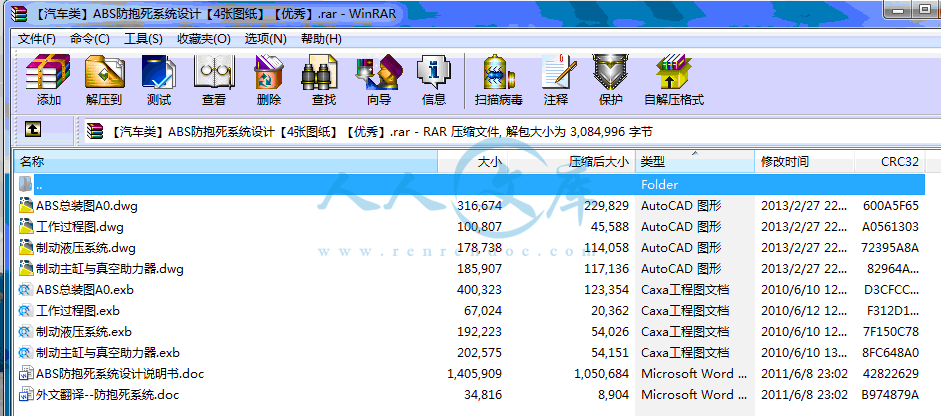

【汽车类】ABS防抱死系统设计【4张图纸】【优秀】

收藏

资源目录

压缩包内文档预览:

编号:419319

类型:共享资源

大小:1.73MB

格式:RAR

上传时间:2015-03-24

上传人:上***

认证信息

个人认证

高**(实名认证)

江苏

IP属地:江苏

39

积分

- 关 键 词:

-

ABS防抱死系统

设计图纸

- 资源描述:

-

ABS防抱死系统设计

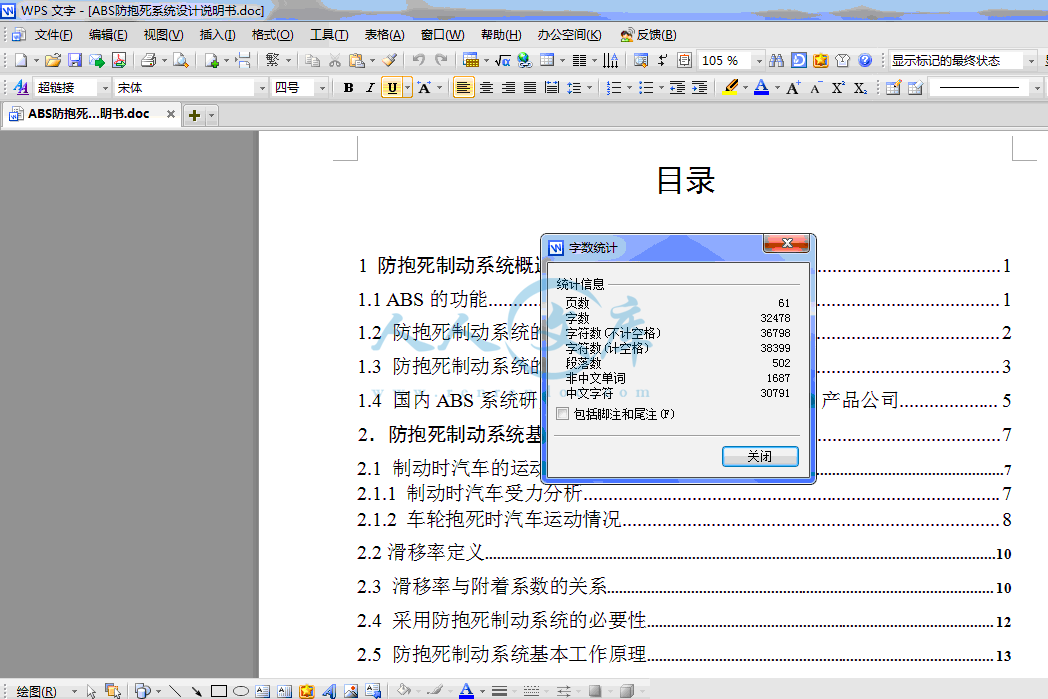

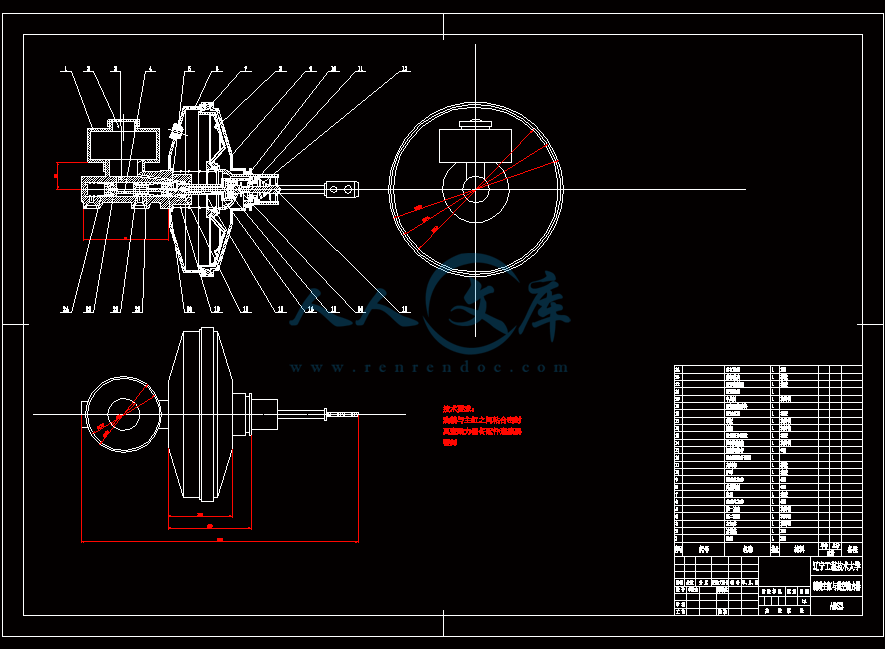

61页 32000字数+说明书+4张CAD图纸【详情如下】

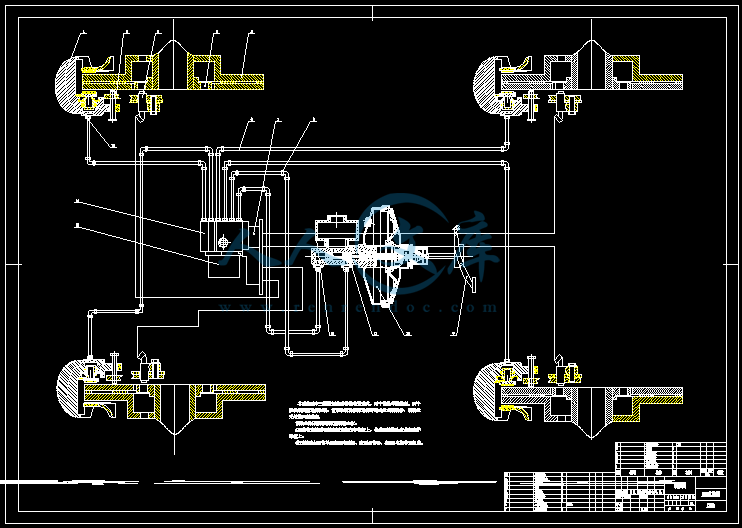

ABS总装图A0.dwg

ABS总装图A0.exb

ABS防抱死系统设计说明书.doc

制动主缸与真空助力器.dwg

制动主缸与真空助力器.exb

制动液压系统.dwg

制动液压系统.exb

外文翻译--防抱死系统.doc

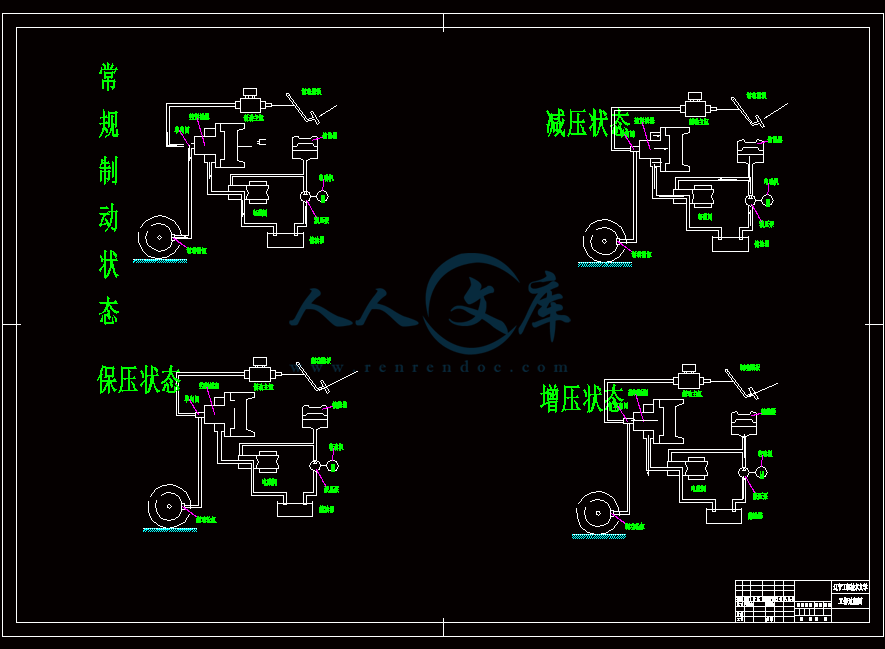

工作过程图.dwg

工作过程图.exb

目录

1 防抱死制动系统概述1

1.1 ABS的功能1

1.2 防抱死制动系统的发展历史2

1.3 防抱死制动系统的发展趋势3

1.4 国内ABS系统研究的理论状态和具有代表的ABS产品公司5

2.防抱死制动系统基本原理7

2.1 制动时汽车的运动7

2.1.1 制动时汽车受力分析7

2.1.2 车轮抱死时汽车运动情况8

2.2滑移率定义10

2.3 滑移率与附着系数的关系10

2.4 采用防抱死制动系统的必要性12

2.5 防抱死制动系统基本工作原理13

3 防抱死制动系统硬件设计17

3.1 防抱死制动系统的布置形式与组成17

3.1.1防抱死制动系统的布置形式17

3.1.2防抱死制动系统的基本组成19

3.2 防抱死制动系统轮速传感器选择21

3.2.1霍尔传感器的设计24

3.2.2霍尔开关电路的选择24

3.2.3传感器齿盘的设计26

3.3 防抱死制动调压系统工作过程27

3.4 电源设计30

3.5 信号输入电路设计31

3.6 电磁阀驱动电路的设计32

3.7 泵电机驱动电路的设计34

3.8 ABS系统报警LED灯设计35

3.9 故障诊断硬件电路设计36

3.10 车轮制动器的选择38

4 防抱死制动系统软件设计40

4.1控制方案和控制参数的选取41

4.2控制参数及其计算42

4.2.1门限减速度的求取42

4.2.2门限加速度的求取43

4.2.3路面识别技术43

4.3控制过程44

4.4程序设计47

5 经济分析49

6 结论与展望50

6.1研究工作总结50

6.2防抱死制动系统发展方向50

致谢53

参考文献54

附录A 译文55

附录B 外文文献58

摘要

ABS系统可以显著提高或改善汽车紧急制动时的操控性和稳定性,缩短了制动距离,是一种新型的汽车电子控制产品,并得到了越来越广泛的应用。

本文展开对汽车ABS的研究,主要完成了以下的工作:通过对单个车轮时的受力分析确定了影响车轮附着系数的主要因素;通过比较电磁感应式轮速传感器和霍尔效应传感器的性能优缺点,采用并设计了霍尔效应式轮速传感器;通过对控制结构的分析设计,包括信号输入电路、控制输出电路、驱动电路等硬件部分;经比较各种控制方案,确定了“逻辑门限制法”作为控制方案,并选用加速度和滑移率的组合作为控制参数。采用事件门限来计算车轮的转速。本文通过学习比较根据所学只是设计了ABS控制系统。从理论上实现了ABS的控制功能,完成了设计要求。在设计过程中对汽车制动理论和制动装置有了较为深入的了解,扩大了自己的知识面,自己解决问题的能力也得到了提高。

关键词:防抱死制动系统;电子控制单元;门限值滑移率;轮速传感器

2.防抱死制动系统基本原理

2.1 制动时汽车的运动

2.1.1 制动时汽车受力分析

汽车在制动的过程中主要受到地面给汽车的作用力、风的阻力和自身重力的作用。地面对汽车的作用力又分为:作用在车轮上垂直于地面的支承力和作用在车轮上平行于地面的力。汽车在直线行驶并受横向外界干扰力作用和汽车转弯时所受到地面给汽车的力如图 2-1所示。其中Fx为地面作用在每个车轮上的地面制动力,他的大小决定于路面的纵向附着系数和车轮所受的载荷。所有车轮上所受地面制动力的总和作为地面给汽车的总的地面制动力,他是使汽车在制动时减速并停止的主要作用力。Fy为地面作用在每个车轮上的侧滑摩擦力,侧滑摩擦力的大小取决于侧向附着系数和车轮所受的载荷,当车轮抱死时,侧滑摩擦力将变得很小,几乎为零。汽车直线制动时,若受到横向干扰力的作用,如横向风力或路面不平,汽车将产生侧滑摩擦力来保持汽车的直线行驶方向,如图2-1(a)

- 内容简介:

-

附录A译文防抱死系统 ABS是目前世界上普遍公认的提高汽车安全性的有效措施之一,可以提高汽车制动过程中的操纵稳定性和缩短制动距离。汽车检测行业在近年来随着汽车制造技术和检测技术的进步,也不断发展壮大,在汽车运行管理部门动态监督汽车技术状况方面发挥着极其重要的作用。特别是随着我国公路建设和道路运输业的飞速发展,道路交通安全问题也越来越突出,要求进一步重视和加强机动车辆安全技术状况检测已成为维护社会安定的一个重要课题。 本文涉及的ABS性能的检测,分软件和硬件两个部分,相辅相成共同完成检测。对一台装备了ABS的汽车进行制动效果,ABS性能的评价和分析。计算机基于Visual Basic编译开发相应的应用程序。检测装备传感器安装在一台具有ABS的实验汽车汽车里并调试,完成对车辆行驶各种信息的采集。软件完成数据的收集和处理通过人机对话,实现对该ABS性能的检测和评价。随着高等级公路的不断增加,车辆平均行驶速度有了显著提高。一方面车辆技术向高速性趋势发展,但另一方面汽车保有量的迅速增加导致了行车密度的加大。因此,人们对汽车行驶安全性提出越来越高的要求。作为主动安全系统代表车防抱死制动系统(ABS是在这种背景提出和发展起来的。这种先进的汽的气塾吻声盼”动系缤协矍卿是在这种背景提出和发展起来的。这种汽车电子控制制动可以提高车辆制动过程中的操纵稳定性和制动强度,改善车辆高速行驶的安全性,减少交通事故的发生。车辆ABS电子控制系统的开发,涉及到机械、电子、液压技术、计算机软硬件开发,以及试验技术等方面。在ABS开发的初期,由于受计算机技术发展的限制,一般靠大量道路试验来摸索控制规律,耗费大量人力、物力和财力,开发周期比较长。在市场激烈竞争和资金周转困难的情况下系统开发手段已经不能适应汽车工业,特别是汽车电子工业高速发展的需要。)针对国内汽车工业发展现状,本文系统提出了一种高质量、低成本、高效率的车辆电子控制系统快速开发方法,并建立了相应的快速开发系统。该开发系统可以最大限度的模拟实际车辆在各种工况下的运行状态,在实验室条件下实现对ABS控制系统的快速开发。整个开发过程包括控制系统概念设计,系统建模, 系统离线仿真,代码自动生成,硬件在环实时仿真以及最终产品试验。由于开发平台是统一的,各个开发阶段之间紧密相连,实现交互式的并行交流,大大克服了多余的中间环节,节约了时间和成本。 实时仿真需要反映问题本质的ABS动力学系统模型,它是车辆ABS决速开发系统中的最重要的组成部分,直接关系到控制器的开发效率和精度。ABS动力学系统模型主要包括整车模型,轮胎神经网络模型,液压系统模型以及制动器模型。对轮胎神经网络模型的深入研究,为获得轮胎神经网络模型学习样本的实车试验方案做出了贡献,并进行了相应的试验。为了从纵向、横向和联合工况的动态特性三个方面来验证ABS动力学模型的正确性和准确性,利用试验样车进行了三种工况下的道路试验,即车辆直线制动试验,纯转向试验和制动转向试验。所有试验结果都表明,文中建立的ABS动力学系统模型理论上是正确的,基本满足仿真精度要求及后继研究工作需要。基于混合仿真技术,本文进行了车辆ABS快速开发系统的总体方案和功能设计,并论述了实时仿真环境的实现方法。以总体方案设计为指导,以ABS快速开发系统功能设计为目标,从软件、硬件和接口三个方面详细论述了车辆ABS快速开发系统的设计和构造。在车辆系统理论建模的基础上,编制了车辆 ABS系统仿真模型;同时根据硬件配置的需要,进行了接口设备、驱动电路和电气系统的设计。应用建成的这一快速开发系统,详细阐述了车辆ABS快速开发的基本方法和基本过程,即从非在线数字仿真,实时数字仿真,硬件嵌入式实时混合仿真,以及实车试验验证整个ABS研究和开发过程。以车辆ABS逻辑门限值控制方法研究与控制系统开发为主要目标,利用该车辆ABS快速开发系统,对ABS实用化控制逻辑进行了全面研究和系统开发,包括ABS控制变量的实用化算法设计,ABS逻辑门限值实时控制算法设计。把自主研制的ABS逻辑门限值控制器嵌入到快速开发系统之中,进行控制器参数的调整。为了验证自行开发的ABS控制器的有效性和实用性,文中进一步阐述了实车ABS的道路试验。利用实车道路试验对ABS控制器参数进行精调,最终完成对ABS控制器的快速开发。实车道路试验结果表明,自行开发的ABS控制器控制有效,运行稳定,达到国外同类产品的控制精度和效果。利用ABS快速开发系统,本文对目前世界上最先进的汽车电子控制系统一车辆稳定性控制若干问题进行了研究。利用前馈补偿和模糊控制技术,以方向盘转角为前馈输入变量,车辆横摆角速度和侧偏角为反馈输入变量,设计了车辆横向稳定性控制器。通过控制前轴左右车轮制动力动态分配,实现车辆在任何行驶工况下都能按驾驶员意图跟踪理想控制目标。以变道工况和高速转向工况为例,进行了车辆横向稳定性控制的实时混合仿真研究。研究结果表明,车辆在高速变道和转向时,当前设计的基于ABS车辆横向稳定性控制器能够有效控制车辆,使其迅速、准确和安全地图行驶;即使在道路条件和行驶条件改变时,该控制器对参数非线性和不确定性具有较强的适应性和鲁棒性。文中建立的ABS快速开发系统是一个开放式的车辆电子控制系统快速开发平台。车辆ABS快速开发方法及其系统在ABS控制器开发中的成功应用,有力地证明了本文的研究工作使在投入少和周期短的情况下开发出合格的汽车ABS电子产品成为可能。附录B外文文献Anti-lock Braking SystemABS is in the present world the universal recognition enhances one of automobile secure effective actions, may enhance the automobile to apply the brake in the process operation stability and reduces the stopping distance. Automobile examination profession in recent years along with automobile manufacture technology and examination technology progress, also unceasingly grows strong, is playing the extremely vital role in the automobile movement control section dynamic surveillance automobile technology condition aspect. Specially along with our country highway construction and the path shipping industry rapid development, the road traffic security problem more and more is also prominent, the request further takes and strengthens the motor vehicle security technology condition examination to become the maintenance society stability an important topic. This article involves the ABS performance examination, is divided software and the hardware two parts, complements one another completes the examination together. Equipped the ABS automobile to carry on applies the brake the effect, the ABS performance appraisal and the analysis. Computer based on Visual Basic translation development corresponding application procedure. The examination equipment sensor installs in has ABS in the experimental automobile automobile and debugs, completes goes each kind of information gathering to the vehicles. Software completes the data the collection and processing through the man-machine dialogue, realizes to this ABS performance examination and the appraisal.With increase of public interest in vehicle performance of safety, emission and ride comfort, vehicle electronic control systems have been developed in generations for the purpose of enhancing overall dynamic behaviors by almost all automakers and parts suppliers for decades. The development of anti-lock braking system (ABS), for improving vehicle braking and handling performance, involves mechanism electronics, hydraulics, hardware and software design and field test validation, and also requires repeated field tests on various road conditions, which are not easily available. In the very beginning of product development for vehicle ABS, a huge amount of vehicle field tests are required to investigate the control laws by a great number of repeated modifications. Moreover, even in most repeatable test environments, the road conditions for field tests cannot be controlled exactly to be identical. This inevitably leads to increase of both development cost and cycle time for ABS product. Because of fierce competition in todays business environment automotive industries suffer constantly increasing pressure of reduction in the development cost and time of new vehicle electronic products to meet the demands of market and urgent effective approaches to innovation of sophisticated vehicle electronic products.In this paper, a new rapid development method is proposed to develop and test ABS control system efficiently in laboratory environment, which covers the whole process of concept and function design, system modeling, off-line simulation, code automatic generation, real-time hardware-in-the-loop (HiL) simulation and final vehicle test validation. This economical ABS rapid development system characterized by a parallel rather than a serial development process is built up with friendly interface for implementation of the present development procedure. The rapid development system is based on HiL simulation technology, and function of sensors and actuators of the control system are replaced by software to simulate a field test environment in a controllable situation. Therefore, consistently reproducible test conditions are provided and critical safety issues may be solved in the stage of electronic product development prior to in-vehicle tests. The present rapid development system is successfully employed in the ABS control system development and the developed control algorithm has been validated in the vehicle filed test. According to the test measures, the control precise is close to that of the original one. It is proved that the method and the rapid development system are effective and efficient in the laboratory for reduction of expenses in field tests and development cycle.By considering a given precision requirement of real-time simulation, a vehicle system dynamic model for ABS should be presented as one important part of the ABS rapid development system, which has strong effect on the efficiency and effectiveness of the controller to be developed. The vehicle system dynamic model consists of vehicle model, neuro-tire model, brake model and hydraulic system model. The scheme for tests to build up and validate the subsystem model has been drawn up. Further, validation of the vehicle dynamic system model integrated by the sub-system model is made for the future research and the vehicle field test without the ABS has also been performed for verification of the precision of the built-up model under three conditions of pure braking, pure steering and braking while steering, respectively. By experimental results, it is shown that the vehicle system dynamic model for the ABS is correct and accurate, and can be used in the rapid development system.The design of the rapid development system and the way to realize its functions in the real-time simulation environment are presented. Under the direction of the proposed scheme, details of construction process of the ABS rapid development system including the software part, hardware part and interface part are discussed with consideration of its functions extended. The whole procedure of rapid development for ABS, i.e., off-line simulation, generic real-time simulation, real-time hardware-in-the-loop simulation and the validation of the vehicle field test, based on this powerful development system, is further investigated by the ABS rapid development system.Use is made of the present method and the ABS rapid development system for research and development of the ABS controller systematically. The practical algorithm for the ABS control variables is presented, and based on the previous research achievements, the ABS controller is designed and embedded seamlessly in the rapid development system. The development procedure has been carried on according to the proposed method, and the developed ABS controller is then applied in the vehicle field test for validation and further modification. The effectiveness of refined ABS control logic is proved to match the original product by results obtained in the vehicle field tests by the two controllers mentioned above.Furthermore, the most advanced vehicle control system, i.e., vehicle stability control system is studied by using the extended ABS rapid development system. By the direct yaw moment control by regulation of braking forces, the vehicle dynamic stability may be improved. The controller makes the vehicle follow the desired dynamic model by feed forward regulation of side slip angle and the state feedback of both the yaw rate and side slip angle. By taking the J-turn and single lane change at the vehicle high speed, for example, the control law has been implemented by the extended ABS rapid development system. By the HiL real-time simulation results it is shown that the present control law is quite effective and robust in keeping the vehicle to follow the desired trajectories quickly and exactly even some parameters changing in the system, such as steering angle input, road friction and vehicle speed. It is demonstrated by theoretical and experimental resu

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号