目 录

1 绪论

1.1 摩托车车轮发展概况………………………………………………………… 1

1.2 铝合金轮毂成形方法的选择与对比………………………………………… 2

1.3 铝合金轮毂铸造方法的选择和对比………………………………………… 3

1.4 国内外低压铸造发展概况…………………………………………………… 4

2 低压铸造基本知识

2.1 低压铸造原理………………………………………………………………… 5

2.2 低压铸造工艺流程…………………………………………………………… 6

2.3 低压铸造的特点……………………………………………………………… 7

2.4 低压铸造工艺规范…………………………………………………………… 8

3 模具总体方案设计

3.1 铝合金轮毂低压铸造模具一般方案………………………………………… 10

3.2 模具总体方案设计与对比…………………………………………………… 12

3.2.1 零件轮辋的主要形式………………………………………………………… 12

3.2.2 轮毂零件的分析……………………………………………………………… 13

3.2.3 铸件毛坯的工艺分析………………………………………………………… 15

3.2.4 模具总体方案1……………………………………………………………… 16

3.2.5 模具总体方案2及与方案1的比较………………………………………… 17

3.3 模具的动作方式……………………………………………………………… 18

3.3.1 模具的分模动作方式………………………………………………………… 19

3.3.2 模具的合模复位动作方式…………………………………………………… 20

4 模具设计

4.1 铸件的材料及其性能………………………………………………………… 22

4.2 机械加工余量的确定………………………………………………………… 22

4.3 铸件收缩率的确定…………………………………………………………… 22

4.4 起模斜度的确定……………………………………………………………… 23

4.5 分型面的确定………………………………………………………………… 23

4.6 模架的设计…………………………………………………………………… 24

4.7 冒口的设计…………………………………………………………………… 25

4.7.1 冒口设计的基本原则………………………………………………………… 25

4.7.2 冒口设置的原因……………………………………………………………… 25

4.7.3 冒口的设置与原理分析……………………………………………………… 26

4.8 推出机构的设计……………………………………………………………… 27

4.8.1 推出机构的组成及特点……………………………………………………… 27

4.8.2 推出距离的计算……………………………………………………………… 28

4.8.3 推杆截面积的计算…………………………………………………………… 29

4.9 尺寸公差的确定……………………………………………………………… 31

4.10 涂料的使用…………………………………………………………………… 31

5 边模的工艺路线

5.1 定位基准的选择……………………………………………………………… 33

5.1.1 精基准的选择原则…………………………………………………………… 33

5.1.2 粗基准的选择原则…………………………………………………………… 33

5.1.3 精基准和粗基准的确定……………………………………………………… 33

5.2 边模表面加工工序的确定…………………………………………………… 34

5.2.1 加工工序顺序的原则………………………………………………………… 34

5.2.2 加工阶段的划分……………………………………………………………… 34

5.2.3 边模的工艺路线……………………………………………………………… 35

5.2.4 边模的工艺规程……………………………………………………………… 35

6 总结 …………………………………………………………………………… 37

参考文献……………………………………………………………………………… 38

致谢…………………………………………………………………………………… 39

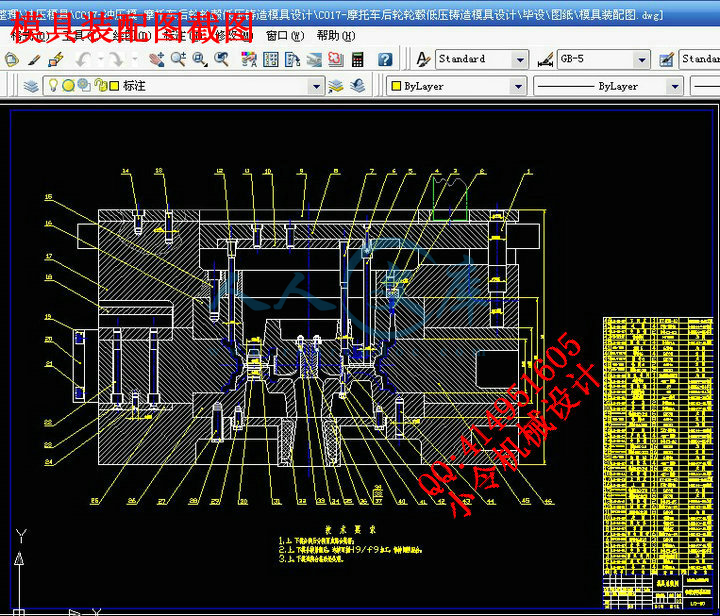

附录…………………………………………………………………………………… 40

摘要:轮毂是踏板摩托车上极为重要的行驶部件和安全部件,应具有良好的综合力学性能,在正常行驶过程中不应发生变形和疲劳失效。而轮毂又属于形状复杂的零件,一般采用铸造方法使其成型。现在,广泛采用低压铸造来生产轮毂。模具在铸造成型方法中是至关重要的一部分,因此,它的设计和制造成了铸造质量的关键所在。

本文对轮毂进行实体造型更形象的了解轮毂的外形。并主要从摩托车轮毂的发展状况、铝合金的成型与铸造方法、低压铸造的工艺及特点,模具总体方案的选择以及模具结构的设计等方面介绍了轮毂低压铸造的模具设计。

该款轮毂的材料采用了铝合金材料(ZL101A),对轮毂的铸造毛坯进行了设计,使其能够满足铸造的工艺要求。设计中将低压铸造与压力铸造、金属型重力铸造、挤压铸造以及差压铸造等铸造方法进行了对比。分析了轮毂零件的特点以及轮辋的主要形式及其特点。另外,主要从铸件收缩率、铸型分型面、冒口的设置以及推出机构等几个方面介绍了模具设计的要点。通过示意图描述了模具的分模与合模的动作方式。并对铸造轮毂的边模进行工艺分析。

关键词:轮毂 低压铸造 模具设计

Abstract: Wheels is an extremely important safety components and moving parts of aPedaling Motorcycle , which should have good mechanical properties, in the normal courseof driving should not be taken deformation and fatigue failure. And Wheel is a part of complex shape. Generally casting method used to shapee. It widely used low-pressure casting to produce wheel currently. Die Casting is a vital part in molding method. So its design andmanufacture is the key of casting quality.

This paper making solid mode-ling for wheels in order to understanding more image about the shape of the wheel ,and it mainly introduces the Wheel mold design of low pressure die casting, fromthe development of motorcycle wheelAluminum alloy molding and casting methods, process and characteristics of Low-Pressure Casting,the choice of the overall program dies the design of die structure Introduced die casting the wheel design by low pressure

Materials of this wheel used alloy material (ZL101A) .The paper Analyses the wheel parts and wheels characteristics of the main forms and characteristicsduring the program design the low-pressure casting and pressure casting, metal-gravity casting, pressure squeeze casting and pressure casting, and other methods are compared. . The Casting blank of the wheel enables it to meet the technological casting requirements. In addition, to introducethe principal Mold design elements, it covers several aspects including the contraction rate of type-casting, Riser set up the institutions and the launch. The actions of Die-Die and mold are described by the cess analysis he side-mode for casting wheel

Keywords: Wheels low-pressure casting mold design

1 绪论

1.1摩托车车轮发展概况

随着工业的飞速发展,摩托车工业也快速的壮大起来,摩托车成为了人们出行所使用的主要交通工具之一。尤其是在发展中国家里,摩托车的拥有数量非常庞大。在我国各大城市里,摩托车已经成为许多家庭的主要交通工具。正是由于摩托车市场的庞大的需求量,从而促使了摩托车企业的快速发展,制造摩托车的工艺也在不断进步。

摩托车车轮是摩托车中极其重要的部件之一,它的质量好坏直接影响着摩托车行驶的安全和可靠。早期的摩托车速度较低,其车轮结构为刚性连接,轮胎为高压胎。随着轮胎及车轮技术的发展,低压轮胎逐渐取代了高压轮胎。与此同时,低压轮胎又出现了无内胎轮胎。

目前,摩托车车轮主要有三种结构形式:轮圈辐条组合式车轮、辐板式整体车轮和轻合金车轮。

轮圈辐条组合式车轮是一种传统的结构型式,该种车轮与早期刚性连接的车轮相比,减震性能较好。但是,这种车轮受结构的限制,车轮的外形变化比较困难,不能适应摩托车外观造型日新月异的需要。并且由于这种结构车轮受轮圈冲孔的限制,不能装配无内胎轮胎,使它的发展大受影响。

辐板式整体车轮分为辐板式整体钢车轮和辐板式整体铝车轮。辐板式整体钢车轮主要用于中、低挡小轮径摩托车。其钢制轮圈的工艺方法是用钢板卷制后焊接成型,使用一段时间后,焊接部位易生锈造成无内胎车轮漏气。辐板式整体铝车轮有质量小、铝辐板形状容易变化等优势。另外,铝合金轮圈和铝辐板通过表面处理后,可以形成车轮所需要的各种颜色,满足了消费者对多种颜色的需求。

川公网安备: 51019002004831号

川公网安备: 51019002004831号