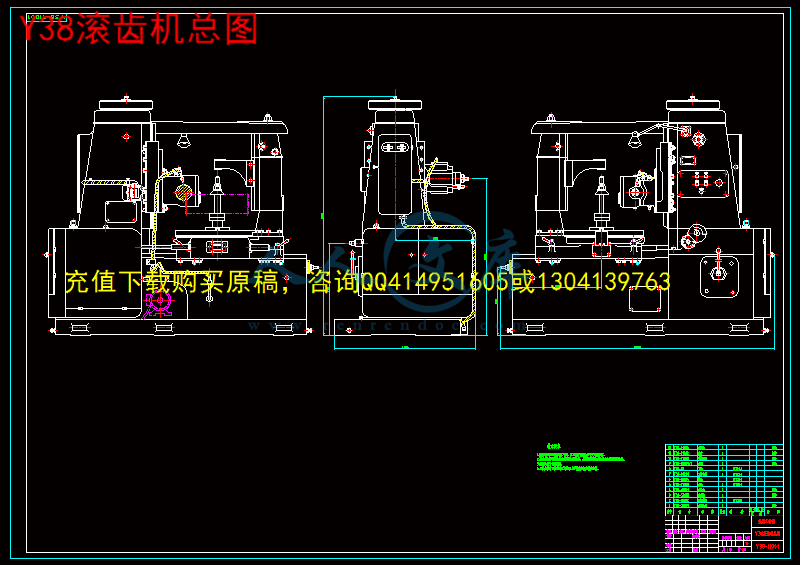

滚齿机床身部件结构设计

摘要:齿轮加工机床是一种技术含量高且结构复杂的机床。滚齿机又是齿轮加工机床中应用最为广泛的一种,滚齿机主要是用于加工圆柱齿轮和蜗轮的。

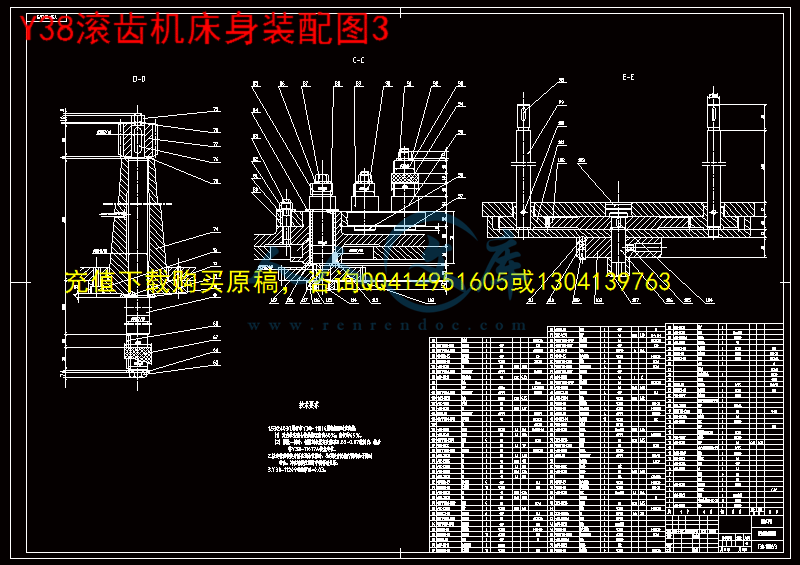

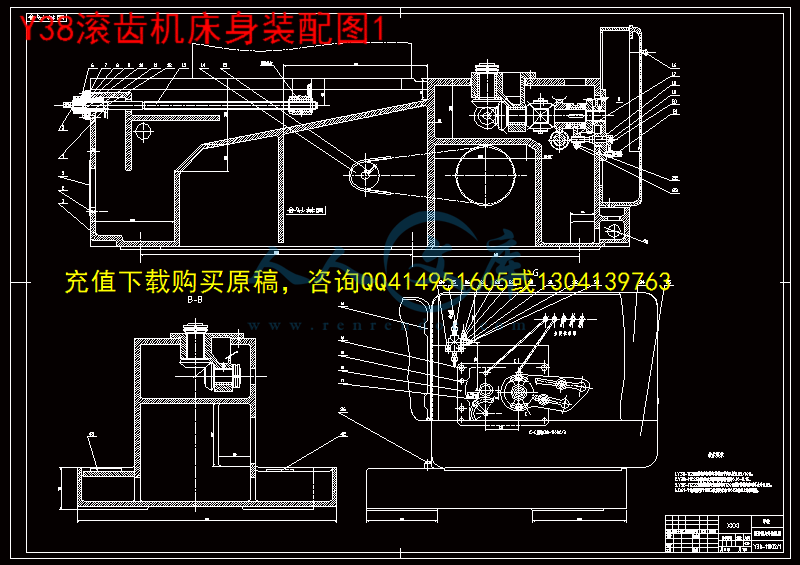

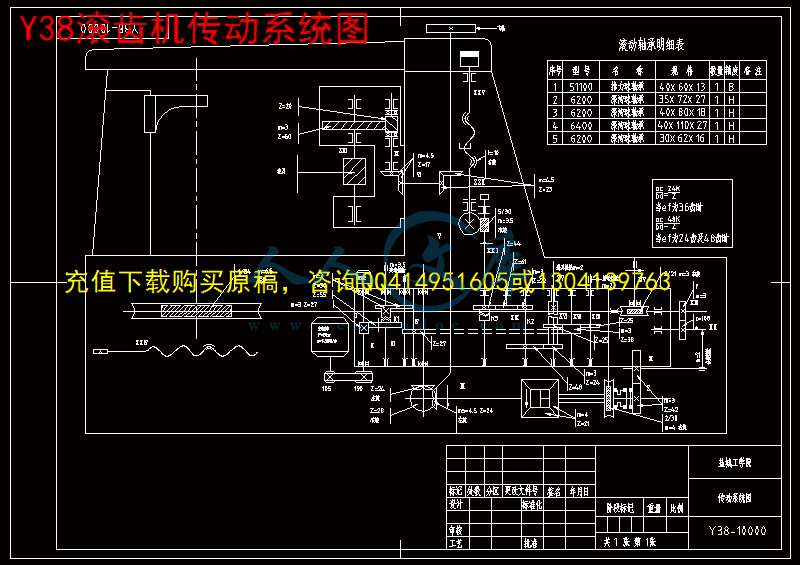

滚齿机床身为箱形结构,与底座铸成一个整体,左上部是方形导轨,留安放工作台之用;右上部是用来固定刀架、立柱;床身内部安装差动机构;床身后端连出分齿挂轮架;背面为主传动牙箱;左面底盘为冷却箱;右面底盘为润滑油箱;主电动机和冷却电动机都安装在床身上,方形导轨中间装一丝杆供移动工作台之用,分度挂轮架处的手柄供铣正齿轮或者斜齿轮时操纵使用。

差动机构是用来加工斜齿轮的,分析了差动机构的组成原理,并进行了相应的设计计算,确定了其结构形状与参数。

这次设计是在传统的设计思路上对原有产品的改造,力求满足强度、刚度、经济性、工艺性等方面的要求。

关键词:滚齿机;床身装配结构;差动机构

Abstract: The gear finishing lathe is one kind of technical content high also the structure complex engine bed. The gear-hobbing machine also is a machine equipment which is applies the most widespread, the gear-hobbing machine mainly is uses in processing the cylindrical gears and the worm gear.

The body of gear-hobbing machine is box shape structure, casts a whole with the foundation upside, the left is the square shape of guide rail, remains places using of the work table; Right upside is uses for the immovable support of the column; The interior of the body installs the differential motion organization; Behind the body is main transmission gear-box; Back transmission is tooth box, in left side of it is a cooling tank; the right side of it is lubricating-oil tank; The main motor and the cooling electric motor all are installed on the lathe bed, among the square shape guide rail installs a lead screw to move the work table, divides the swing frame gear place handle for when milling spur gear or the helical gear operates the use.

The differential device is uses for to process the helical gear, analyzed the differential device composition principle, carried on the corresponding design calculation, and determined its structure shape and the parameter.

This design improves product transformation on the basic of traditional design, makes effort to satisfy the request as intensity, rigidity, efficiency, process.

Key words: Gear-hobbing machine; assembling structure of the body; Differential motion mechanism

目 录

1 前 言1

2 总体设计3

2.1滚齿机工作原理3

2.1.1加工直齿轮时机床的运动和传动原理3

2.1.2加工斜齿圆柱齿轮时的运动和传动原理3

2.2拟定选择传动方案4

2.3 主切削力的估算及电动机的选择8

3 机床床身装配结构设计9

3.1 滚齿机床身的特性9

3.2 滚齿机床身的结构分析9

3.3 床身材料的选择10

3.4 床身导轨及机床的润滑11

4 差动机构设计13

4.1 总传动比的计算13

4.2 传动比的分配13

4.3 设计计算14

4.3.1 螺旋伞齿轮的设计14

4.3.2 运动合成机构设计15

4.3.3差动蜗轮设计16

4.3.4圆柱直齿轮的设计20

5 结束语25

参考文献26

致 谢27

附件清单28

1 前 言

齿轮加工机床是一种技术含量高而且机构复杂的机床系统,由于齿轮使用的量大面广,齿轮加工机床已成为机械等行业的关键设备。特别是,随着汽车行业的高速发展,对齿轮的需求量日益增加,对齿轮加工的效率、质量及加工成本的要求愈来愈高,使齿轮加工机床在汽车、摩托车等行业中占有越来越重要的作用。滚齿机是齿轮加工机床中的一种,其占齿轮加工机床拥有量的40%~50%。它主要用来加工圆柱齿轮和蜗轮等。传统滚齿机在加工过程中有以下特点:

a.滚削钢齿轮时,应用切削液可提高刀具寿命,改善加工表面的质量和利于排出切削热而不致引起机床的热变形;

b.机床漏、混油严重;

c.加工成本高;

d.生产效率低下,加工质量差,难以满足现代企业生产的要求。

近几年,我国在滚齿机设计技术方面研究的主要内容经历了从传统机械式滚齿机通过数控改造发展为2-3轴(直线运动轴)实用型数控高效滚齿机,到全新的六轴四联动数控高速滚齿机的开发。滚齿机加工(钢件)全部采用湿式滚齿方式。目前,国内主要滚齿机制造商重庆机床厂及南京二机床有限责任公司生产的系列数控高效滚齿机已采取全密封护罩加油雾分离器和磁力排屑器的方式部分地解决环保问题。世界上滚齿机产量最大的制造商——重庆机床厂从2001 年开始研究面向绿色制造的高速干切滚齿技术,2002年初研制成功既能干切又能湿切的YKS3112六轴四联动数控高速滚齿机,2003年初又开始研制面向绿色制造的YE3116CNC7高速干式切削滚齿机,即将进入商品化阶段。

川公网安备: 51019002004831号

川公网安备: 51019002004831号