您若下载本次文件,将获得(CAD图纸+word文档),以下为本次文件的目录及部分图纸截图。【需要其他机械类资料可以联系QQ97666224】

摘 要

JDM-30型无极绳绞车是一种新型的矿山辅助运输设备。其主要适用于煤矿井下长运距,多起伏的运输巷道,特别适用于大型综采设备的运输牵引和长运距矿车及材料的运输。能大大提高运输效率和运输安全可靠性,防止放打滑现象。该绞车的设计对于完善无极绳绞车起着重要的基础作用。

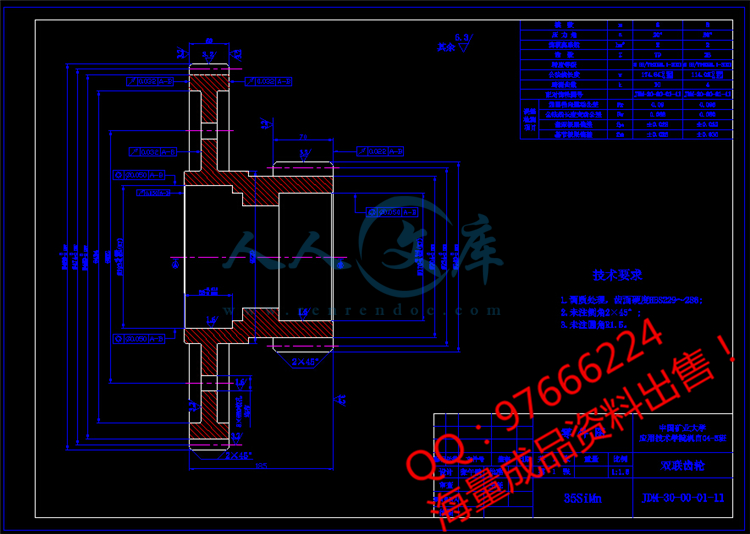

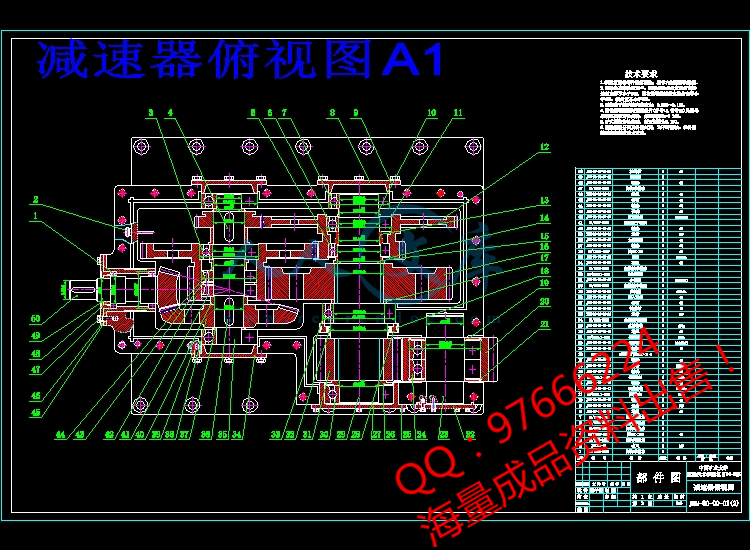

JDM—30型无极绳绞车主要由电动机、联轴器、减速器、卷筒和制动闸等组成。本毕业设计的重点是减速器的设计,该传动系统采用了五级传动,第一级为直齿圆锥齿轮传动,其余为圆柱直齿轮传动,采用了两个双联齿轮,最后一级的小齿轮和大齿轮靠过桥齿轮连接,形成封闭的传动路线。传动原理简单、可靠、高效。

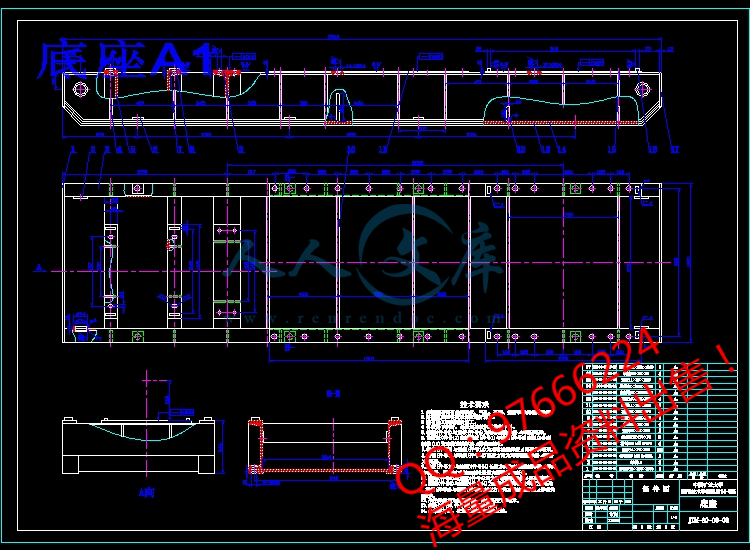

JDM—30型无极绳绞车具有良好的防爆性能和制动性能,容绳量大、适用条件强、使用寿命长、传动效率高等特点。该绞车结构紧凑,外形尺寸小,能够整机下井;结构为近似对称布置,外形美观,成长条形,底座呈雪橇状;绞车重心低,底座刚性好,可安装地锚,运转平稳,安全可靠,维护方便。

关键词:无极绳绞车; 运输; 传动

ABSTRACT

JDM-30-Promise rope winch is a new type of mine-assisted transport equipment. The main application is long distance in the coal mine, more ups and downs of the roadway, especially for large transport fully mechanized coal mining equipment traction and long distance transport cars and materials. It can greatly improve transport efficiency and transport safety and reliability and prevent-skid phenomenon. The winch design plays an important basic role in improving the Promise of the rope winch.

JDM-30-Promise rope winch is mainly composed of the motor, coupling, reducer, brake drum gates, and other components. The graduation project focused on the design of the reducer, the drive system uses five transmission, the first class uses straight bevel gear, the rest is straight cylindrical gear transmission, it uses two pairs of gears, and the small gear and the big gear of the last one are c onnected by the bridge gear.It formed a closed transmission line. Transmission principle is simple, reliable and efficient.

JDM-30-Promise rope winch has a good explosion-proof performance and braking performance, large capacity to justice, conditions of application strong, long-life, high efficiency drive. The winch has compact structure, small shape size, can go down with overall unit; structure is similar to symmetrical layout, aesthetic appearance, growth strip, a sled-shaped base; the gravity centerof the winch is low, rigid base, and can be installed to anchor, a smooth operation, safe and reliable , easy maintenance.

Keyword : promise rope winch ; transport; drive

目 录

1 绪论1

1.1引言1

1.2绞车运输及国内外的发展状况1

1.3无极绳绞车的类型及工作原理1

1.3.1无极绳绞车的类型2

1.3.2无极绳绞车的工作原理2

1.4无极绳运输的安全注意事项2

2 总体设计2

2.1设计总则2

2.2已知条件3

2.3牵引钢丝绳直径的确定及滚筒直径的确定3

2.3.1钢丝绳的选择3

2.3.2滚筒参数的确定3

2.4滚筒强度的计算4

2.5传动系统的确定、运动学计算及电机的选择4

2.5.1传动系统的确定4

2.5.2计算传动效率5

2.5.3各级传动比分配及总传动比6

2.5.4计算总传动比6

2.5.5确定钢丝绳在卷筒上的拉力及卷筒上的功率6

2.5.6选择电机型号7

2.5.7验算电机闷车时,钢丝绳在里层的安全系数7

2.5.8传动装置运动参数的计算8

3 齿轮设计8

3.1第一级直齿锥齿传动设计8

3.1.1初步设计8

3.1.2几何计算定9

3.1.3齿面接触疲劳强度校核12

3.1.4齿根抗弯疲劳强度校核14

3.2第二级直齿圆柱齿轮传动设计15

3.2.1基本参数15

3.2.2强度校核16

3.3第三级直齿圆柱齿轮传动的强度校核20

3.3.1基本参数20

3.3.2强度校核21

3.4第四级直齿圆柱齿轮传动的强度校核25

3.4.1基本参数25

3.4.2强度校核26

3.5第五级直齿圆柱齿轮传动前级的强度校核30

3.5.1基本参数30

3.5.2强度校核30

3.6第五级直齿圆柱齿轮传动后级的强度校核34

3.6.1基本参数34

3.6.2强度校核35

4 齿轮轴传动的设计计算39

4.1锥齿轮轴的设计计算与强度校核39

4.1.1轴的初步计算39

4.1.2轴的结构设计40

4.1.3轴的疲劳强度校核40

4.1.4锥齿轮轴上键的强度验算45

4.1.5锥齿轮轴上轴承的寿命验算45

4.2二轴的设计计算与强度验算46

4.2.1轴的初步计算46

4.2.2轴的结构设计46

4.2.3轴的疲劳强度校核47

4.2.4二轴上键的强度验算53

4.2.5二轴轴承的寿命验算54

4.3花键轴的设计计算与强度验算55

4.3.1轴的初步计算55

4.3.2轴的结构设计56

4.3.3轴的疲劳强度校核56

4.3.4花键轴上花键的强度验算64

4.3.5花键轴上轴承的寿命验算65

4.4过桥轮轴的设计计算与强度验算67

4.4.1初定轴的直径67

4.4.2轴的疲劳强度校核67

4.4.3过桥轮轴的轴承寿命验算68

4.5卷筒轴的设计69

4.5.1对卷筒进行受力分析69

4.5.2对卷筒轴进行受力分析71

4.5.3轴的直径的初步确定72

4.5.4轴的疲劳强度校核72

4.5.5卷筒轴上轴承的寿命验算74

5 绞车及主要部位的检查维护76

6 绞车的常见故障原因76

结论79

参考文献80

英文原文81

中文译文86

致谢90

川公网安备: 51019002004831号

川公网安备: 51019002004831号