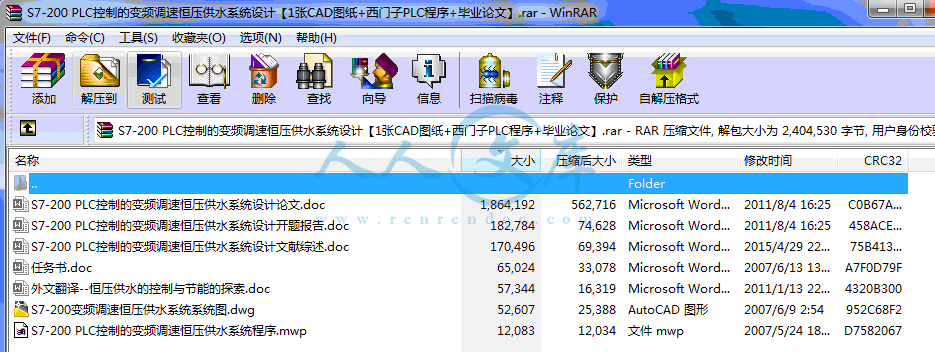

S7-200 PLC控制的变频调速恒压供水系统设计

50页 29000字数+说明书+任务书+开题报告+文献综述+外文翻译+1张CAD图纸【详情如下】

S7-200 PLC控制的变频调速恒压供水系统程序.mwp

S7-200 PLC控制的变频调速恒压供水系统设计开题报告.doc

S7-200 PLC控制的变频调速恒压供水系统设计文献综述.doc

S7-200 PLC控制的变频调速恒压供水系统设计论文.doc

S7-200变频调速恒压供水系统系统图.dwg

任务书.doc

外文翻译--恒压供水的控制与节能的探索.doc

摘 要

传统的供水系统存在着占地面积大、建设费用高、管理维护复杂困难、供水质量低下等缺点和不足。为了解决这些问题,本文采用控制技术和变频调速技术相结合的方法来研究恒压供水系统,该系统与现场液位传感器、压力传感器一起组成了两个独立的闭环控制子系统。设计好的系统每天24小时不间断按预先设定的水压恒定地向城市供水,保证了水厂的不间断生产。

通过该项目的研制和应用,不仅能够节约宝贵的水、电资源,降低了生产成本,减少设备维护,降低维修成本;而且提高了整个水厂的生产调度管理水平,减轻工人劳动强度,有效的提高了生产率。

关键字:恒压供水,控制,变频器,

ABSTRACT

Traditional water supply system has the shortages including occupying wide surface area、high expenses、management complex and difficult、water pollution again, and so on. In order to solve these problems, this paper combines control technology and transducer technology to research constant pressure water supply system. Two independent sub-systems are irrespectively built with water place sensor and pressure sensor. The finished system can fulfill constantly supplying water to city day and night according to the water pressure given to assure the continuously produce.

With the research and use of this project, we can save large sum of precious water、electrical source, and decrease the produce price, reduce device management and lessen repair price. Moreover, this system also can improve the lever of produce and management, lighten the work’s strength, and increase the productivity

Key Words: constant water supply system, control transducer,

目 录

第1章 绪论1

1.1 采用恒压供水系统的目的和意义[1、2、7、9]1

1.2 恒压供水的特点1

1.2.1 恒压供水方式讨论1

1.2.2 恒压供水的实现2

1.3 现行高楼供水的模式[19]2

1.3.1 恒速泵供水2

1.3.2 高位水箱供水2

1.3.3 气压罐供水3

1.4 毕业设计的主要任务3

第2章 变频调速恒压供水分析4

2.1 变频恒压供水的工艺调节过程介绍[6]4

2.2调速系统的构建[25-29]4

2.2.1 调速原理4

2.2.2 恒压供水系统的组成5

2.2.3 调节系统的计算方法[12、13]5

2.2.4变频恒压供水频率变化分析7

2.3 节能分析[3]8

2.3.1 水泵的基本参数和特性[14-18,36,37]8

2.3.2 水泵调速运行的节能原理11

第3章 恒压供水系统13

3.1 系统概述[31]13

3.2 控制系统的组成13

3.2.1 供水系统的组成13

3.2.2 系统功能说明13

3.3 恒压供水系统的机理及调速泵的调速原理14

3.3.1 恒压供水系统的工作原理14

3.3.2 调速泵系统构成14

3.4 变频器[6]14

3.4.1 变频器输入输出接口14

3.4.2 变频器外围设备的选择及保养15

3.5变频调速恒压供水系统的特点16

第4章 可编程控制器PLC17

4.1 的定义[20-22]17

4.2 的发展阶段及发展方向17

4.3 的特点与应用领域18

4.3.1 可编程序控制器的特点18

4.3.2 可编程序控制器与继电器控制系统的比较19

4.3.3 可编程序控制器的应用领域19

4.3.4 在现代自动控制系统应用中所面临的问题20

4.4 我国常用的性能比较研究20

4.4.1 的一般结构20

4.4.2 基本工作原理22

4.5 我国常用的性能特点23

4.5.1 SIMATIC S7系列 [24]23

4.5.2 S7-200系列可编程序控制器23

4.5.3 控制系统设计内容24

4.5.4 控制系统设计步骤24

4.5.5 控制系统的硬件设计25

4.6 控制系统的软件设计26

4.6.1 软件设计概述26

4.6.2 软件设计27

4.6.3 程序设计的常用方法28

4.6.4 程序设计步骤29

第5章 PLC控制系统的设计31

5.1 概述31

5.2 输入输出分配31

5.2.1 输入口31

5.2.2 输出口31

5.2.3 辅助触点31

5.3 控制系统功能介绍32

5.4 恒压供水系统的流程图33

5.5 控制系统的可靠性及应用程序设计34

5.5.1 程序的优化设计34

5.5.2 应用程序的设计35

5.5.3 故障检测程序的设计37

第6章 系统调试38

6.1 变频器关键参数的设定38

6.2 的调试38

致 谢43

附录 PLC程序44

1.3.2 高位水箱供水

采用电流及电压的相位大小等变化特性对高位水箱泵组进行控制。供水系统利用高位水箱及地下水池的水位变化来自动启闭水泵,以向各水箱供水。改供水方式可控性差。

1.3.3 气压罐供水

气压供水设备是利用压缩空气的涨力将水送往用水点的通用供水设备。气压供水整套设备高压密封,没有外部污染,内部不长青苔。并且供水压力可以根据需要很方便地在控制器上进行调整,不象高位水箱当放置的高度确定后,水压就已确定,无法调整。但是气压供水能耗大,且控制水压能力有限,不如水泵供水的压力控制。

1.4 毕业设计的主要任务

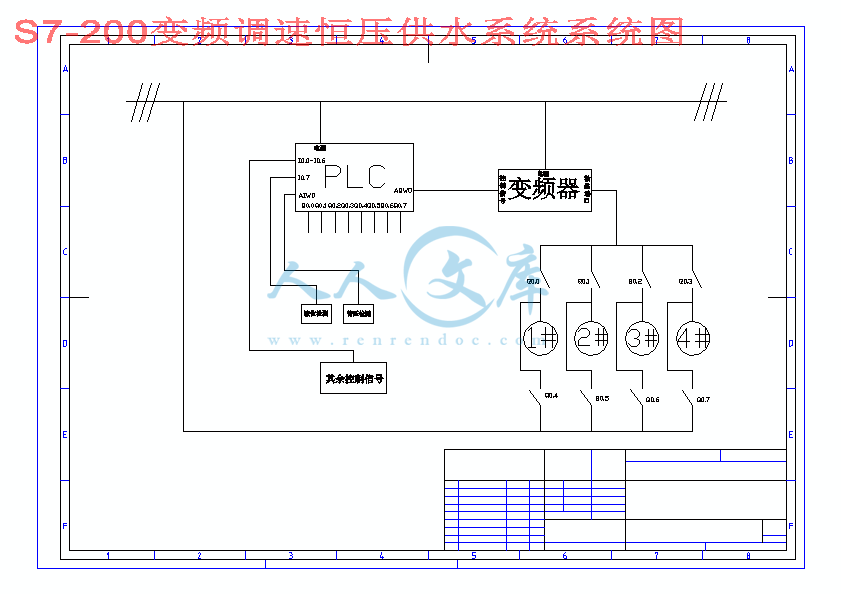

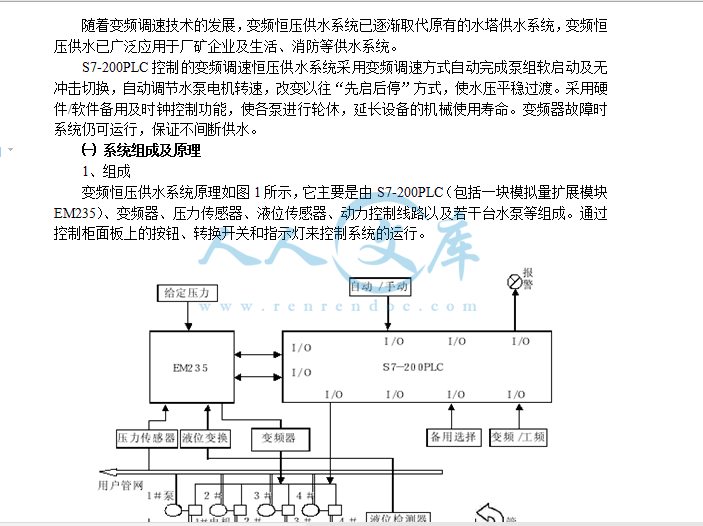

随着变频调速技术的发展,变频恒压供水系统已逐渐取代原有的水塔供水系统,变频恒压供水已广泛应用于厂矿企业及生活、消防等供水系统。

S7-200控制的变频调速恒压供水系统采用变频调速方式自动完成泵组软启动及无冲击切换,自动调节水泵电机转速,改变以往“先启后停”方式,使水压平稳过渡。采用硬件/软件备用及时钟控制功能,使各泵进行轮休,延长设备的机械使用寿命。变频器故障时系统仍可运行,保证不间断供水。从以上各图可以看出调节之后的效果。

图6-1可以看出系统的稳态误差。

图6-2可以看出图1系统的各参数。

图6-3、6-4可以看出调节的效果,系统的输出随中间变量的变化而变化。

调试过程

本次设计我是在浙江工业大学浙西分校信电系一楼过控实验室进行调试的,起初程序并没有现在复杂,一开始只有8个子程序,一个中断,而现在有12个自程序,每个子程序都有各自的功能上面都已经介绍过了,下面我介绍以下调试时遇到的问题好。

例如:课本上的置位与复位,只需要写SET或者RESET,再标注哪一个触点就可以了,但是在-7中编辑程序时,在置位与复位下面还有一个数字,一开始始终不了解这个数字是干什么用的,一开始始终认为是要置位到1,或者复位到0,所以一直再下面输1或者0,但是程序总有错误,上网查资料,再查说明书,再加上不停的调试,总算知道这个数字是表示从该触点的内存位置开始置位或者复位多少位。

再如,起初我在程序中大部分使用的是输出,而不是置位,但是经过调试之后我发觉有些位置使用输出是不行的,例如加泵子程序中因为使用了许多互锁,因为这些互锁的原因,程序也修改了多次。

面对上述以及许多零星错误,自己的失误,和对部分数据判断的错误,我经过不懈努力,多次尝试,以及指导老师的讲解,终于全部克服,完成任务。

参考文献

[1] 宋序彤.我国城市供水发展有关问题分析[J].城镇供水.2001, 2: 22~27.

[2] 崔玉川,傅涛.我国城市给水发展现状与特点[J].中国给水排水.1999 (2):52~54.

[3] 刘黎成,孙伟.离心泵压力自控调速系统的节能[J].中国给水排水.1993, (5):58~61.

[4] 赵相宾,刘国林.变频调速和软起动技术的现状和发展[J].自动化博览.2000,(6): 1~6.

[5] 蒋艺,杨俊生.变频调速器在供水系统中的应用闭.山东冶金.1999, 21(5):49~50.

[6] 邱文渊,童国道.国内外变频器技术的现状及我国发展策略初探[J].电子与自动化,1995, (5): 3~5.

[7] 黄金波,郭丽春.可编程控制器在自动给水系统中的应用[J].辽宁工程技术大学学报(自然科学版),2002, (3): 338~339.

[8] 贺玲芳等.基于控制的全自动变频恒压供水系统[J].西安科技学院学报,2000,(3): 243~245.

[9] 罗锁玉.“南化”自备水厂变频改造实现恒压自动供水[J].电力需求与管理,2002,(2): 43~44.

[10] 丁学又,金大海.交流电机变频软起动时的问题及解决方法[J].电力电子技术,2001,(5): 1~5.

[11] 胡纲衡,唐瑞球.高(中)压变频器应用基础许座,第三讲高压交频器的切换[J].变频器世界,2001(10): 43~45 .

[12] 杨凌云.调节器在恒压供水系统中的应用闭.微机算计信息, 1996, 12(5):49~51.

[13] 郁汉琪.基于专家调节的变频调速恒压供水系统的研究[J].电气传动自动化,1998, 1(20): 65~68.

[14] 田家山.水泵及水泵站[M].上海:上海交通大学出版社,1989: 92~105.

[15] 王维新,流体力学,北京:煤炭工业出版社,1986, 10: 72~78.

[16] 周漠仁.流体力学、泵与风机[M].北京:中国建筑工业出版社,1994: 310~324.

[17] 崔金贵,变频调速恒压供水系统在建筑给水应用的理论探讨[J].兰州铁道学院学报,2000, 19(1): 84~88.

[18] T云飞.变频调速水泵的能耗分析[J].流体机械,2001. 12 ,29(3): 25~27.

[19] 吕树清.恒压供水系统在高层建筑中的应用探讨[J].南昌水专学报,2001, 9,20(3): 39~34.

[20] 廖常初.可编程程序控制器应用技术[M].重庆:重庆大学出版社,1998, 10:59~65.

[21] 耿红旗,吕冬艳.可编程序控制器应用教程[M].北京:中国水利水电出版社,2001,12:45~60.

[22] 常斗南.可编程序控制器原理、应用及通信[M].北京:机械工业出版社,1997:68~96.

[23] 张桂香,王辉编著.计算机控制技术[M].成都:电子科技大学出版社,1999

[24] SIEMENS Company. S7-200 manual, 2001,3.

[25] 黄一大.微型计算机控制技术.北京[M]:机械工业出版社,1998.

[26] 王占奎.变频调速应用百例[M].北京:科学出版社,1999.

[27] 高新陵,宋晓平.变频调速恒压供水系统研制[J].河海大学学报, 2001, 1,

[28] 宁耀斌,明正峰.变频调速恒压供水系统的原理与实现[J].西安理工大学学报,2001,5,17(3): 305~308.

[29] 张戟.单台变频器实现多台水泵软起动空调恒压供水方法[J].计算技术与自动化,1999. 4: 18~20.

[30] 汤蕴#l.电机学.北京:机械工业出版社[M] , 1999, 5: 140~142.

[31] 邓巍.及变频器在多台泵自动恒压供水系统中的应用[J].新石油学院学报,2001,6. 13(2): 67~69.

[32] 武雅莉,王鹊.利用8031单片微机在线检测相位差[J].西安:现代电子技术,1995,2:25~27.

[33] 任冠众等.相位测量技术[LJ].电测与仪表,1990, 27(9): 41~60.

[34] 史健芳.用单片机测量相位差的新方法[J].电脑开发与应用,2000, 13(7): 30~31.

[35] Paul.C.l. Phase measuring with increased accuracy. Electron .Eng, 1991,4: 52~55.

[36] 田会山,杨爱华.水泵及水泵站[M].北京:中国建筑工业出版社,1986.

[37] 陈国华,风机水泵调速节能手册[M].北京:机械工业出版社社,1987, 12:92~105.

[38] 张海藩编著.软件工程导论[M].北京:清华大学出版社,1992, 6.

[39] 金以慧主编.过程控制[J].清华大学出版社,2001, 7.

[40] (美)Steve Teixeira Xavier Pacheco(徐新华译).Delphi4开发大全(上、下)[M].北京:人民邮电出版社,1999, 8.

[41] 蒋方帅,潇湘工作室编著.Delphi5程序员指南[M].北京:人民邮电出版社,2001,8.

[42] 李睿,方坤等编著。Delphi开发高级界面实例[M].北京:人民邮电出版社,2000,10.

川公网安备: 51019002004831号

川公网安备: 51019002004831号