摘要

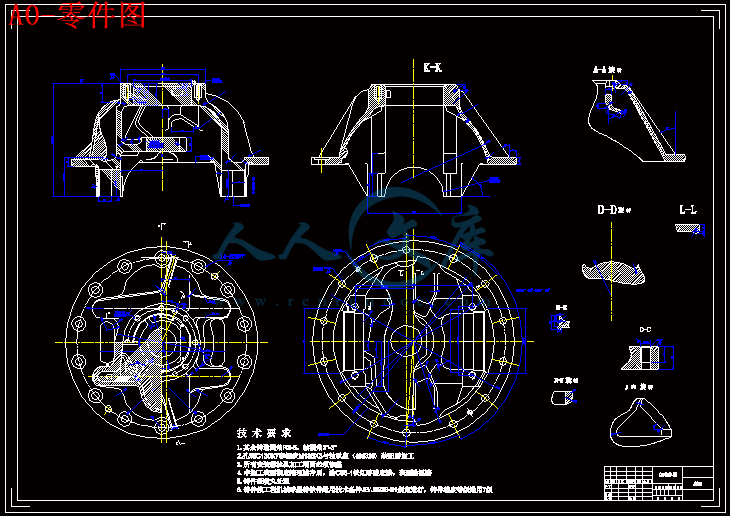

本次设计的题目是404312B后桥托架加工工艺与工艺装备设计

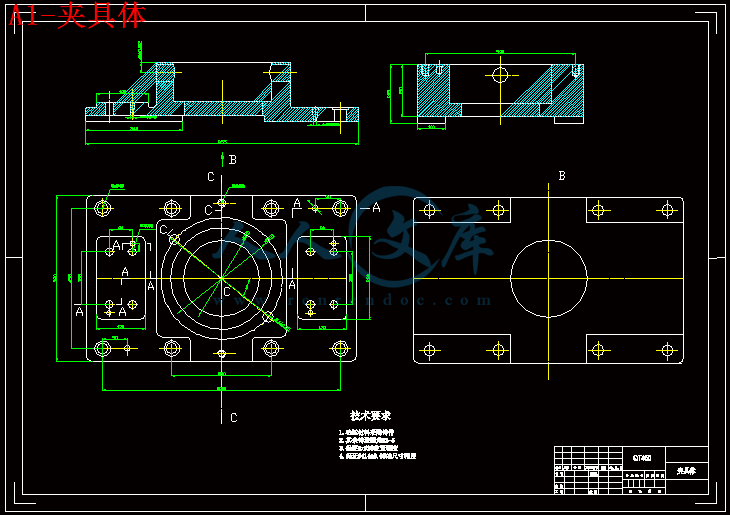

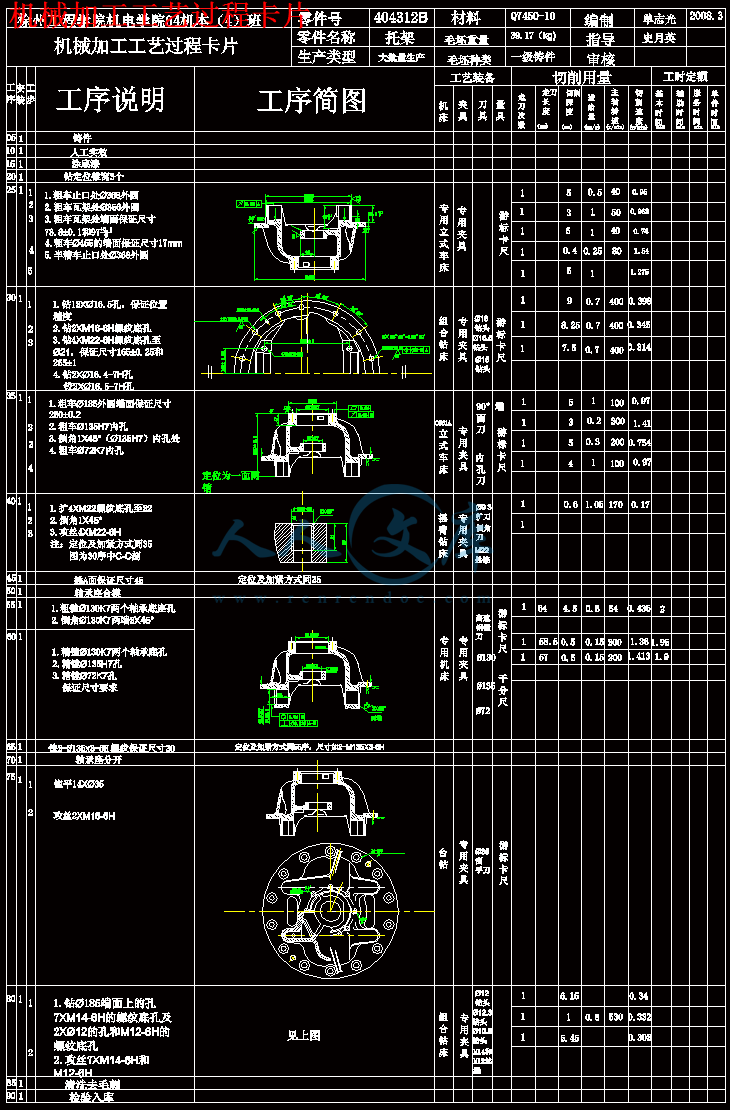

本设计是根据给定的托架零件图及其生产纲领(5000件/年),对同类产品进行调研分析,综合考虑托架零件本身的结构特点,功用,以及加工精度等要求,合理制定其加工工艺规程。对已制定的加工工序,选择其中一道工序设计其专用夹具,本次设计选择精镗孔工序,设计其专用夹具,并绘制工序卡片,夹具总图以及夹具零件图等。

关键字:工序;镗孔;夹具

Abstract

The design is entitled 404312B brackets after the bridge processing technology and process equipment design.

The design is base on a given map of the brackets and parts production programme(5000/year),

The similar products of research , considers itself part of bracket features of the structure, function and accuracy of processing requirements and reasonable development of their processing of a point of order. Has been developed for processing. Choose a design process for its fixture, this design choice fine boring process, the design of their special fixture, and the mapping process card, the fixture plans and fixture pares, and other plans.

Keywords: Working procedure Bore hole Clamp

目 录

绪论1

第一章 零件的分析2

1.1.零件的作用2

1.2.零件的材料及技术要求2

1.3.加工工艺过程分析2

1.3.1.粗基准的选择2

1.3.2.精基准选择原则3

第二章 零件工艺规程设计6

2.1.确定零件的生产类型6

2.2.确定零件的毛坯制造形式6

2.3.制定工艺路线6

2.3.1.工艺过程的安排6

2.3.2.各主要表面的工序安排如下6

2.4.托架工艺路线方案一7

2.5.工艺方案路线二7

2.6.工艺方案的比较与分析8

2.7.确定机械加工余量,工序尺寸及毛坯尺寸8

2.8.确定各工艺装备及切削用量9

2.9.确定粗精镗的工时定额17

第三章 夹具设计19

3.1.概述19

3.2. 设计目的19

3.3.夹具设计的基本要求19

3.4.方案设计20

3.4.1. 夹具体方式的确定20

3.4.2. 定位方式及元器件选择21

3.4.3.夹紧方式及元器件选择22

3.5.主要零件设计的说明26

3.5.1.夹具体26

3.5.2.压紧螺钉26

3.5.3.镗套26

3.5.4.螺柱及定位销27

3.6.定位误差分析与计算27

3.7.夹具的装配要求28

3.8.夹具的操作步骤29

3.9.夹具使用注意事项、保养及维护29

结论30

致谢31

参考文献33

附录34

附录134

附录243

绪论

毕业设计是理工科教学过程中一个实践性的教学环节,它是对学生在校期间所学知识的综合考察,也是对知识转化为能力的实际测验。

毕业设计的主要目的:培养学生综合运用所学的基础理论课,技术基础课和专业课的知识和技能去分析和解决本专业范围内的一般工程技术问题的能力,培养学生建立正确的设计基础,掌握工程技术的一般程序,规范和方法,通过毕业设计进一步巩固,扩大和深化我们所学的基本理论、基本知识和基本技能,提高学生设计,计算,制图,编写技术文件,正确使用技术资料、标准、手册等工具书的独立工作能力,培养学生严肃认真,一丝不苟和实事求是的工作作风,树立正确的生产观点、经济观点和全局观点,从而实现学生向工程人员的过渡。

毕业设计是理论与实践的结合,具有一定的水平,是对即将毕业的进入社会的学生的一次全面的,系统的,目的明确的教学训练,有利于加强和巩固所学的知识,补充一些知识上的不足。

本次设计说明书正文共分三章,第一章是零件的分析,对零件的作用,材料,技术要求及工艺要求进行分析;第二章是零件工艺规程设计,主要确定零件的生产类型,制定工艺路线、确定机械加工余量,工序尺寸,毛坯尺寸,工艺装备及计算切削用量和粗精镗的工时定额;第三章是夹具设计,包括夹具的设计要求,方案设计,夹具主要零件说明,夹具的装配和使用方法,定位误差分析等等。

夹具在机械加工中具有重要的作用,它能保证加工精度,提高产品质量,减轻工人的劳动强度,保证安全,提高劳动生产率,能以优质、高效、低耗的工艺去完成零件的加工和产品的装配。而使用了分度钻的好处在于, 可采用多工位加工,能使加工工序集中,从而减轻工人的劳动强度和提高生产率。

使用夹具的最根本目的是获得好的经济效益。所以设计夹具也和其它技术工作一样,不仅是一个技术问题,而且是个经济问题。每当设计一套夹具之前,都要进行必要的技术经济分析,使所设计的夹具获得最佳的经济效果。

对设计夹具进行经济技术分析时,应从精度设计和结构设计两方面考虑。

在设计过程中,由于组合机床大部分是由标准零件构成,另外一些非标准件尽量适应工厂的生产条件,使加工和维修方便,大大减少了设计工作量。

限于本人知识水平有限,又没有工作的实践经验,本设计中定存在不到之处,敬请老师同学批评指正,提出宝贵意见,以便及时纠正。

川公网安备: 51019002004831号

川公网安备: 51019002004831号