【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

第1章 前言··········································································1

1.1播种机的常识和技术现状·······················································1

1.2播种方式及常见播种类型·······················································3

1.2.1条播·············································································3

1.2.2穴播·············································································4

1.2.3撒播·············································································4

1.2.4精密播种·······································································4

1.2.5联合作业机和免耕播种························································5

1.3播种工作过程和机械构造·······················································5

1.3.1工作过程·······································································5

1.3.2机械构造·······································································6

1.4播种机械的发展趋势·····························································7

第2章 总体设计····································································9

2.1 概述···············································································9

2.2 设计任务········································································10

2.3 设计目的········································································10

2.4 动力方案选择···································································10

2.5 设计题目分析及设计思想·····················································12

2.6 设计主参数及机构类型确定··················································12

2.6.1工作速度······································································12

2.6.2播量的确定···································································13

2.6.3种、肥箱的容积······························································13

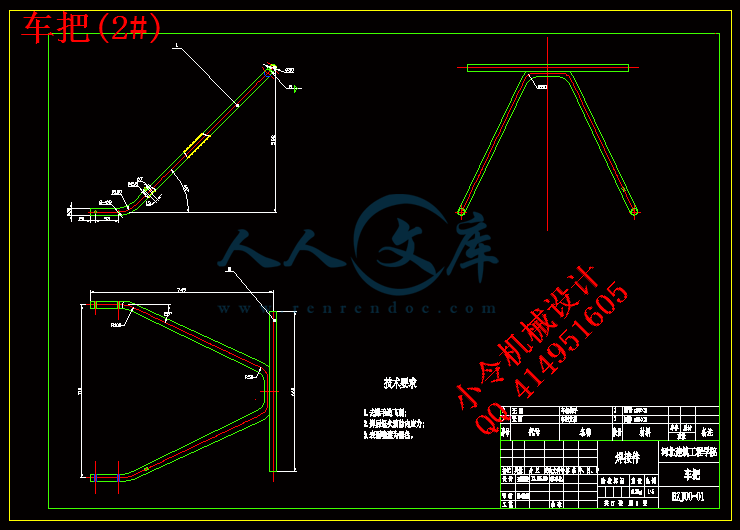

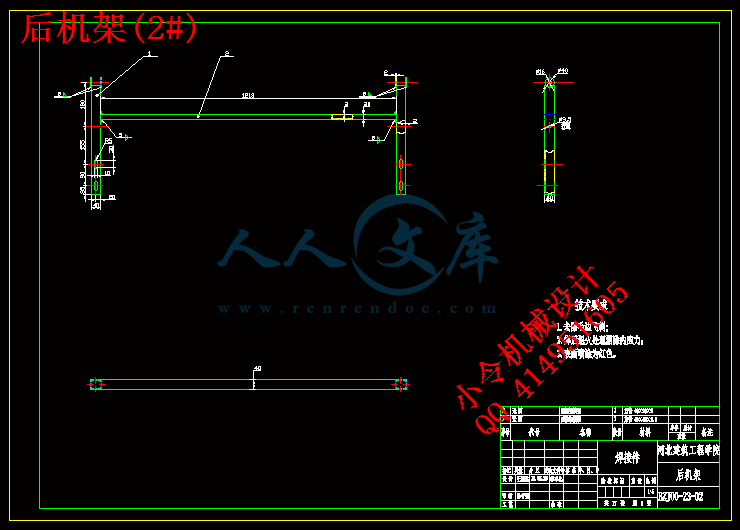

2.6.4机架设计······································································14

2.6.5工作幅度······································································14

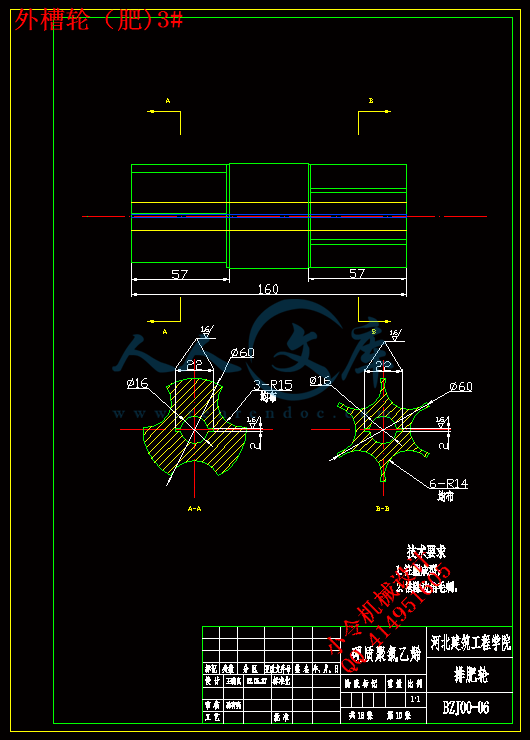

2.6.6 排种、排肥机构设计·························································14

2.6.7开沟器设计····································································18

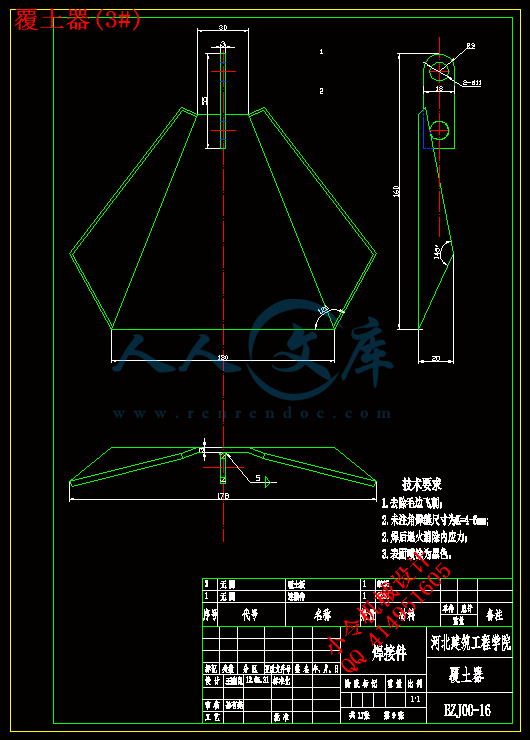

2.6.8覆土器设计···································································22

2.6.9镇压轮设计····································································23

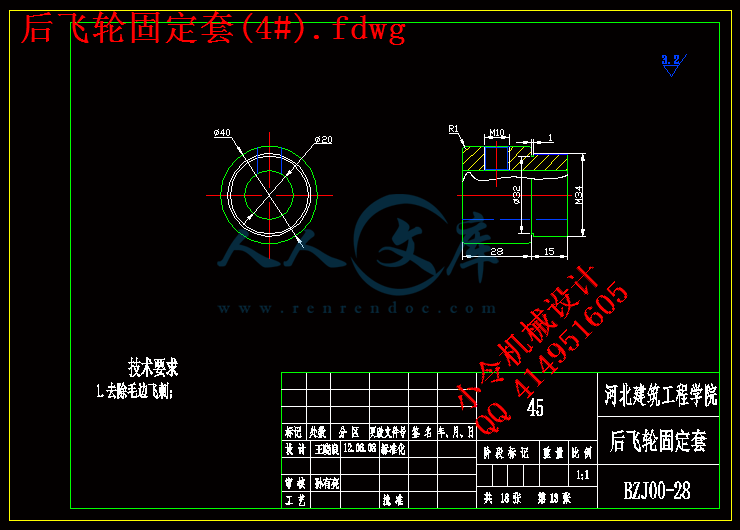

2.6.10 地轮设计····································································23

第3章 传动设计及播种技术措施···········································25

3.1传动原理简图和动力传递路线图····································25

3.1.1传动原理简图·································································25

3.1.2动力传动路线图······························································25

3.2传动原理·········································································25

3.3技术措施·········································································26

3.3.1播种均匀性和各行排量一致性措施·········································26

3.3.2降低破种率措施······························································27

3.3.3种肥同播时,肥料的利用率··················································27

第4章 零部件设计·······························································28

4.1种箱及肥箱设计·································································28

4.2开沟器设计及校核······························································29

4.3排种器···········································································31

4.4地轮参数确定···································································32

4.4.1轮子直径和轮辋宽度的确定·················································32

4.4.2轮子滚动阻力计算····························································32

4.5汽油机的选择及链轮设计······················································33

4.5.1汽油机总功率确定····························································33

4.5.2汽油机及减速器的选择······················································34

4.5.3传动比的确定·································································35

4.5.4链轮选择及设计计算·························································36

4.6地轮轴设计······································································41

4.7键的校核·········································································47

4.8销的校核·········································································48

4.9轴承的校核······································································49

第5章 播种机使用·······························································50

5.1播种量调整······································································50

5.2实际操作说明···································································51

5.2.1播种作业前准备······························································51

5.2.2播种机的试播及作业·························································53

5.2.3播种机的保养与保管·························································54

5.2.4播种质量检查·································································54

第6章 毕业设计小结····························································57

参考文献·············································································59

摘要

随着近来温室大棚的发展以及环保发展意识的日益增强,小型机的需求就显得更为重要,尤其是微动力装置的机械。然而目前广泛应用的播种机是以内燃机及人力为动力装置。本设计电动小型播种机与传统的播种机相比.新颖之处在于播种机采用汽油机为动力装置,从而改善了人们在田间作业时的工作环境,况且更符合环保发展的观点。

本设计主要用于农户田间播种和设施种植播种.增加部分装置也可用于施肥、耙磨、除草等田间作业。详细介绍了播种机的结构组成以及各部件的形式、要求以及功用。详细介绍了汽油机驱动小型播种机动力装置及各部件要求,包括播种机的动力选择、机械传动的选择及尺寸、排种轮设计、排肥轮的设计、开沟器的设计、轴的设计、链轮的设计、其他的各部件设计以及播种机的工作要求、播种前的准备及播种机的使用等。在设计中考虑播种深度连续可调、播种行距连续可调、播种穴距可调、种子破碎率和播种均匀度符合国家标准。设计中在考虑实用的同时,兼顾经济节约,从而达到结构合理、生产成本低、能耗小、效率高,而且操作方便的目的。

关键词:汽油机 小型 播种机

Abstract

With the development of the greenhouse and the consiousness of protecting our ervironment ,boosting up ,the apply of the powy machine becomes more important ,especially the machine with electric power .but at the present time the seeding-machine which is adopted abroadly is drived ba gad engine or man power .this kind of minitype seeding-machine knows from the conventional seeding-machine .Its novel aspect is its drive set which are drived by electric power completly ,so they will improve the work condition ,and accord with euthenics .

This design is applied mostly with the farms of the farmers ,they can also used to fertilize、abrade、get rid of grass and so on ,when we incress some equipment .My design introduce the structure of the seeding-machine and the types of many parts 、some request an fuction .My design introduce the drive equipment of the machine and the types of many parts 、request and fuction .My design also introduce the drive equipment of the machine and the request of the parts which consist of the selecting of the power 、the size 、the design of the axial 、chain wheel 、some other parts and so on .We must consider suiting well of the depth 、the row spacing 、the distance of scoop and the rate of seeds breaking up when seeding .In my design ,while thinking over applied ,I give attention to saving econmy ,consequently achieve structure in reason 、the cost of produce lowness 、the cost of power lowness 、the effidiency highness and convenient when operating .

KEY WORDS gasoline engine minitype seeding-machine

川公网安备: 51019002004831号

川公网安备: 51019002004831号