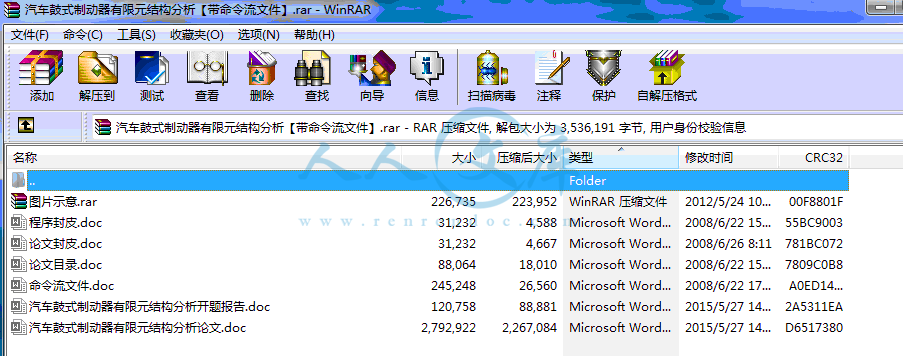

汽车鼓式制动器有限元结构分析

66页 24000字数+说明书+开题报告+命令流文件【详情如下】

命令流文件.doc

图片示意.rar

汽车鼓式制动器有限元结构分析开题报告.doc

汽车鼓式制动器有限元结构分析论文.doc

程序封皮.doc

论文封皮.doc

论文目录.doc

摘 要

随着中国经济的高速发展,汽车已经进入普通家庭,人们对汽车在安全性、舒适性方面的要求已迅速向国际水平靠拢。汽车的噪声问题,特别是制动器噪声问题,不但影响驾驶的舒适性,损害汽车零部件,甚至导致灾难。而且严重影响人们的生活环境。可见,寻找制动噪音的根源,设计一种制动噪音低的鼓式制动器,无论是从降低噪音污染、满足顾客要求、提高鼓式制动器的产品开发进度还是提高汽车整车的销售水平来说都是非常有意义的。

本文通过对国内外制动器噪声研究现状的综述,了解了制动器噪声研究的方法、主要成果及存在问题。为了进一步了解鼓式制动器噪声发生的机理,利用ANSYS软件分别建立了制动蹄、制动鼓和摩擦衬片的三维有限元模型,并且对有限元模型进行模态分析,通过分析结果,确认重点研究的范围。在模态分析和模态振型的基础上提出了修改制动蹄和制动鼓的结构参数、材料参数以及在模型上添加质量块或加强筋的方法以错开各零部件的固有频率范围降低振动噪声。

在制动期间产生的热量约有95%为制动鼓吸收,使制动鼓温度升高。而制动鼓温度过高,将引起热应力增加,同时会使制动力矩减小,使制动效能迅速下降,甚至使制动鼓产生热变形,这将直接影响制动器的性能和寿命。因此本文对制动鼓分别进行了热分析、结构分析和热-结构耦合分析。通过分析结果的比较,说明温度载荷对制动鼓的强度和刚度均有很大影响;同时,在机械载荷和热载荷共同作用下,两种模型的最大应力均未超过材料的许用值,满足制动鼓的强度要求。

关键词:鼓式制动器;噪声振动;有限元;静力分析;模态分析;耦合分析

ABSTRACT

Along with the Chinese economy high speed development, the automobile already entered the ordinary family, meanwhile, customer's expectation on safety and comfort are rapidly catching the world class level. Noise of Automobile question, especially brake noise question, not only influence driving comfortableness, harms the automobile spare part, even causes the disaster. Moreover serious influence people's living conditions. So, finding the root of brake noise and designing a kind of low-noise drum brake assembly, whether from reducing noise pollution, making customers satisfied and improving product development of drum brake assembly or raising the sales level of automobile plants are very meaningful.

A summery of previous study on brake noise is presented to focusing on brake noise research methodology and major achievements. To further understand the mechanism of drum brake noise, the 3D model of brake shoe, brake drum and friction lining are established and meshed and then the finite element models of brake parts are established. By modal analysis of finite element model finding and confirming scope of researching.Proposed in the modal analysis and in the modality mode of vibration's foundation the revision brake shoe and brake drum's design parameter, the material parameter as well as increase the quality block or stiffener's method on the model stagger various spare parts the natural frequency scope to reduce the drumming noise.

During the brake, produces the quantity of heat approximately is the brake drum absorbed about 95%, making brake drum temperature escalate. But the brake drum hyperpyrexia, will cause the thermal load to increase, simultaneously will cause the braking moment to reduce, will make the brake potency to drop rapidly, will cause the brake drum to have the thermal deformation, this immediate influence performance and life of brake. Therefore this article has carried on the thermal analysis, the structure analysis and the hot - structure coupling analysis separately to the brake drum. Through the analysis result of comparison, showed that the temperature load has the very tremendous influence to brake intensity and the rigidity of drum; At the same time, in the mechanical load and under the hot load combined action, two kind of model biggest stresses have not surpassed ultimate strength of the material, satisfied intensity of brake drum request.

Key words: Brake Drum;Vibration and Noise;Finite Element;Static Analysis;Modal Analysis;Coupling Analysis

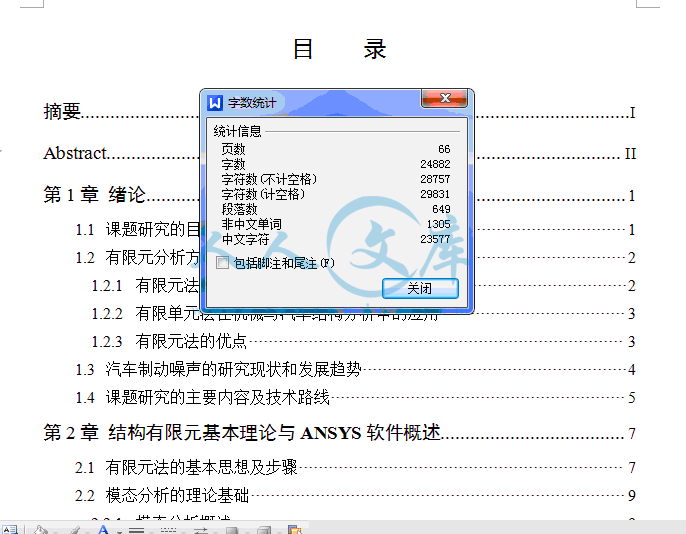

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1 课题研究的目的和意义 1

1.2 有限元分析方法的发展与研究状况 2

1.2.1 有限元法概述 2

1.2.2 有限单元法在机械与汽车结构分析中的应用 3

1.2.3 有限元法的优点 3

1.3 汽车制动噪声的研究现状和发展趋势 4

1.4 课题研究的主要内容及技术路线 5

第2章 结构有限元基本理论与ANSYS软件概述 7

2.1 有限元法的基本思想及步骤 7

2.2 模态分析的理论基础 9

2.2.1 模态分析概述 9

2.2.2 模态分析的基本理论 11

2.2.3 模态分析基本步骤 13

2.3 热-结构耦合分析的理论基础 13

2.3.1 热-结构耦合分析概述 13

2.3.2 热分析的基本理论 13

2.3.3 热稳态分析 14

2.3.4 耦合分析 14

2.4 有限元分析软件ANSYS概述 15

2.4.1 ANSYS软件的主要功能 16

2.4.2 ANSYS分析步骤 17

2.5 本章小结 18

第3章 制动器有限元模型的建立 19

3.1 力学模型 19

3.3 实体模型 20

3.3.1 实体建模的优点和方法 20

3.3.2 实体模型的建立 20

3.3 制动器有限元模型的建立 22

3.3.1 单元的选取及材料参数的确定 22

3.3.2 模型的网格划分 23

3.4 本章小结 25

第4章 鼓式制动器的静态特性分析 26

4.1 制动器的受力分析 26

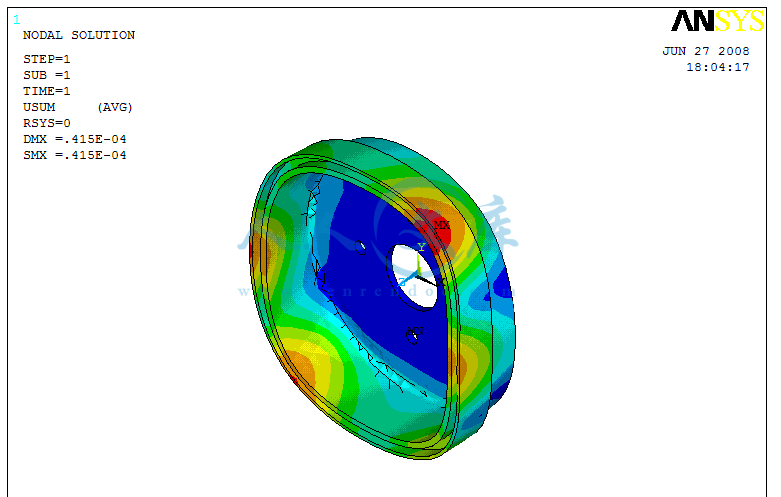

4.2 制动鼓的静态特性分析 29

4.2.1 制动鼓的边界条件与载荷的施加 29

4.2.2 制动鼓的静力学计算结果及分析 29

4.3 制动蹄的静态特性分析 30

4.3.1 制动蹄的边界条件与载荷的施加 30

4.3.2 制动鼓的静力学计算结果及分析 31

4.4 本章小结 32

第5章 制动器的振动模态特性分析 33

5.1 制动鼓振动特性分析 33

5.2 摩擦衬片振动特性分析 38

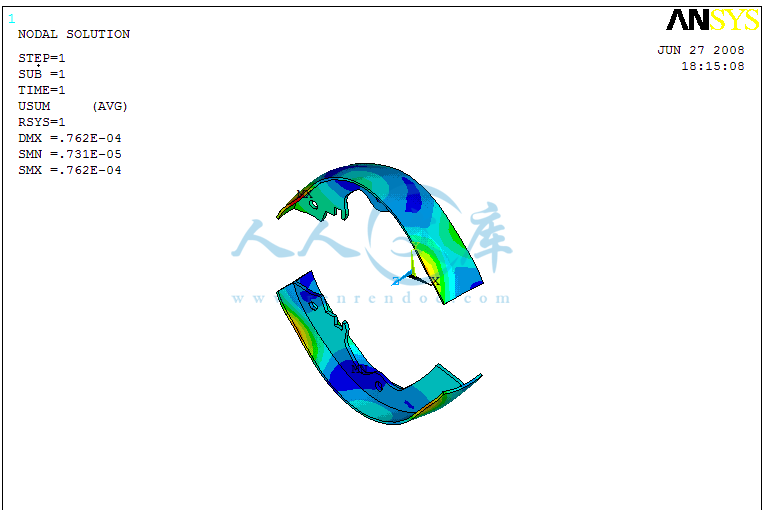

5.3 制动蹄振动特性分析 43

5.4 本章小结 49

第6章 制动鼓的热-结构耦合分析 50

6.1 鼓式制动器生热与散热过程 50

6.2 单元类型选择与边界条件的处理 51

6.2.1 单元类型选择 51

6.2.2 边界条件的处理 51

6.3 计算结果分析 52

6.3.1 制动鼓的热分析 52

6.3.2 制动鼓的结构分析 53

6.3.3 制动鼓的耦合分析 53

6.4 本章小结 55

结论 56

参考文献 58

致谢 60

6.4 本章小结

综合对制动鼓的热分析、结构分析和热-结构耦合分析的结果,可以得到以下结论:本次计算中热-结构耦合分析所得的制动鼓的最大径向位移比单独在机械载荷作用下结构分析中的大3.5倍,所得的应力也大于结构分析,说明温度载荷对制动鼓的强度和刚度均有很大影响;在机械载荷和热载荷共同作用下,两种模型的最大应力未超过材料的许用值,满足制动鼓的强度要求。

结 论

汽车制动器是汽车制动系统的主要工作装置,其强度、刚度及动态特性直接影响制动系统的工作特性及使用寿命,影响整车的安全性、舒适性、噪声、操纵稳定性等基本性能。在制动器的结构设计中,通过有限元法对制动器结构部件进行静态分析、固有特性分析和动态分析。将分析结果返回到设计过程中,修改其中不合理的参数,使得制动器在设计阶段就可保证满足使用要求从而缩短设计试验周期,节省大量的试验和生产费用,它是提高汽车设计的可靠性、经济性、适用性的方法之一。因此,为了保证其设计的精确性和缩短设计周期,基于有限元分析,研究它的静、动态力学特性,研究其振动噪声,是非常重要和必须的。

本文根据汽车鼓式制动器的结构及机械性能参数的要求,在有限元理论的基础上,建立了制动器结构部件的有限元模型,并使用ANSYS软件对其进行了结构分析、模态分析以及对制动鼓的热-结构耦合分析。

在此过程中,主要完成工作及结论如下:

(1)阐述了汽车制动振动噪声的研究现状,通过对当前汽车制动振动噪声研究的分析确定噪声研究的重点频率范围为500~1000Hz,并且主要分布在800Hz的倍频程范围内;阐述了机械结构有限元分析方法的基本内容、思想与分析步骤,介绍了模态分析与热-结构耦合分析的基本概念以及基本理论,为后序章节奠定了有限元结构分析的理论基础。最后简要地概述了课题研究应用的有限元分析软件ANSYS的主要功能和分析的基本步骤。

(2)建立有限元模型,分析振动特性。在ANSYS中建立3D模型,利用ANSYS进行网格划分和计算,分别为制动鼓、制动蹄和摩擦衬片建立三维有限元模型。

(3)对鼓式制动器的主要零件进行了静力学分析,其中难点是各部件的边界条件与力学分析。从对鼓式制动器的静力学分析得出:对于旋转体的径向变形是其考虑的重要方面,而制动蹄的强度略超出材料屈服极限,可能导致的原因是由于最大摩擦力的施加有一定偏差。另外,制动器的理论上应力的分布与实践比较相符合,所以采用有限元分析是符合实际的。

(4)阐述了结构动力学有限元分析理论,在此基础上对制动鼓、制动蹄和摩擦衬片的有限元模型进行了模态分析,得出各自的前十阶振动频率及振型图。通过振动特性分析,提出了修改制动鼓、制动蹄的方法来降低制动噪声。

(5)阐述了制动器特殊工作环境下的传热问题以及研究意义,在传热理论的基础上,对制动鼓进行稳态热分析,得到在单一温度下,制动鼓的温度分布情况,确定其热应力场的分布,为制动鼓热-结构耦合问题的温度分布、变形及热应力的变化作为重要的基础。

(6)对制动鼓在单一的温度载荷和机械载荷作用下,以及在上述两类载荷共同作用下的热-结构耦合问题的温度分布、变形及热应力的变化进行了研究。通过分析对比,表明在温度载荷作用下,制动鼓的变形及热应力的变化。说明温度载荷对制动鼓的强度和刚度均有很大影响。在制动鼓的强度分析时,应考虑温度影响。

但是,在本文的研究设计中还存在着一些不足:

(1)由于制动器结构部件的不规则,本次有限元模型分析中的大多采用自由网格,使得计算结果的精确性有所影响。

(2)本文只对于制动器结构的改进只提出了一些建议,没有进行更深入的研究并给出较为详细的改进方案。

ANSYS软件在汽车制动器有限元结构分析上的应用研究具有深远意义,需要研究的内容也十分广泛,而本文的研究非常有限,对许多问题未能进行更深入的探讨和研究,唯有在未来的研究中更加努力工作,以弥补缺憾。

参考文献

[1]王立功.有限元的发展及应用[M].北京:人民交通出版社,2003:3-7.

[2]魏涛.基于ANSYS的盘式制动器结构分析及振动噪声研究[D].吉林大学硕士学位论文,2006.10.

[3]管迪华,宿新东.制动振动噪声研究的回顾、发展与评述[J].工程力学,2004,8:150-155.

[4]李善锋.基于ANSYS的鼓式制动器及振动噪声研究[D].吉林大学硕士学位论文,2006.10.

[5]庞剑,何华等.汽车噪声与振动:理论与应用[M].北京:北京理工大学出版社,2006:32-33.

[6]叶先磊,史亚杰.ANSYS工程分析软件应用实例[M].北京:清华大学出版社,2003.

[7]潭继锦.汽车有限元法[M].北京:人民交通出版社,2005:2-3.

[8]刘惟信.汽车制动系的结构分析与设计计算[M].北京:清华大学出版社,2004:172-174.

[9]马迅,秦剑.基于有限元法的制动鼓的耦合分析[J].机械设计与研究,2005,2:68-71.

[10]蔡旭东,蒋伟康.鼓式制动器噪声机理及对策研究[J].汽车工程,2002,5:391-407.

[11]陈兴旺.鼓式制动器温度场的研究[D].长安大学硕士学位论文,2006.06.

[12]鼓育辉. 汽车制动系统关键零部件的强度分析[D].南京理工大学硕士学位论文,2000.01.

[13]王良模等. 双向自增力鼓式制动器效能因数的计算研究.江苏省汽车工程学会第五届年会论文[C].南京:1997.

[14]赖锋.重型汽车制动系统结构分析及其设计方法研究[D].武汉理工大学硕士学位论文,2006.4.

[15]管迪华,朱新潮.鼓式制动器噪声的结构闭环耦合理论模型[J] .清华大学学报,1994,2:26-33

[16]《机械设计手册》编委会.机械设计手册.联轴器、离合器与制动器[G].北京:机械工业出版社,2007.6.

[17]刘立刚,王学林.鼓式制动器的有限元分析[J].专用汽车,2003,3:21-23.

[18]蒋伟康,西择男,高田博.鼓式制动器振动与啸叫的研究[J].机械强度,1998,2:81-86.

[19]张静双.基于知识的汽车制动器设计专家系统的研究与开发[D].重庆大学硕士学位论文,2003.05.

[20]袁伟.鼓式制动器温升计算模型及其应用研究[D].长安大学硕士学位论文,2003.6.

[21]毛智东.鼓式制动器的三维有限元模拟及分析[D].华中科技大学硕士学位论文,2002.4.

[22]中国科学院计算机语言信息研究中心.汉英汽车技术词典.北京:人民交通出版社,2003.12

[23]Matysiak S J , Yevtushenko A , Ivanyk E G. Contact temperature and wear of composite friction elements during braking. International Journal of Heat and MassTransfer , 2002,45 :193-199.

[24]Hohmann C , Schiffner K, Oerter K, et al. Contact analysis for drum brakes and disk brakes using ADINA.Computers and Structures , 1999 , 72 :185~198.

川公网安备: 51019002004831号

川公网安备: 51019002004831号