地下自卸汽车工作设计

地下自卸汽车转向液压系统设计

地下自卸汽车工作、转向液压系统参数计算及轮边制动器的设计

地下自卸汽车轮边制动器的设计

地下自卸汽车工作、转向液压系统参数计算

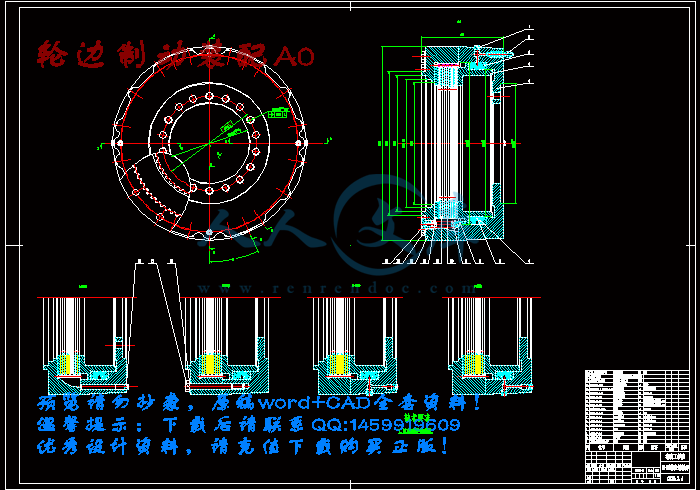

轮边制动器的设计

CA-20地下自卸汽车工作、转向液压系统参数计算及轮边制动器的设计【优秀含14张CAD图纸+机械工程毕业设计】

【带任务书+开题报告+外文翻译】【54页@正文20200字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】

2摩擦动片A2.dwg

2摩擦片垫板A2.dwg

CA-20地下自卸汽车工作、转向液压系统参数计算及轮边制动器的设计.doc

CAXA制图

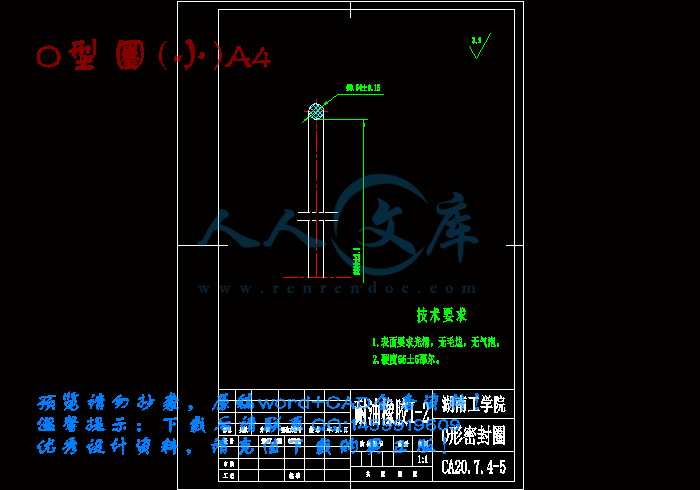

O型圈(小)A4.dwg

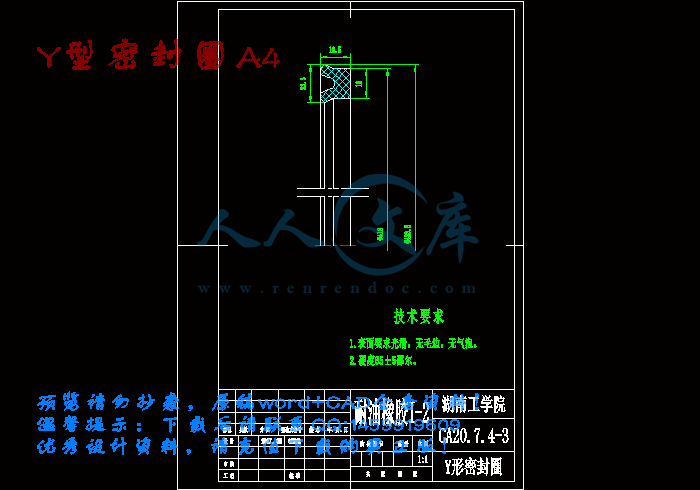

Y型密封圈A4.dwg

任务书.doc

单刃刀具-中文翻译.doc

单刃刀具-外文文献.doc

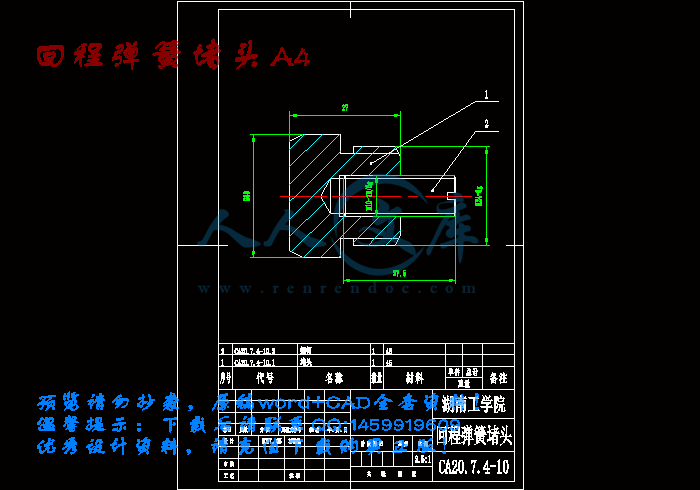

回程弹簧堵头A4.dwg

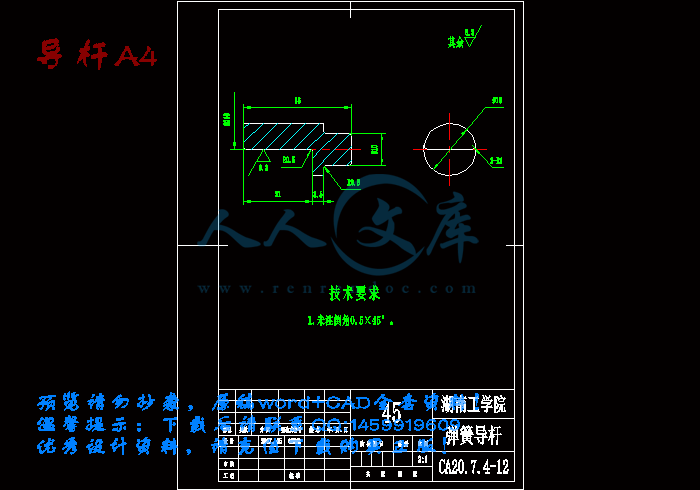

导杆A4.dwg

封面.doc

工作液压系统原理图A2.dwg

开题报告.doc

摘要和目录工作、转向.doc

正文副本.doc

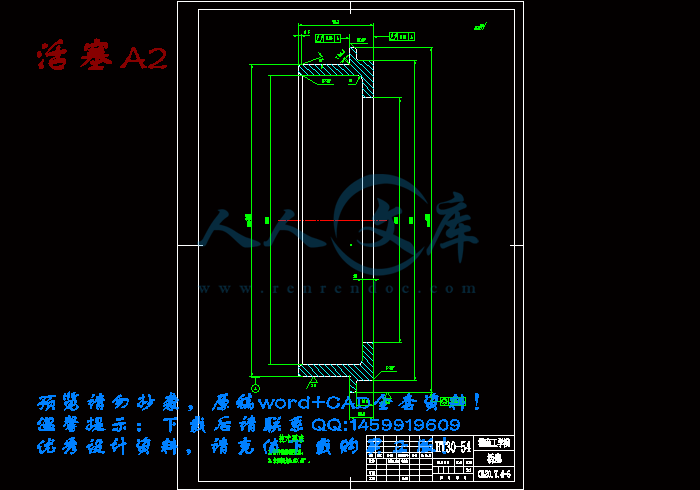

活塞A2.dwg

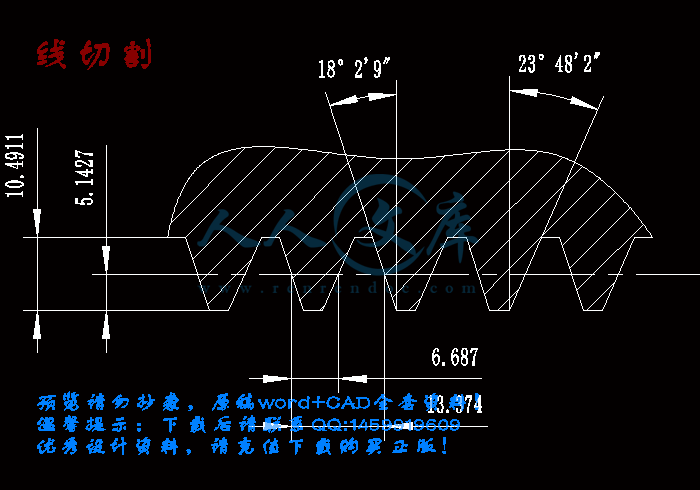

线切割.dwg

转向液压系统原理图A2.dwg

轮边制动装配A0.dwg

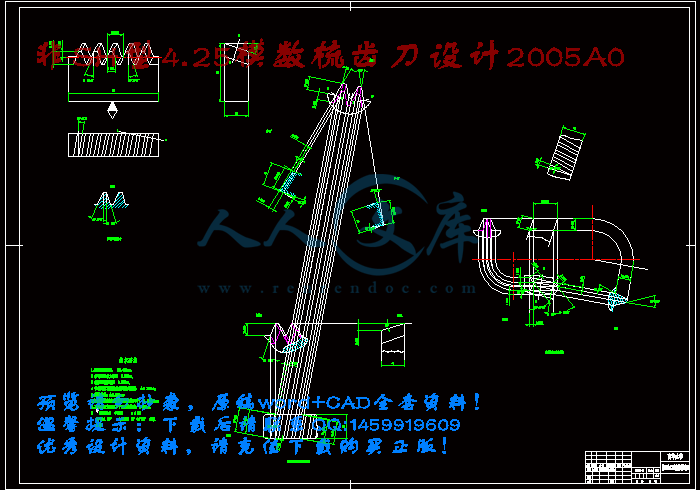

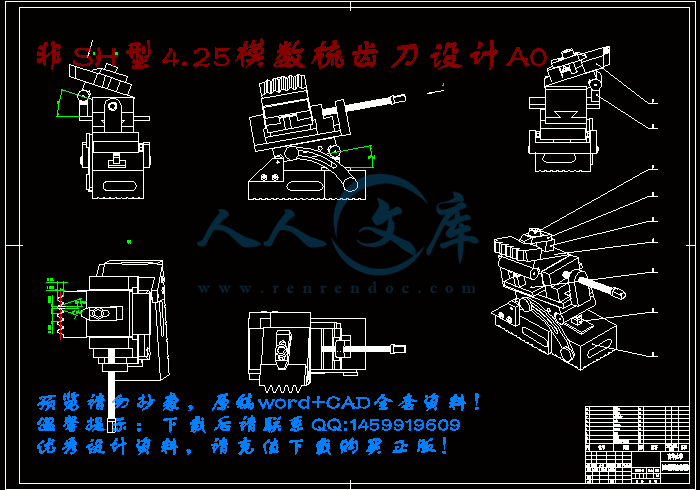

非SH型4.25模数梳齿刀设计2005A0.dwg

非SH型4.25模数梳齿刀设计A0.dwg

非SH型梳齿刀(右旋).dwg

任务书

设计(论文)内容及要求:

1.对汽车的结构进行深入了解,通过对《地下装载机-结构设计使用》、《工程机械构造(底盘)》、《工程机械修理(底盘)下册》的学习,加强液压系统理论知识、汽车轮边制动器设计的基础和机械结构的设计知识,通过各种资料初步确定液压系统的设计方案。

2.对工作液压系统、转向液压系统设计及参数的计算并确定液压系统的设计方案,根据各系统所受的最大作用力确定各系统的系统压力和流量选定各系统液压泵及其他液压元件,完成液压系统原理图

3.利用以上液压参数求出不同工况变矩器输入功率与力矩,并进行变矩器与发动机的优化匹配。

4.参考衡阳冶金机械总厂及外文资料的结构确定湿式多盘轮边制动器的参数计算以及结构、精度的设计,并进行零部件的设计和零部件图纸绘制。

5.编写好设计说明书。

序言

我们本次毕业设计课题是地下矿山自卸车工作、转向液压系统参数计算及轮边制动器的设计

国外的地下矿山自卸汽车应用的比较好,技术也比较先进,因此我国大多使用进口地下自卸车,但价格比较高。因此,CA—20地下矿山自卸汽车的开发对地下矿山设备国产化当起到极其重要的作用,具有重大意义。

20吨地下矿山自卸汽车是我国矿山应用较多的一种机型,它比较适合中型规模的地下矿山。我国的20吨地下矿山自卸汽车目前还停留在研制阶段。

在整车设计中有我门机械工程学院的优秀老师指导,在这个课题开发过程中,我们可以更加系统全面的学习设计方法和专业知识。

在老师的指引下,我们首先花了一个月的时间认真学习了衡阳有色冶金总厂教授级高工高梦熊编著的《地下装载机结构设计与使用》及中国人民解放军工程兵机械学校编著的《工程机械构造(底盘)》、《工程机械修理(底盘)下册》三本书,对其有了一定了解。在接下来的设计工作中,利用手中所有的资料来设计属于我国自己的地下自卸车。

在设计中令我难忘的是设计当中指导老师和我们一起共同进退,力求在规定的时间完成设计。

谢谢老师们的指导、帮助、教诲,谢谢老师们为我们所付出辛苦和操劳。

摘 要:详细介绍了CA-20地下自卸汽车工作液压系统和转向液压系统的设计,为四个步骤:根据各个系统的功能和整车布置拟定液压系统原理图;根据翻倾及转向角度分别计算工作油缸的行程;根据各系统所受的最大作用力确定系统压力;根据各系统的系统压力和流量选定各系统的泵及其他液压元件。实践CA-20地下自卸汽车液压系统是安全、可靠和高效的。

关键词:地下自卸汽车;工作液压系统;转向液压系统;泵;油缸;

Abstract: In this paper the design of the hydraulic systems of working and steering for CA-20 Rear Dump Truck is introduced. The design include four steps. First of all according to the feature of each hydraulic system, we can draw the principle diagrams of the hydraulic systems of working and steering. Then we can calculate the travels of the dumping cylinders and steering cylinders by the angles of dumping and steering. And then we can decide the pressure of each hydraulic system through the maximal force on each system. At last may chose the pumps and other hydraulic parts according to the pressure and the flow of each hydraulic system, The fact has proved that the hydraulic system of the truck is safe, reliable and efficient.

Key words: Rear dump truck Hydraulic system of working hydraulic system of steering Pump Cylinder

目录

一、绪论

(一)立项背景 1

(二)国内外研究现状与发展趋势 3

(三)项目实施的主要内容、技术关键与创新点、预期目标 5

(四)应用或产业化前景与市场需求 6

(五)现有工作基础、条件和优势 7

二、液压系统参数计算

(一)概述 8

(二)工作液压系统参数计算 8

(三)转向液压系统参数计算12

(四)变矩器与发动机优化匹配MATLAB程序的编制 18

(五)液压缸装配、维护、修理工艺 30 37

三、参考文献 50

谢辞51

附页52

一、绪 论

(一)立项背景:

地下自卸汽车是实现无轨开采技术的主要运输设备,它具有机动灵活和经济的优越性,广泛用语条件适宜的地下矿山。随着无轨采矿技术的发展,对地下自卸汽车的需求量也愈来愈大,对它的经济性、生产能力与可靠性的要求也愈来愈高,生产地下自卸汽车的厂家也愈来愈多。除了专门生产地下自卸汽车的厂家之外,生产露天自卸汽车的厂家也纷纷将露天自卸汽车改造后用于地下,企业之间的竞争愈来愈激烈。各企业为了适应市场的变化,提高市场的竞争力,不断推出新技术、新品种、新结构和新材料,促进了无轨采矿技术与设备的发展。

国内研制地下自卸汽车始于20世纪70年代中期,由于各种原因,至今发展不快,只有几个生产厂,技术水平只相当于国外20世纪80年代末的水平,数量与质量也远远满足不了国内矿山发展的需要。我们加入了WTO之后,地下自卸汽车行业面临着极大的压力和挑战,为了对付这严峻的形势一方面要引进更多更好的国外产品与相关技术,另一方面必须迅速发展民族工业。

参考文献

1. 高梦雄 .地下装载机——机构设计与使用 .冶金工业出版社,2002

2. 陈伟,战凯 .DKC-12地下自卸汽车工作及转向液压系统的设计 .矿冶,1996 年6月(第8卷 第2期):16~19

3. 战凯. DKC-12地下自卸汽车制动系统设计及制动过程分析. 矿冶,1997年12月(第6卷 第4期):9~13

4. 袁哲俊,刘华明,唐宜胜. 齿轮刀具设计. 新时代出版社,1983

5. 汽车工程手册编辑委员会 .汽车工程手册 .人民交通出版社,2000

6. 齿轮手册编委会 .齿轮手册(上册)第二版 .机械工业出版社,2000

7. 唐增宝,何永然,刘安俊 .机械设计课程设计 .华中科技大学出版社 ,1998

8. 廖念钊,莫雨松,李硕根 .互换性与技术测量 .中国计量出版社,1981

9. 濮良贵,纪名刚 .机械设计 .高等教育出版社,2000

10. 周志雄,孙宗禹 .机械设计制造及自动化英语教程 .湖南大学出版 社,2000

11. 蔡春源 .新编机械设计手册 .辽宁科学技术出版社,1993

12. 天津齿轮机床研究所 .齿轮工手册 .天津人民出版社,1974

13. 北京第一通用机械厂 .机械工人切削手册 .机械工业出版社,1977

14. 中国第一汽车集团公司编写组 .机械工程材料手册 .机械工业出版社,1997

15. 机械传动装置选用手册编委会 .机械传动装置选用手册 .机械工业出版社,1999

16. 辛一行 .现代机械设备设计手册第一卷设计基础 .机械工业出版社,1996

17. 刘鸿文 .材料力学上册第三版 .高等教育出版社,1991

18. 线值计量技术编写组 .齿轮测量 .上海科学技术出版社,1978

19. 机械工程手册,电机工程手册编辑委员会 .机械工程手册第十二卷机械产品(二) .机械工业出版社,1982

20. 机械工程手册,电机工程手册编辑委员会 .机械工程手册第四卷机械设计(一) .机械工业出版社,1982

21. 中国人民解放军工程兵机械学校 .工程机械构造(底盘) .(内部资料)

22. 中国人民解放军工程兵机械学校 .工程机械修理(底盘)下册 .(内部资料)

23. 王沫然 .MATLAB6.0与科学计算 .电子工业出版社,2001

24. 四川省机械工业局 .复杂刀具设计手册 .机械工业出版社,1979

川公网安备: 51019002004831号

川公网安备: 51019002004831号