!【详情如下】CAD图纸+word设计说明书.doc[13000字,48页]【需要咨询购买全套设计请加QQ97666224】.bat

28马力轮式拖拉机变速箱设计(有cad图+文献翻译).doc

中英文摘要、目录.doc

农用拖拉机--文献翻译.doc

外文译文.doc

设计开题报告.docx

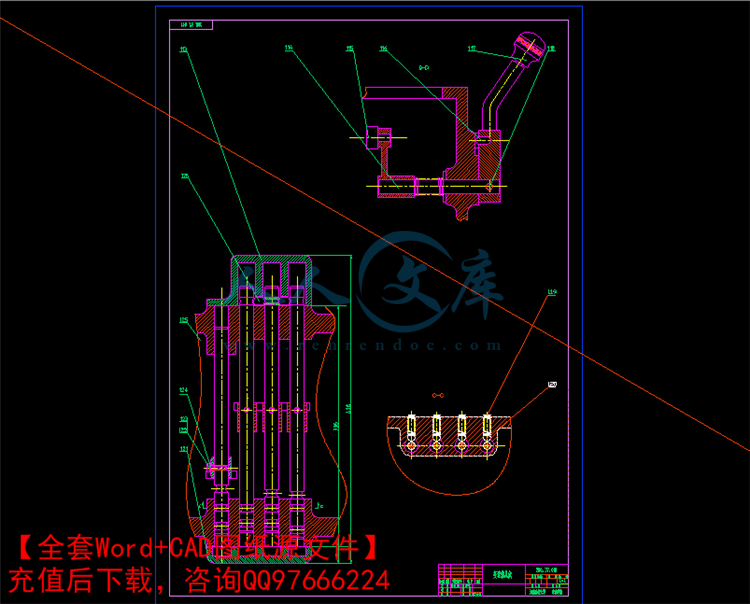

变速箱俯视fd.dwg

总成4.dwg

总成4GAI.dwg

操纵机构.dwg

28马力轮式拖拉机变速箱设计

摘 要

为了获得适合各种农业工作的不同速度和牵引力,我们就必须通过变速箱来降低从发动机传出的较快的转速并将动力传递给驱动装置来行走或作业。在田间或公路运输时要求有较快的行驶速度,但是在田间作业和工程施工时则需要较慢的速度和较大的牵引力。

为了实现这种目的,大部分必要的减速通常通过变速箱总成中的滑移齿轮来实现,进一步的减速则是通过中央传动和最终传动的大、小齿轮的啮合来实现的。在现代的拖拉机中,拖拉机不仅被用来田间作业,还用来搞运输、粉碎饲料等。为了满足不同工况的需要和提高经济性,一般都是多挡位的,本设计采用8个前进挡的设计方案。

对于拖拉机来说,一般变速箱总成都采用直齿圆柱齿轮以降低成本,则用滑移齿轮前后移动与中间轴上齿轮啮合以获得需要的速度。为了满足拖拉机的中耕和其它作业需要,例如耕地、耙地、工程施工等。都需要在设计中设计动力输出装置,通过动力输出轴将从发动机传来的扭矩传到拖拉机后部,以带动各种机具工作。

关键词: 拖拉机, 变速箱, 滑移齿轮, 动力输出轴

TRANSMISSION DESIGN OF 28 HP TRACTOR

ABSTRACT

We must reduce the relatively fast speed of the engine and transmit its power to the driving menbers to obtain suitable speeds and pulling power for the different farm jops. You may want a fst forward speed for hauling form the field or on the highway but a much slower fortions.Aslo,you msut have some means of reversing the direction of rotation of the driving members.

Much of the necessry speed reduction is accomplished by the sliding(speed-changing)gears of the assembly which is ususlly called the “transmission.”Further reduction is secured at the differential and by the final drive pinions and bull gears.In today’s tractors there are still more gear combingations giving more forward speeds; these are needed for the many operations now performed with farm tractors.

You select the speed you want by shifting one of the sliding gears,which are splined to be transmission shaft.With the gear shift lever,you can move then forward or backward;you can mesh any certain sliding gear with it’s mating gear on the counter-shaft.Live power take-off is an asset with many p.t.o.driven machine .

KEY WORDS: tractor, transmission,sliding gears,power take-off

目 录

第一章 前 言1

第二章 结构分析与设计2

§2.1 概述2

§2.1.1变速箱的功用、要求2

§2.2 布置方案的分析与确定2

§2.2.1传动机构的方案分析与确定2

§2.2.2 变速箱零、部件结构分析与确定3

§2.2.3 发动机和轮胎选择6

第三章 变速器主要参数的确定7

§3.1 概述7

§3.2 变速器主要参数的确定7

§3.3 常啮合齿轮参数的确定10

第四章 变速器圆柱齿轮的结构和设计12

§4.1 齿轮的变位12

§4.2 齿轮的强度计算13

第五章 中央传动主要参数的确定16

§5.1 概述16

§5.2 中央传动主要参数的确定16

§5.3 圆柱齿轮的结构与计算17

§5.4 齿轮强度计算18

第六章 最终传动参数的确定20

§6.1 概述20

§6.2 最终传动主要参数的确定20

§6.3 圆柱齿轮的结构与计算21

§6.4 齿轮强度计算22

第七章 轴的校核24

§7.1 概述24

§7.2 轴的强度计算24

§7.3 轴的刚度计算25

第八章 轴承的校核28

§8.1 概述28

§8.2 轴承的校核28

结论30

参考文献31

致谢32

川公网安备: 51019002004831号

川公网安备: 51019002004831号