【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

包装机是一个产品生产和外包的机器的统称,其主要功能是包装各种产品,而包装机推包机构则是给包装机提供包装产品的机构,其主要功能就是从生产线将产品输送到包装机的相应入口,推包机构的运动是一个按一定轨迹的循环往复运动。它推送物品到达指定包装工作台,该机构取代了传统的人工移动物品,改善了工作效率低的缺点。

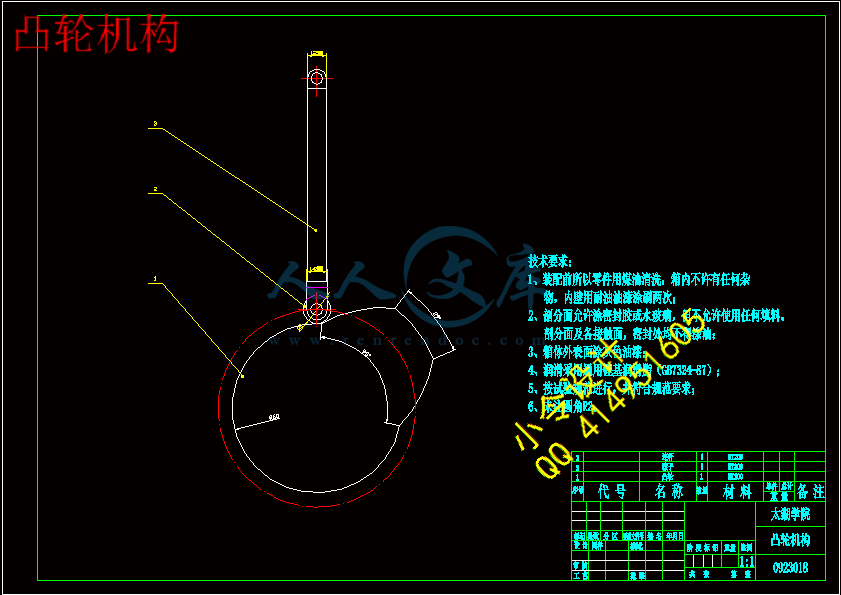

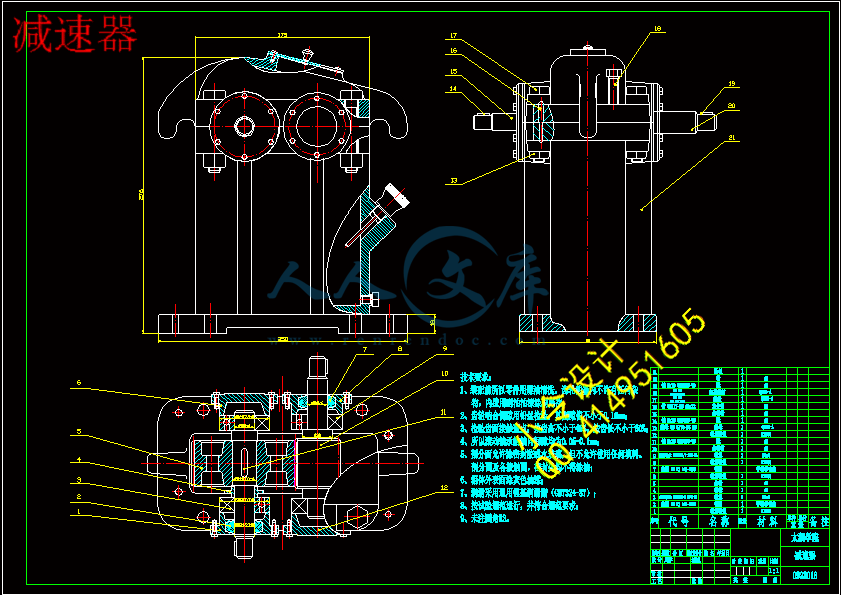

本文所设计的推包机构,有回程一体的全自动化功能,其主要设计思路来自于对传统工艺的分解,然后按照相应功能的机构部件进行设计,对比,选定,以及优化组合。综合利用凸轮的往复运动,齿轮的传动运动,以及减速器的定值调速比的设定。再利用Auto Cad软件强大绘图功能,和Word的编辑功能,把设计方案图文并茂,栩栩如生的展现出来。在本系统中,用激光感应被包装工件并通过单片机对推包机构进行控制。激光测得被推物体确认到达后,由感光板上发出脉冲,通过89C51单片机及步进电动机驱动芯片ULN2803对步进电动机进行控制。同时被包装工件的件数由LED显示器显示。对推包机构则采用偏置滑块机构与盘形凸轮机构的组合机构相结合。其中,偏置滑块机构控制推头的水平方向上运动,凸轮机构则控制推头垂直方向的运动。在本设计中,在推头回程过程中不影响下一个工件的到来,从而总体来讲提高了效率。

关键词:包装机;推包机构;减速机;齿轮

Abstract

Packing machine is a machine of a production and outsourcing collectively, Its main function is the packaging of various products, However, the packaging machine push package body is the institutions of packaging products, packaging machine, Its main function is to transport products from the production line to the corresponding entry of the packaging machine, the agency's movement is a movement of the cycle by a certain trajectory. The agency push items arrived at the designated packing table, the agency replaces the traditional manual movable objects inefficiency.

I designed the push package institution push package, return one of the fully automated,its main design ideas comes from the decomposition of traditional technology,then designed follow the corresponding function body parts, contrast, selected, and optimized. The use of the cam reciprocates, the movement of the gear drive, and the set value of the speed ratio of the reducer. The use of the powerful drawing features Auto Cad software and Word editing features, design illustrated, lifelike. In this system, laser sensor packaging workpiece to push package institutions controlled by the microcontroller. Laser test object to be driven to confirm arrival, photosensitive plate pulses, stepper motor controlled by the 89C51 microcontroller and stepper motor driver chip ULN2803. The same time, the number of pieces of packaging workpiece by the LED display shows. Push institutions using the combined mechanism of the the bias slider mechanism and disc-shaped cam mechanism, among them, the bias slider mechanism controls the pusher in the horizontal direction movement,and the cam mechanism controls the pusher in the vertical direction movement. In this design,in the return process it does not affect the arrival of the next workpiece, and thus in general, to improve efficiency.

Key words: packing machine; push institution; reducer;gear

目 录

摘 要III

AbstractIV

1 绪论1

1.1 本课题的研究内容和意义1

1.2 国内外的发展概况2

1.3 本课题应达到的要求3

2 机械部分的设计4

2.1 方案的选择4

2.2 凸轮及杆的设计6

2.2.1 设计要求及计算7

2.2.2 校核各杆的压杆稳定性9

2.2.3 校核各杆的强度9

2.2.4 校核凸轮的强度9

2.3 减速器概述10

2.4 电动机的选择11

2.4.1 初步确定负载推力11

2.4.2 电动机选择步骤12

2.4.3 确定传动装置的总传动比及其分配14

2.4.4 计算传动装置的运动及动力参数14

2.5 齿轮的设计14

2.5.1 齿轮传动特点与分类14

2.5.2 齿轮传动的主要参数与基本要求14

2.5.3 齿轮组的设计与强度校核15

2.6 轴的设计19

2.6.1 轴的分类19

2.6.2 轴的材料19

2.6.3 轴的结构设计20

2.6.4 低速轴的设计与计算21

2.6.5 高速轴的设计与计算25

2.6.6 选择和校验键联接26

2.7 轴承的选用26

2.7.1 轴承种类的选择26

2.7.2 深沟球轴承结构26

2.8 联轴器的选择27

2.8.1 联轴器的功用27

2.8.2 联轴器的类型特点27

2.8.3 联轴器的选用28

2.8.4 联轴器材料28

3 控制部分的设计29

3.1 控制系统的功能与设计要求29

3.2 系统总体方案的设计29

3.3 控制原理图32

4 结论与展望33

4.1 结论33

4.2 不足之处及未来展望33

致 谢34

参考文献35

1 绪论

包装机械是指能完成全部或部分包装过程的机器。作用是给有关行业提供必要的技术装备,以完成所要求的产品包装工艺过程。包装机械是使产品包装实现机械化、自动化的根本保证,因此包装机械在现代工业生产中起着相当重要的作用。机械包装的生产能力往往比手工包装提高几倍、十几倍甚至几十倍,无疑这将会更好地适应市场的实际需要,合理安排劳动力,为社会多创造财富。 现代包装机械所能完成的工作已远远超出了简单地模仿人的动作,甚至可以说在很多场合用巧妙的机械方法包装出来的成品,不论在式样、质地或精度等方面,大都是手工操作无法胜任和媲美的。随着商品的多样化,这一点越来越引起了人们的重视。有些产品的卫生要求很严格,如药品、食品等,采用机械包装,避免了人手和药品、食品的直接接触,减少了对产品的污染。同时由于机械包装速度快,食品、药品在空气中停留时间短,从而减少了污染机会,有利于食品和药品的卫生和金属制品的防锈防蚀。 另外,由于包装机械的计量精度高,产品包装的外形美观、整齐、统一、封口严密,从而提高了产品包装的质量,提高了产品销售的竞争力,可获得较高的经济效益。采用真空、换气、无菌等包装机械,可使食品和饮料等流通范围更加广泛,延长食品的保质期。采用自动包装生产线,产品和包装材料的供给是比较集中的,各包装工序安排比较紧凑,节约了包装的场地和仓储面积,并改善了后道包装工序的工艺条件。

包装机械的特点 包装机械即具有一般自动化机械的共性,也具有自身的特性,主要有如下特点:

(1) 大多数包装机械结构复杂,运动速度快,动作精度高。为了满足性能要求,对零部件的刚度和表面质量等都具有较高的要求。

(2) 用于食品和药品的包装机械要便于清洗,与食品和药品接触的部位要用不锈钢或经过化学处理的无毒材料制成。

(3) 进行包装时作用力一般都较小,所以包装机械的电动机功率较小。

(4) 包装机械一般都采用无级变速装置,以便灵活调整包装速度、调节包装机的生产能力。因为影响包装质量很多,诸如包装机的工作状态、包装材料和包装物的质量等。所以,为了便于机器的调整,满足质量和生产能力的需要,往往把包装机设计成无级可调的,即采用无级变速装置。

(5) 包装机械是特殊类型的专业机械,种类繁多,生产数量有限。为便于制造和维修,减少投资设备,在各种包装机的设计中应注意标准化、通用性及多功能性[1]。

1.1 本课题的研究内容和意义

研究内容:(1) 方案设计。并确定传动系统中各机构的运动尺寸和各构件尺寸。

(2) 机械部分设计。确定电动机的功率与转速,并确定其尺寸。

(3) 进行推包及结构设计。绘制其装配图。

意义:迄今,一些科学技术发达的国家,在食品、医药、轻工、化工、纺织、电子、仪表和兵器等工业部门,已经程度不同地形成了由原料处理、中间加工和产品包装三大基本环节所组成的包装连续化和自动化的生产过程,有的还将包装材料加工、包装容器成型及包装成品储存系统都联系起来组成高效率的流水作业线。大量事实表明,实现包装的机械化和自动化,尤其是实现具有高度灵活性(或称柔性)的自动包装线,不仅体现了现代生产的发展方向,同时也可以获得巨大的经济效益[2]。

(1) 能增加花色品种,改善产品质量,加强市场竞争能力

(2) 能改善劳动条件,避免污染危害环境

(3) 能节约原材料,减少浪费,降低成本

(4) 能提高生产效率,加速产品的不断更新

1.2 国内外的发展概况

90年代以来,包装机械工业每年平均以20%~30%的速度增长,发展速度高于整个包装工业平均增长速度的15%~17%,比传统的机械工业平均增长4.7个百分点。包装机械工业已经成为我国国民经济发展中不可缺少的新兴行业。我国目前从事包装机械生产的企业约有1500多家,其中具有一定规模的企业近400家。产品有40类,2700多种,其中有一批既能满足国内市场需要,又能参与国际市场竞争的优质产品。我国包装机械行业近些年取得了相当显著的成绩,但与国外产品相比仍存在20年左右的差距。[3]

国外包装机械水平高的国家主要是美国、日本、德国。美国的包装工业发展较早,门类齐全,基础扎实,水平很高。仅就包装机械制造业而论,实力相当雄厚,其品种与总产值均居世界首位。由于国内已实现了工业现代化,自选市场蓬勃兴起,客观上要求包装机械沿着自动化方向发展,并将电子计算机及其他有关新技术广泛应用于生产过程。日本已建立起独立的包装工业体系,其包装工业总产值约为美国的一半而跃居世界的第二位。日本拥有一批规模不大的包装机械制造厂,侧重于开发中小型、半自动的包装机及配套设备,其技术水平好多已进入国际的先进行列。由政府资助的日本包装技术协会主要搞技术情报交流。另外设有日本包装机械工业协会,它乃是本行业的全部业务活动中心。而德国的包装机械在设计、制造及技术性能等方面则居于领先地位。德国包装机械的77%为出口。中国是德国包装机械的主要出口国。最著名的是克朗斯公司(KRONES),2002年销售额达到20亿欧元,中国知名的啤酒企业都进口过他们的设备[4]。最近几年德国设备表现出如下特点:

(1) 工艺流程自动化程度越来越高。

(2) 提高生产效率,降低工艺流程成本,最大限度地满足生产要求。

(3) 适应产品变化,设计具有好的柔性和灵活性。

(4) 成套供应能力强。

(5) 包装机械设计普遍使用仿真设计技术。

我国包装机械行业存在的问题:研发经费少,技术力量薄弱。低水平重复太多。行业科技力量不足。国际贸易人员匮乏。应变能力不强。

我国包装机械行业发展的新趋势:

(1) 生产效率化。①机械功能多元化。②结构设计标准化、模块化。③控制智能化。

(2) 资源的高利用化

(3) 产品节能化

(4) 新技术实用化

(5) 大力加强科研、开发能力

我国装机械既面临着国外先进产品的挑战和竞争,同时也面临着巨大的国内外市场和较好的发展机遇。进入21世纪,我国国民经济整体水平和综合国力又迈上了一个新的台阶,国际国内的环境都为我国经济的进一步发展提供良好的机遇[5]。

1.3 本课题应达到的要求

运动控制技术在国内的发展特别快,但是在胶带机包装机械行业的发展动力却显得上升乏力。运动控制产品及技术在包装机械上的作用主要是达到精确的位置控制和严格的速度同步的要求,主要用在装卸、输送、打标、码垛、卸垛等工序。运动控制技术是区别高、中、低端胶带机包装机械的关键因素之一,也是中国包装机械升级的技术支撑。因此,需要对包装机的推包机构的运动方式做设计改善。经过考虑现在包装机械的现状及发展趋势后, 为了更好地实现包装机械的自动化控制,改进推包机构的设计以提高生产效率而给定的。

推包机构能够实现推送,回程全自动一体化的一个机构。它由推刨机构,回程机构以及电动机组成。现需要设计某一包装机的推包机构,要求待包装的工件先由输送带送到推包机构的推头的前方,然后由该推头将工件由推至包装工作台,再进行包装。为了提高生产率,希望在推头结束回程时,下一个工件已送到推头的前方。这样推头就可以马上再开始推送工作。这就要求推头在回程时先退出包装工作台,然后再低头,即从台面的下面回程。因而就要求推头实现“平推—水平退回—下降—降位退回—上升复位”的运动。

我的设计是每5-6s包装一个工件,且假定:滑块移动距离L=400mm, 推头在返程阶段到达离最大推程距离S=100mm, 推头回程向下的距离H=50mm。行程速比系数K在1.2-1.5范围内选取,推包机由电动机推动。在推头回程中,除要求推头低位退回外,还要求其回程速度高于工作行程的速度,以便缩短空回程的时间,提高工效。

川公网安备: 51019002004831号

川公网安备: 51019002004831号