挖掘装载机装载部分的设计【7张图纸】【优秀】

收藏

资源目录

压缩包内文档预览:

编号:422407

类型:共享资源

大小:1.73MB

格式:RAR

上传时间:2015-04-03

上传人:上***

认证信息

个人认证

高**(实名认证)

江苏

IP属地:江苏

39

积分

- 关 键 词:

-

挖掘

装载机

部分设计

图纸

优秀

挖掘装载机装载

- 资源描述:

-

挖掘装载机装载部分设计

57页 20000字数+说明书+外文翻译+7张CAD图纸【详情如下】

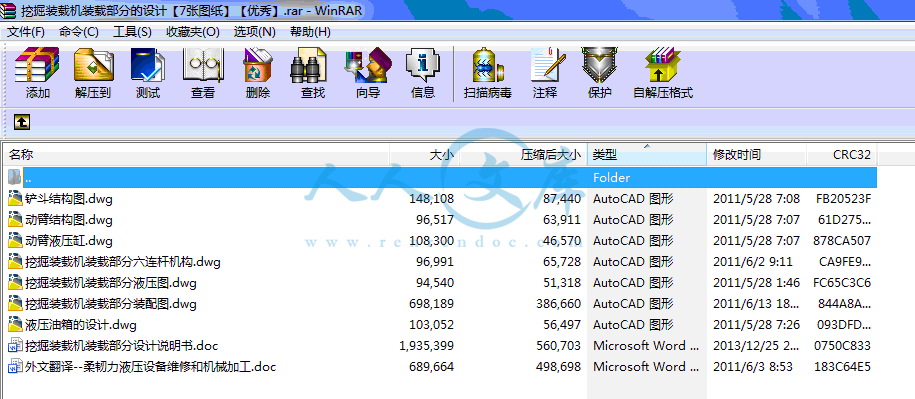

动臂液压缸.dwg

动臂结构图.dwg

外文翻译--柔韧力液压设备维修和机械加工.doc

挖掘装载机装载部分六连杆机构.dwg

挖掘装载机装载部分液压图.dwg

挖掘装载机装载部分装配图.dwg

挖掘装载机装载部分设计说明书.doc

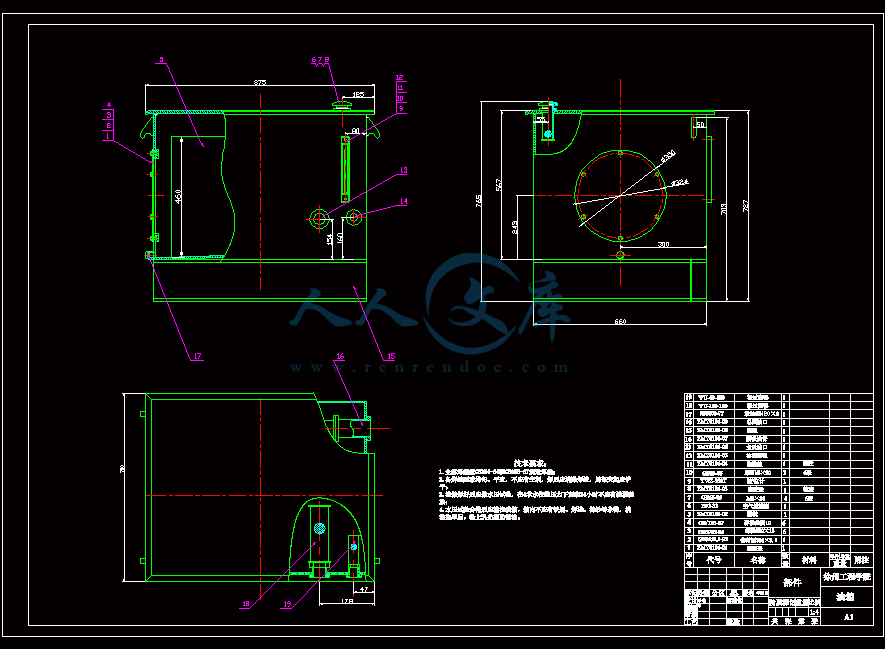

液压油箱的设计.dwg

铲斗结构图.dwg

目录

摘要I

AbstractII

1 绪论1

1.1 挖掘装载机简介和分类1

1.2挖掘装载机在国内的现状与发展趋势1

2挖掘装载机装载部分工作装置设计概述4

2.1 工作装置设计概述4

2.2 装载部分工作装置结构型式选择4

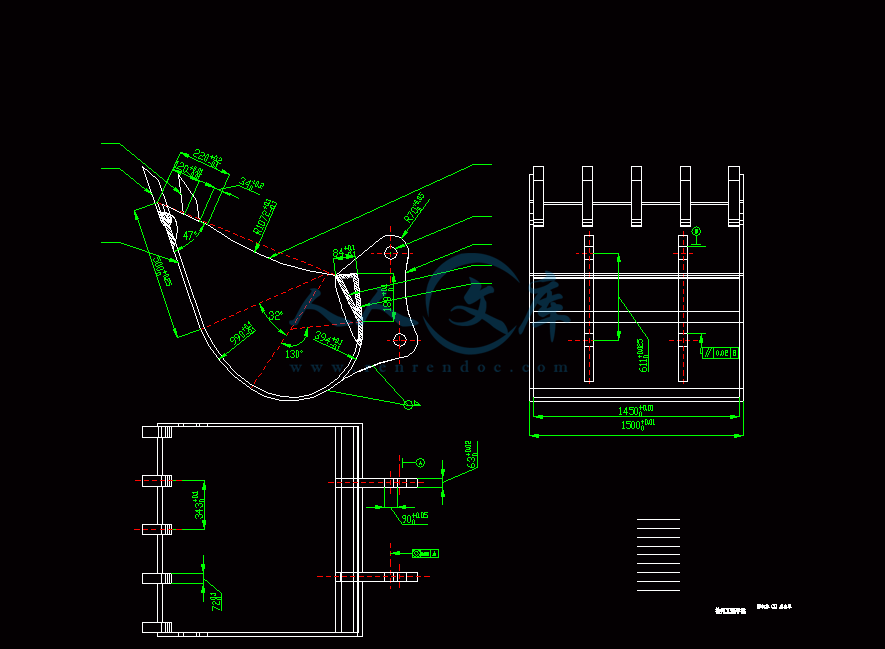

3 铲斗设计5

3.1 设计要求5

3.2斗型结构分析5

3.2.1 切削刃形状5

3.2.2 铲斗斗齿5

3.2.3斗刃6

3.2.4 斗体形状6

3.3 铲斗基本参数确定6

4 装载部分工作装置结构设计9

4.1工作机构连杆系统尺寸参数设计9

4.2 机构分析9

4.3 设计方法10

4.4 尺寸参数设计图解法10

4.4.1 动臂与铲斗、摇臂、机架的三个铰接点B、E、A的确定10

4.4.2 连杆与铲斗和摇臂两个铰接点C、D的确定11

4.4.3举升油缸与动臂和机架的铰接点H及M点确定11

5 工作装置强度计算13

5.1 计算位置13

5.2 外载荷确定13

5.3 工作装置受力分析15

5.4 工作装置强度校核20

5.4.1动臂21

5.4.2 铰销24

5.4.3 连杆25

5.4.4摇臂26

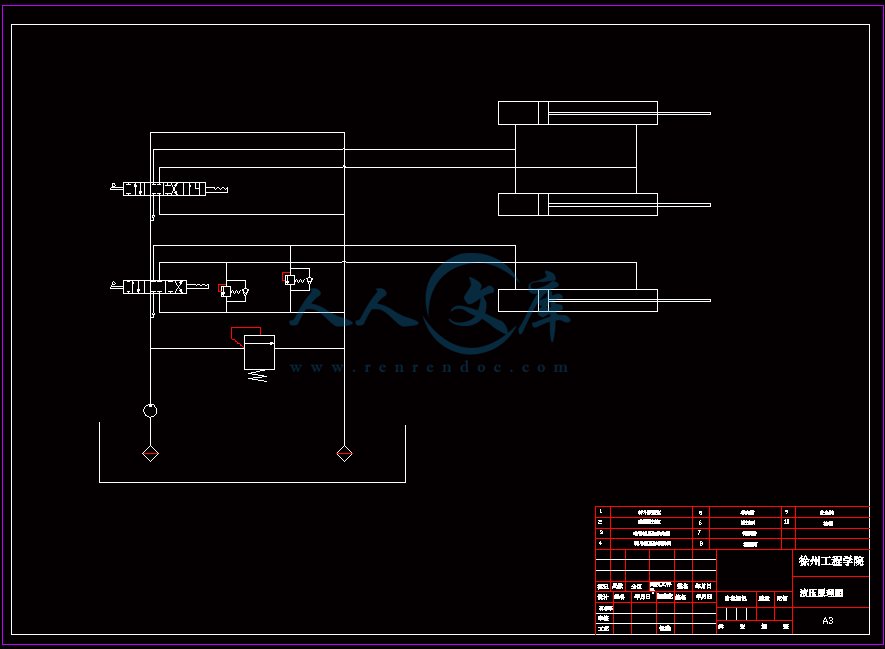

6 挖掘装载机液压系统设计30

6.1概述工况30

6.2 初选系统工作压力30

6.3 液压系统原理图30

6.4液压缸设计和计算31

6.4.1转斗油缸作用力确定31

6.4.2活塞33

6.4.3活塞杆34

6.4.4缸筒35

6.4.5 活塞杆校核39

6.4.6卡环连接计算40

6.4.7活塞杆导向套40

6.4.8 油口40

6.4.9密封件、防尘圈41

6.4.10转斗油缸与机架铰接处销轴校核41

6.5动臂举升油缸设计和计算41

6.5.1动臂举升油缸作用力确定41

6.5.2活塞42

6.5.3活塞杆43

6.5.4缸筒44

6.5.5活塞杆校核46

6.5.6卡环连接计算47

6.5.7焊接缸筒计算48

6.5.8活塞杆导向套48

6.5.9密封件、防尘圈48

6.5.10举升油缸与机架铰接处销轴校核48

6.6 泵的选用49

结论50

致谢51

参考文献52

关键词 工程机械 挖掘装载机 装载部分 工作装置

国内的挖掘装载机竞争企业与国内的发展趋势

①出口型:如四川公路机械厂生产的多功能工程机械80%以上都外销,而且销路一直很好,另外,桂林林业机械厂专门生产小型履带式挖掘装载机,产品绝大部分出口。②国外进件、国内组装型:如上海的CASE的580/590系列产品。国外进口、国内代理型:如JCB的2CX/3CX/4CX;VOLVO的B160/B171;CASE的580/590等目前都有代理。③国内生产企业:国内生产企业有10余家,其产品为低档的挖掘装载机。价格为:38万元以内。因此,挖掘装载机的国内的发展趋势是引进国外的先进技术,开发高质量、多功能、多品种、多规格的挖掘装载机系列产品,加强基础元件、部件的生产,尤其是提高挖掘装载机液压元件的质量,以达到在满足产品可靠性的前提下,降低挖掘装载机产品成本,并提高挖掘装载机产品的售后服务水平。

1 绪论

1.1 挖掘装载机简介和分类

挖掘装载机俗称“两头忙”。因为它具有独特的构造,前端是装载装置,后端为挖掘装置。在工地内,您只需要转动一下座椅,即可完成从挖掘机到挖掘机操作手角色的转变。挖掘装载机主要用于城市和农村的公路建设及养护、电缆铺设、电力和机场工程、市政建设、农田水利建设、农村住宅建设、开山取石以及各种小型建筑队所从事的各种建筑施工工程。“两头忙”属于小型多功能工程机械的一种,一般在大工程完成后的小工程中使用。挖掘装载机分类如下:结构上:从结构上来分,挖掘装载机有两种形式:一种是带侧移架,另一种不带侧移架。前者的最大特点是挖掘工作装置可以侧移,便于在特殊场地作业,它在运输状态时重心较低,有利于装载和运输。缺点是:由于结构上的限制,支腿多为直腿,支撑点在车轮边缘以内,两支撑点距离较小,挖掘时整机稳定性差(特别是挖掘工作装置侧移到一侧时)。这种型式的挖掘装载机功能重点在装载方面,在欧洲生产得较多;后者的挖掘工作装置不能侧移,整个挖掘工作装置可通过回转支承绕车架后部中心作180°回转,支腿为蛙腿式支撑,支撑点可伸到车轮外侧偏后,挖掘时稳定性好,有利于挖掘能力的提高。由于没有侧移架,整机造价相应降低。缺点是收斗时铲斗悬挂在车后部,外型尺寸长,机车处于运输和装载状态时,稳定性差,对装载和运输有一定影响,此种机型功能重点在挖掘方面,以美国生产居多。从动力分配上来分:挖掘装载机有两轮(后轮)驱动和四轮(全轮)驱动两种形式。前者不能完全利用附着重量,使机车与地面的附着力以及牵引力比后者下降,但造价比后者低得多。底盘上来分:小型多功能工程机械常用的三种底盘中,微型挖掘机的动力大多在20kW以下,整机质量1000-3000kg、采用履带行走机构,行走速度不足5km/h,多用于农场、园林等小规模的土方作业。由于其机型偏小,造价较高,目前在国内尚难以普及;挖掘装载机的动力多在30-60kW机重较大,质量约在5000-8000kg之间,挖掘能力较强,多采用轮式行走机构,全轮驱动,利用转向驱动桥或铰接转向,车速较高,达20km/h以上,国外大量用于农场、基建、道路维修等工程的土石方作业和大型施工现场的辅助性作业。该机型外形较大,灵活性较差,一般难以适应狭小场地的作业。

摘要

挖掘装载机是工程机械的主要机种之一,广泛用于建筑、矿山、水电、桥梁、铁路等部门。我国挖掘装载机装载部分在设计上存在很多问题,工作装置对于挖掘装载机装载部分来说又是重中之重,所以工作装置的设计好坏直接影响到挖掘装载机装载部分工作装置的使用寿命以及工作效率等。装载部分工作装置的转斗六连杆机构是由与液压缸,铲斗相关联的两个四连杆机构组合而成。装载部分在作业时,靠改变液压缸的长度来使铲斗获得所要求的收斗角和卸料角。机构中各杆件长度及其结构参数确定后,需要对该机构作某些特定计算,以判断机构设计的正确性。在工作循环中速度与加速度变化合理;油缸活塞行程为最佳值;工作装置运动平稳、无干涉、无死点、无自锁;动臂从最底位置到最大卸载高度的举升过程中,保证铲斗中物料不洒落;在卸载后,动臂下放至铲掘位置。

- 内容简介:

-

英文文献 HYDRAULIC EQUIPMENT OF PLIABLE FORCE FOR MAINTENANCE AND MECHANICAL WORKINGAbstract.The collaboration between the Hydraulic and Pneumatic Acting Systems Engineering Department and the SC HYDRAMOLD SRL firm led to the realization of some performances products on the hydraulics and pneumatics segment.The paper proposes to offer the most representative hydraulic pliable equipments force for mechanical working and maintenance.A big part from the hydraulic equipments is patented or claim of patent,the technology and technological originality being totally part of those. Because the paper has a prevalent technical character,in the presentation will be got off especially the performance characteristics of the areas used and the hydraulic equipments advantages of the pliable force.Key words:hydraulic equipment,maintenance,mecanical working. 1. IntroductionThe multi-functional modular equipments,pliable,for mechanical working, that are based on the hydraulic drive are destined to the manufacturing plant IMM also to the manufacturing plant of maintenance of the big company framework from energetic,petrochemistry,transport.All the equipments what are adduced in work are submitted in the framework of DISAHP research and make the study of other papers.Taking account the finite space of a work,there will be proposed from the large palette of hydraulic pliable equipments force a new or modernized equipments series from each segment developed by the SC HYDRAMOLD SRL firm(pressure sources,hydraulic presses,hydraulic tools, hydraulic equipment of 3000 bar,hydraulic lift equipment),following as in the next works it will be published other modern hydraulic equipments. 2.Hydraulic Equipments Analysis Force 2.1 Pressure Sources The pressure sources of the force hydraulic equipments yielded by the SC HYDRAMOLD SRL are:the hydraulic acting units that have electric or thermal engine and the hydraulic manual or pedal pumps.Hydraulic drive unit description with electric engineThe electro-hydraulic drive units HUEH are high pressure sources for the hydraulic cylinder supplying with simple or double action from some equipments structure,hydraulic installations or appliances,and they work with relative small rate flow and pressures of until 700 bars,(Fig.1).The working developed pressure can be adjusted depending on task:30-700 bar. Fig.1The electro-hydraulic drive unit11- electric engine;2-multiplier;3-oil receiver;4-operators desk.Table 1AdvantagesThe electro-hydraulic drive unit advantages(HUEH)are:they offer the possibility to maintain into the pressure,respectively the hydraulic obstruct of the task and dispose of a precise setting of the pressure depending on the task until 700 bar;it allows the permanent control of the cylinder stroke and also the automatic commutation from the first step to the second pressure step respectively from the fast start to the technological breakthrough;it allows electric remote command,while the charging voltage is of 24 Vcc,having the oil temperature monitoring possibility and the automatic disconnect to the value of 55C;it has the hydraulic components of the hydraulic panel(pump,valve, slide valve)and it functions in optimal behavior to maximum from the half nominal pressure,providing for advanced reliability;it has a low level noise (under 70 db);it confers the simultaneous supplying possibility of 2,3 or 4 cylinders-through to an attached branch2,3.The hydraulic drive unit description with heat engineThe hydraulic drive units with heat engine(HUMUTH)proceed from the new products scale with a distinguished resilience into the field,and they function with small flow rate and pressures of until 700 bar,(fig.2).Fig.2The hydraulic drive unit with heat engine41- heat engine;2-multiplier;3-operators desk;4-oil receiver.Table 2The hydraulic drive unit characteristics with heat engine1.The hydraulic drive unit with heat engine has a manual command for thestart and the changing of the pressure steps from the 1st step to the 2nd step itmakes manual too4.AdvantagesThe hydraulic drive unit offers similar advantages with those presented at the hydraulic drive unit with electric engine.The additional advantage consists of the mobility into the field as the result of a low weight and it doesnt depend of a fixed power source(for example the connected of the unit to the line system).2.2.Hydraulic PressesThe hydraulic press workshop HPH-075 is composed from a stand shut framework(fixed top traverse columns,adjustable bottom traverse,basic plate) removable,a hydraulic cylinder with double action HCHD-075.150 installed on a transversal carriage,a plates set,pressing bolts and nuts,(Fig.3).Fig.3.The hydraulic press 75tf1- Basic plate;2-Columns;3-Bottom traverse;4-Hydraulic cylinder HCHD-075.125; 5-Top traverse;6-Pressing bolts;7-Pressing plates.Table 3The hydraulic press characteristics1.Among the direct applications of this hydraulic presses deserve reminded: pressing and gear puller off of the transmission shafts from the gear boxes; pressing and puller ball bearings from the attack pinions from the tapering groups;pressing and extraction from jammed subsets;cold deformation for various proof sample.AdvantagesThe hydraulic press has a modular construction,removable,having an indexed settlement system of the inferior traverse,at the various determinate heights of range of 75mm.The transverse carriage of press represents an easy settlement system of the hydraulic cylinder position allowing thus the pressing axle regulation;The hydraulic press has plates set,bolts and pressing nuts for the realization of all technological operations; From the press project result an optimal report between its weight and achieved force owing to the acting to maximum pressures 700 bar,as effect of a reduced weight it is easy of carried. 2.3.Hydraulic toolsThe hydraulic tool scale used in the mechanical processing and maintenance is various,with many applications in the mechanical engineering.There are reminded among these hydraulic tools:the device of the bending pipes and the hydraulic device of cutting.The Device Description of Bending PipesThe bending template,fixed on acting rod of the hydraulic cylinder and having the suitable skewers profile so pipe dimension as well as inflexion beam,it will act over pipe that follows to be distorted;the pipe guides on the two ferries of the rest,fixed between the device plates.The superior plate of the appliance it can bate to allow the introduction of the template and of the ferries of the rest(Fig.5). The device of bending pipes type HDIT.M-020.300 is an equipment, hydraulic driven and it is destined to the bending at cold of the installations pipes in the maintenance and repairs sectors. Table 4 The device characteristics of bending pipes1 Fig.5.The device of bending pipes11- Tripod;2-Fixed plate;3-Turnover plate;4-Bolt;5-Hydraulic cylinder HCHD-020.300,6-Form. Table 5The working characteristics of device of bending pipes HDIT.M-020.3001 The Hydraulic Device Description of Cutting 20tfThe device is formed from a metallic body,realized through welded construction,a hydraulic cylinder with simple action HCHS-020.028,a movable knife jointly mounted with the cylinder rod and a fixed knife body, (Fig.6).The hydraulic cylinder acting it realizes through the connection to a highpressure source(manual pump HPHM-700 or hydraulic pedal pump HPHP-700),through a fast coupling and hydraulic flexible pipe.The semi-finished product it installs between the two knives,while the cutting knife and the counter-knife establish the debiting of the semi-finished product from the steel.The retirement of the cutting knife it realizes by a spring incorporated into a cylinder.The hydraulic device of cutting HFMO-020.028 is a hydraulic drive device,used in the producing processes and maintenance with the view of cuttings at cold of the circular,square,hexagonal and flat bars steel.The movable knife run is of 28mmand the maximum pressure 700bar,1.Fig.6.The hydraulic device of cutting 20tf1-2-Movable knife;3-Fixed knife;4-Feed nipple with oil under pressure.Table 6The working characteristics of hydraulic device of cutting type HFMO-020.028,1.AdvantagesThere are important to notice,among the hydraulic device advantages of cutting:the compact structure and modern design;the easy drivability and the reduced weight;it eliminates the useless physicals work of the operator;it lowers the appropriated time procedure. Scaling Behaviour of Pressure-Driven Micro-Hydraulic SystemsABSTRACTThis paper presents a lumped network approach for the modelling and design of micro-hydraulic systems.A hydraulic oscillator has been built consisting of hydraulic resistors,capacitors and transistors(pressure controlled valves).The scaling of micro-hydraulic networks consisting of linear resistors,capacitors and inertances has been studied.An important result is that to make smaller networks faster,driving pressures should increase with reducing size. 1 INTRODUCTIONMicro-hydraulic systems can be modeled and designed using a generalized physical system description1,2.This approach is based on the assumption that it is possible toseparate and concentrate properties of a system into interconnected subsystems.It has proven its great value in the design of electronic circuits.The lumped network approach also offers a powerful design tool for microfluidic systems3-5.To illustrate the far-reaching analogy between different physical domains,we have rebuilt an electronic astable multivibrator network in the hydraulic domain4.The system consists of hydraulic capacitors, resistors,transistors and(parasitic)coils.Based on this micro-hydraulic system the scaling behaviour of low Re (Reynolds number)hydraulic systems has been analyzed. 2 HYDRAULIC FUNDAMENTALS In every physical domain a conserved quantity q can be distinguished1.The flow is the rate of exchange of this conserved quantity between subsystems.In the hydraulic domain the flow variable is the volume flow. The effort is the tension that governs the exchange of the conserved quantity between subsystems.In the hydraulicdomain the effort variable is the pressure pPa.2.1 Hydraulic Resistors The hydraulic resistor physically is a liquid flow restriction,symbolically represented as in fig.1a.For a linear flow resistor,the resistance R is defined by:Where p12=p1p2 is the pressure drop across the resistor, and the volume flow through the resistor.At sufficient low Re the flow in a duct is laminar and fully developed (Poisseuille flow),and the pressure drop p across the duct is proportional to the volume flow rate.For a duct of arbitrary cross section the resistance is given by6:Where f is the Fanning friction factor,L is the length of the channel,is the viscosity of the liquid,Dh the hydrodynamic diameter,and A the cross sectional area.For a laminar fully developed flow the product f*Re=k,a dimensionless constant only depending on the shape of the cross section.The hydraulic resistors we have tested,were realized by anisotropic KOH-etching into asilicon wafer and closing of the channel by anodic bonding of a glass wafer onto the silicon.Fig.1b-d show a side view,a cross section and a top view of the implemented restrictionsrespectively.Figure 1:Hydraulic resistor.a)Symbolic representationb)Side-view of realized restrictions c)Cross section ofealized restrictions d)Top view of a realized restriction.For these triangular channels with a top width of 2w the resistance is given by:The limits of the linear regime have been determined analytically and verified experimentally for liquids7. Entrance and exit effects result in a non-linear relationbetween p12 and.They can be neglected if the channel is long compared to the hydrodynamic entrance length.At low Re the entrance length Lhy increases linearly with Re.For circular channels with a diameter d this is expressed by 6: 2.2 Hydraulic CapacitorsThe hydraulic capacitor physically is an elastic membrane across which a pressure difference can be maintained.It is symbolically represented in fig.2a.The capacitor establishes a relation between the pressure drop across the membrane and the displaced volume.For a linear capacitor the capacitance C is defined by:Where V is the volume of the displaced liquid by bending of the membrane.Because the volume V is created by accumulation of the volume flow,(5)can be rewritten tofind a relation between effort and flow:Figure 2:Hydraulic capacitor a)Symbolic representation b)Cross section of a capacitor realized in glass-silicon-glass technology,showing the deflection of the membrane under influence of a pressure difference.Fig.2b shows a cross section of a capacitor realized in a glass-silicon-glass sandwich.For deflections smaller than the thickness of the membrane there is a linear relation between the applied pressure difference and the membrane deflection.In this case a simple expression for the capacitance can be derived:Where a is the radius of the membrane,and D is the flexural rigidity of the membrane,defined by ,in which E Pa is the Youngs modulus,- the Poissions ratio,and hm the thickness of the membrane.中文翻译柔韧力液压设备维修和机械加工摘要:液压和气动代理系统工程部门和SC HYDRAMOLD SRL公司的合作实现了一些表演上的液压与气动领域的产品. 文章提出了提供最具代表性的为机械加工和维护液压圆滑设备力量。液压设备的大部分组成部分是有专利的或是专利的要求,技术或技术创新即这些专利的整个部分 因为文章有一个普遍的技术特征,在演示文稿将完成特别是使用地区和液压设备的柔韧力优势的性能特点。 关键词:液压装置、维修、力学性能工作。介绍使机械工作具有柔韧性的多功能模块化设备,这在液压传动基础上,实现了IMM的生产厂从有力的石化,交通方面的公司向维护大公司的框架生产公司的转化。所有的同时考虑到有限的工作空间,将有提出从大型液压设备的调色板柔韧力由公司的SC HYDRAMOLD(压力源,液压机,液压工具,液压设备而开发的每一段新的或现代化的设备系列3000酒吧,液压升降设备),在它下面将公布下一液压设备等现代作品。在工作中用到的设备呈现在DISAHP框架研究报告中并对其他文件作了研究。2. 液压设备分析力2.1压力源力量水力设备的压力来源由SC HYDRAMOLD SRL产生了是:有电或热量引擎和水力指南或脚蹬泵浦的水力代理单位 与电引擎的水力驱动装置描述电动液压的驱动装置HUEH是供应以简单或双重行动的液压缸的高压来源从一些设备结构、水力设施或者装置,并且他们与直到700个酒吧一起使用相对小率流程和压力, (Fig.1)。工作被发展的压力可以根据任务被调整:30-700吧。 Fig.1电动液压的驱动装置11- 电引擎; 2乘算器; 3油接收器; 4-工作台。表 1电动液压驱动驱动装置特点1油接收器l 10;20;30;40电引擎kw 1.5-4高压流速l/min 0.5-1.5低压流速l/min 6-16最大压力吧 700重量kg 84-176 优势电动液压的驱动装置好处(HUEH)是:他们提供可能性维护入压力,各自水力阻碍任务并且根据直到700吧的任务处理压力的一个精确设置; 它允许圆筒冲程的永久控制并且从第一步的自动换向到第二压力步分别从快速的开始到技术突破; 它允许电遥远的命令,而电荷电势是24 Vcc,有油温监视可能性和自动断开对55C的价值; 它有水力盘区(泵浦、阀门,滑阀)的液压元件,并且它在优选的行为起作用对从半公称压力的最大值,提供先进的可靠性; 它有低级噪声(在70 db以下); 它同时供应的可能性的2,3或4圆筒通过对一个附上分支2,3。 用热引擎的液压驱动装置描述用热引擎(HUMUTH)的液压驱动装置从与卓越的韧性的新产品标度入领域和他们进行起作用与直到700吧小流速和压力, (fig.2)。 图2-热发电机的液压驱动装置41 - 热机,2加速器; 3操作台,4油接收器 表 2 用热引擎1的水力驱动装置特征 油接收器L 10 电动发动机功率kw 1.2 高压流速L/min 0.35 低压流速L/min 3.3 最大压力巴 700 重量Kg 40 用热机的液压驱动装置有一个开始的命令,压力的变化从第一步到第二步同样使人工操作化4. 优点水力驱动装置提供与那些的相似的好处被提出在与电引擎的水力驱动装置的优点。另外的好处包括流动性到由于低重量的领域里和它不依靠一个固定的电源(例如被连接对于系统的单元)。 2.2液压机液压机是用于各种各样的应用的设备例如:冷的变形、切割,固化,煞车皮和推力板, 压力轴承拉出器。这些水压机可以为其他适合他们是需要的机械的应用按提取强迫要求作用。 液压机描述水压机车间HPH-075从被关闭的立场组成框架(固定的上面横断专栏、可调整的底部横断,基本的板材) 可移动的,在具有双重作用的HCHD-075.150的液压缸上安装的一横截支架,被设置的板材,按螺栓和螺母, (Fig.3)。 Fig.3.液压机75tf1基本盘; 2专栏;3底部横断;4液压缸HCHD-075.125; 5上部横断; 6压力螺栓; 7压力板材。 表3液压机特点 力tf 70 冲程mm 150 压力bar 700在直接应用这之中水压机该当提醒:脱套和齿轮制帽工人从工具箱的传动轴; 从攻击小齿轮末端的紧迫和制帽滚珠轴承从逐渐变细的小组; 从被阻塞的子集的按和提取; 各种各样的证明样品的冷的变形。 优点液压机具有模化构造,可移动,并且有下等横断的一个被标注的解决系统,在各种各样的75 mm的范围的确定高度。锻压横向支架代表液压缸位置的一个容易的解决系统因而允许紧迫的轨章程; 液压机有实现所有技术操作的板材设置,螺栓和紧迫螺母; 从这个项目结果,因为减少的重量的作用它是容易运载,在它的重量和达到的力量之间的一个优选的报告由于行动对最大值达到700吧。 2.3 液压工具在机械加工和维修的过程中使用的工具是多种多样的,许过应用在机械工程里。那些在液压工具之中被提到的:弯曲管道的设备和切割的液压设备。弯曲的管子的设备描述弯曲的模板,固定在液压缸的代理标尺和有适当的串描出,因此用管道输送维度并且变化射线,它将行动在跟随被变形的管子; 在休息的二条轮渡的管子指南,固定在设备板材之间。它可能降低允许模板介绍和剩余装置的优越板材(Fig.5)的渡轮。 弯曲管子类型设备HDIT.M 020.300是液压驱动的设备,并且它注定在维护的并且修理区段的设施管子寒冷时弯曲。表 4 弯管的设备特点描述1 过载tf 200 冲程mm 60 管直径 2”-4” 压力bar 700 图5 弯管设备1 1三脚架; 2固定板材; 3转板; 4螺栓;5 HCHD-020.300,6型液压缸 表 5HDIT.M-020.300型弯管设备的工作特点1管的弯曲外径toli/mm3/8171/221,253/43/426,4133,511/442,2511/248,25260壁厚mm2,753,25 3,5444,254,5形式曲率半径 mm5064 90120 150200 235最大弯曲角度 grad 120 指导数 2支 , 普遍的切割20t

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号