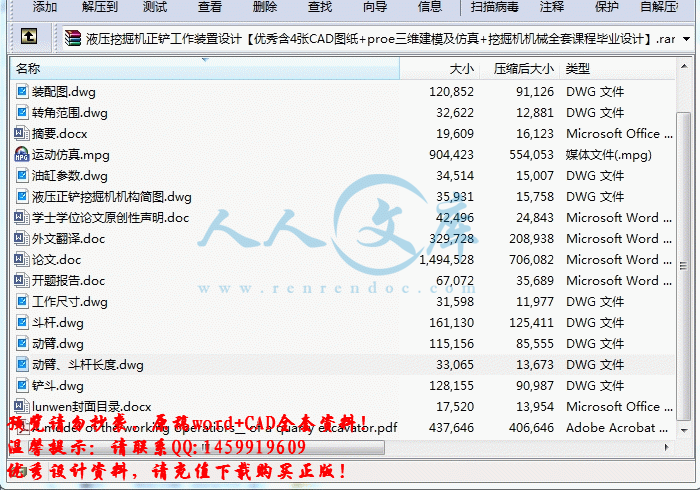

液压挖掘机正铲工作装置设计【优秀含4张CAD图纸+proe三维建模及仿真+挖掘机机械全套课程毕业设计】

【带开题报告+外文翻译】【39页@正文13600字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】

A model of the working operatiors__ of a quarry excavator.pdf

lunwen封面目录.docx

外文翻译.doc

学士学位论文原创性声明.doc

开题报告.doc

摘要.docx

论文.doc

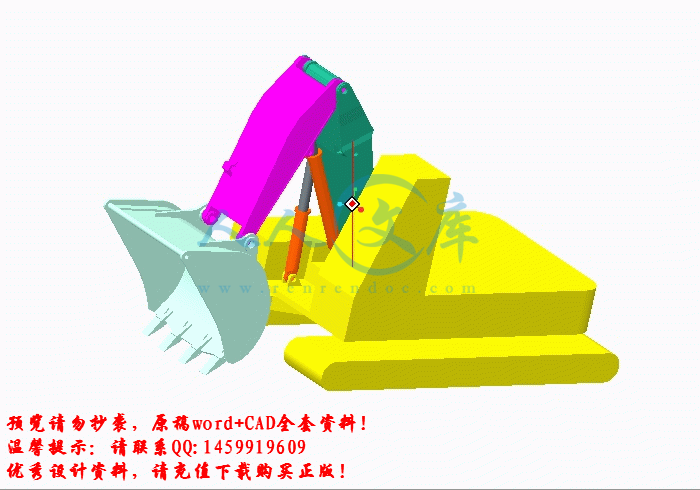

proe三维建模

动臂.dwg

动臂、斗杆长度.dwg

工作尺寸.dwg

斗杆.dwg

油缸参数.dwg

液压正铲挖掘机机构简图.dwg

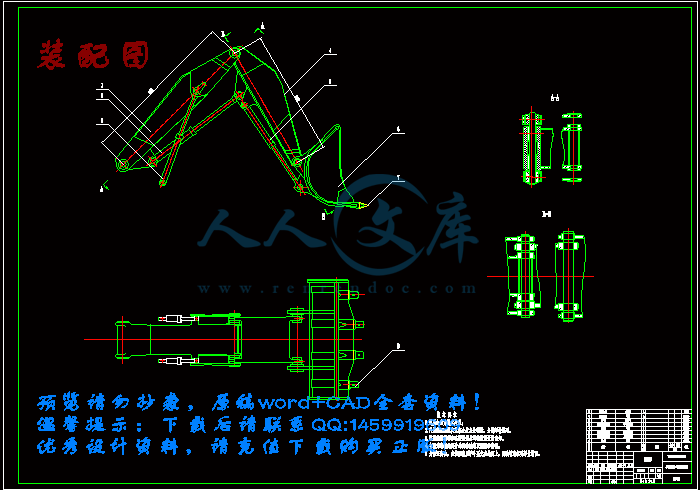

装配图.dwg

设计文档

转角范围.dwg

运动仿真.mpg

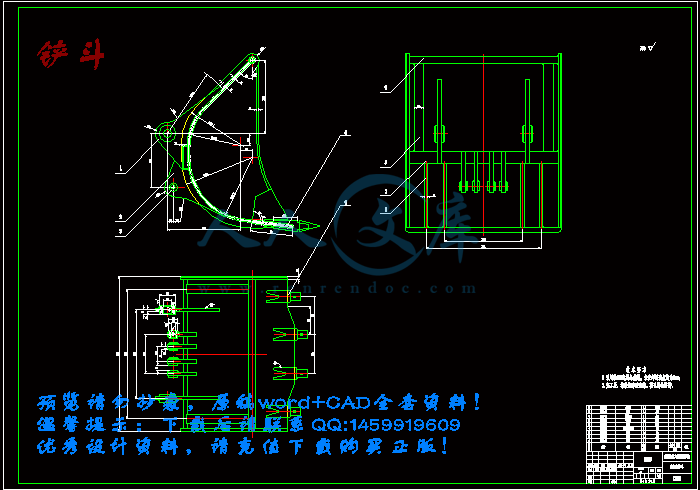

铲斗.dwg

液压挖掘机的的发展及设计

摘要:近年来,随着钢铁业、煤炭业、电力业的持续迅猛发展,挖掘机等工程机械的需求日益增加,并广泛地运用于房屋建筑、筑路工程、水利建设、农林开发、港口建设、国防工事的土石方施工和矿山采掘工业中。由于其作业工况复杂多变,挖掘方式往往是凭借操作者的经验,根据实际作业工况决定,为了减小操作者的挖掘经验对挖掘效果的影响,就迫切需要建立起铲斗挖掘轨迹与各液压缸的直接对应关系,实现挖掘机操作的自动化。同时由于挖掘机的工作环境的复杂性及工况的多变性,就要求液压挖掘机本身结构要根据环境的不同作相应的调整,这就决定了挖掘机设计的平凡性、重复性。然而液压挖掘机的工作装置又是一个多自由度的多杆系统,各铰点的确定非常复杂,这些因素就造成了液压挖掘机的投资大、设计周期长,严重地影响了厂商的经济效益及国民经济的发展。

本文主要的设计工作主要有以下几个方面:在现场测绘及参考有关资料的基础上了解液压挖掘机的工作方式及工作环境。确定液压挖掘机各个工作装置的结构,查找相关资料并结合经验公式对挖掘机工作装置的总体进行设计,用比例法和经验公式计算出工作装置各部分的基本尺寸并对其进行应力分析,然后绘制出其二维CAD图纸,继而用PRO/E画出各装置的三维模型。将各装置装配后对其进行运动模拟仿真。

关键词:挖掘机;工作装置;CAD;PRO/E;运动仿真

The development and design of hydraulic excavator

Abstract:In recent years, as steel, coal industry and quarrying continued rapid development, excavators engineering machinery requirement increasingly, and is widely used in housing construction, road engineering, water conservancy construction, forestry development, port construction, national defense construction and conditions of fortifications mining extraction industryDue to the complex and changeable, mining operation condition is often with operator way according to the actual working experience, decision, in order to reduce homework to excavate the mining experience operator, the effects will is in urgent need to build up the bucket with various hydraulic cylinder dig trajectory direct corresponding relation, realize the automation. Excavator operationAt the same time because of the complexity of an excavator working environment and conditions, requires the fluidity of hydraulic excavator itself according to the different structural environment makes the corresponding adjustment, this determines the excavator design of ordinary sex, repeatability. However hydraulic excavator working device is a much more freedom, the hinge point bar system to determine the very complex, these factors will cause the hydraulic excavator big investment, design cycle is long, the serious influence on the economic benefits of the manufacturers and national economic development.

This paper mainly design work mainly in the following aspects: in the field surveying and mapping and reference on the basis of relevant information about the hydraulic excavator way of working and working environment Determine the hydraulic excavator, each working device search relevant material and structure of practical experience formula of the overall work device for excavators designed, use proportion method and experience calculation work device each part of basic size and carries on the stress analysis, and then plot its two-dimensional CAD drawings, and then painted with PRO/E 3d model of each device. After each device assembly of its motion simulation

Keywords: Hydraulic Excavator; Working device; Boom;Stick;Face-shovel

目录

1 前言1

1.1课题研究的背景和意义1

1.2 液压挖掘机研究现状及发展动态1

1.2.1 国外的研究现状及发展动态2

1.2.2 国内的研究现状及发展动态3

1.3 本文研究的主要内容4

2液压正铲挖掘机工作装置的运动分析5

2.1 液压正铲挖掘机的基本组成和工作原理5

2.2 工作装置结构方案的确定6

2.3 工作装置运动分析9

2.3.1动臂运动分析9

2.3.2斗杆运动分析11

2.3.3斗齿尖的几种特殊工作位置的计算12

3 工作装置尺寸的设计确定15

3.1应用举例15

3.1.2动臂及斗杆长度确定16

3.1.2机构转角范围确定17

3.2 油缸铰点及行程确定17

3.2.1动臂油缸的铰点及行程确定17

3.2.2 斗杆油缸铰点及行程确定17

3.2.3 铲斗油缸铰点及行程确定18

3.3工作装置的位置模型建立18

3.3.1 动臂与平台铰点位置C的确定18

3.3.2 动臂及斗杆长度的确定19

3.3.3 机构转角范围确定19

3.4工作装置油缸铰点及行程确定24

3.4.1动臂油缸的铰点及行程确定24

3.4.2斗杆油缸铰点及行程确定27

3.4.3铲斗油缸铰点及行程确定30

3.5液压正铲挖掘机三维模型32

4 结论33

参考文献34

致谢35

1 引言

1.1课题研究的背景和意义

目前我国露天矿的开采规模逐渐扩大,为了适应日益增大的矿用汽车铲装的需要,这就需要较大斗容的挖掘机,由于挖掘机愈大,每单位土石方的施工成本愈低,而液压挖掘机较机械式挖掘机有很多优点,但是国内对大型液压正铲挖掘机的研究较少,液压挖掘机工作装置是完成挖掘机各项功能的主要构件,其结构的合理性直接影响到挖掘机的工作性能和可靠性,对其研究是整机开发的基础,对工作装置进行优化,目的在于缩短研究和开发周期,降低产品成本,提高设计质量,本课题的任务就在于此[1]。

现代化建设速度,在很大程度上取决于各种工程建设速度,而工程机械水平的高低,又直接对工程建设速度发挥着促进或抑制作用。传统研发管理及设计方法只是被动地重复分析产品的性能,而不是主动地设计产品的参数。作为一项设计,不仅要求方案可行、合理,而且应该是某些指标达到最优的理想方案。随着电子计算机的应用,在机械设计领域内,已经可以用现代化的设计方法和手段进行设计,来满足对机械产品提出的要求。利用优化设计方法,人们就可以从众多的设计方案中寻找出最佳设计方案,从而大大提高设计效率和质量。可靠性是我国工程机械的致命弱点,我们要正视差距,增强科研开发力度,提高技术水平,更多地发展具有自主知识产权的高质量产品,进一步促进工程机械的发展[1]。

参 考 文 献

1.王新中.国内外矿用挖掘机发展状况[J].矿山机械,2004(9):52-53

2.矿用挖掘机发展方向[J].中国矿业报,2002,16(7):255

3.张宏,赵光.从慕尼黑 bauma 展看当今挖掘机技术发展[J],建筑机械化,2007,6:8-10

4.张润利,刘伯颖.工程机械专利信息之小型挖掘机篇[J],工程机械,2006(4):21-26

5.方良周.MX80 液压挖掘机工作装置的仿真与铲斗机构的优化[D].沈阳:东北大学,1996

6.同济大学等.单斗液压挖掘机(第二版)[M].北京:中国建筑工业出版社,1986,12:50-114

7.赵培训.单半液压挖掘机工作机构运动分析参数优化和动态模拟系统的研究[D].西安:西安公路交通大学,1998

8.范进桢,孟宪慧等.挖掘机挖掘作业工程的动力学研究[J].矿山机械,2005,09:39~41

9.史清录,林慕义,康健.挖掘机的最不稳定姿态研究.农业机械学报[J],2004(9): 32~35

10.张石强.正铲液压挖掘机挖掘性能通用分析方法研究[D].重庆:重庆大学硕士学位论文,2006,10

11.冯培恩,陈文平,潘双夏.复杂机械CAD系统开发策略及应用实例[J].机械工程.1989 (4): 6-9

12.潘双夏,冯培恩,郭建瑞,全永新.液压挖掘机智能CAD策略研究.机械工程[J], 1991(10):19-22

13.曹善华.单斗挖掘机[M].北京:机械工业出版社,1988:1-102

14.唐银启主编.工程机械液压与液力技术[M].北京:人民交通出版社,2003,5:85-86

15.(日)村冈虎雄著,李宗国译.油缸[M].北京:机械工业出版社,1974,9:69-72

16.赵应樾.常用液压缸与其修理[M].上海:上海交通大学出版社,1996,2:12-15

17.Serwach Andrzej; Frydlinski Stefan;Jabikowski, etc. Parametric Optimization of the Hydraulic System of the Excavator [J]. Staub-Reinhaltung der Luft, 1974,(30):26-31

19.BRACH I.Hydraulic excavator systematic study of jib/lift cylinder connections.Foerdern Heben.1971, 21(5):56-60

20.Ward Peter, Wakeling Andrew;Weeks Richard,etc.Design Of An Excavator Arm Using Optimization Techniques [J].SAE Technical Paper Series, 1987,(5):64-67

川公网安备: 51019002004831号

川公网安备: 51019002004831号