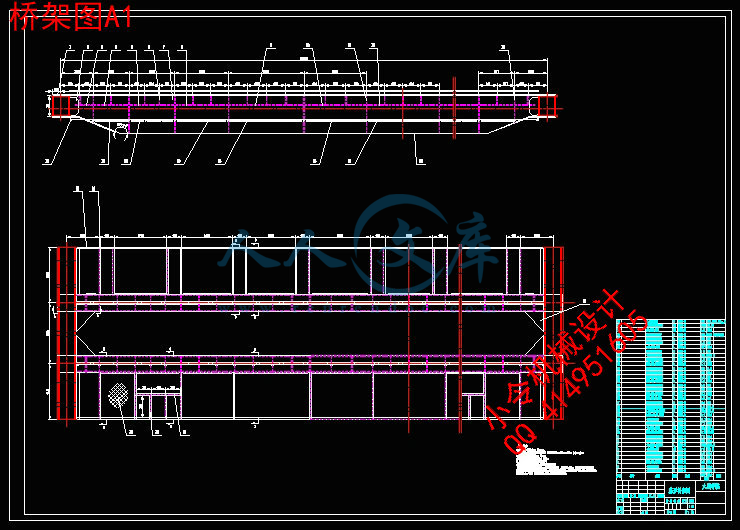

第三部分为桥架结构的设计,该部分包括桥式起重机主要尺寸如大车轮距、主梁高度、端梁高度、加劲板的布置尺寸等和计算载荷,箱型结构主梁,主要焊缝的验算。

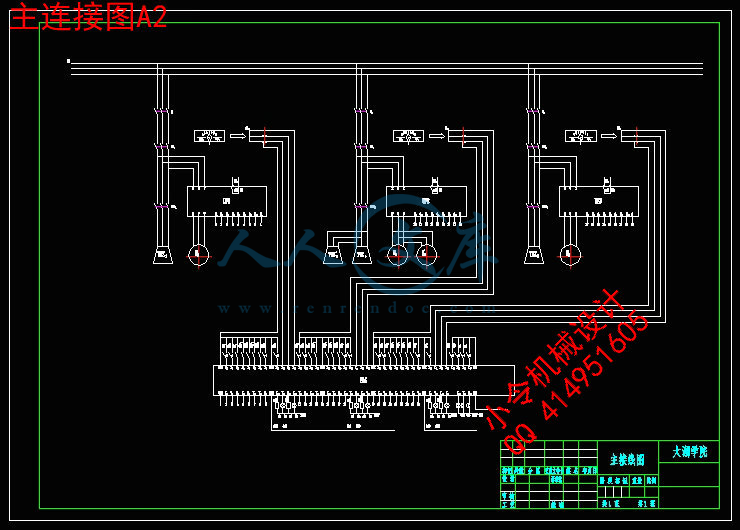

第四部分为电气部分的设计,该部分介绍了变频调速的基本原理及发展现状,桥式起重机的变频调速,起升机构的变频调速,大小车的变频调速及整体PLC设计。

第五部分为结论及展望部分,对本设计进行分析总结,论证桥式起重机基本尺寸和电气部分的可靠性,同时也指出其不足待改进之处。

关键词:桥式起重机;起升机构;桥架结构;PLC

Abstract

After more than ten years of development, the industrialization of China has continuously promoted, and the crane industry demands further increase.Overhead travelling crane is the main type of overhead type crane and it has the following advantages: high field utilization rate,greater scope of work, wide range adaption,good universality and so on. In general,overhead travelling crane is composed of srane span structure,hoisting mechanism ,wheeling mechanism,travelling mechanism of the larger traveller ,control carbin,the car conductive device,the general supply conductive device of srane etc.This design uses the electric double girder overhead travelling crane research.

The full text is divided into 5 parts to complete this design topic content:

The first part is the preface.In this part,the effect of crane, the development of the situation and existing problems of lifting equipment at home and abroad,the development direction of China will be introduced.

The second part is the determination of the overall layout of the structure.This part mainly analyzes the work characteristics and technical parameters of the crane.The constiturnt part of layout scheme include hoisting mechanism , wheeling mechanism,travelling mechanism of the larger traveller and calculation of wheel pressure will also be mentioned.This part include

The third part is the design of the bridge structure.It includes the main dimensions of overhead travelling crane such as the wheelbase of cart,height of main beam,end beam heigt,layout size of the stiffened plate and so on. We will consider the checking of calculating load,box structure beam and main weid.

The fourth part is the design of electrical part.The fundamental and development status of frequency control will be talked about. Overhead travelling crane,hoisting mechanism,cart

and trolley all need consider frequency control.There is a design of global PLC.

In the last part ,according to the conclusion,the paper has made analysis and summary to this design,giving the basic size and electrical part of Overhead travelling crane to be proved,pointing to the deficiencies and needing improvements of the argument.

Key words: Overhead travelling crane; ,hoisting mechanism; bridge structure; PLC

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 引言 1

1.2 国外发展现状 1

1.3 国内发展现状和目标 1

2 起重机总体结构的布置方案 2

2.1 起重机工作时的特点 2

2.2 起重机主要参数的确定 2

2.3 起重机的主要组成部分 2

2.3.1 起升机构的布置方案 2

2.3.2 小车运行机构的布置方案 3

2.3.3 大车运行机构的布置方案 4

2.4 起重机的轮压的计算 4

2.4.1 桥架支撑反力的计算 4

2.4.2 小车支承反力的计算 6

3 桥式起重机桥架结构的计算 7

3.1 主要尺寸的确定 7

3.1.1 已确定尺寸 7

3.1.2 大车轮距的计算 7

3.1.3 主梁高度的计算 7

3.1.4 端梁高度的计算 7

3.1.5 桥架端部梯形高度的计算 7

3.1.6 主梁腹板高度的选用 7

3.1.7 主梁截面尺寸的确定 7

3.1.8 加劲板的布置尺寸 8

3.2 计算载荷 10

3.2.1 固定载荷的计算 10

3.2.2 移动载荷的计算 11

3.2.3 水平惯性载荷的计算 11

3.2.4 车轮侧向载荷的计算 12

3.2.5 载荷组合 12

3.3 箱形结构主梁的计算 13

3.3.1 主梁垂直方向最大弯矩和剪力的计算情况 13

3.3.2 主梁水平方向最大弯矩的计算 14

3.3.3 主梁的强度验算 15

3.3.4 主梁的垂直刚度验算 17

3.3.5 主梁的水平刚度验算 17

3.4 主要焊缝的计算 18

3.4.1 主梁与端梁的连接焊缝 18

3.4.2 主梁上盖板焊缝 18

3.5 计算总结 19

4 电气部分的设计 20

4. 1 变频调速的基本原理及发展现状 20

4.1.1 变频器工作原理 20

4.1.2 变频调速的方式 20

4.1.3 变频器的类型 21

4.1.4 变频调速时电动机的过渡状态 21

4.1.5 变频器的功能 22

4.2 桥式起重机的变频调速 23

4.2.1 桥式起重机的负载特点 23

4.2.2 桥式起重机的调速方法和节能比较 23

4.2.3 电动机容量选择 25

4.2.4 变频器容量选择 25

4.3 起升机构的变频调速 25

4.3.1 起升机构的转矩分析 25

4.3.2 起升过程中电动机的工作状态 26

4.3.3 起升机构对拖动系统的要求 27

4.3.4 起升机构变频器的调速方案 27

4.4 大车的变频调速 29

4.4.1 大车拖动系统 29

4.4.2 大车变频调速控制要点 29

4.5 小车的变频调速 30

4.6 PLC控制系统的设计 30

4.6.1 PLC控制系统的设计原则 30

4.6.2 PLC控制系统的设计步骤 31

4.6.3 PLC制控系统的类型 31

4.6.4 PLC控制系统设计 31

5 结论与展望 42

5.1 结论 42

5.2 不足及展望 42

致谢 43

参考文献 44

1 绪论

1.1 引言

起重机最基本要求是对物体进行垂直升降,同时带动物体在较短的一段距离进行移动,以此来适应物体在不同状态下的需求。随着时代的发展,起重机在现代生活中扮演着越来越重要的角色,它为人们节省了大量的人力、物力并在机械自动化方面得到进一步的发展。

因为看起来像金属的桥架,桥式起重机因此得名。桥式起重机主要被放置在仓库、工厂等场所并只能在指定的区域内进行工作。

1.2 国外发展现状

在国外,起重机发展速度较快,水平较高。国外在集成电路、微处理器、微型计算器及电子监控技术等方面具有较大的运用,并在节能、环保方面等方面加大了投入。

1.3 国内发展现状和目标

随着时代的发展,我国起重机械的种类不断增加,但在集成电路和微型计算机方面仍需不断加强。对比国外发展情况,我国应大力发展机电一体化产品,加强起重机可靠性和技术水平,应用新技术来改善恶劣工作条件,进一步提高产品质量。

相关业内人士指出,未来全球起重机行业将向重点产品大型化、高速化和专业化方向,系列产品模块化、组合化、标准化和实用化方向及通用产品小型化、轻型化、简易化和多样化方向发展。因此本土起重行业应加大开发,注重人才的培养和引进,切实增强行业的核心竞争力,积极参与国际市场竞争。

2 桥式起重机总体结构上布置方案的确定

2.1 起重机工作时的特点

起重机械是间歇动作并具有一定的重复特点,在搬运物体时,首先起升重物,然后进行水平方向的移动,随着降落被吊物会回到原始位置。像起升机构包括空载和负载两种升降情况,而对于大车这类运行机构则具有空载和负载下的往复运动。对于起重机械的一个工作循环,即搬运一次物品的过程中,相关的工作机构需要进行一次正向和反向的运动。对于起重机械和连续运输机械的区别就在于前者是以周期性的短暂工作循环往复运送物品,而后者是以长期连续单向的工作运送物品。就是这种差异导致起重机械与连续运输在结构和用途上有着区别。

川公网安备: 51019002004831号

川公网安备: 51019002004831号