1 前言

1.1 课题内容

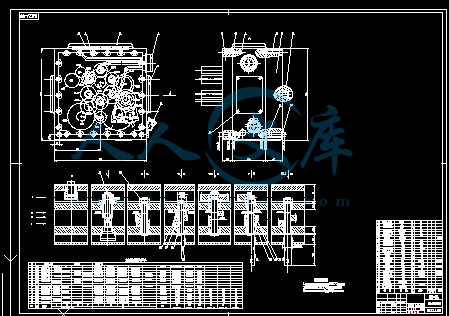

本组课题是为保证S195柴油机气缸体三面孔加工及保证相应的位置精度,需设计一台三面精镗卧式组合机床。在完成“三图一卡”的基础上,主要完成机床总体和后主轴箱设计。

1.2 课题来由

1.2.1 课题背景

课题来源于盐城市江动集团。为保证S195柴油机气缸体三面各主要孔的加工精度及保证相应的位置精度,需要设计一台三面精镗的组合机床。

1.2.2 课题要求

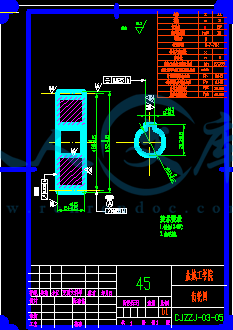

本加工工序的内容是:左端:钻螺纹底孔14×Φ6.7,Φ12.4,表面粗糙度均为 Ra12.5。右端:钻螺纹底孔9×Φ6.7,Φ8.5, 表面粗糙度均为Ra12.5。后端:钻螺纹底孔6-Φ12.4,表面粗糙度均为Ra12.5。

为了保证零件的加工精度,在整个设计过程中应满足以下几点要求:

a.加工部位的位置尺寸应与定位基准直接发生关系。

b.机床应运转平稳,工作可靠,结构简单。

c.装卸方便,便于维修,调整。

d.当本工序有特殊要求时必须标明。

1.3 组合机床国内外发展概述

组合机床是以系列化、标准化的通用部件为基准,配以少量的专用部件组成的专用机床。组合机床是随着生产的发展,由万能机床和专用机床发展来的。这种机床既具有专用机床的结构简单、生产率和自动化程度较高的特点,又具有一定的重新调整能力,以适应工件变化的需要,组合机床可以对工件进行多面、多主轴加工。组合机床兼有低成本和高效率的优点,在大批、大量生产中得到广泛应用,并可用以组成自动生产线。

随着科学技术的进步和市场需求的变化,现代机械制造业得到了较快的发展。多品种、小批量生产方式将成为今后的主要生产形式,制造系统正向着柔性化、集成化、智能化的方法发展,机床越来越多地采用先进的技术,加工效率不断地提高。机械产品的加工精度日益提高,高精度的机床大量出现。为了适应生产发展的需要,机床夹具正在向柔性化、高效化、自动化、精度化、标准化方向发展。

1.4 本课题主要解决的问题和总体设计思路

1.4.1 主要解决的问题

A 组合机床工艺方案的拟定。

B 组合机床总体设计,主要完成“三图一卡”的设计。

a)工序图;

b)加工示意图;

c)机床联系尺寸总图;

d)生产率计算卡。

C 后主轴箱设计

a)左主轴箱装配图;

b)箱子补充加工图;

c)零件图;

d)有关计算、校核。

1.4.2 总体设计思路

后主轴箱的设计,首先,在完成对组合机床的总体设计并绘制出“三图一卡”的基础上,绘制后主轴箱设计的装配图;主轴箱设计是组合机床设计中的重要部分,主轴箱设计的合理与否,直接影响到被加工精度等参数。首先确定工件的定位与夹紧方式,然后进行误差分析,对主轴箱的主要零件进行结构设计和验算。

2组合机床总体设计

2.1工艺方案的拟定

2.1.1被加工零件的特点

本设计是为钻削ZH1105W柴油机气缸体的三面31个轴孔的工序而专门设计的,为了能到达质量好、效率高,我们采用了工序集中的原则进行设计。

机床的配置型式主要有卧式和立式两种。卧式组合机床床身由滑座、侧底座及中间底座组合而成,其优点是加工和装配工艺性好,无漏油现象;同时安装、调试与运输也都比较方便;而且机床重心较低,有利于减小振动。其缺点是削弱了床身的刚性,占地面积大。立式组合机床床身由滑座、立柱及立柱底座组成。其优点是占地面积小、自由度大、操作方便。其缺点是机床重心高、振动大。

由于被加工的零件为ZH1105W柴油机气缸体的三面31个孔,该柴油机的体积小、重量较重,且为三面加工。根据零件的特点及生产纲领,应选用卧式床身,通过左右后三个动力头驱动三个主轴箱对零件三端面的31个孔进行加工较为妥当。

通过以上分析,初定本次设计方案为卧式三面组合钻床,三个动力头左右后布置。

2.1.2工艺路线的确定

工艺路线如下:

工序1 铸造

工序2 时效

工序3 粗铣底面、顶面

工序4 粗铣左面、右面

工序5 粗铣前面、后面

工序6 精铣底面、顶面

工序7 精铣左面、右面

工序8 精铣前面、后面

工序9 三面粗镗孔

工序10 三面半精镗孔

工序11 三面精镗孔

工序12 钻左面、右面、后面孔

工序13 钻顶面、底面、前面孔

工序14 攻丝

工序15 钻、扩、铰顶杆孔

工序16 最终检验

工序12的加工内容为:

a) 左端,钻螺纹底孔14×φ6.7、φ12.4,表面粗糙度均为Ra12.5;

b) 右端,钻螺纹底孔9×φ6.7、φ8.5,表面粗糙度均为Ra12.5;

c) 后端,钻螺纹底孔6×φ12.4,表面粗糙度均为Ra12.5。

各孔的位置精度及具体要求详见ZH1105W气缸体的工序图。

川公网安备: 51019002004831号

川公网安备: 51019002004831号