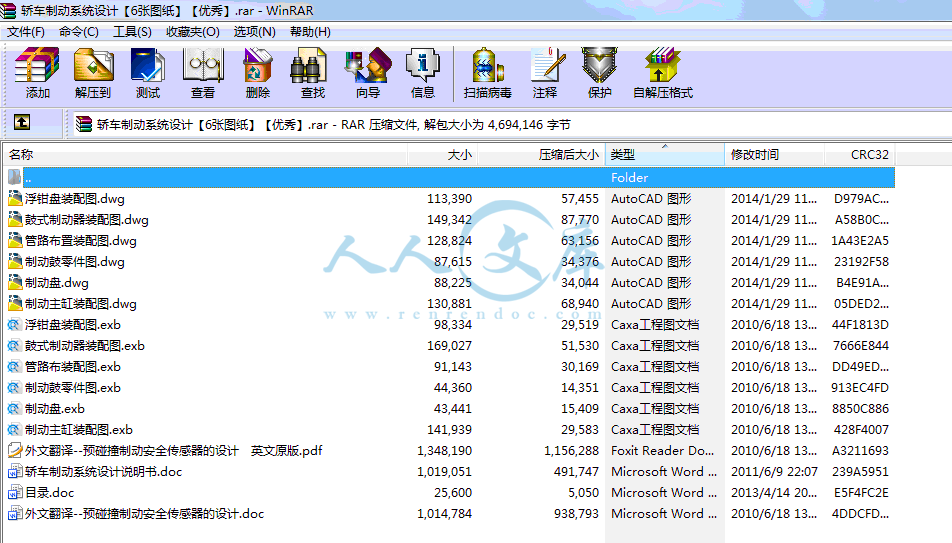

资源目录

压缩包内文档预览:

编号:422826

类型:共享资源

大小:2.97MB

格式:RAR

上传时间:2015-04-07

上传人:上***

认证信息

个人认证

高**(实名认证)

江苏

IP属地:江苏

39

积分

- 关 键 词:

-

轿车

制动系统

设计

图纸

轿车制动系统

- 资源描述:

-

轿车制动系统设计

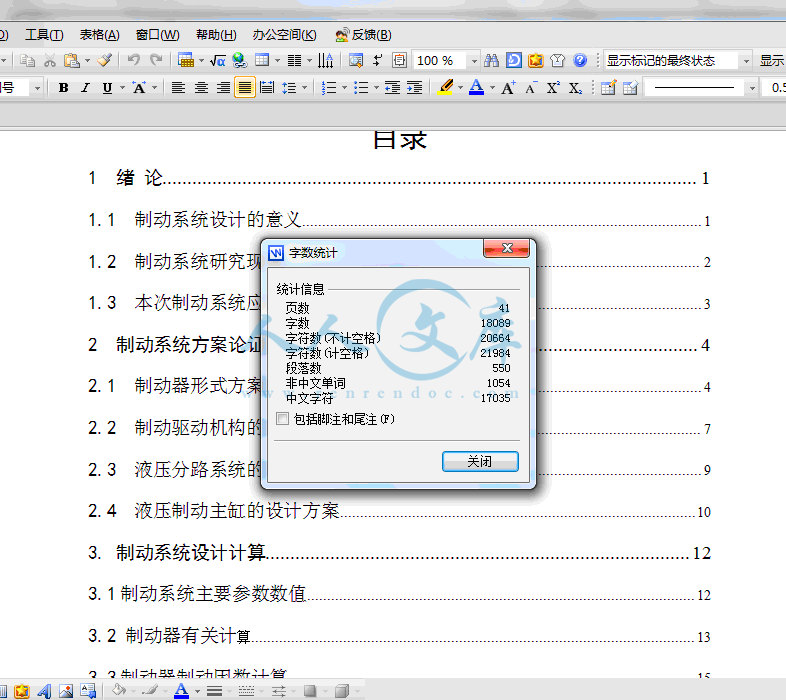

41页 18000字数+说明书+外文翻译+6张CAD图纸【详情如下】

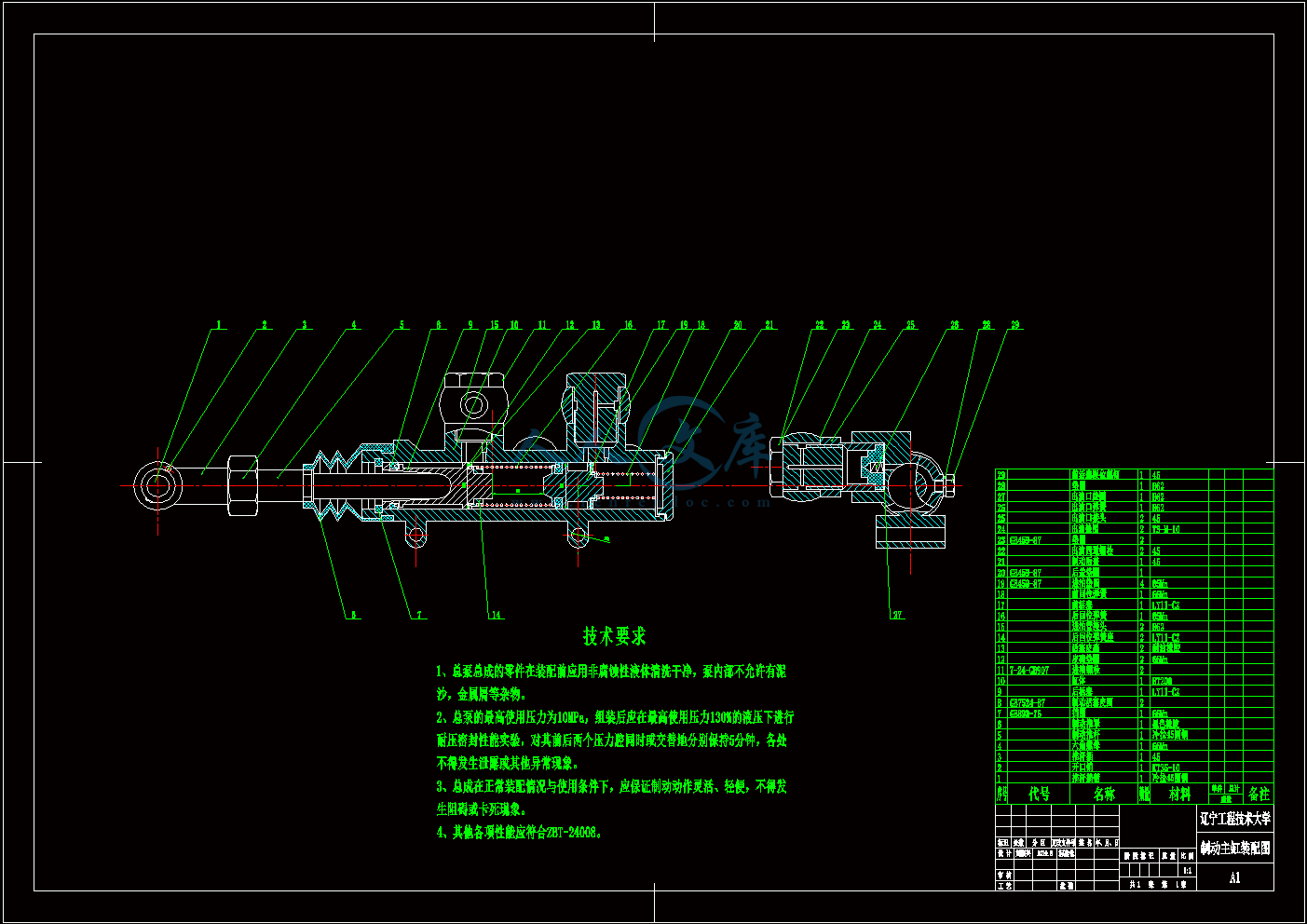

制动主缸装配图.dwg

制动主缸装配图.exb

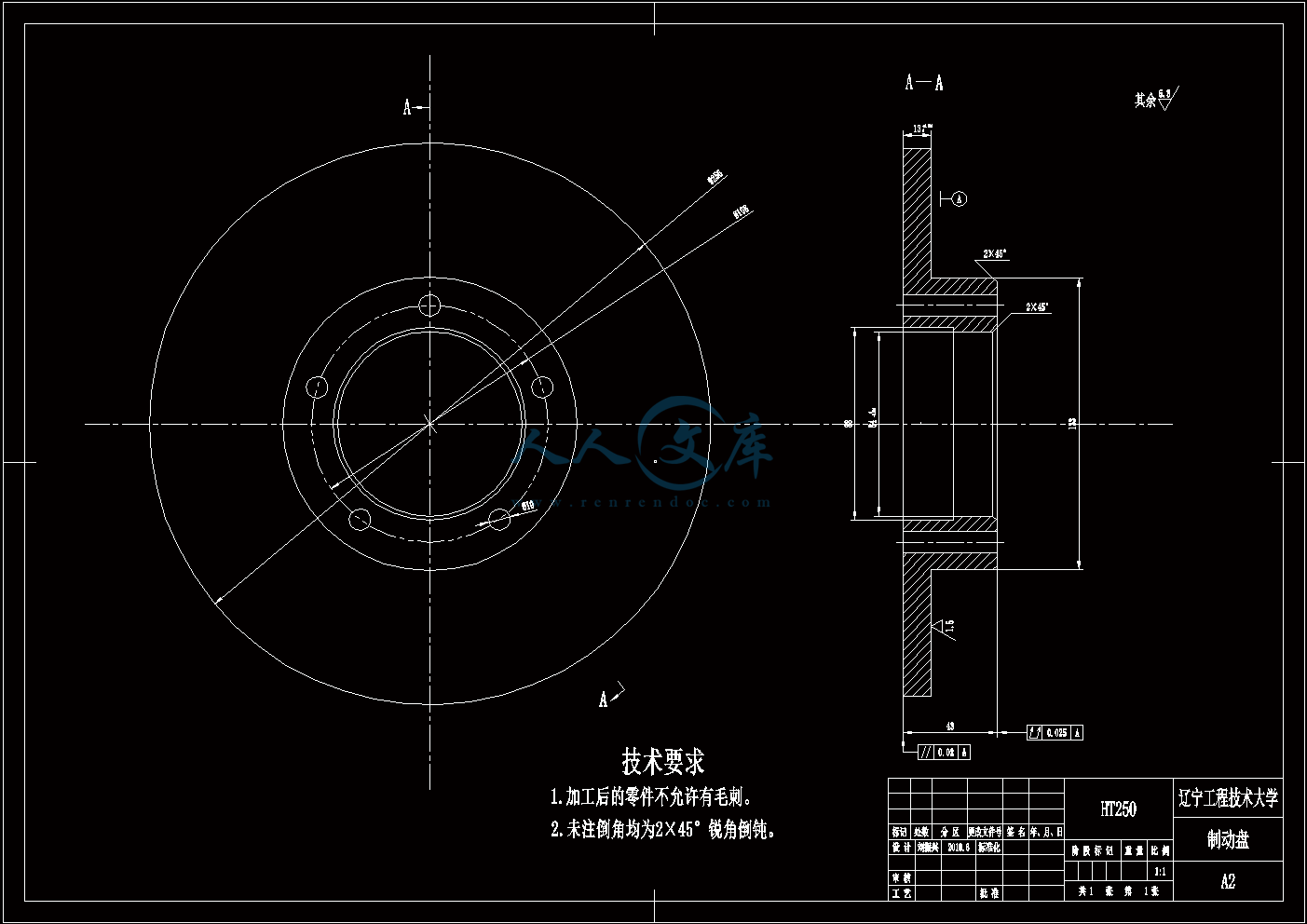

制动盘.dwg

制动盘.exb

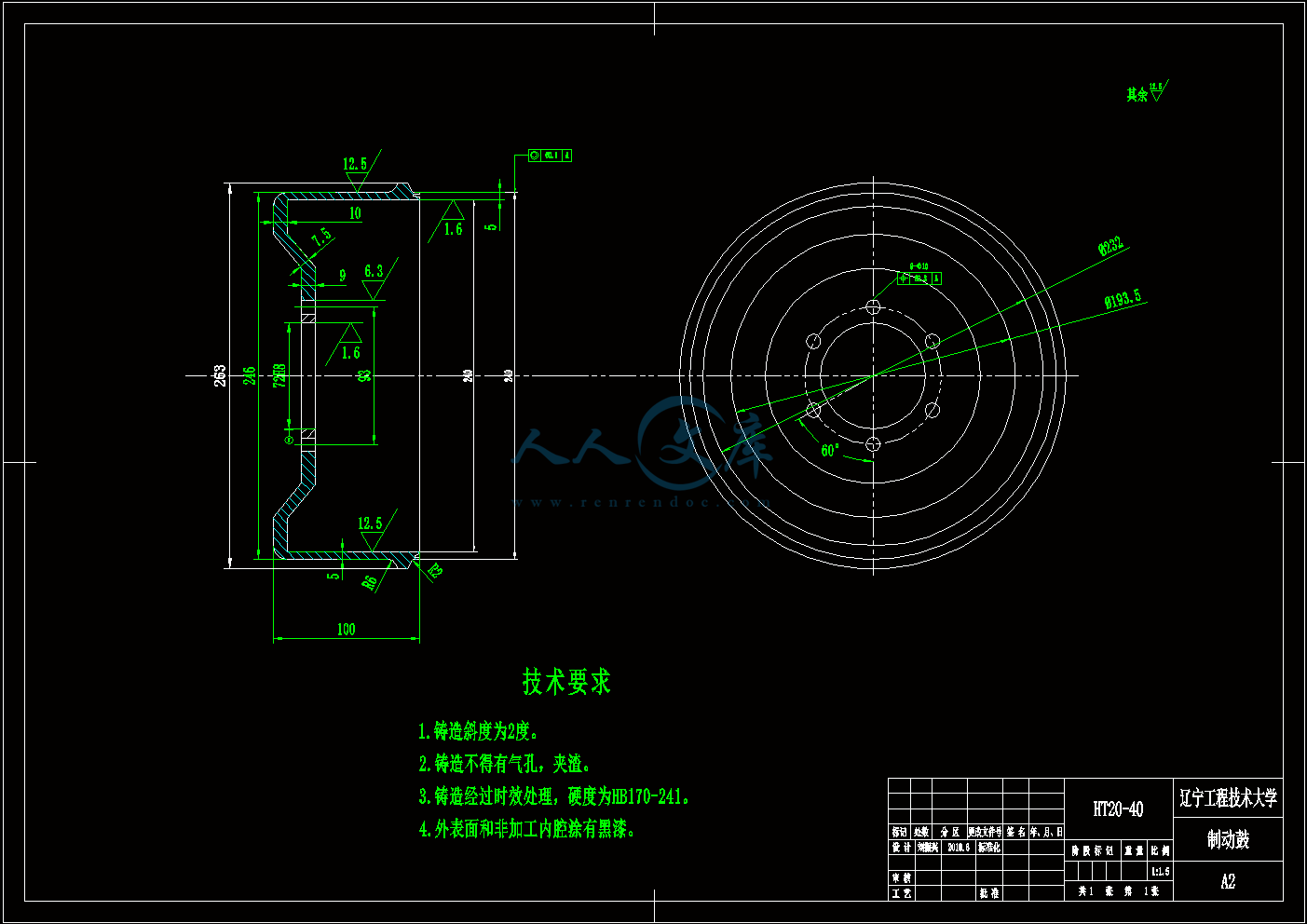

制动鼓零件图.dwg

制动鼓零件图.exb

外文翻译--预碰撞制动安全传感器的设计 英文原版.pdf

外文翻译--预碰撞制动安全传感器的设计.doc

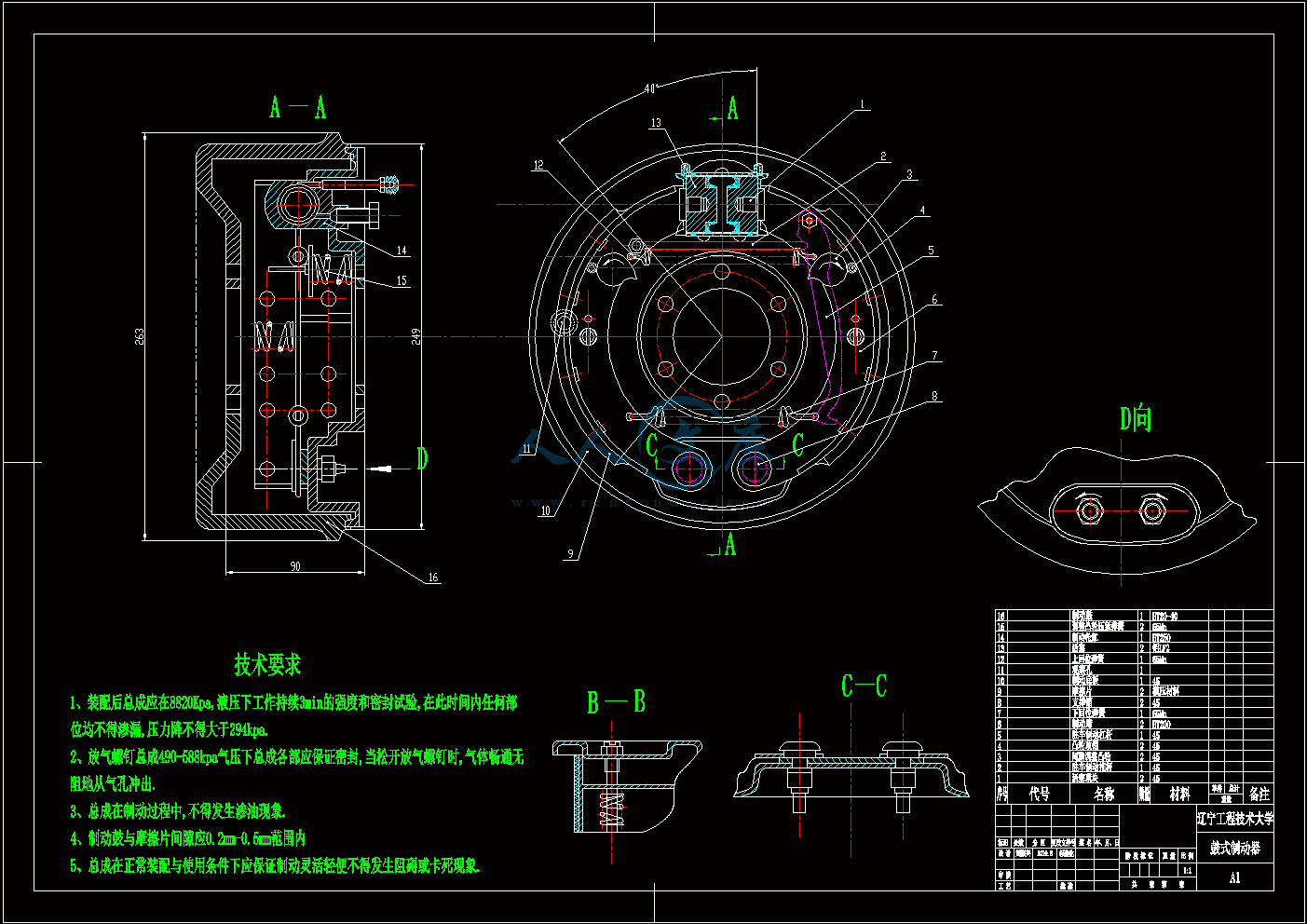

浮钳盘装配图.dwg

浮钳盘装配图.exb

目录.doc

管路布置装配图.dwg

管路布装配图.exb

轿车制动系统设计说明书.doc

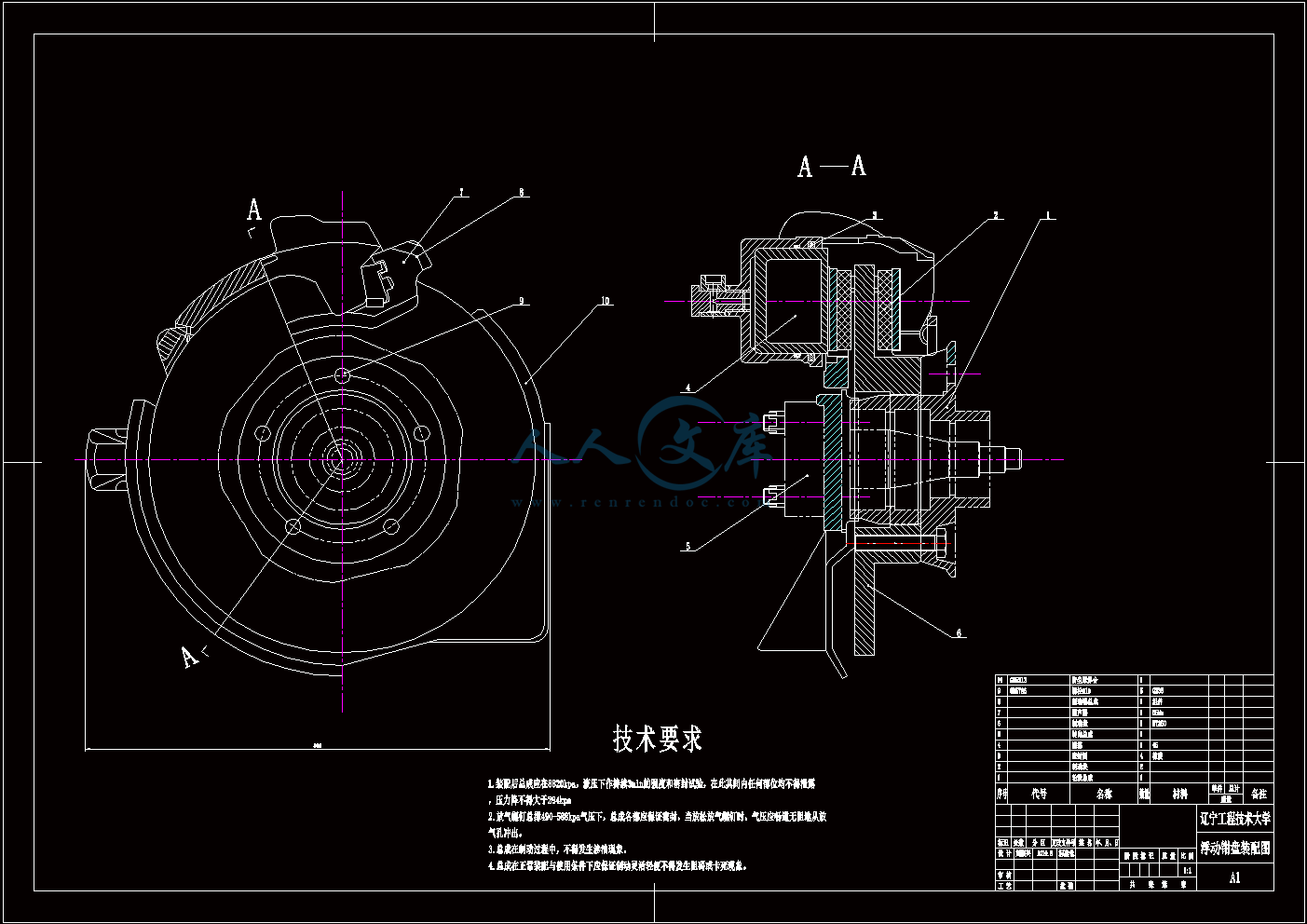

鼓式制动器装配图.dwg

鼓式制动器装配图.exb

目录

1 绪 论1

1.1 制动系统设计的意义1

1.2 制动系统研究现状2

1.3 本次制动系统应达到的目标3

2 制动系统方案论证分析与选择4

2.1 制动器形式方案分析4

2.2 制动驱动机构的结构形式选择7

2.3 液压分路系统的形式的选择9

2.4 液压制动主缸的设计方案10

3. 制动系统设计计算12

3.1制动系统主要参数数值12

3.2 制动器有关计算13

3.3制动器制动因数计算15

3.4鼓式制动器的设计计算16

3.5盘式制动器的设计计算19

3.6制动器主要零部件的结构设计19

4.液压制动驱动机构的设计计算22

4.1后轮制动轮缸直径与工作容积的设计计算22

4.2前轮盘式制动器液压驱动机构计算22

4.3制动主缸与工作容积设计计算23

4.4 制动踏板力与踏板行程24

5.制动性能分析26

5.1 制动性能评价指标26

5.2 制动效能26

5.3 制动效能的恒定性26

5.4 制动时汽车的方向稳定性26

5.5制动器制动力分配曲线分析27

5.6 制动减速度28

5.7 制动距离S29

5.8摩擦衬片(衬块)的磨损特性计算29

5.9驻车制动计算30

6.技术经济性分析32

7.总 论33

致 谢35

附录A译文36

附录B外文文献44

汽车是现代交通工具中用得最多,最普遍,也是最方便的交通运输工具。汽车制动系是汽车底盘上的一个重要系统,它是制约汽车运动的装置。而制动器又是制动系中直接作用制约汽车运动的一个关健装置,是汽车上最重要的安全件。汽车的制动性能直接影响汽车的行驶安全性。随着公路业的迅速发展和车流密度的日益增大,人们对安全性、可靠性要求越来越高,为保证人身和车辆的安全,必须为汽车配备十分可靠的制动系统。本次毕业设计题目为轿车制动系统设计。

从汽车诞生时起,车辆制动系统在车辆的安全方面就扮演着至关重要的角色。近年来,随着车辆技术的进步和汽车行驶速度的提高,这种重要性表现得越来越明显。它不仅是衡量汽车好坏的一个指标,重要的是它还关系到乘车人员的生命安全问题.在选购汽车方面客户也比较看重此项的好坏,所以研究制动系统对于开拓市场,增加汽车销量也有重要作用!汽车制动系统种类很多,形式多样。传统的制动系统结构型式主要有机械式、气动式、液压式、气—液混合式。它们的工作原理基本都一样,都是利用制动装置,用工作时产生的摩擦热来逐渐消耗车辆所具有的动能,以达到车辆制动减速,或直至停车的目的。以捷达CT轿车为例,它要求制动系统制动平顺,制动距离更短,制动过程中避免因制动效能过高而导致的车轮抱死的情况,满足汽车的安全性和乘员舒适性,因此制动系统的良好设计有利于提高汽车的整体性能。

通过查阅相关的资料,运用专业基础理论和专业知识,确定捷达CT轿车制动系统的设计方案,进行部件的设计计算和结构设计。使其达到以下要求:

具有足够的制动效能以保证汽车的安全性;

本系统采用X型双回路的制动管路以保证制动的可靠性;

采用真空助力器使其操纵轻便;

同时在材料的选择上尽量采用对人体无害的材料。

相关主要技术参数

整车质量: 空载:1030kg

满载:1520kg

质心位置: a=1.35m b=1.25m

质心高度: 空载:hg=0.95m

满载:hg=0.85m

轴 距: L=2.6m

轮 距(前/后): 1422/1429mm

最高车速: 190km/h

车轮工作半径:370mm

轮 胎: 195/60R14 85H

同步附着系数:=0.6

- 内容简介:

-

International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 41 Fabrication of Auto-Braking System for Pre-Crash Safety Using Sensor Eung Soo Kim Div. Digital Media Engineering, Pusan University of Foreign Studies, Busan, Korea e-mail: eskimpufs.ac.kr Abstract The auto-braking system was designed by VHDL and fabricated to keep a distance between two cars. It provides pre-crash safety system for intelligent car. This module can detect the distance between front vehicle and drivers vehicle to keep a constant distance using a sensor and operate the brake system forcibly if the driver does not decrease the speed of car. The system displays the distance between the two vehicles and the speed of your vehicle. The performance of the system was good. Keywords: Auto-Braking System, Pre-cash safety, Sensor 1. Introduction An automobile has been used to move human beings or something since the automobile was invented and the automobile technology has been developed within the last few years. Recently, the automobile is thought as daily necessaries because we spend much time in an automobile and enjoyed the entertainment such as game, e-mail, DVD, mp3, and internet etc. in the car. In nowadays, the intelligent car with adaptive cruise control, lane keeping technology, auto-parking system, tire pressure monitoring system (TPMS), and prevent pre-crashing system has been equipped because we need the convenient and intelligent car 1-3. These new automobile technologies are made possible by the development of semiconductor technology, optical technology and software technology. The use of electronic components in automobiles is set to accelerate and with ongoing efforts to improve safety and comfort. 250 electronic components are used in a car, for example, 50 MCUs are used in a car. Therefore, car makers in Europe and Japan are developing for safety such as both collision safety and preventive safety and new car technology for intelligent car such as intelligent transport system (ITS), rear view camera system, Road-to-vehicle and Inter-vehicle Communication Systems, auto-parking system, hybrid car, electric car, and hydrogen fueled car 4. In addition, some vehicle networks will enter commercial use, such as the FlexRay interface instead of CAN bus for onboard local area network (LAN), which supports high-speed transfer, and MOST (media oriented systems transport) or IDB-1394, which can move multimedia data, that is audio and video signals, from multiple camera systems or multimedia devices, such as DVD, navigation system, mp 3, TV tuner, and CD changer etc. at once. Car makers are beginning to develop equipment for high-end vehicles with systems to sense roadway conditions using cameras, radar, sensors and such in an effort to avoid accidents. The traffic accident is increasing as automobile production has been increasing. It is important to prevent accidents and to protect the driver and pedestrian when accidents were occurred. Therefore, pre-crashing system will be demanded. The pre-crash system is to prevent front-end, rear-end, right-turn and left-turn International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 42 accidents on roads with poor visibility by using sensor network to find invisible vehicles, which are to be detected by autonomous on-vehicle sensors. The pre-crashing system is processing the sensor data and controlling the vehicle to prevent front-end, rear-end accidents and accidents caused by careless driving. The development of such systems to automatically control vehicles and avoid accidents will accelerate in the future. In this paper, we designed the auto-braking system which keeps a distance between the front car and driver car to prevent accident using sensor and fabricated it using FPGA and VHDL 5. The power consumption of system was very small and another sensor or camera will be added easily. The performance of the system was good. 2. Design and Implementation The fabricated auto-braking system has the sensor part and signal processing part to prevent an accident as shown in Figure 1. It performed monitoring the environment and sensor signal processing. The sensor embedded in vehicle will detect the road environment, such as self-velocity, distance from front vehicle, and surroundings vehicles, using infrared sensor and ultrasonic sensor. These sensors were operated all the time during driving. The processing part accepted the signal from sensors and processed the signals and generated the instructions and transferred the generated instruction to control unit of transmission and brake of vehicle. There are three cases occurred in real situations. One case is that the distance between the front car and drivers car is far enough to defend crashing and self-velocity is the same velocity of front car or slower than that of front car. In this case, the drivers car is continuously running without changing its velocity. Another case is that the distance between the front car and drivers car is near and self-velocity is slower than that of front car. In this case, the drivers car is also continuously running without changing its velocity. Another case is that the distance between the front car and drivers car is near and self-velocity is faster than that of front car. In this case, the drivers car is continuously running only when the driver reduce speed. But if the driver does not reduce speed, the auto-braking system may forcibly reduce the speed of drivers car to protect an accident. The reason is that if the driver does not reduce speed, the accident will be occurred and the driver will be hurt. Figure 1. The operation principle of the fabricated auto-braking system. International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 43 The important thing in auto-braking system is detect the distance and speed of front vehicle to prevent a traffic accident. We chose an ultrasonic sensor used to detect the distance between a front car and drivers car because we mounted the fabricated system on a miniature car with a reduced scale of 1:20. The detectable range of the ultrasonic sensor was up to 3m. We have made 4 MHz clock signal to generate ultrasonic sensor signal. The generated sensor signal was PWM (pulse width modulation) signal when 10 s input signal was given as shown in Figure 2(a). Fig 2 (b) shows the simulation result of sensor input signal to detect the distance. The simulation was carried out by VHDL. The PWM signal which was reflected from the front car was varied from 1 ms to 11 ms according to the distance between the front car and drivers car. Figure 3 (a) shows the simulation result of distance measurement from front car sensor using 4MHz input signal. The input pulse of sensor with duration of 2ms was displayed in Figure 3 (a). Figure 3 (b) output signal with 1ms pulse duration time. Figure 3 (c) shows the sensor output signal with 10ms pulse duration time. The duration of PWM sensor signal was increasing as the distance between the front car and drivers car is increasing. We divided the reflected sensor signal into 10 values in according to the pulse duration of the reflected sensor signal. The motor of miniature car was varied from low speed to high speed according to these 10 different values, which are sensor output signals. The motor control signal is consists of 4bits and the clock signal of the stepping motor was changed as the variation of the sensor signal. The stepping motor was controlled by the reflected sensor signal, that is, the speed of automobile became slow as the distance became close with the front automobile. If the pulse duration of the reflected sensor signal becomes narrow, it means that our car get near to the front car. So, the driver must decrease the speed of car. If a driver does not reduce the speed of car, the fabricated auto-braking system forcibly makes speed low. The output PWM signal from ultrasonic sensor displayed by 15bits and decided the control signal of motor to (a) (b) Figure 2. (a)Sensor input signal with 10 s in oscilloscope screen and (b) simulation result of input signal. International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 44 (a) (b) (c) Figure 3. (a) the simulation result. PWM sensor output signal with (b) 1ms and (c) 11 ms in oscilloscope screen. control the speed of motor. Figure 4 shows the source program to detect the motor speed. We used the division by 4000 counters to detect the car speed. Figure 5 shows the simulation result of the program as shown in Figure 4, where the length of arrow means the one rotation of motor. As above mentioned, the motor has 4bits control signal such as 1100, 0110, 0011, and 1001. The stepping motor was controlled by these 4 bits signal. We counted the 1100 signal to measure the speed. Figure 4. The source program to detect the motor speed. International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 45 Figure 5. The simulation result of the motor control signal The auto-braking system moved the brake pedal to reduce the speed if the distance between the front car and drivers car. If the distance between front car and drivers car was far, the pulse duration was the same and the auto-braking system does not work. We use servo motor to move the brake pedal. The brake pedal was controlled by PWM signal, which is different according the distance between the front car and drivers car. The speed of the car was changed according to the angle of the brake pedal. The angle of the brake pedal was varied at the degree of 0, 35, 70, and 90. The speed of the car was decreasing as the angle of the brake pedal was increased. The car was stopped as the angle of brake pedal was 90. We used servomotor to work the brake pedal. Figure 6 (a) shows the source program to control the brake pedal and simulation result. And Figure 6 (b) shows the simulation result at the PWM signal when the state of steeping motor was 0000, that is stepping motor was stopped. In Figure 6, servo_clk is output PWM signal and Figure 6 (c) shows the simulation result when the state of stepping motor was 1010. We decided the state of stepping motor as arbitrary to simulate the operating of brake pedal. The output PWM signal of brake pedal was varied as the state of steeping motor. The speed of drivers car slowed down as the angle of brake was decreased. Figure 7 shows the block diagram of auto-braking system, where four input signals, clk, rst, direct, and in_clk, were needed in the auto-braking system. The clk input was clock signal, rst input was reset signal stop the operation of ultrasonic sensor, direct input made the stepping motor rotate opposite direction, and the output signal from the ultrasonic sensor was counted by in_clk input signal. The SOUND_CLK part generated sensor signal of the ultrasonic sensor to detect the distance. The sensor signal had 10 s of pulse duration and the period was 5ms. If the rst signal was inputted, the sensor did not work. The high value of PWM sensor signal was counted at the COUNTBOX part and the count value used 15 bits. International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 46 (a) (b) (c) Figure 6. (a) The source program to control the brake pedal, (b) the simulation result at the PWM signal with 0000, and (c) the simulation result at the PWM signal with 1010. Figure 7. Block diagram of auto-braking system. The SELSIGNAL part chose the control signal to select the period of the stepping motor clock signal. It selected one of 10 different values of stepping motor speed and the speed of car was varied by the selected signal. The SERVO part generated the control signal which decided the degree of the servomotor according to the select signal. The degree of the servomotor controlled the speed of the stepping motor. We generated 1 KHz signal to calculate the speed by dividing 4 MHz by 4000. It was performed at FQ_DIV4000 part. We have known the speed of stepping motor as counting how many times “1100” appears. This showed the rotation speed of stepping motor. We fabricated the auto-braking system using International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 47 FPGA. The distance, the RPM of stepping motor, and the angle of brake pedal was displayed in the LCD panel as shown in Figure 8. In this case, the LCD display showed that the drivers car is running without reducing the speed. The distance can be converted as real distance value. The operation of the system was good. Figure 8. LCD screen displayed distance, speed, and angle We also implemented the system using Labview and added surrounding sensing system to prevent an accident. Figure 9 shows the computer monitor which displayed the car speed and the angle of brake pedal by Labview program. It makes easy to implement user interface. Figure 9. The screen executed by Labview 3. Conclusions The auto-braking system was designed by VHDL and fabricated using FPGA to prevent accident. The system was mounted on a miniature car and tested. When the distance was getting closer, the auto-braking system was working and the speed will slow down if a driver does not reduce the speed of automobile. We also fabricated the auto-braking system using Labview. We will replace an ultrasonic sensor with a radar sensor as the auto-braking system is mounted on a real automobile. 4. Accknowledgment We thank Jong Hui Park, Kyung Wha Cho for test. International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 International Journal of Control and Automation Vol. 2 , No. 1, March, 2009 48 5. References 1 J. H. Kim, “Application and prospect of information technology: transport,” TTA Journal, vol. 117, May 2008, pp. 3031, (in korean). 2 For example, Editor, “Research on the road to intelligent cars,” ScieneDaily, Mar 2006. (Electronic publication). 3 See the www.toyota.co.jp. 4 S.Mastumoto, M. Ishigura, “The latest hybrid car”, Automobile Technology, 2007. 5 J. Kang et al, Digital systems design using VHDL, SciTech, 1998. International Journal of Control and AutomationVol. 2, No. 1, March, 2009Fabrication of Auto-Braking System for Pre-Crash SafetyUsing SensorEung Soo KimDiv. Digital Media Engineering, Pusan University of Foreign Studies, Busan, Koreae-mail: eskimpufs.ac.krAbstractThe auto-braking system was designed by VHDL and fabricated to keep a distance between two cars. It provides pre-crash safety system for intelligent car. This module can detect the distance between front vehicle and drivers vehicle to keep a constant distance using a sensor and operate the brake system forcibly if the driver does not decrease the speed of car. The system displays the distance between the two vehicles and the speed of your vehicle. The performance of the system was good.Keywords: Auto-Braking System, Pre-cash safety, Sensor1. IntroductionAn automobile has been used to move human beings or something since the automobile was invented and the automobile technology has been developed within the last few years. Recently, the automobile is thought as daily necessaries because we spend much time in an automobile and enjoyed the entertainment such as game, e-mail, DVD, mp3, and internet etc. in the car. In nowadays, the intelligent car with adaptive cruise control, lane keeping technology, auto-parking system, tire pressure monitoring system (TPMS), and prevent precrashing system has been equipped because we need the convenient and intelligent car 1-3. These new automobile technologies are made possible by the development of semiconductor technology, optical technology and software technology.The use of electronic components in automobiles is set to accelerate and with ongoing efforts to improve safety and comfort. 250 electronic components are used in a car, for example, 50 MCUs are used in a car. Therefore, car makers in Europe and Japan are developing for safety such as both collision safety and preventive safety and new car technology for intelligent car such as intelligent transport system (ITS), rear view camera system, Road-to-vehicle and Inter-vehicle Communication Systems, auto-parking system,hybrid car, electric car, and hydrogen fueled car 4. In addition, some vehicle networks will enter commercial use, such as the FlexRay interface instead of CAN bus for onboard local area network (LAN), which supports high-speed transfer, and MOST (media oriented systems transport) or IDB-1394, which can move multimedia data, that is audio and video signals,from multiple camera systems or multimedia devices, such as DVD, navigation system, mp 3,TV tuner, and CD changer etc. at once. Car makers are beginning to develop equipment for high-end vehicles with systems to sense roadway conditions using cameras, radar, sensors and such in an effort to avoid accidents. The traffic accident is increasing as automobile production has been increasing. It is important to prevent accidents and to protect the driver and pedestrian when accidents were occurred. Therefore, pre-crashing system will be demanded. The pre-crash system is to prevent front-end, rear-end, right-turn and left-turn accidents on roads with poor visibility by using sensor network to find invisible vehicles,which are to be detected by autonomous on-vehicle sensors. The pre-crashing system is processing the sensor data and controlling the vehicle to prevent front-end, rear-end accidents and accidents caused by careless driving. The development of such systems to automatically control vehicles and avoid accidents will accelerate in the future.In this paper, we designed the auto-braking system which keeps a distance between the front car and driver car to prevent accident using sensor and fabricated it using FPGA and VHDL 5. The power consumption of system was very small and another sensor or camera will be added easily. The performance of the system was good.2. Design and ImplementationThe fabricated auto-braking system has the sensor part and signal processing part to prevent an accident as shown in Figure 1. It performed monitoring the environment and sensor signal processing. The sensor embedded in vehicle will detect the road environment,such as self-velocity, distance from front vehicle, and surroundings vehicles, using infrared sensor and ultrasonic sensor. These sensors were operated all the time during driving. The processing part accepted the signal from sensors and processed the signals and generated the instructions and transferred the generated instruction to control unit of transmission and brake of vehicle. There are three cases occurred in real situations. One case is that the distance between the front car and drivers car is far enough to defend crashing and self-velocity is the same velocity of front car or slower than that of front car. In this case, the drivers car is continuously running without changing its velocity. Another case is that the distance between the front car and drivers car is near and self-velocity is slower than that of front car. In this case, the drivers car is also continuously running without changing its velocity. Another case is that the distance between the front car and drivers car is near and self-velocity is faster than that of front car. In this case, the drivers car is continuously running only when the driver reduce speed. But if the driver does not reduce speed, the auto-braking system may forcibly reduce the speed of drivers car to protect an accident. The reason is that if the driver does not reduce speed, the accident will be occurred and the driver will be hurt.Figure 1. The operation principle of the fabricated auto-braking system.The important thing in auto-braking system is detect the distance and speed of front vehicle to prevent a traffic accident. We chose an ultrasonic sensor used to detect the distance between a front car and drivers car because we mounted the fabricated system on a miniature car with a reduced scale of 1:20. The detectable range of the ultrasonic sensor was up to 3m.We have made 4 MHz clock signal to generate ultrasonic sensor signal. The generated sensor signal was PWM (pulse width modulation) signal when 10 s input signal was given as shown in Figure 2(a). Fig 2 (b) shows the simulation result of sensor input signal to detect the distance. The simulation was carried out by VHDL. The PWM signal which was reflected from the front car was varied from 1 ms to 11 ms according to the distance between the front car and drivers car. Figure 3 (a) shows the simulation result of distance measurement from front car sensor using 4MHz input signal. The input pulse of sensor with duration of 2ms was displayed in Figure 3 (a). Figure 3 (b) output signal with 1ms pulse duration time. Figure 3 (c) shows the sensor output signal with 10ms pulse duration time. The duration of PWM sensor signal was increasing as the distance between the front car and drivers car is increasing. We divided the reflected sensor signal into 10 values in according to the pulse duration of the reflected sensor signal. The motor of miniature car was varied from low speed to high speed according to these 10 different values, which are sensor output signals. The motor control signal is consists of 4bits and the clock signal of the stepping motor was changed as the variation of the sensor signal.The stepping motor was controlled by the reflected sensor signal, that is, the speed of automobile became slow as the distance became close with the front automobile. If the pulse duration of the reflected sensor signal becomes narrow, it means that our car get near to the front car. So, the driver must decrease the speed of Figure 2. (a)Sensor input signal with 10 s in oscilloscope screen and (b)simulation result of input signal.Figure 3. (a) the simulation result. PWM sensor output signal with (b) 1ms and(c) 11 ms in oscilloscope screen.car. If a driver does not reduce the speed of car, the fabricated auto-braking system forcibly makes speed low. The output PWM signal from ultrasonic sensor displayed by 15bits and decided the control signal of motor to control the speed of motor. Figure 4 shows the source program to detect the motor speed. We used the division by 4000 counters to detect the car speed. Figure 5 shows the simulation result of the program as shown in Figure 4, where the length of arrow means the one rotation of motor. As above mentioned, the motor has 4bits control signal such as 1100, 0110, 0011, and 1001. The stepping motor was controlled by these 4 bits signal. We counted the 1100 signal to measure the speed.Figure 4. The source program to detect the motor speed.Figure 5. The simulation result of the motor control signalThe auto-braking system moved the brake pedal to reduce the speed if the distancebetween the front car and drivers car. If the distance between front car and drivers car was far, the pulse duration was the same and the auto-braking system does not work. We use servo motor to move the brake pedal. The brake pedal was controlled by PWM signal, which is different according the distance between the front car and drivers car. The speed of the car was changed according to the angle of the brake pedal. The angle of the brake pedal was varied at the degree of 0, 35, 70, and 90. The speed of the car was decreasing as the angle of the brake pedal was increased. The car was stopped as the angle of brake pedal was 90. We used servomotor to work the brake pedal. Figure 6 (a) shows the source program to control the brake pedal and simulation result. And Figure 6 (b) shows the simulation result at the PWM signal when the state of steeping motor was 0000, that is stepping motor was stopped. In Figure 6, servo_clk is output PWM signal and Figure 6 (c) shows the simulation result when the state of stepping motor was 1010. We decided the state of stepping motor as arbitrary to simulate the operating of brake pedal. The output PWM signal of brake pedal was varied as the state of steeping motor. The speed of drivers car slowed down as the angle of brake was decreased. Figure 7 shows the block diagram of auto-braking system, where four input signals, clk, rst, direct, and in_clk, were needed in the auto-braking system. The clk input was clock signal, rst input was reset signal stop the operation of ultrasonic sensor, direct input made the stepping motor rotate opposite direction, and the output signal from the ultrasonic sensor was counted by in_clk input signal. The SOUND_CLK part generated sensor signal of the ultrasonic sensor to detect the distance. The sensor signal had 10 s of pulse duration and the period was 5ms. If the rst signal was inputted, the sensor did not work.The high value of PWM sensor signal was counted at the COUNTBOX part and the count value used 15 bits.Figure 6. (a) The source program to control the brake pedal, (b) the simulation result at the PWM signal with 0000, and (c) the simulation result at the PWM signal with 1010.Figure 7. Block diagram of auto-braking system.The SELSIGNAL part chose the control signal to select the period of the stepping motor clock signal. It selected one of 10 different values of stepping motor speed and the speed of car was varied by the selected signal. The SERVO part generated the control signal which decided the degree of the servomotor according to the select signal. The degree of the servomotor controlled the speed of the stepping motor. We generated 1 KHz signal to calculate the speed by dividing 4 MHz by 4000. It was performed at FQ_DIV4000 part. We have known the speed of stepping motor as counting how many times “1100” appears. This showed the rotation speed of stepping motor. We fabricated the auto-braking system using FPGA. The distance, the RPM of stepping motor, and the angle of brake pedal was displayed in the LCD panel as shown in Figure 8. In this case, the LCD display showed that the drivers car is running without reducing the speed. The distance can be converted as real distance value. The operation of the system was good.Figure 8. LCD screen displayed distance, speed, and angleWe also implemented the system using Labview and added surrounding sensing system to prevent an accident. Figure 9 shows the computer monitor which displayed the car speed and the angle of brake pedal by Labview program. It makes easy to implement user interface.Figure 9. The screen executed by Labview3. ConclusionsThe auto-braking system was designed by VHDL and fabricated using FPGA to prevent accident. The system was mounted on a miniature car and tested. When the distance was getting closer, the auto-braking system was working and the speed will slow down if a driver does not reduce the speed of automobile. We also fabricated the auto-braking system using Labview. We will replace an ultrasonic sensor with a radar sensor as the auto-braking system is mounted on a real automobile.4. AccknowledgmentWe thank Jong Hui Park, Kyung Wha Cho for test.5. References1 J. H. Kim, “Application and prospect of information technology: transport,” TTA Journal, vol. 117, May 2008, pp. 3031, (in korean).2 See the www.toyota.co.jp.3 S.Mastumoto, M. Ishigura, “The latest hybrid car”, Automobile Technology, 2007.4 J. Kang et al, Digital systems design using VHDL, SciTech, 1998.译文国际自动化控制学报第一卷2,第1号,2009年3月预碰撞制动安全传感器的设计金英书数字媒体工程,釜山外国语大学,釜山,韩国 电子邮件:eskimpufs.ac.kr摘要汽车制动系统采用VHDL语言设计与制造,两辆车之间保持一定距离。它提供了预碰撞安全系统的智能汽车。该模块可检测前方车辆和司机之间的车距保持恒定距离使用传感器和制动系统强行操作,如果驱动程序不减少汽车的速度。系统显示两车之间的和您的车辆行驶速度的距离。该系统性能良好。关键词:汽车制动系统,预碰撞安全,传感器1 介绍汽车已被用作人类移动的东西被发明以来,汽车和汽车技术已在过去数十年的发展。最近,汽车被认为是日常必需品,因为我们花很多时间在汽车和享受上,如游戏娱乐,电子邮件,DVD,MP3和互联网等在车里进行。在今天与之适应的巡航控制的智能车,行车线保持技术,自动停车系统,轮胎压力监测系统(TPMS),并防止碰撞系统已具备,因为我们需要的方便、智能的汽车1-3。这些新的汽车技术,是通过对半导体技术的发展,光学技术和软件技术的发展而发展起来的。典型的刹车系统包括刹车前面的磁盘和磁盘或鼓中的管子链接在每个车轮的刹车总泵刹车系统连接在后方。与制动系统有关的其他系统包括停车制动器,电力制动助力器和防抱死系统等。 汽车电子组件的应用加速了正在努力进行的安全性和舒适性的提高。250个电子元件被广泛应用于汽车,例如,50个微控制器在汽车中使用。因此,汽车制造商在欧洲和日本正在开发,如预防碰撞安全技术和智能汽车新技术,例如汽车智能交通系统(ITS),后视摄像系统,道路对车辆和车辆间通信系统,自动停车系统,混合动力汽车,电动汽车,氢燃料汽车4。此外,一些车辆将被连接进入网络,而不是如用于车载总线的CAN局域网络(LAN的FlexRay接口商业使用),支持高速传输,而且大多数(媒体导向系统传输)或IDB - 1394,其中可以传输多媒体数据,即音频和视频信号从多个摄像系统或多媒体设备传输,如DVD,导航系统,熔点3,电视调谐器和CD转换等的一次。汽车制造商已经开始制定与系统设备的高端车感巷道条件下使用相机,雷达,传感器等,努力避免发生意外。越来越多的交通意外的汽车产量已经提高。重要的是要防止意外发生,保护司机和行人时,意外发生。因此,预碰撞系统将要求。预碰撞系统是为了防止利用传感器网络,以找

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号