示教型雕铣机设计

33页 11000字数+说明书+外文翻译+9张CAD图纸【详情如下】

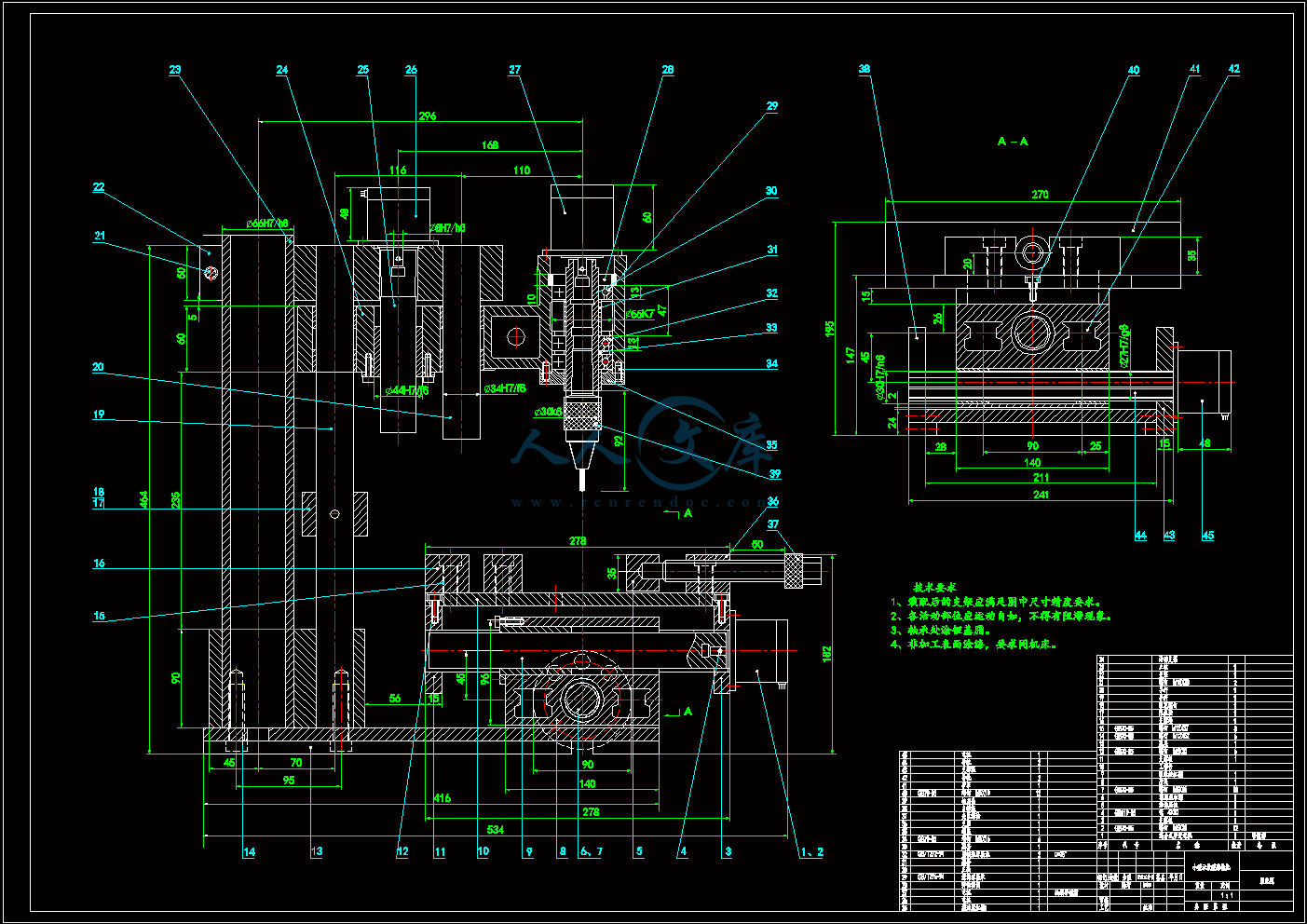

A0装配图.dwg

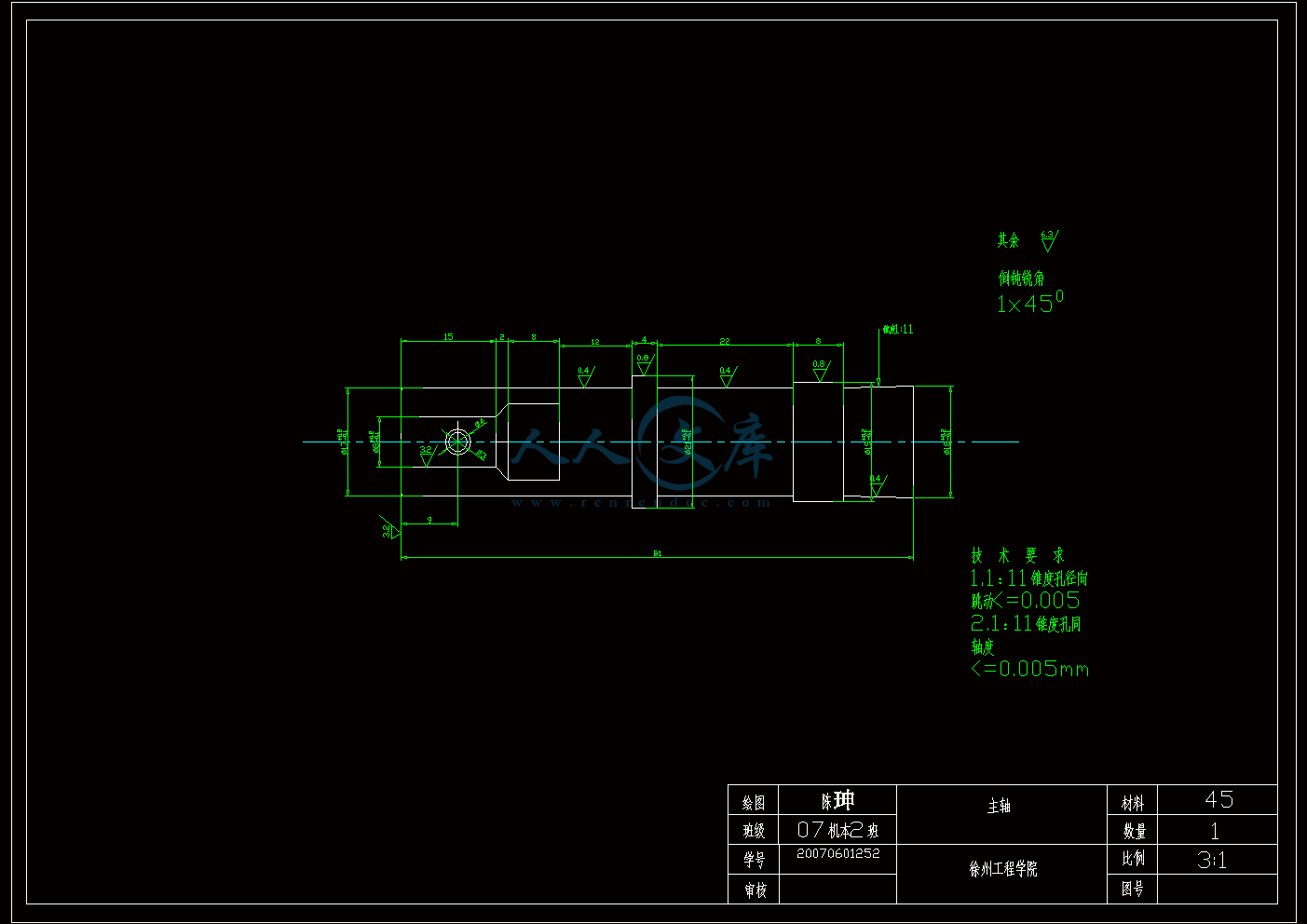

主轴.dwg

外文翻译--三轴并联铣床的功能仿真器 中文版.doc

外文翻译--三轴并联铣床的功能仿真器 英文版.pdf

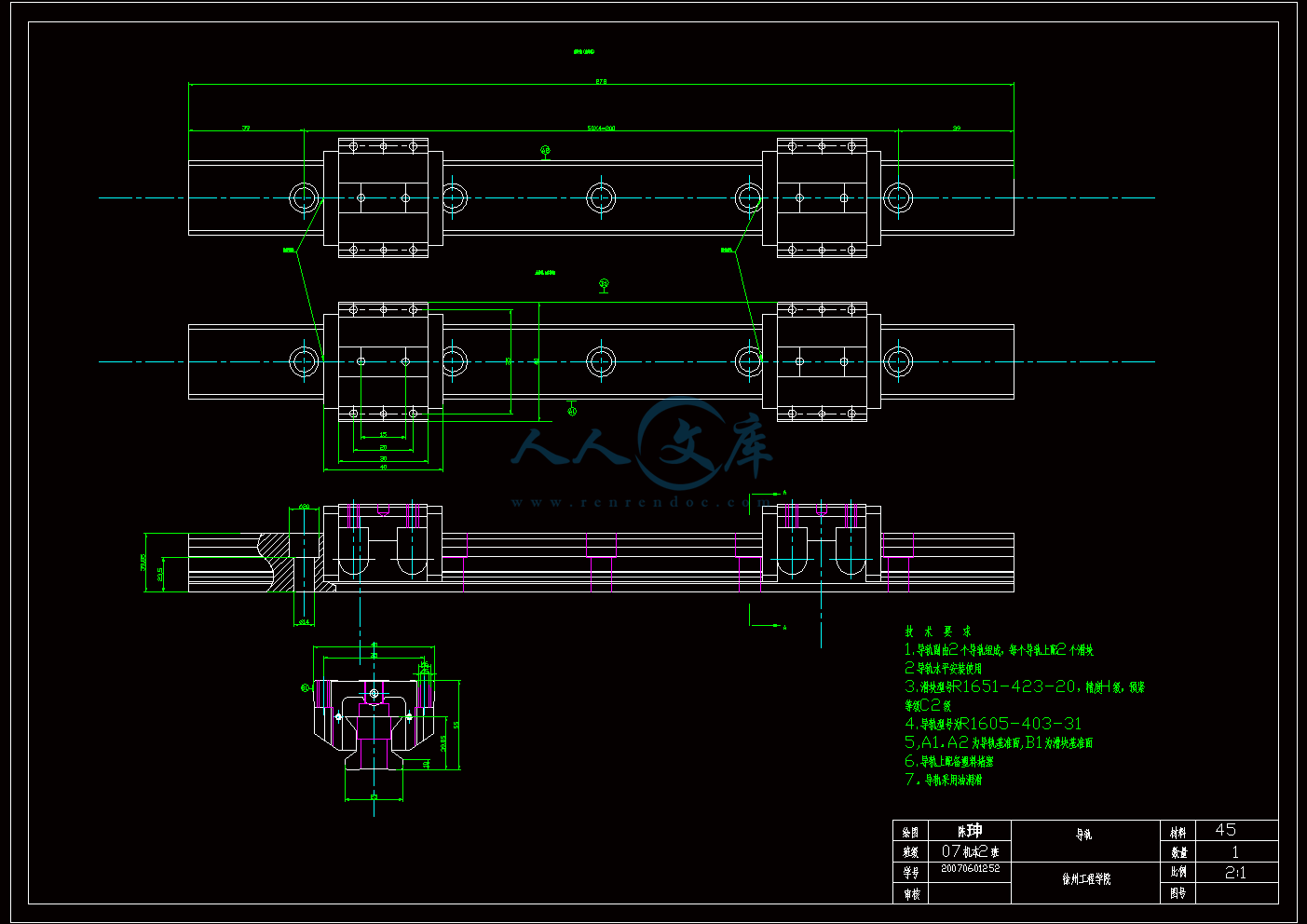

导轨.dwg

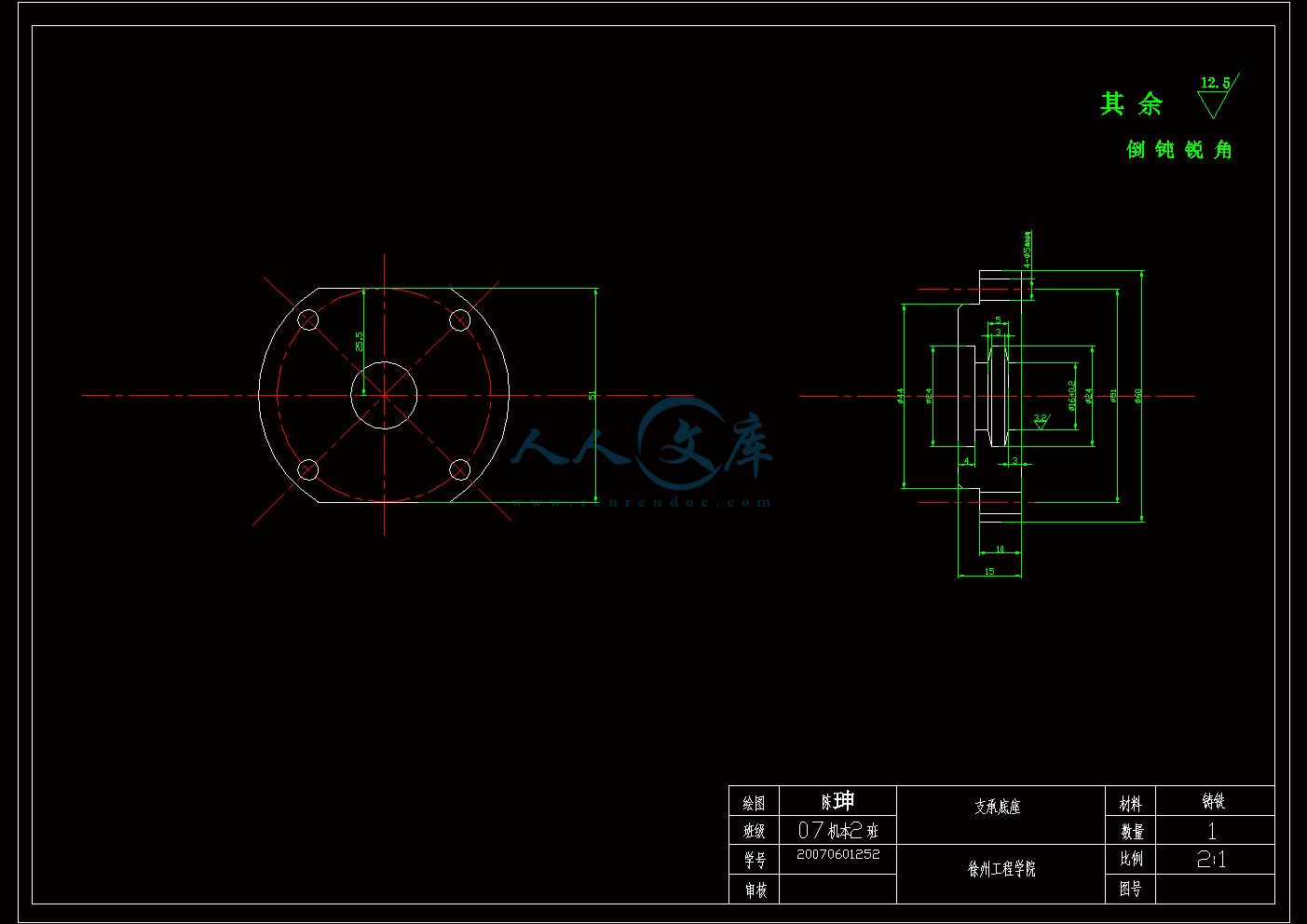

支撑底座.dwg

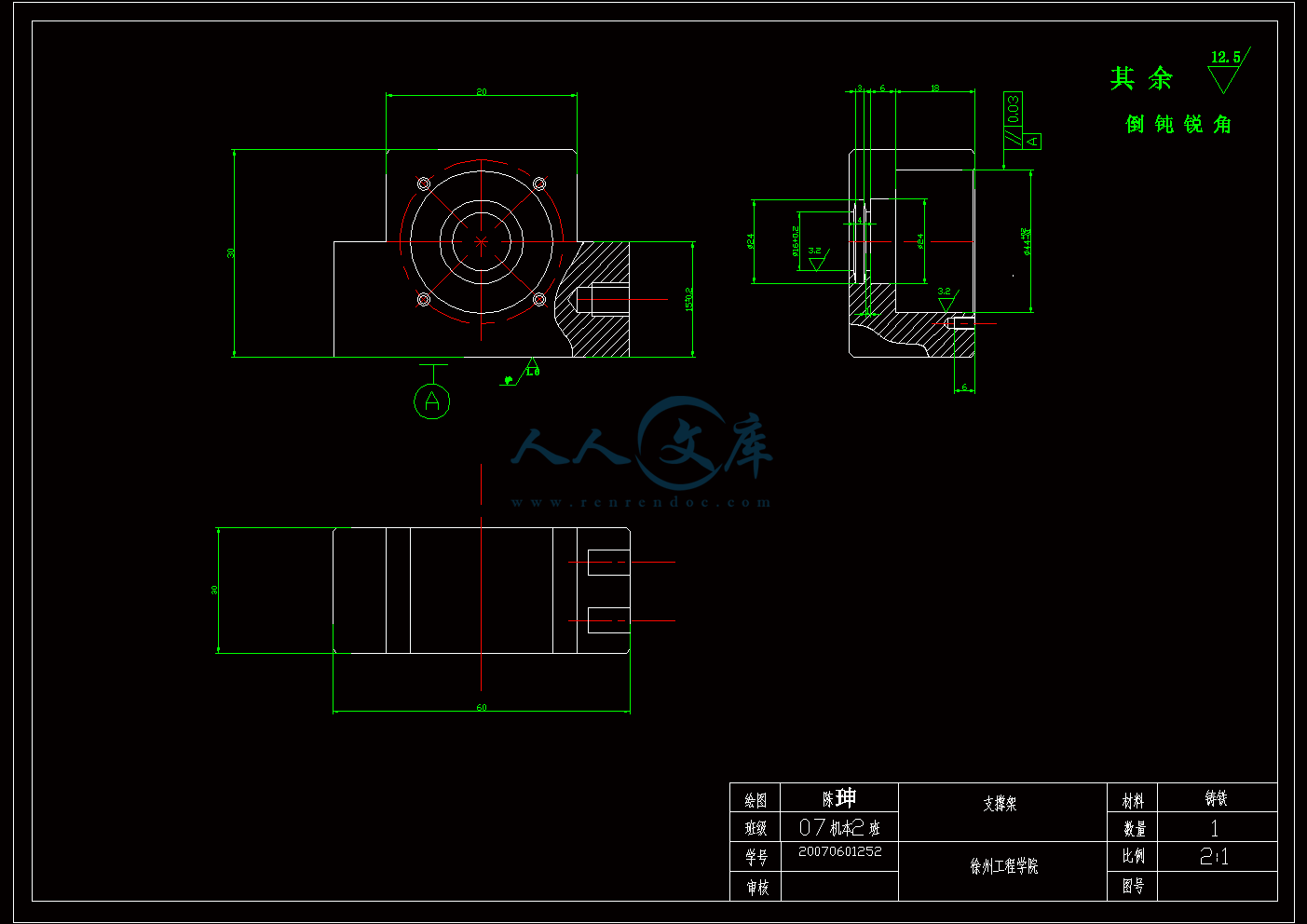

支撑架.dwg

支架.dwg

滚珠丝杠副.dwg

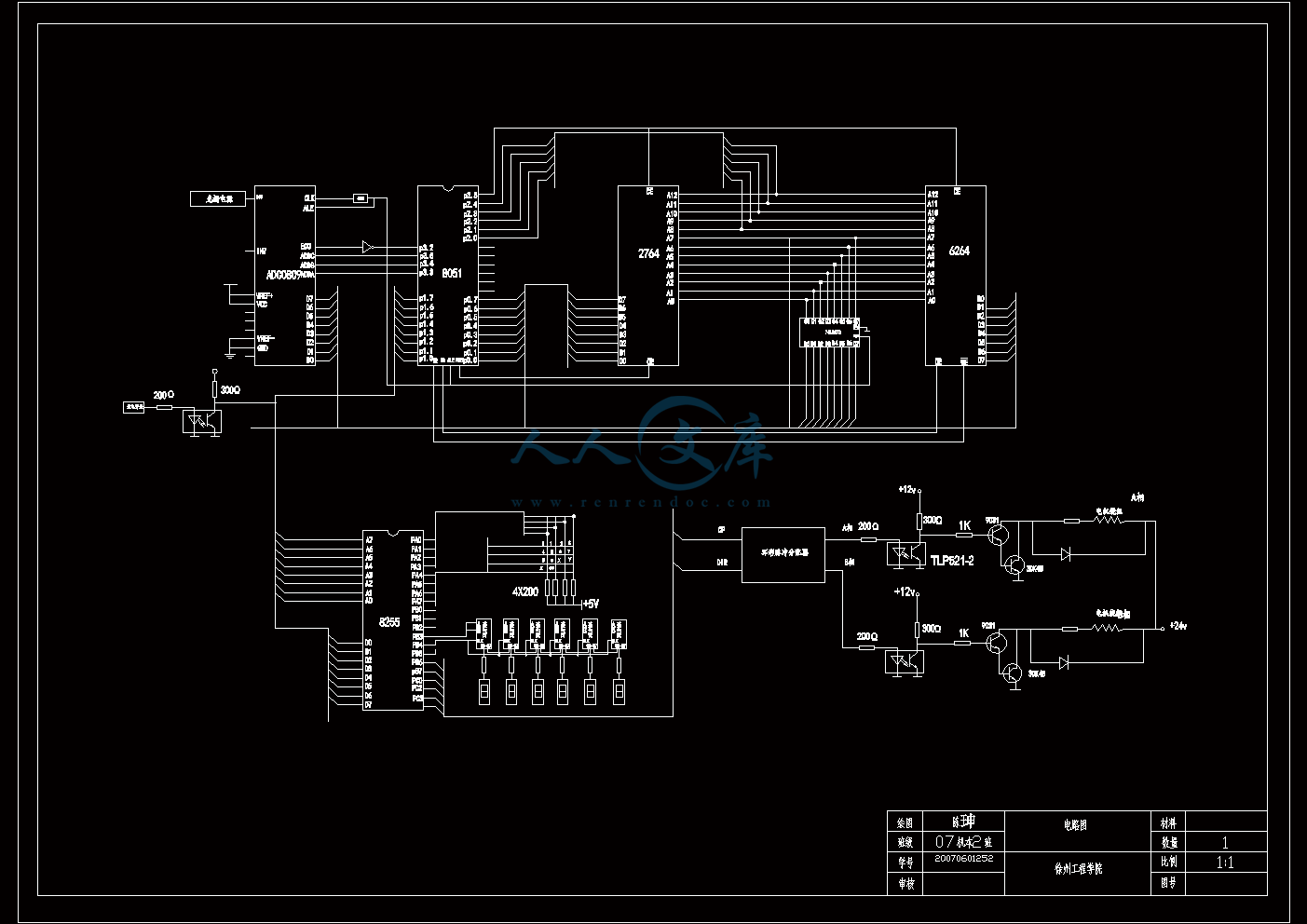

电路图.dwg

示教型雕铣机设计说明书.doc

论文.doc

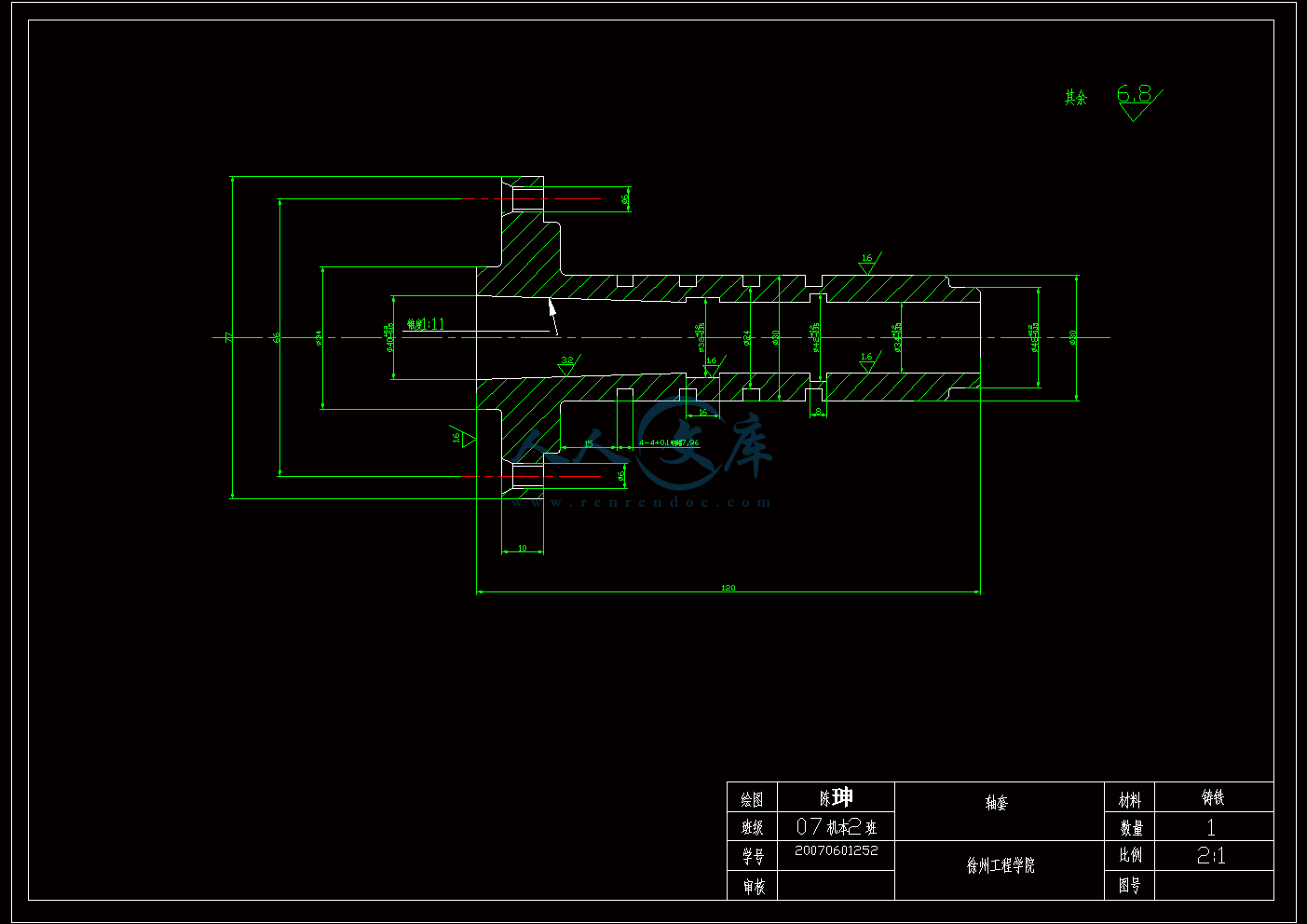

轴套.dwg

目录

摘要I

AbstractII

1绪论2

1.1示教型雕铣机课题介绍2

1.2小型示教型雕铣机的特点及现状2

1.2.1 国内数控雕铣机的发展和现状2

1.2.2 典型数控雕铣机的介绍3

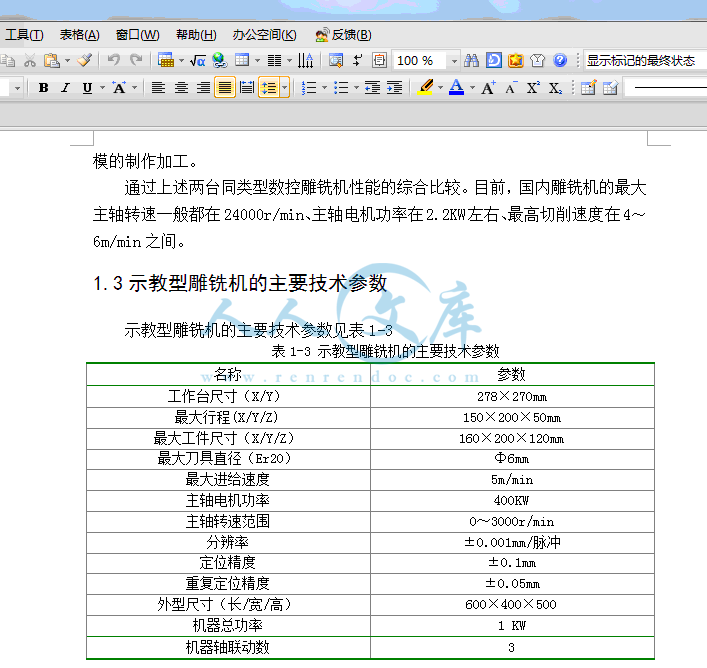

1.3示教型雕铣机的主要技术参数5

2示教型雕铣机总体布局设计方案6

2.1机床总体布局设计6

2.2 设计方案分析6

3各轴系统的设计方案8

3.1 Z向主传动系统的方案设计8

3.2 进给系统方案设计8

3.2.1 滚珠丝杠副的选择8

3.2.2 滚珠丝杠的支承结构9

3.2.3 支承轴承的选择10

3.2.4 滚珠丝杠的制动装置10

3.2.5 步进电机与进给丝杠的联结结构10

3.2.6 导轨11

4主轴系统零部件的计算与校核12

4.1 主轴系统的重力计算12

4.2 主轴铣削力计算12

4.3 滚珠丝杠副的选择计算13

4.4 进给伺服电机功率的计算及选择20

5电气部分设计25

5.1 硬件部分电路设计25

5.2 80C51外部电路扩展25

5.3控制系统总体设计26

结论28

致谢29

参考文献30

1绪论

1.1示教型雕铣机课题介绍

随着微电子技术的突飞猛进,直接推动微型计算机的急剧发展。微电子技术和微型计算机技术带动整个高科技群体飞速发展,从而使雕铣机的发展有了质的飞跃。使其完成了从二维到三维加工技术的变革。随着生活水平的不断提高, 人们对产品的性价比也越来越高,这就对雕铣机的研制提出了更苛刻的要求。因此,功能完善,性能稳定,造型美观并且价格合理的产品是我们不懈的追求。

雕铣机引入教学领域,使教与学更生动、有趣,学生更容易接受那些抽象的东西, 便于提高数控技术课程的教学效果。因此,本课题拟设计一款价格低廉,功能完善的雕铣机用于教学演示。

1.2小型示教型雕铣机的特点及现状

示教技术是随着数控技术发展起来的,目前,对示教系统的性能及精度等方面都提出了较高要求。现在市面上的雕铣机主要有以下几特点:

1.应用PC机的强大计算功能,将刀补、译码、插补、加减速控制等放在PC上解决。最后PC上形成的是各种步进电机的控制脉冲。

2.应用PC机的并口直接输出各向步进电机的控制脉冲,以控制工作台的移动。

3.步进电机的驱动采用集成的驱动芯片。

4.通过限位开关以及各运动方向的开关来保证雕铣机的安全工作。

示教型雕铣机是一款模拟经济实用的高精密数控雕铣设备,该款设备主要模拟雕铣机的运动,实现简单的示教雕铣功能。

1.2.1 国内数控雕铣机的发展和现状

随着家具制造业、广告招牌业、模具业的发展,尤其是模具业对表面加工要求的提高,以及传统电火花加工的不足,最近的一两年综合铣削与高速雕刻优点的CNC雕铣机在国内有了较大的发展。

2007年我国的雕铣机产业产能已经超过11000台/年,产值超过15亿RMB。目前雕铣机的生产主要以广东、北京、浙江三大板块主导。国内几家著名的数控机床厂在这个领域里面都有较好的成绩。比如北京精雕、广东佳铁、南京四开、上海洛克等都是国内著名的数控雕铣机厂家。在雕刻CAD/CAM技术、CNC数控技术、精密雕刻机设计技术工艺等领域取得了重大的突破,并真正实现了先进技术向产业化的转化。

1.2.2 典型数控雕铣机的介绍

北京精雕-睿雕系列Carver600G_U

北京精雕生产的睿雕Carver600G_U机械性能参数指标见表1-1。模型见图1-1。

表1-1 Carver600G_U机械性能参数指标

主要性能指标项标准值

工作台尺寸700×650mm

X、Y、Z轴工作行程600×500×300mm

快速移动速度10m/min

主轴转速2100-24000rpm

最高切削进给速度6m/min

X/Y/Z轴运动定位精度0.008/300mm

X/Y/Z轴重复定位精度0.005mm

机床外形尺寸2042×1890×2144mm

川公网安备: 51019002004831号

川公网安备: 51019002004831号