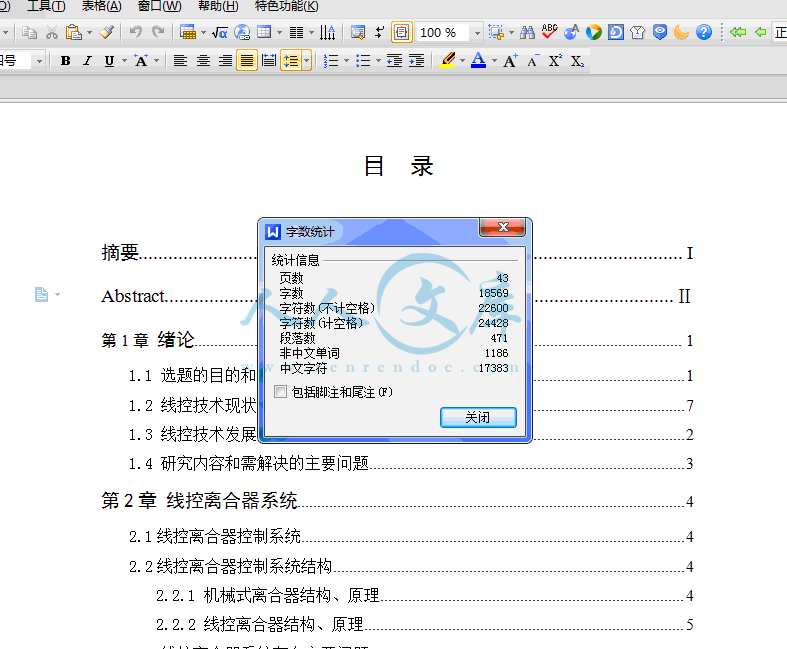

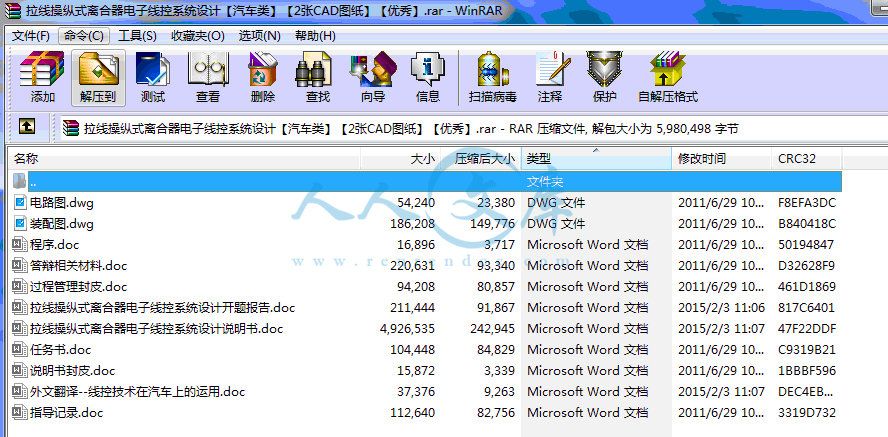

拉线操纵式离合器电子线控系统设计

43页 18000字数+说明书+任务书+开题报告+外文翻译+2张CAD图纸【详情如下】

任务书.doc

外文翻译--线控技术在汽车上的运用.doc

拉线操纵式离合器电子线控系统设计开题报告.doc

拉线操纵式离合器电子线控系统设计说明书.doc

指导记录.doc

电路图.dwg

程序.doc

答辩相关材料.doc

装配图.dwg

说明书封皮.doc

过程管理封皮.doc

摘 要

随着汽车电子技术、自动控制技术的逐步成熟和汽车网络通信技术的广泛应用,汽车线控技术也逐步得到青睐和深入研究是汽车未来的发展趋势。

汽车线控技术就是将驾驶员的操纵动作经过传感器变成电信号,通过电缆直接传输到执行机构的一种系统。目前包括线控换档系统、线控制动系统、线控悬架系统、线控增压系统、线控油门系统及线控转向系统。其中线控转向系统在高级轿车、跑车及概念车上有广泛的应用,它为自动驾驶提供了良好的平台。

汽车离合器操纵形式有液压和拉线式两种。其中拉线式布置方便,摩擦损失大机械式受车架、车身变形影响大,两种机械式操纵机构的比较杆系传动优点:结构简单;成本低;寿命长;可靠性高;缺点:关节点多,摩擦损失大,不适合远距离操纵,受车身或车架的变形影响。拉线传动优点:结构简单;成本低;克服了杆系传动的不适合远距离操纵,受车身或车架的变形影响缺点;可采用吊挂式的踏板;缺点:寿命短,拉伸刚度小;拉伸变形导致增加踏板行程。

本设计针对拉线操纵式离合器设计线控操纵系统,可与原系统的功能进行切换工作。

关键词:线控离合器;H桥;PWM控制;控制策略;传感器

ABSTRACT

As automobile electronic technology , Automatic control technology gradually mature and car network communications technology is widely used , Automotive wire control technology is also gradually gain favour is car further research and the future trend of development.

Automotive wire control technology is the driver through sensor into electrical signal manipulation of action, Through the cable directly transmission to the actuator a system. Currently include wire control shift system, line control servo system, line control suspension system, Wire control the pressurization system, line oil-control door system and wire control steering system. Including wire control steering system in limousines, sports car And concept car, it is widely used for automated driving to provide a good platform.

Clutch manipulations hydraulic and farrowed type two kinds. Including farrowed type decorates convenient, Friction loss is big, By frame, body spurt type deformation great influence, Two kinds of mechanical control mechanisms of comparative bar transmission advantages: simple structure; Cost is low; Long life. High reliability; Faults: jointing, friction loss more big, do not suitable for long-distance manipulation, The body or frame by deformation. Farrowed transmission advantages: simple structure; Cost is low; Overcome the rod is not suitable for long-distance manipulation of transmission of, The body or frame by deformation faults. Can use hanging pedal; Faults: short life, stretching stiffness is small; Tensile deformation to lead to a rise in pedal stroke.

This design for farrowed manipulate type clutch design control systems, can wire with the original system function shifts.

Keywords: wire control clutch; H bridge; PWM control; Control strategies; sensor

目 录

摘要I

AbstractⅡ

第1章绪论1

1.1 选题的目的和意义1

1.2 线控技术现状分析7

1.3 线控技术发展前景2

1.4 研究内容和需解决的主要问题3

第2章 线控离合器系统4

2.1线控离合器控制系统4

2.2线控离合器控制系统结构4

2.2.1 机械式离合器结构、原理4

2.2.2 线控离合器结构、原理5

2.3 线控离合器系统存在主要问题7

2.3.1 线控离合器的优点7

2.3.2 系统存在的主要问题8

2.4 本章小结8

第3章 线控离合器数学模型和控制策略10

3.1 系统建模10

3.1.1 线控离合器机构10

3.1.2 工作过程分析10

3.1.3 齿轮传动及齿隙影响10

3.2 控制策略分析11

3.3 本章小结12

第4章 控制系统硬件设计13

4.1 控制系统结构13

4.2 控制系统电路设计14

4.2.1 单片机的选择14

4.2.2 飞思卡尔单片机的简介及优点15

4.2.3 信号处理电路设计17

4.3 驱动电路设计18

4.3.1 H桥驱动电路18

4.3.2 PWM模块及工作原理20

4.3.3 使能控制和方向逻辑22

4.4 直流电机控制原理23

4.4.1直流电机控制原理23

4.4.2 直流电机的可逆 PWM控制电路24

4.4.3 PID控制原理25

4.5 本章小结27

第5章 控制系统软件设计29

5.1 软件系统总体分析29

5.2 控制功能软件设计30

5.2.1 功能子程序设计30

5.2.2 控制功能程序编写31

5.3 本章小结35

结论36

参考文献37

致谢38

第1章 绪 论

1.1 选题的目的和意义

目的:随着汽车电子技术、自动控制技术的逐步成熟和汽车网络通信技术的广泛应用,汽车线控技术也逐步得到青睐和深入研究是汽车未来的发展趋势。

汽车线控技术就是将驾驶员的操纵动作经过传感器变成电信号,通过电缆直接传输到执行机构的一种系统。目前包括线控换档系统、线控制动系统、线控悬架系统、线控增压系统、线控油门系统及线控转向系统。其中线控转向系统在高级轿车、跑车及概念车上有广泛的应用,它为自动驾驶提供了良好的平台。

汽车离合器操纵形式有液压和拉线式两种。其中拉线式:布置方便,摩擦损失大机械式受车架、车身变形影响大两种机械式操纵机构的比较杆系传动:优点:结构简单;成本低;寿命长;可靠性高;缺点:关节点多,摩擦损失大,不适合远距离操纵,受车身或车架的变形影响。拉线传动:优点:结构简单;成本低;克服了杆系传动的不适合远距离操纵,受车身或车架的变形影响缺点;可采用吊挂式的踏板;缺点:绳索的寿命短,拉伸刚度小;拉伸变形导致增加踏板行程。本设计针对拉线操纵式离合器设计线控操纵系统,可与原系统的功能进行切换工作。

1.4 研究内容和解决的主要问题

本设计需对离合器的分离过程和分离力进行研究、计算,对分离和接合的过程进行分析,建立相应的力学模型,从而确定PWM脉冲输出的频率和电机输出的转矩。还有需要有正确的程序,来控制电机的转动。还需设计传动机构、传动比、齿轮支架和传感器支架等。同时,需保证此机构动作的响应性要足够快,而且动作不能有缓冲,最后就是把各机械部件可靠连接保证工作的可靠性,最重要的是需要写出正确的程序来驱动整个装置,并可以实际应用。

线控技术研究的难点在于高性能控制器的研制,要求在整个系统中有精确高速的通讯协议网络,使控制中心和执行器之间能完全协调、匹配工作;而且需要高效的容错技术,使得系统出现故障时能够保障一定的安全,即系统有好的可靠性。

目前线控技术在汽车中的应用还不成熟。但随着汽车各系统的电子化、集成化的发展需要,线控技术发展迅速,作为一种汽车高新电子技术,线控技术必将得到广泛的应用。但电子化不可能完全取代机械化,机械系统的损坏通常都是有过程的,而线控制系统的失效是瞬间的。如果线控制系统失效那一刻汽车的速度行驶过高,造成的后果就可能非常严重。电子控制要完全取代机械操作还需要时间。

结 论

本文对线控离合器控制系统的模型和控制实现进行了分析和研究。内容主要包括线控离合器的技术、产品发展及现状调研;离合器运动系统建模及控制器设计;直流电机驱动芯片的选择;在经过理论分析和实验研究以后,对离合器运动系统和控制系统有了一定的理解和掌握。

归纳起来主要研究工作内容和结果叙述如下:

1.线控离合器的组成部分及其特性的研究,为控制系统的设计提供依据。从硬件方面讲,必须设计直流电机的驱动电路,完成闭环反馈控制;从软件角度讲,要获得精确控制,必须考虑复位弹簧引起的非线性。

2.以飞思卡尔9S12XS128为主芯片开发的硬件控制系统可以完成线控离合器的闭环控制。

3.离合器动态特性的研究发现,由于复位弹簧在静态位置前后扭矩方向的改变,离合器分离度范围及开度的变化趋势不同时,所需的控制量不同,使得离合器控制系统存在非线性,要获得精确的控制,必须采用非线性控制方法。

参 考 文 献

[1]王晓明,电动机的单片机控制(第3版)[M],北京:北京航空航天大学出版社. 2011

[2]王吉忠.尹宁霞.王泽鹏,车用单片机系统[M],实验教程.中国电力出版社,2009.

[3]孙同景.陈桂友,Freescale9S12十六位单片机原理及嵌入式开发技术[M],机械工业出版社,2010.

[4]李涵武.赵雨旸,汽车电器与电子技术[M],哈尔滨工业大学出版社,2009.

[5]任桂周.侯树展.曲金玉,汽车电子新兴技术—线控技术[J].山东理工大学,2007.

[6]卢静.陈非凡.张高飞,基于单片机的无刷直流电动机控制系统设计[J],北京:北京机械工业学院学报,2002

[7]王鉴光,电动机控制系统[M],北京:北京机械工业出版社,1994.

[8]储爱华.张植保.朱磊,无刷直流电动机在混合动力汽车电控离合器系统中的应用 [J],电控离合器,2009.

[9]徐石安.江发潮,汽车离合器[M],北京:清华大学出版社,2005.

[10]陶永华,新型PID控制及其应用[M],机械工业出版社.,2002

[11]谢世杰.陈生谭.楼顺天,数字PID算法在电机控制中的应用[J],汽车电子技术. 2004

[12]席军强.陈慧岩.丁华荣,电机驱动自动离合器可行性研究[J],车辆动力与技术2001

[13]胡波.孟永钢.温诗铸,电控摩擦离合器的初步实验研究[J],北京:清华大学摩擦学国家重点实验室学报,2004

[14]潘新民.王燕芳,微型计算机控制技术[M].北京:电子工业出版社,2003.

[15]胡寿松,自动控制原理[M].北京:国防工业出版社,1994.

[16]王田苗.机电控制基础理论及应用[M].北京:清华大学出版社,2003.

[17]胡跃明.非线性控制系统理论与应用[M].北京:国防工业出版社,2002.

[18]Chiang RY.Safonov MGH ∞ synthesis using a bilinear pole shifting transform[C],1992

[19]Dai HY.Zhang H Q. Zhang WH Robust performance analysis of active suspension with model uncertainty using structured singular value u approach [C],1998

川公网安备: 51019002004831号

川公网安备: 51019002004831号