摘 要

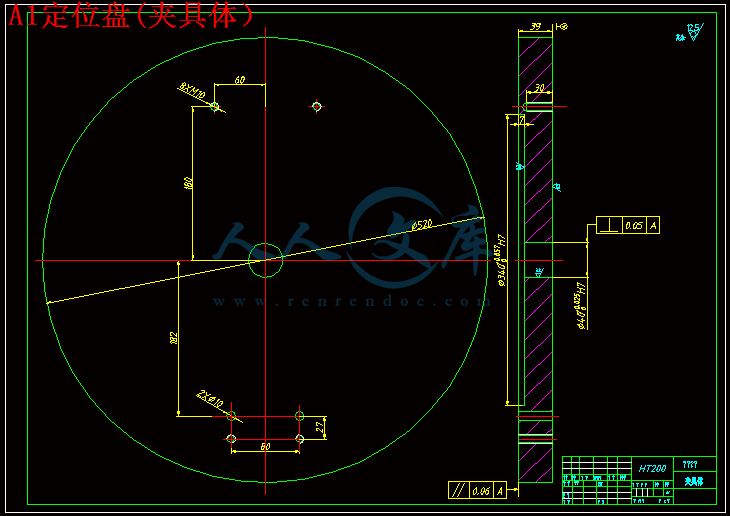

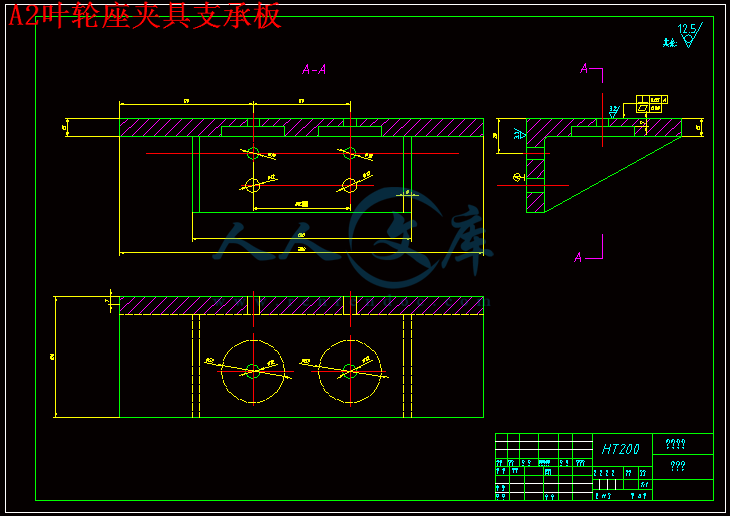

本论文主要研究叶轮座的加工工艺与其专用夹具的设计。根据零件使用要求,分析零件的机械加工工艺性,编制零件机械加工工艺规程,形成全套工艺文件,即工艺过程卡、机加工工艺卡、工序卡;绘制零件图;在制定工艺过程中,要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间。设计叶轮座零件加工的专用夹具,绘制夹具装配图及全套非标零件图,分析夹具的定位精度,切削力、夹紧力。

关键词:加工工艺;专用夹具;全套工艺文件;定位精度

Abstract

This thesis mainly studies the impeller machining process and its special fixture design. According to parts use requirement, manufacturability analysis of machining parts, prepare the parts machining process planning, formed a full range of technology document, namely the process sheet, machining process CARDS, process CARDS; Draw the part drawing; In the process of making process, to determine the installation location of each process step and the work of the process need, locomotives and machine tools in processing the process feed, cutting depth, spindle speed and cutting speed, the process of fixture, cutting tools and measuring tool, and feeding frequency and feeding length, finally calculated the process of basic time, auxiliary time and service time is carried out. Special fixture design of impeller parts processing, fixture assembly drawings and a full range of non-standard parts charting, analysis of fixture locating precision, cutting force, clamping force.

Key words: process; Special fixture; Full set of process documents; Positioning accuracy

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 本课题的研究内容和意义1

1.2 国内外的发展概况1

1.3本课题应达到的要求1

2 零件分析2

2.1 零件作用与分析2

2.2零件的生产纲领与生产类型2

2.3零件的工艺分析2

2.3.1 主要加工面:3

2.3.2主要基准面3

3叶轮座加工的主要问题和工艺过程设计所采取的相应措施4

3.1 确定毛坯的制造形式4

3.2基面的选择4

3.2.1粗基准的选择4

3.2.2精基准的选择4

3.3确定加工工艺路线4

3.4 机械加工余量、工序尺寸及毛坯尺寸的确定6

3.5 确定切削用量9

4专用夹具设计25

4.1零件的加工工艺分析25

4.2定位基准的选择25

4.3定位夹紧方案的确定25

4.4切削力的计算26

4.5定位元件的设计27

4.6定位误差计算27

4.6.1 工件孔与定位心轴的定位误差分析27

4.6.2 一面两销定位误差分析28

4.7夹紧元件的设计30

4.7.1夹紧力的计算30

4.7.2 自锁条件30

4.7.3 斜楔增力特性与升角关系31

4.7.4 斜楔夹紧机构的类型与计算31

5 结论与展望33

5.1 结论33

5.2 不足之处与未来展望33

致 谢34

参考文献35

1 绪论

1.1 本课题的研究内容和意义

本论文研究的是叶轮座零件加工工艺及专用夹具设计。根据零件使用要求,分析零件的机械加工工艺性,编制零件机械加工工艺规程,形成全套工艺文件,即工艺过程卡、机加工工艺卡、工序卡;绘制零件图;在制定工艺过程中,要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间。设计叶轮座零件加工的专用夹具,绘制夹具装配图及全套非标零件图,分析夹具的定位精度,切削力、夹紧力。

叶轮座是泵体的主要零部件之一,其加工精度,不但影响到泵的性能,而且影响到整机运行的平稳性。在普通卧式镗床的工作台上,安装一通用的分度盘,通过中间的通孔定位,用螺栓、压板和螺栓螺母将工件压紧,虽然这种加工方法可以满足设计要求,但由于镗床的对刀不方便,精度不易控制,因此加工效率低,加工成本高。而且利用镗床加工这样小的零件,机床的功能得不到充分发挥,不够经济。所以我们设计了专用工装,便能轻易地在普通车床上完成叶轮座上的孔加工。

川公网安备: 51019002004831号

川公网安备: 51019002004831号