目 录

摘 要III

AbstractIV

第一章 前 言1

1.1选题背景1

1.2 课题相关调研1

1.2.1 本课题及相关领域的国内外现状及发展1

1.2.2 模具技术的发展现状2

第二章 工艺分析计算3

2.1 零件及其冲压工艺性分析3

2.2 确定工艺方案4

2.3主要工艺参数计算7

2.3.1 落料尺寸7

2.3.2拉深道次及各道次尺寸9

第三章 模具设计14

3.1 落料、拉深复合模14

3.1.1模具结构14

3.1.2 模具工件部分尺寸及公差计算15

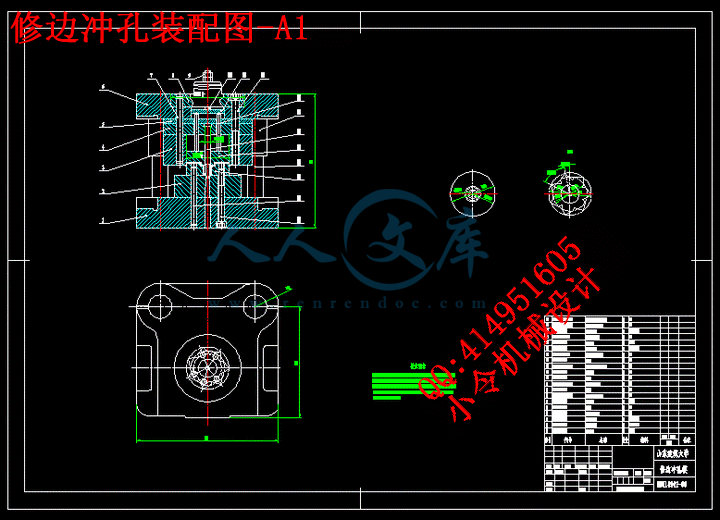

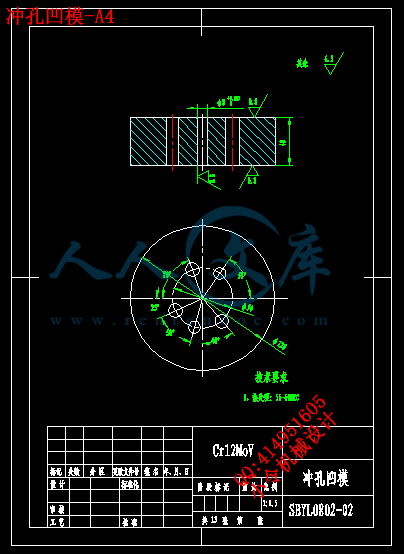

3.2修边冲孔模17

3.2.1模具结构18

3.2.2 模具工件部分尺寸及公差计算18

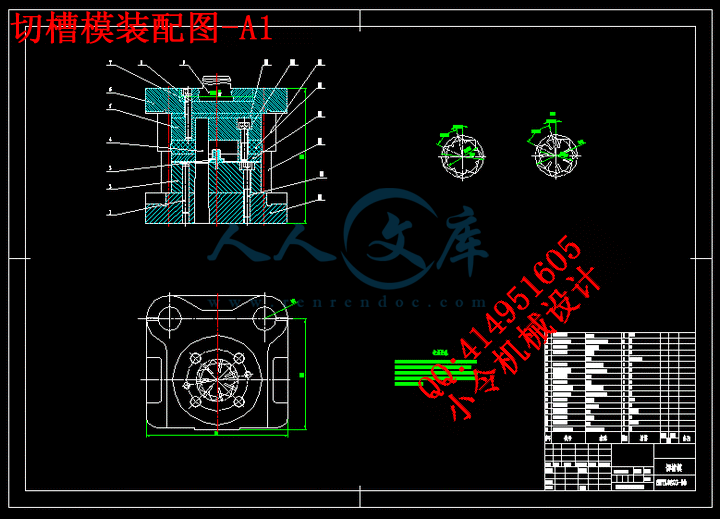

3.3 切槽模21

3.3.1模具结构21

3.3.2 模具工件部分尺寸及公差计算22

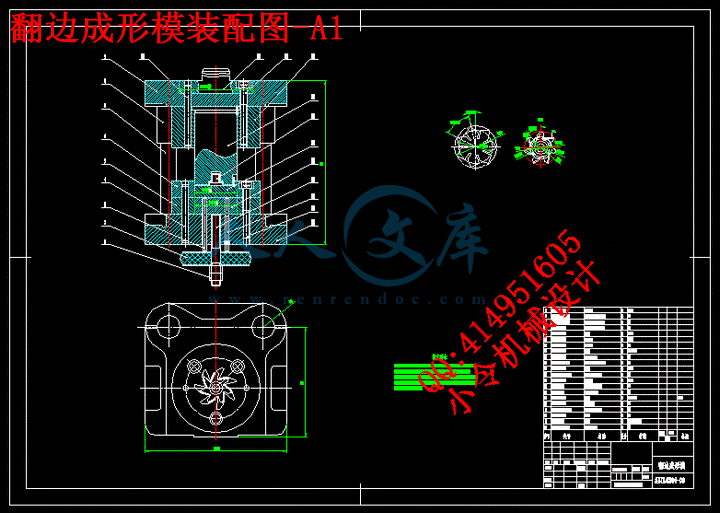

3.4 翻边模23

3.4.1模具结构23

3.4.2 模具工件部分尺寸及公差计算24

第四章 结 论27

参考文献28

谢 辞29

摘 要

水泵叶轮是微型汽车上发动机冷却系统中离心式水泵的重要零件。本文分析了水泵叶轮零件的结构特点, 计算了该叶轮的展开尺寸, 确定了该工件的冲压成形工艺及各工序尺寸, 对全套模具的总体结构设计进行了比较详细的论述,并在此基础上确定了叶轮冲压模具零件的具体结构和尺寸,在生产合格零件的基础上尽量提高生产效率,降低生产成本。主要介绍了叶轮零件冲压成形应包括的基本工序方案,工艺参数计算,模具结构设计、尺寸等。

关键词:水泵叶轮; 冲压; 工序; 模具设计

The Pressing Process Analysis and Die Design of Pump Impeller

ABSTRACT

The pump impeller is an important parts of the centrifugal pumps which was used for the minicar’s engine cooling system. The structure characteristics of the pump impeller were analyzed, and calculated the expanding dimension of this parts, determined pressing forming process of the pump impeller and dimensions of each working procedure, and described the structure design of whole sets of dies in detail, And on that basis determine the structure and size of the impeller stamping die specific parts. To maximize production efficiency and reduce production costs in the production of qualified on the basis of parts. Main introduction of this text leaf round project of basic work preface for spare parts washing pressing take shaping should including; The craft counts the calculation; Molding tool construction design, size...etc.

Key words: pump impeller; pressing process; die design;

第一章 前 言

1.1选题背景

在现代汽车工业中,微型汽车上发动机冷却系统离心式水泵内叶轮由铸铁等金属或工程塑料制成,采用向后弯曲的半圆弧、双圆弧或多圆弧形叶片,其叶型与水流方向一致,泵水效率较高。塑料叶轮容易实现小型化和轻量化,且耐腐蚀性能好,有越来越多的汽车发动机水泵使用了塑料叶轮。但塑料叶轮容易开裂或叶轮磨损后从泵轴上松脱,使冷却液循环速度变慢,容易引起发动机温度过高的故障。损坏的叶轮在旋转时还可能撞击水泵壳体,造成壳体碎裂。铸铁制成的水泵叶轮机械强度较高,但其质量较大。因此一种能综合现在采用材料优点而又避其缺点的产品就应时而生了。

1.2 课题相关调研

水箱在汽车的冷却、散热中有着重要的作用。因为汽车的冷却系统是用来为发动机散热的,一般常见的发动机过热问题。发动机是由冷却液的循环来实现的,强制冷却液循环的部件是水泵,它由曲轴皮带带动水泵叶轮推动冷却液在整个系统内循环。

为了保证冷却效果,汽车冷却系统一般由以下几部分组成:散热器、节温器、水泵、缸体水道、缸盖水道、风扇等组成。据资料显示:导致汽车抛锚的故障中,冷却系统故障位居第一。由此可见,汽车冷却系统保养对汽车安全运行起着重要的作用。

叶轮用于微型汽车上发动机冷却系统的离心式水泵内,工件时以1500-3000r/min左右的速度旋转,使冷却水在冷却系统中不断地循环流动。为保证足够的强度和刚度,叶轮采用厚度为2mm的Al脱氧镇静钢冷轧板。

川公网安备: 51019002004831号

川公网安备: 51019002004831号