轻型载货汽车车架有限元静力学分析

93页 23000字数+说明书+任务书+开题报告+外文翻译+1张CAD图纸【详情如下】

任务书.doc

外文翻译--具有车架结构车辆的怠速震动分析.doc

封面.wps

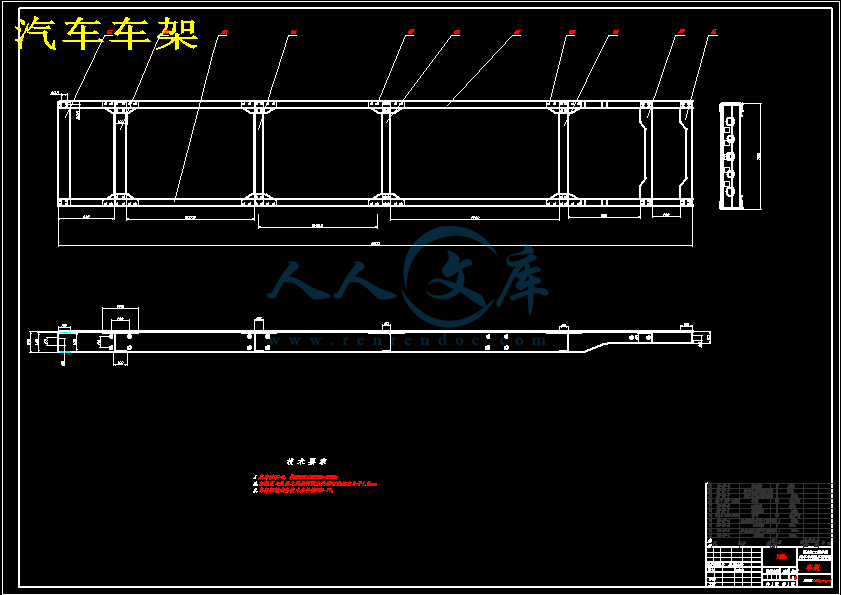

汽车车架.dwg

轻型载货汽车车架有限元静力学分析开题报告.doc

轻型载货汽车车架有限元静力学分析说明书.doc

过程管理封皮.doc

过程管理材料.doc

摘 要

汽车车架作为汽车总成重要的一部分,车辆受到来自道路和装载的各种复杂载荷最终都会传递给车架,并且汽车上许多重要总成都是以车架为载体,因而车架的强度和刚度在汽车总体设计中起了非常重要的作用。因此,车架结构性能的好坏关乎这整车设计的成败。若用传统经典力学方法计算,结果失真太大;而用试验法进行测试,成本高,周期长。为此本文采用了有限元分析技术,来实现车架结构设计合理化和轻量化的目的从而大大减少设计费用,缩短设计周期,同时提高设计工作的效率。因为,ANSYS在对实体模型分析上具有强大的功能,在结构静力学分析以及优化设计方面相比很多其他软件拥有十分明显的优越性。本文利用三维建模软件Pro/E和有限元分析软件ANSYS对某轻型载货汽车车架进行了Pro/E建模和ANSYS分析。通过对Pro/E和ANSYS软件的的了解和学习,采用Pro/E实体建模,导入ANSYS进行网格划分,应力加载,求解得出经动态分析结果,得出结论,之后可根据需要对已设计的实体单元为基础的车架结构进行拓扑优化模型和简单的尺寸优化模型,以车架的纵梁截面尺寸为设计变量,以车架结构的总体积最下为优化目标,对车架纵梁截面尺寸进行优化并分析优化结果。通过对初步设计出的轻型车架结构的实体建模及有限元分析,得到一些对车架设计有所帮助的结论,为今后车架的设计工作提供一定的指导作用。

关键词:轻型货车车架;三维建模;载荷;有限元静力学分析;模态分析

ABSTRACT

Automobile frame, as an important part of the vehicle, the vehicle being loaded from the road and the complex will eventually be passed to the load frame, and the car is the frame number of important general in Chengdu as the carrier, and thus the strength and the framestiffness of the overall design of the car plays a very important role.Therefore, the performance is good or bad frame structure about the success of this vehicle design.If the traditional method of classical mechanics, the result is too large distortion; and tested using test method, high cost and long period.To this end this paper, the finite element analysis, design of the frame structure to achieve the purpose of rationalization and lightweight thus reducing design costs and shorten design cycles, while improving the efficiency of design work.Because, ANSYS solid model in the analysis of powerful features in the structure of static analysis and design optimization software, compared with many other obvious advantages.In this paper, three-dimensional modeling software Pro / E and the finite element analysis software ANSYS, a light truck chassis is a Pro / E modeling and ANSYS.

On Pro / E and ANSYS software, understanding and learning, the use of Pro / E solid modeling, meshing into ANSYS, the stress load, obtained by solving the dynamic analysis of the results, draw conclusions, and then as needed for. The solid element has been designed based on the topology optimization of frame structure model and the size of a simple optimization model to frame the longitudinal cross-section dimensions of design variables, the total volume of the frame structure to optimize the next goal, on the framelongitudinal section size optimization and analysis of optimization results.The preliminary design by a light frame structure of solid modeling and finite element analysis, get some help on the conclusions of the frame design, frame design for the future to provide some guidance.

Key words:Frame of track; Three-dimensional modeling; loads; Finite element static analysis; Modal analysis

目 录

摘要I

AbstractII

第1章 绪论1

1.1 研究目的和意义1

1.2 车架国内外研究现状2

1.3 主要设计内容4

1.4 拟解决的主要问题5

第2章 轻型货车的车架设计6

2.1 车架的概述6

2.1.1 车架的设计要求6

2.1.2 车架的结构型式6

2.1.3 纵梁、横梁及其联接10

2.1.4 车架的制造工艺及材料11

2.2 车架的结构设计12

2.2.1 车架设计参考12

2.2.2 车架参数的确定13

2.2.3 车架的弯矩及弯曲应力计算14

2.2.4 车架的挠度计算16

2.3 本章小结18

第3章 车架三维模型的建立19

3.1 Pro/E软件介绍19

3.2 三维模型的建立20

3.3 本章小结24

第4章 车架有限元分析25

4.1 ANSYS的特点25

4.2 ANSYS的基本组成和功能26

4.3 Pro/E与ANSYS接口的创建28

4.4 车架有限元的静力分析30

4.4.1 三维实体模型的网格划分30

4.4.2 施加约束条件31

4.4.3 车架4种工况分析32

4.5 车架有限元的模态分析42

4.6 本章小结48

结论49

参考文献50

致谢51

1.1 研究目的和意义

在汽车制造市场竞争日益激烈的今天,汽车制造技术越来越先进,作为载货车主要承载结构的车架,它们的质量和结构形式直接影响车身的寿命和整车性能,如动力性、经济性、操纵稳定性。汽车的轻量化,就是在保证汽车的强度和安全性能的前提下,尽可能地降低汽车的整备质量,从而提高汽车的动力性,减少燃料消耗,降低排气污染。实验证明,汽车质量降低一半,燃料消耗也会降低将近一半。当前,由于环保和节能的需要,汽车的轻量化已经成为世界汽车发展的潮流。轻量化是21世纪整车发展趋势之一,减轻汽车质量意味着节约了能源和材料。车辆设计中,在满足载货车运营中对车架的刚度、强度及工艺改造等因素要求的同时,应当尽可能减轻它们的质量和降低制造成本。 综合分析这些文献可知,当前国内对于有限元法应用于车架结构分析的研究只是限于对车架和车架结构在静态扭转、弯曲载荷以及几种极限工况载荷作用下的分析,得出车架结构的静态应力分布,并对其进行了局部的修改,由于软硬件对计算模型规模的限制,模型的细化程度不够,因而结构的刚度、强度分析的结构还比较粗略,计算结构多用来进行结构的方案比较,离虚拟实验的要求还有相当大的差距。

1.3 主要设计内容

本课题通过参考国内外轻型载货车车架的结构及工作原理的基础上,对车架进行设计计算和校核,利用Pro/E建模并应用ANSYS软件对的车架进行有限元分析,具体工作如下。

结合某汽车公司生产实际要求,在参考以往的研究成果以及国内外发展的现状,确定主要研究内容。

(1)研究应用弹性力学、有限元、静态分析、模态分析理论以及所有软件基础。

(2)车架设计方法以及设计步骤的研究。

(3)以某轻型货车车架为参考设计车架并对其进行PROE建模,将建成的PROE车架模型导入到ANSYS中准备进行有限元分析。

(4)分析研究建立有限元模型要考虑的问题,比如结构的简化,单元的选取,单元数量的控制,单元质量的检查,网格的布局以及连接方式的模拟。

(5)研究影响有限元分析结果的因素,比如单元厚度,单元大小,加强筋以及部件连接的模拟方法。

(6)对车架有限元模型进行刚度强度分析、模态分析;找出车架结构中需要改进的部位,并依据分析结果提车改进方案。

(7)对研究的车架进行惊呆性能评价。建立优化分析模型进行优化设计提出科学的改进方案。

1.4 拟解决的主要问题

(1)如何设计车架基本结构

(2)车架载荷及其约束的处理

(3)静态工况下弯曲工况的分析处理

(4)计算结果的处理

(5)有限元模型的创建方法

(6)对模型进行加载及求解的方法

(7)对分析出的图形、数据的处理以及如何对车架进行优化

钢板经冷冲成形后,其疲劳强度要降低,静强度提高、延伸率小的材料的降低幅度更大。常用车架材料在冲压成形后的疲劳强度约为140~160MPa。

轿车车架纵梁、横梁的钢板厚度约为3.0~4.0mm,货车根据其装载质量的不同,轻、中型货车冲压纵梁的钢板厚度为5.0~7.0mm,重型货车冲压纵梁的钢板厚度为7.0~9.0mm。且槽形断面纵梁上、下翼缘的宽度尺寸约为其腹板高度尺寸的35%~40%[1]。

2.2 车架的结构设计

2.2.1 车架设计参考

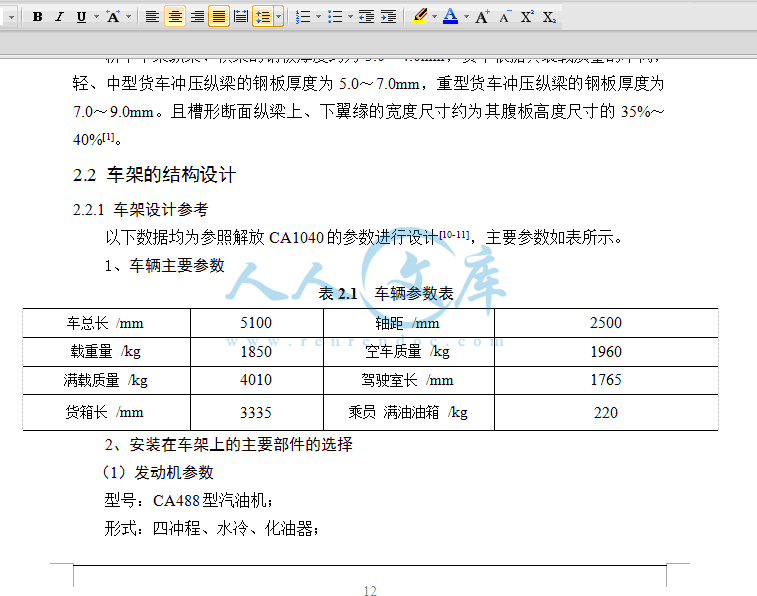

以下数据均为参照解放CA1040的参数进行设计[10-11],主要参数如表所示。

1、车辆主要参数

表2.1 车辆参数表

车总长 /mm5100轴距 /mm2500

载重量 /kg1850空车质量 /kg1960

满载质量 /kg4010驾驶室长 /mm1765

货箱长 /mm3335乘员 满油油箱 /kg220

2、安装在车架上的主要部件的选择

(1)发动机参数

型号:CA488型汽油机;

形式:四冲程、水冷、化油器;

最大功率:65kw;

最大扭矩:157N·m;

外形尺寸(长宽高):659602671.5(mm);

质量:135kg。

(2)变速器参数

型号:CAS5-20A机械变速器;

中心距:85mm;

最大输出转矩:196N·m;

壳体长度:285mm;

静质量:铸铁壳体56kg。

(3)货箱车头参数

货箱:钢板冲压货箱800kg;

车头:车头以及内部部件450kg。

(4)钢板弹簧参数

车架上加装钢板弹簧,参数如表2.2所示。

表2.2 钢板弹簧

前钢板弹簧后钢板弹簧

作用长度 /mm12001300

片厚12-612-8

片宽 /mm7070

片数36

2.2.2 车架参数的确定

1、选取梯形车架,由两个纵梁与5根横梁铆接而成。其弯曲刚度较大,而当受扭矩时,各部分同时产生弯曲和扭转。其优点是便于安装车身、车箱和布置其他总成,易于汽车的改装和变形因此被广泛地用在载货汽车。车架全长等宽,取750mm。车架长度大致接近整车长度,约为轴距的1.4~1.7倍,取车架长度为4500mm,在纵梁的全长范围内具有相等的高度和宽度。纵、横梁均由5mm厚的16Mn钢板冲压而成(轻、中型货车冲压纵梁的钢板厚度为5~7mm。槽型断面纵梁上、下翼缘的宽度尺寸约为其腹板高度尺寸的35%~40%,纵梁槽形断面如图2.8所示。

结 论

本文运用有所学知识,根据资料对车架结构进行设计,同时运用有ANSYS对车架进行静态有限元分析。在现代有限元分析软件的支持下,在分析了车架结构力学特性的基础上建立了某载货车车架有限元模型,进行了车架静力分析,全面掌握了车架的应力分布情况,为车架的结构试验及其优化设计提供了良好的理论基础。通过本课题的研究,最终得出以下结论:

1、完成了车架结构设计,初步选择了车架结构形式、材料,同时经过计算得出该设计方案满足车架设计的所要求的刚度,挠度应在满足车架本身的刚度,挠度,在此基础上,可以利用ANSYS对已设计出的车架进行结构优化,使最终设计出来的车架在不影响使用性能的前提下,达到节省材料,结构轻量化的要求。

2、对载货车车架这类大型结构进行了有限元建模,采取了车架设计经常应用的单元类型,以及适当调整网格划分的精度,在不影响分析结果的前提下,使得设计求解时间更加快速,提高了车架设计和有限元分析工作的效率。

3、对于建模中经常出现的不能网格划分,以及模型边界,应力的问题,通过ANSYS中软件自动指出错误进行模型修改,另优设计分析更加快速精确,同时也了解了车架设计当中需要注意的问题,同时在设计中还可以在不影响车架分析结果的前提下,对车架模型进行当如ANSYS过程中的简化,使得加载分析过程更加快速,避免了不必要的操作。

参考文献

[1]刘惟信.汽车设计[M].北京:清华大学出版社,2006.1

[2]汽车车身结构与设计[M].北京:机械工业出版社

[3]余志生.汽车理论[M].北京:机械工业出版社,2010.1

[4]姜勇,张波.ANSYS7.0基础教程与实例详解[M].北京:中国水利水电出版社

[5]詹友刚.Pro/ENGINEER中文野火版4.0曲面设计教程[M].北京:机械工业出版社,2009.1

[6]刘坤,吴磊.ANSYS有限元方法精解[M].北京:国防工业出版社,2004.8

[7]段进,倪栋,王国业.ANSYS10.0结构分析从入门到精通[M].北京:兵器工业出版社,2006.10

[8]冯国胜.汽车车架结构参数的优化设计[J].计算结构力学及其应用.1994(2):218—220

[9]刘新田,黄虎,刘长虹等.基于有限元的汽车车架静态分析.上海工程技术大学学报,2007,6:112~116

[10]宋允祁,王中亭.解放CA1040系列轻型货车构造与维修[M].吉林科学技术出版社,1995.

[11]宋允祁.中国第一汽车集团公司汽车产品构造图册[M].人民交通出版社,2000.

[12]唐金松.简明机械设计手册[M].上海科学技术出版社,2000.

[13]成大先.机械设计手册[M].化工工业出版社,2001.1.

[14]文晁云,曹利钢,陈立伟,张晓宇.基于ANSYS的螺簧车架静态强度分析[J].机械设计与制造2009(6)

[15]牛跃文. 基于ANSYS的矿用汽车车架有限元模态分析[J].煤矿机械2007,28(4)

[16]谷安涛,常国振.汽车车架设计计算的有限元法[J].汽车技术.1977(6):54.65

[17]钟佩思,赵丹,孙雪颜,魏群.基于ANSYS的汽车车架的建模与模态分析[j],机械设计与制造,2008(6)

[18]尹辉俊,志林.沈光烈货车车架的有限元分析[J]械设计 2005(11)

[19]安晓卫.马星国.祝宝发汽车车架的有限元模态分析[J], 沈阳工业学院学报1999

[20]Hassani B,Hinton E.A review ofhomogenization and topologyoptimization I-homogenization theory formedia、衍th periodicstructure[J].Computers and Structures.1998.69:707-717.

川公网安备: 51019002004831号

川公网安备: 51019002004831号