组合机床主轴箱及夹具设计

摘 要:根据设计任务书的要求,本设计说明书针对连杆大小头双端面铣削组合机床的设计及专用夹具设计进行说明。主要内容包括组合机床工艺方案的制定、组合机床配置型式的选择、组合机床总体设计以及主轴箱设计。

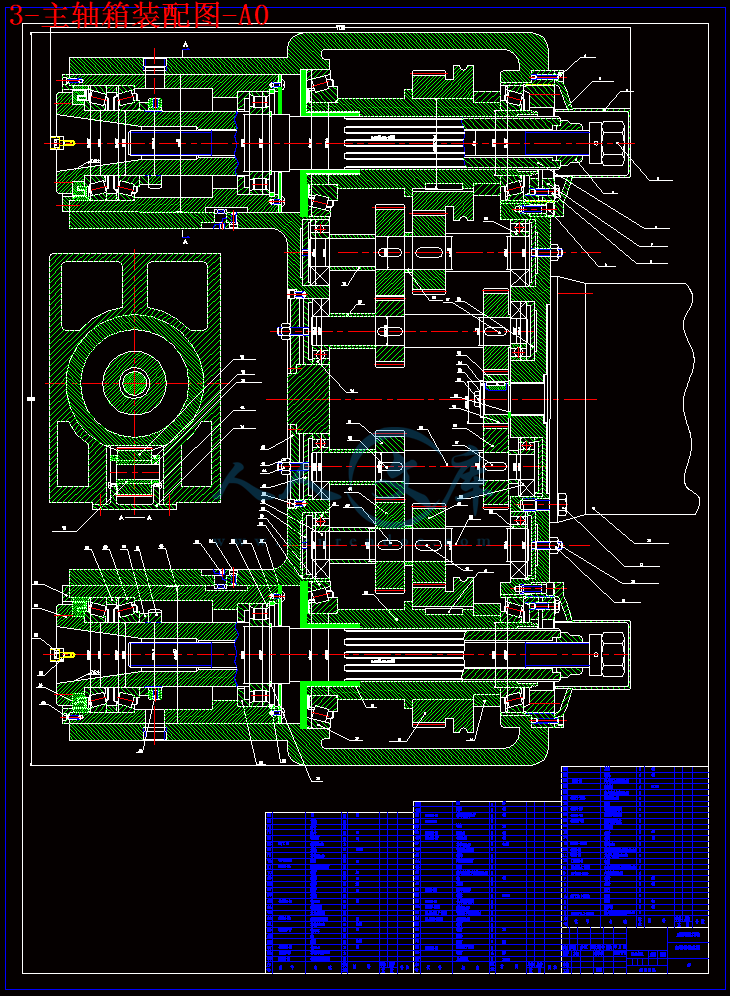

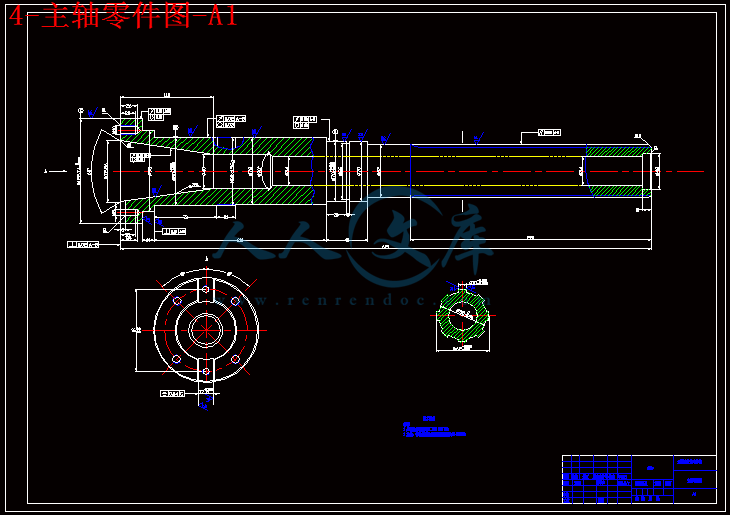

全文主要包括组合铣床的总体设计和主轴箱设计两部分。机床总体设计主要是在选定工艺方案并确定机床配置形式、结构方案基础上确定“三图一卡”,主轴箱设计根据“三图一卡”,整理编绘出主轴箱原始依据图,重点分析传动系统,经过各种方案的比较,最后确定最优方案。此外,为了提高劳动生产率,降低劳动强度,保证加工质量,需设计专用夹具。

关键词:主轴箱;组合机床;夹具

Combination Machine Tool Spindle boxes and fixture design

Abstract:According to designs the project description the request,This design instruction booklet carries on the explanation in view of the connecting rod reducing socket double face milling aggregate machine-tool design and the unit clamp design. Main content including aggregate machine-tool craft plan formulation, aggregate machine-tool configuration choice, aggregate machine-tool system design as well as headstock design.

The full text mainly includes combines the milling machine the system design and the headstock designs two parts. The engine bed system design mainly is in the designation craft plan and the determination engine bed disposition form, in the structure plan foundation determined "a three charts card", the headstock design basis "a three charts card", reorganizes the compilation to leave the headstock primitive basis chart, the key analysis transmission system, passes through each kind of plan comparison, finally determines the most superior plan. In addition, in order to enhance the labor productivity, reduces the labor intensity, guaranteed the processing quality, must design the unit clamp.

Keyword:headstock ;aggregate machine-tool;jig

目 录

第一章 绪 论………………………………………………………………………1

1.1 组合机床的特点………………………………………………………………1

1.2 组合机床的分类和组成……………………………………………………………………1

1.3组合机床的方案选择………………………………………………………………………2

第二章 组合机床总体描述………………………………………………………3

2.1 组合铣床工艺方案的制定…………………………………………………… 3

2.2 确定切削力、切削功率………………………………………………………4

2.3 组合机床配置型式的选择…………………………………………………… 5

2.4影响总体布置的因素………………………………………………………… 5

2.5组合铣床的总体分析——三图一卡………………………………………… 6

2.5.1被加工零件工序图…………………………………………………………6

2.5.2 加工示意图……………………………………………………………… 7

2.5.3组合机床联系尺寸图………………………………………………………10

2.5.4 生产率计算卡………………………………………………………………11

第三章 组合机床主轴箱设计……………………………………………………12

3.1主轴箱设计的原始依据………………………………………………………12

3.2 运动参数和动力参数的确定…………………………………………………12

3.2.1 传动系统传动比分配………………………………………………………12

3.2.2 计算传动装置的运动和设计参数…………………………………………12

3.2.3齿轮模数的估算及其叫校核………………………………………………13

3.2.4 轴各参数估算及强度校核……………………………………………… 16

3.3主轴箱的坐标计算……………………………………………………………25

第四章 组合机床夹具设计…………………………………………………… 27

4.1 组合机床夹具概述………………………………………………………… 27

4.2 定位支承系统概述………………………………………………………… 28

4.2.1定位支承系统……………………………………………………………… 29

4.2.2夹紧机构…………………………………………………………………… 30

第五章 总 结…………………………………………………………………… 31

致谢……………………………………………………………………………… 32

参考文献………………………………………………………………………… 33

第一章 绪 论

1.1 组合机床的特点

组合机床是由大量的通用部件和少量专用部件组成的工序集中的高效率专用机床。它能够对一种(或几种)零件进行多刀、多轴、多面、多工位加工。在组合机床上可以完成钻孔、扩孔、铣削磨削等工序,生产效率高,加工精度稳定。

组合机床与通用机床、其他专用机床比较,具有以下特点:

(1) 组合机床上的通用部件和标准零件约占全部机床零、部件总量的70~80%,因此设计和制造的周期短,投资少,经济效果好。

(2) 由于组合机床采用多刀加工,并且自动化程度高,因此比通用机床生产效率高,产品质量稳定,劳动强度低。

(3) 组合机床的通用部件是经过周密设计和长期生产实践考验的,又有厂成批制造,因此结构稳定、工作可靠,使用和维修方便。

(4) 在组合机床上加工零件时,由于采用专用夹具、刀具和导向装置等,加工质量靠工艺装备保证,对操作工人水平要求不高。

(5)当被加工产品更新时,采用其他类型的专用机床时,其大部分件要报废。用组合机床时,其通用部件和标准零件可以重复利用,不必另行设计和制造。

(6)组合机床易于联成组合机床自动线,以适应大规模的生产需要。

组合机床常用的通用部件有:机身、底座、立柱、动力箱、动力滑台,各种工艺切削头等。对于一些按循序加工的多工位组合机床,还具有移动工作台或回转工作台。

动力箱、各种工艺切削头和动力滑台是组合机床完成切削主运动或进给运动的动力部件。其中还有能同时完成切削主运动和进给运动的动力头。

机身、立柱、中间底座等是组合机床的支承部件,起着机床的基础骨架作用。组合机床的刚度和部件之间的精度保持性,主要是由这些部件保证。

川公网安备: 51019002004831号

川公网安备: 51019002004831号