摘 要

模具是工业生产的基础工艺装配,广泛应用于机械、汽车、电子通讯、家电等行业,其中有80%以上的产品零件均通过模具生产而成。在国际上,模具又有“工业之母”之称。模具分为冷冲压模具、热锻模具、塑料模具、铸造模具、橡校模具和玻璃模具等。其中冷冲压模具在各种模具中所占比重最多,占整个模具市场的60%以上,具有广泛的发展前景。

冷冲压模具是在室温下,借助于设备提供的压力,利用模具使板料发生分离成塑性变形的一种加工方法。加工对象主要是金属或非金属的板料。

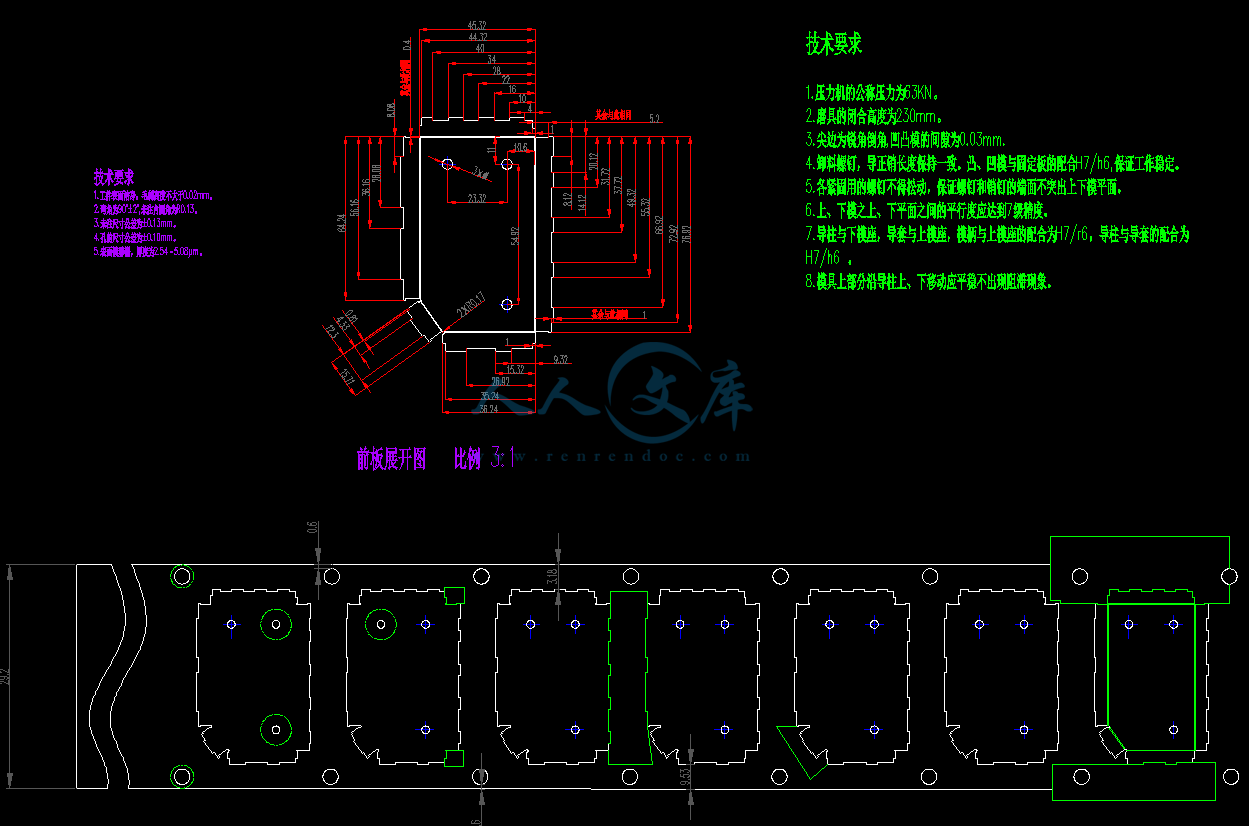

本设计是对给定的模具产品图进行冲压工艺分析和连续模设计,在综合考虑了加工产品的经济性、零件的冲压工艺性以及复杂程度和精确度等诸多因素的基础上进行冲压工艺分析与计算的,并提出了合理的工艺方案和结构形式;最后,结合产品的工艺及现有加工方法合理设计连续模排样方案及加工方法最终达到省时省料、节约资源的目的。本设计介绍了模具设计中的排样与送料方式和卸料与导向方式,讨论了主要工作件间隙的确定和刃口尺寸及冲压力的计算,并选择合适的压力机,设计中主要对模具工作部分尺寸进行计算和主要零部件的设计以及加工工艺的制定。

总而言之冲压模的加工生产效率高,加工成本低,材料利用率高,产品的一致性好,制件质量符合生产要求且操作简单。

关键词:前板 冲压 工艺分析 连续模

Abstract

Mold is the basis of industrial production assembly process is widely used in machinery, automobile, telecommunications, home appliances and other industries, including more than 80% of the product parts are made through the mold production. At the international level, mold and "Mother of industry" called. Is divided into cold stamping die mold, forging mold, plastic mold, die casting, rubber mold school, such as mold and glass. One cold stamping die mold in a variety of the largest share, accounting for the entire mold more than 60% of the market, has a broad development prospects.

Cold stamping die is at room temperature, the pressure through the use of equipment, the use of sheet metal dies so that the separation took placeinto a plastic deformation process. Processing object is a metallic or non-metallic sheet.

The design of stamping process analysis and die design for a given moldproducts, in comprehensive consideration of the stamping process of economy,parts processing products and complexity and accuracy factors on stamping process analysis and calculation, and put forward the reasonable process scheme and structure; finally, combined with the product of the process andthe existing processing method of rational design of progressive die layoutand processing method of saving time and material, reach the purpose of saving resources. This design introduced the mold design of nesting and feeding and discharging and guiding mode, the main pieces of determining clearance and edge size and blanking force calculation are discussed,and select the appropriate machine design, design of the main working parts of die size calculation and main parts and processing technology .

All in all, the production of Die efficient processing, low processing costs, material utilization high, the product of good consistency, the product quality is suit for the production needs, and easy to operate.

Key words:foreplate ,stamping,analysis of manufacturing ,modulus of continuity

目 录

第1章 前言················1

1.1 冲压的概念、特点及应用····························1

1.2 冲压的基本工序及模具······························2

1.3 连续模介绍·············3

1.4 连续模结构分析············3

1.5 连续模设计要点···············4

第2章 连续模设计过程·························8

2.1 冲件工艺性分析·······························8

2.1.1 冲裁件结构工艺性·····························8

2.1.2 冲裁件的精度和毛刺·····························8

2.2 工艺方案的设定··········9

2.3 间隙的含义及间隙值的选择·······················10

2.3.1 冲裁间隙分析···········10

2.3.2 间隙值的选择········11

2.4 冲压加工工序及排样图设计·······················11

2.5 凸模、凹模尺寸的计算····························12

2.5.1 外形尺寸的计算···········12

2.5.2 内形尺寸的计算············13

第3章 落料件凸凹模尺寸计算过程··········15

3.1 刃口尺寸计算····················15

3.2 冲孔部分凸凹模尺寸计算·······················19

第4章 冲压力的计算·····························20

4.1 冲裁件的力学性能分析·····························20

4.2 冲裁件冲裁力的计算································20

4.3 冲裁件卸料力的计算·······························21

4.4 冲裁件推件力的计算···························21

4.5 冲裁件顶件力的计算························22

4.6 冲裁件弯曲力的计算·····················22

4.7 冲裁件压力中心的计算···································23

第5章 排样计算·······························25

第6章 模具结构设计·······························29

6.1 模具的总体结构介绍····························29

6.2 主要零部件设计·······························29

6.2.1 压力机的选择·······························29

6.2.2 模架的选择····························31

6.2.3 上、下模座的选择························32

上模座的设计选择··························33

下模座的设计选择·······················34

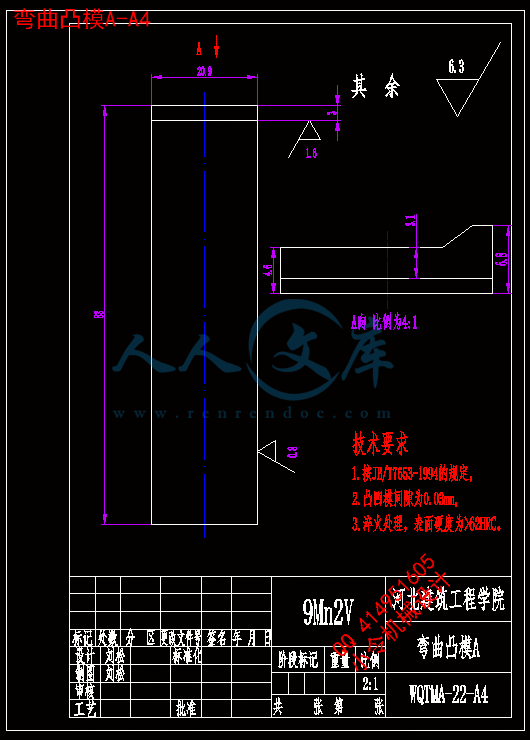

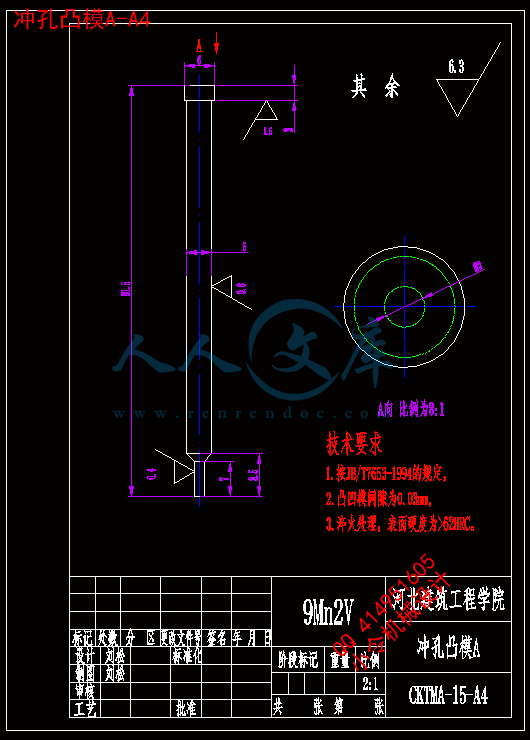

6.2.4 凹、凸模的设计选择·····························35

凸模设计选择···························35

凹模的设计选择···························36

6.2.5 模柄的设计与选择····························37

6.2.6 导柱和导套的选择··························38

6.2.7 卸料装置的设计与选择························39

6.2.8 顶料装置的选择与计算························41

6.2.9 挡料和导正装置的设计与选择················42

第7章 其他零部件的设计与选择················43

7.1 卸料装置中弹性元件的计算·····················43

7.1.1 卸料块的设计···································43

7.1.2 弹性元件橡胶的设计与选择····················43

7.2 卸料板的设计与选择······························46

7.3 垫板的设计与选择······························46

7.4 固定板的设计与选择·······························49

7.5 导料销的设计与选择······························50

7.6 卸料螺钉的选择·······························50

7.7 定位零件的设计与选择····························51

7.7.1 挡料销的选用······························51

7.7.2 销钉的选取·····························51

7.8 推杆的设计与选择····························53

7.9 打料板的设计与选择························53

7.10 顶杆的设计与选择······························53

参考文献··················56

毕业实习报告··············57

附录或后记················62

附:英文翻译···············63

英文原文···············69

第1章 前言

1.1冲压的概念、特点及应用

冲压是利用安装在冲压设备(主要是压力机)上的模具对材料施加压力,使其产生分离或塑性变形,从而获得所需零件(俗称冲压或冲压件)的一种压力加工方法。冲压通常是在常温下对材料进行冷变形加工,且主要采用板料来加工成所需零件,所以也叫冷冲压或板料冲压。冲压是材料压力加工或塑性加工的主要方法之一,隶属于材料成型工程术。

冲压所使用的模具称为冲压模具,简称冲模。冲模是将材料(金属或非金属)批量加工成所需冲件的专用工具。冲模在冲压中至关重要,没有符合要求的冲模,批量冲压生产就难以进行;没有先进的冲模,先进的冲压工艺就无法实现。冲压工艺与模具、冲压设备和冲压材料构成冲压加工的三要素,只有它们相互结合才能得出冲压件。

与机械加工及塑性加工的其它方法相比,冲压加工无论在技术方面还是经济方面都具有许多独特的优点。主要表现如下:

(1)冲压加工的生产效率高,且操作方便,易于实现机械化与自动化;

(2)冲压时由于模具保证了冲压件的尺寸与形状精度,且一般不破坏冲压件的表面质量,而模具的寿命一般较长,所以冲压的质量稳定,互换性好等特征;

(3)冲压可加工出尺寸范围较大、形状较复杂的零件,如小到钟表的秒表,大到汽车纵梁、覆盖件等,加上冲压时材料的冷变形硬化效应,冲压的强度和刚度均较高;

川公网安备: 51019002004831号

川公网安备: 51019002004831号