钢管切管机设计

49页 15000字数+说明书+6张CAD图纸【详情如下】

传动系统装配图.dwg

外文翻译--中国石油管的现状和前景.doc

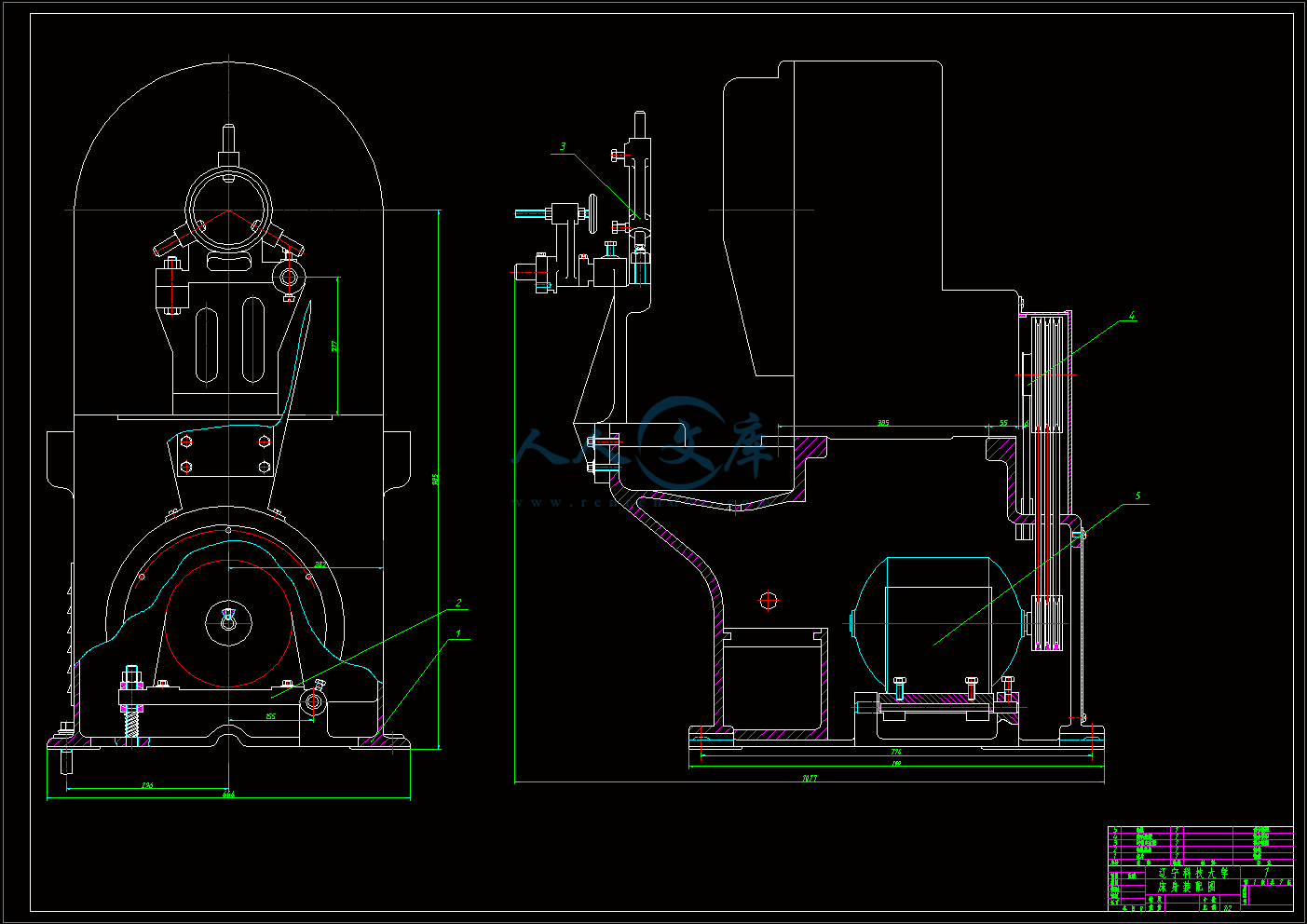

床头箱装配图.dwg

床身装配图.dwg

总装配图.dwg

摘要.doc

目录.doc

轴.dwg

钢管切管机设计说明书.doc

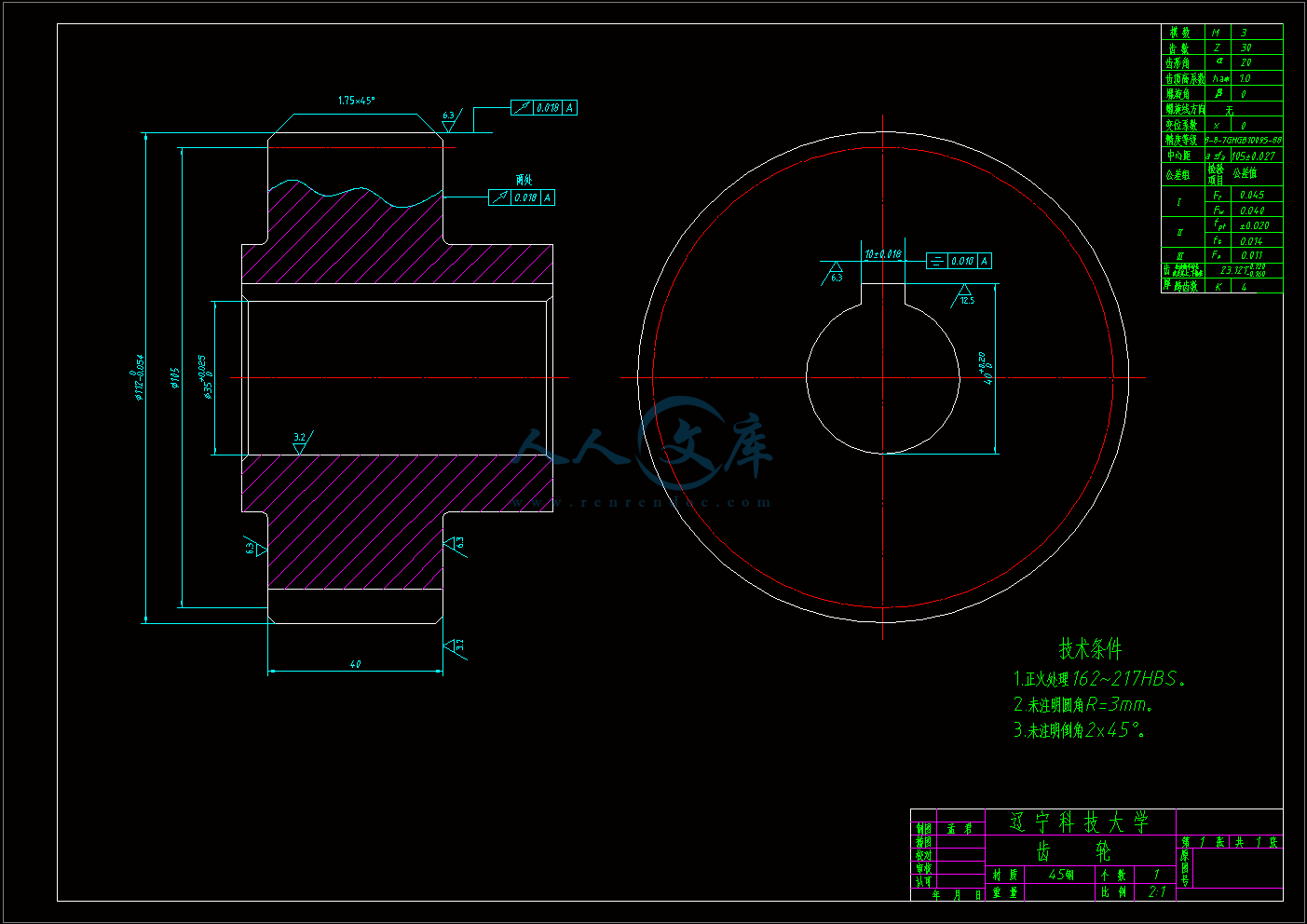

齿轮.dwg

目 录

1 绪论1

1.1 引言1

1.2 切管机的作用1

1.3 国内外切管机的发展状况2

1.4 研究内容与方法2

1.4.1切管机在现场的布置2

1.4.2研究内容与方法3

2方案选择与评述5

2.1切管机功能原理设计5

2.2 切管机的结构设计8

3 主要参数选择与计算9

3.1电机容量选择9

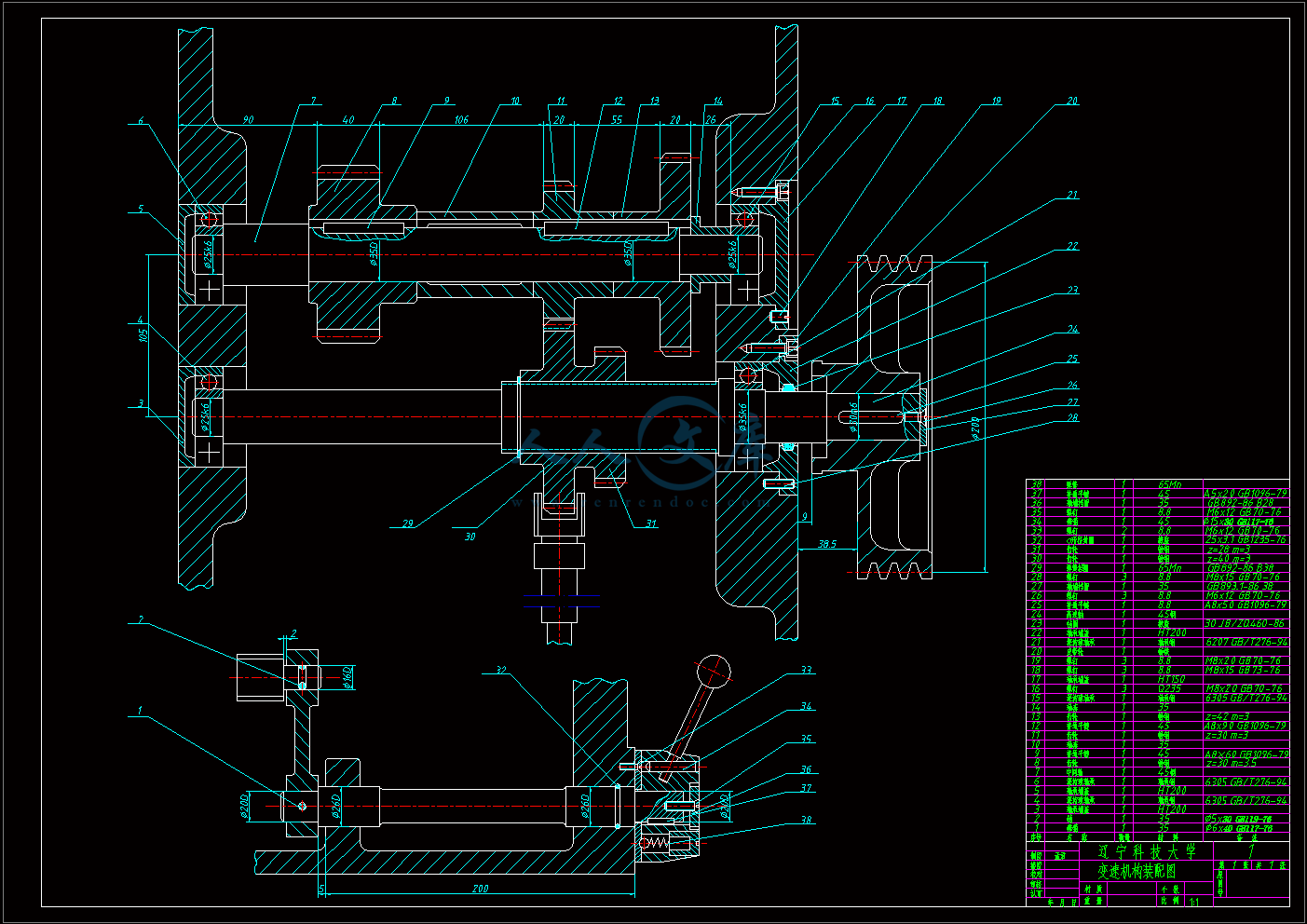

3.2传动装置的设计10

3.2.1分配传动比10

3.2.2 传动装置的整体布置10

3.2.3 传动装置的运动和动力参数计算11

4 主要零件的设计及强度计算13

4.1 V带传动的设计计算13

4.2齿轮传动的设计计算15

4.2.1高速轴与中间轴之间的齿轮啮合15

4.2.2低速轴与中间轴之间的齿轮啮合23

4.2.3齿轮的润滑27

4.3轴的设计及轴承的选择28

4.3.1轴的设计28

4.3.2轴的强度校核29

4.4轴承的强度校核37

4.4.1高速轴上的轴承强度校核37

4.4.2中间轴上的轴承强度校核38

4.5键的较核39

4.5.1高速轴上的键校核40

4.5.2中间轴上的键校核40

5 减速器齿轮轴的应力分析41

结束语44

致谢45

参考文献46

摘 要

钢管是一种多功能的经济断面钢材。它在国民经济各部门应用愈来愈广泛,需求量也越来越大。管材的需要量之所以急剧增长,是因为管子能用各种材料来制造。而且质量和精度也高。随着钢管的需求量的日益增大,钢管的生产也显得尤其的重要,至此,这里先对切管机这一钢管生产中的设备做一下介绍。首先,切管机在钢管精整工段中占有很重要的地位。根据钢管产品标准的规定,凡是成品钢管共两端必须切齐整,且切头断面应与钢管中心线垂直。而热轧并经矫直后的管子均达不到上述技术条件的要求,钢管两端往往有裂纹、撕破、结疤和壁厚不均等缺陷,故需要切头尾。成品钢管按订货要求的定尺或倍尺,还有待处理品的改尺,均需要切断。此外,冷拔冷轧钢管生产时,中间管料和成品钢管都需切断和切头尾。本设计对钢管固定式Q119型切管机的主传动部分进行原理性设计。包括切削功率的计算,主传动部分的设计和校核等。详细内容见正文部分。

关键词:钢管;切管机;切削功率;校核

钢管主要用来输送流体(一般叫做输送管、英文叫“pipe”)和用作锅炉等的热交换器管(叫做管子,英文叫“tube”)。

钢管是一种多功能的经济断面钢材。它在国民经济各部门应用愈来愈广泛,需求量也越来越大。管材的需要量之所以急剧增长,是因为管子能用各种材料来制造。而且质量和精度也高。

钢管作为输送管广泛地用于输送油、气、水等各种流体,如石油及天然气的钻探开采与输送、锅炉的油水与蒸汽管道、一般的水煤气管道。化工部门一般用管道化方式生产与运输各种化工产品。所以钢管被人们称为工业的“血管”。

钢管作为结构管大量地用于机械制造业和建筑工业,如用于制作房架、塔吊、钢管柱、各种车辆的构架等。在断面面积相同的条见下,钢管比圆钢、方钢等的抗弯能力大,刚性好,其单位体积的重量轻。因此,钢管是一种抗弯能力较强的结构材料。

钢管还作为中空的零件毛坯用于制造滚动轴承、液压支柱、液压缸简体、空心轴、花键套、螺母以及手表壳等,这既节约金属又节省加工工时。

钢管又是军队工业中的重要材料,如用于制造枪管、炮筒及其他武器。随着航空、火箭、导弹、原子能与宇宙空间技术等的发展,精密、薄壁、高强度钢管的需求量正迅速增长。

随着钢管的需求量的日益增大,钢管的生产也显得尤其的重要,至此,本文将对切管机这一生产设备做一下介绍。

1.2 切管机的作用

首先,切管机在钢管精整工段中占有很重要的地位。根据钢管产品标准的规定,凡是成品钢管共两端必须切齐整,且切头断面应与钢管中心线垂直。而热轧并经矫直后的管子均达不到上述技术条件的要求,钢管两端往往有裂纹、撕破、结疤和壁厚不均等缺陷,故需要切头尾。成品钢管按订货要求的定尺或倍尺,还有待处理品的改尺,均需要切断。此外,冷拔冷轧钢管生产时,中间管料和成品钢管都需切断和切头尾。

其次,在长距离输油气管线建设与维护作业中,管材必须经切管机切断,然后才能使用。

总体上讲切管机的作用是:

(1)按合同要求将飞锯、矫直后的钢管切成定尺长度或通常长度;

(2)对钢管端而进行加工,使符合技术标准的要求;

(3)对有缺陷的待修钢管进行中间切断,切除缺陷部分,钢管改尺(通常长度或短尺长度)交货;

(4)将飞锯切断的倍尺长度的钢管切成单倍尺长度。

川公网安备: 51019002004831号

川公网安备: 51019002004831号