您若下载本次文件,将获得(CAD图纸+word文档),以下为本次文件的目录及部分图纸截图。【需要其他机械类资料可以联系QQ97666224】

目 录

摘要…………………………………………………………………………………Ⅰ

Abstract……………………………………………………………………………Ⅱ

前言 …………………………………………………………………………………1

1、总体设计方案……………………………………………………………………6

1.1 设计特点……………………………………………………………………6

1.2 设计产品的用途和应用领域………………………………………………6

1.3 设计目标……………………………………………………………………6

1.4 研究内容……………………………………………………………………7

1.5 设计方案……………………………………………………………………7

1.6 题目的可行性………………………………………………………………9

1.7 传统破碎机的改进…………………………………………………………10

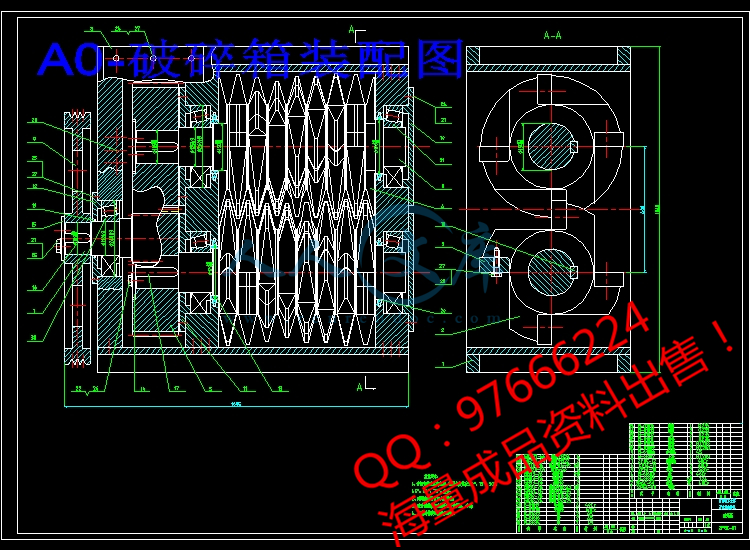

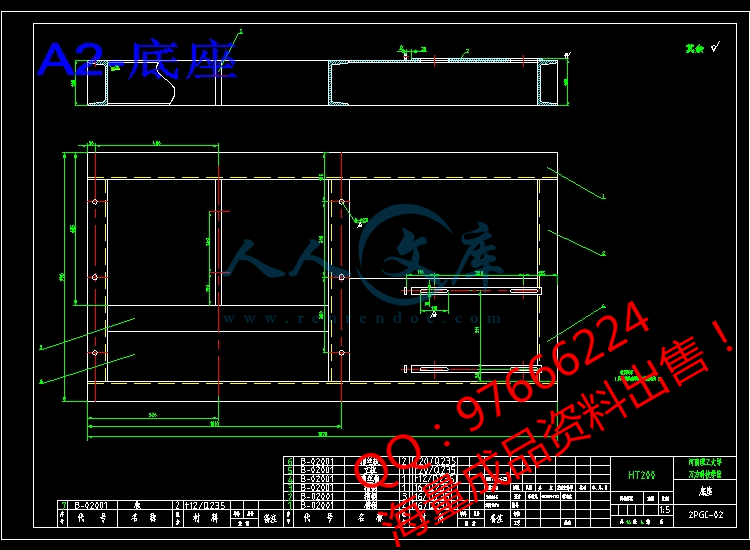

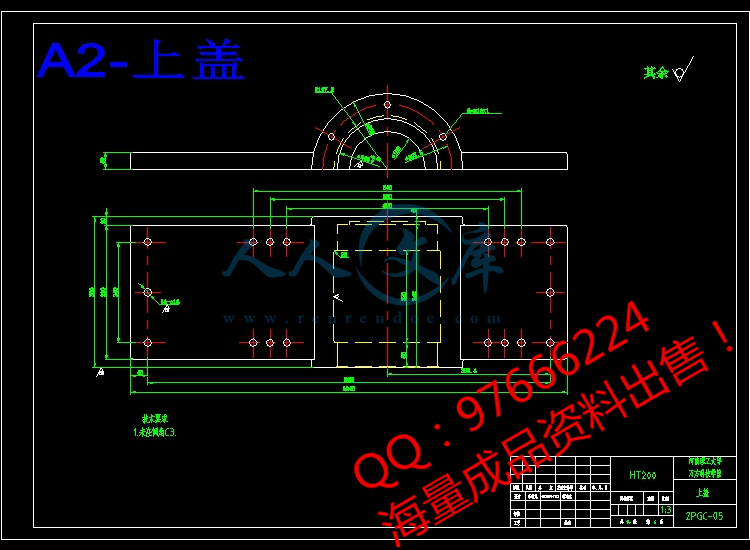

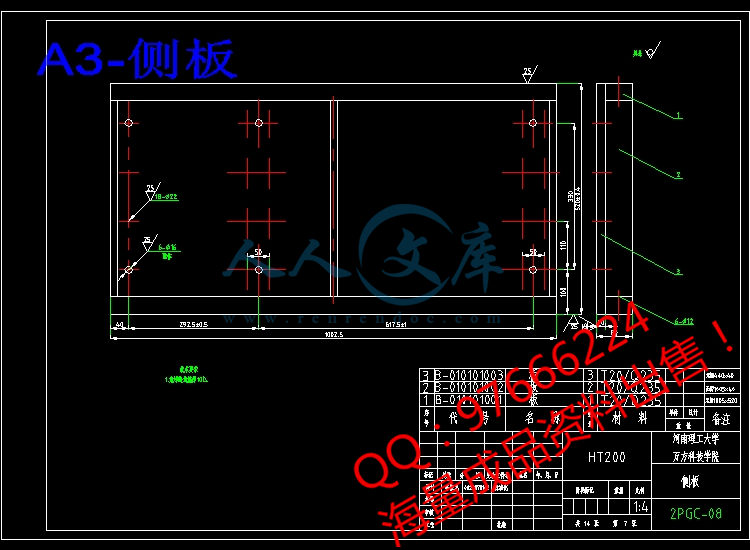

2、破碎机的结构设计………………………………………………………………12

2.1 结构的选择与比较…………………………………………………………12

2.2 破碎机参数的初步确定……………………………………………………14

2.2.1 性能………………………………………………………………………14

2.2.2 计算参数…………………………………………………………………14

2.3 原动机的确定………………………………………………………………18

2.4 传动机构的选择与比较……………………………………………………19

2.4.1 传动机构的重要性………………………………………………………19

2.4.2 传动类型选择……………………………………………………………19

3、破碎机的总体设计………………………………………………………………23

3.1 带传动设计…………………………………………………………………23

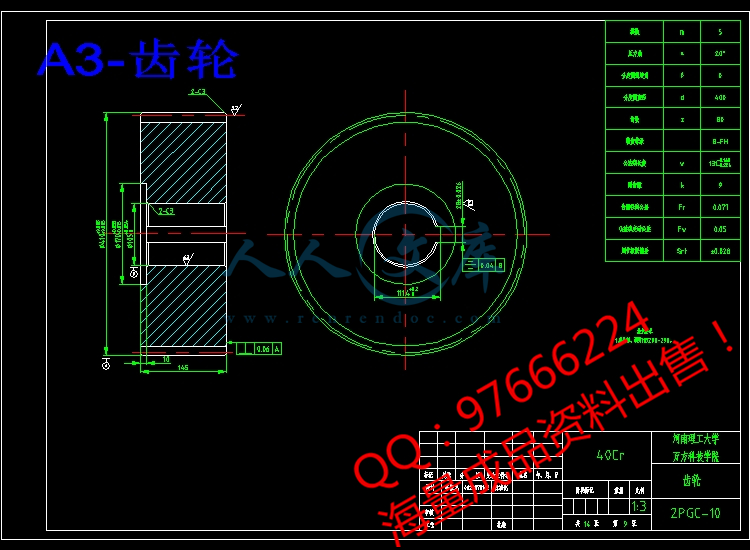

3.2 齿轮传动设计………………………………………………………………27

3.2.1选定齿轮类型,精度等级,材料及齿数 ………………………………27

3.2.2 按齿面接触强度设计……………………………………………………28

3.2.3 按齿根弯曲强度设计……………………………………………………31

3.2.4 几何尺寸计算……………………………………………………………33

3.3 齿轮强度校核………………………………………………………………34

3.3.1 齿面接触疲劳强度校核…………………………………………………34

3.3.2 齿根弯曲疲劳强度校核…………………………………………………40

3.3.3 齿轮静强度校核计算……………………………………………………43

3.4 轴、轴承及键的设计………………………………………………………44

3.4.1 估算轴径…………………………………………………………………45

3.4.2 齿轮轴的结构设计………………………………………………………45

3.4.3 轴上受力分析如下面弯矩转矩图………………………………………48

3.4.4 求支反力…………………………………………………………………49

3.4.5 作弯矩和转矩图…………………………………………………………50

3.4.6 轴的强度校核……………………………………………………………52

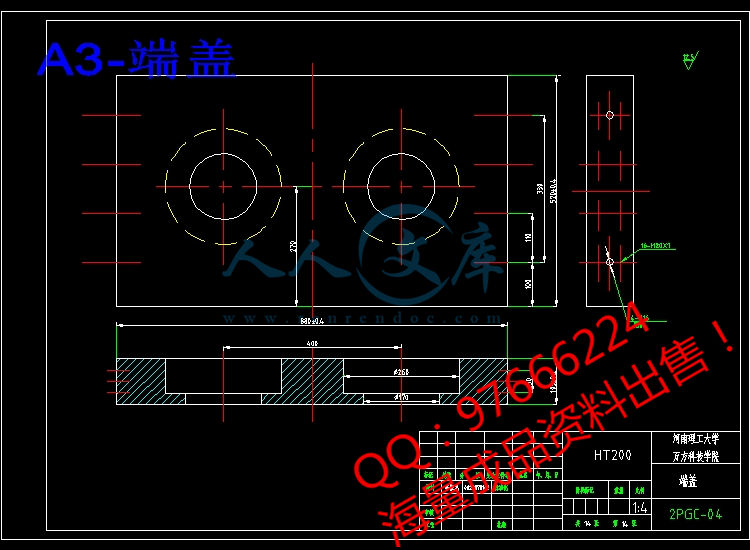

3.5 破碎机的总体结构设计……………………………………………………54

4、绿色设计…………………………………………………………………………57

4.1 绿色设计产生的背景………………………………………………………57

4.2绿色产品的定义和特点……………………………………………………57

4.2.1绿色产品的定义…………………………………………………………58

4.2.2绿色产品的特点…………………………………………………………58

4.3绿色设计的主要内容和设计原则…………………………………………59

4.3.1设计内容…………………………………………………………………59

4.3.2设计原则…………………………………………………………………59

结论 …………………………………………………………………………………60

致谢 …………………………………………………………………………………61

参考文献 ……………………………………………………………………………62

外文资料与中文翻译 ………………………………………………………………63.

摘 要

国内目前原煤的破碎一般采用锤式破碎机或齿辊式破碎机。锤式破碎机是以高速运动的锤头打击物料,在破碎腔内受到相互破碎冲击和剪切。齿辊式破碎机是在齿的作用下对物料进行劈碎,破碎后的物料直接排出,因此破碎粒度比较均匀。目前的双齿辊破碎机由于整体结构的不合理和破碎齿磨损快不能修复等原因,使用效果大大降低甚至很差。

我所设计的新型双齿辊破碎机是在吸取国内外先进技术的基础上研制和设计出来的破碎机,很有发展前景和市场前景。通过资料收集、整理和设计,我设计的双齿辊破碎机完成了。通过对资料的搜集、查找,我找到了很多对设计有用的参考资料,从而保证了设计的顺利进行。这次设计是对我大学四年所学知识的一次综合检验和全面总结。在这个过程中我学会了独立思考、在实践中找答案、在前人的基础上求创新。

关键词:双齿辊破碎机 破碎 设计 Abstract

Domestic current coal is broken generally using hammer breakers or toothed roll breakers. Hammer breakers is based on the high speed movement of the hammer and blow materials which is broken by impact and shear in crushing cavity.Toothed roll breakers chop materials by teeth action,then immediatly output.So its particle is well-distributed.Current toothed roll breakers is very bad in using effects because the whole structure is unreasonable and teeth is wearing out very fast.

New double toothed roll breakers which is designed by me absorb developed technology which is developed and designed as breakers.It has a bright vista in development and maket.Double toothed roll breaker which I designed is complete by collect and tidy data.I found many useful information through find and collect and guarantee the developing of design.This design is a composite test for my university knowledge.I learnt think by myself found answer in practice and created something new based on former.

Key words:double toothed breaker crush design

川公网安备: 51019002004831号

川公网安备: 51019002004831号