曲轴搬运上线机械手设计

多关节式工业机械手的设计

五自由度的曲轴搬运上线机械手的设计【优秀含8张CAD图纸+工业机械手全套课程毕业设计】

【带任务书+开题报告+实习报告+外文翻译】【57页@正文26100字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

A3活塞零件图.dwg

UG图

后盖.dwg

回转缸体.dwg

手腕.dwg

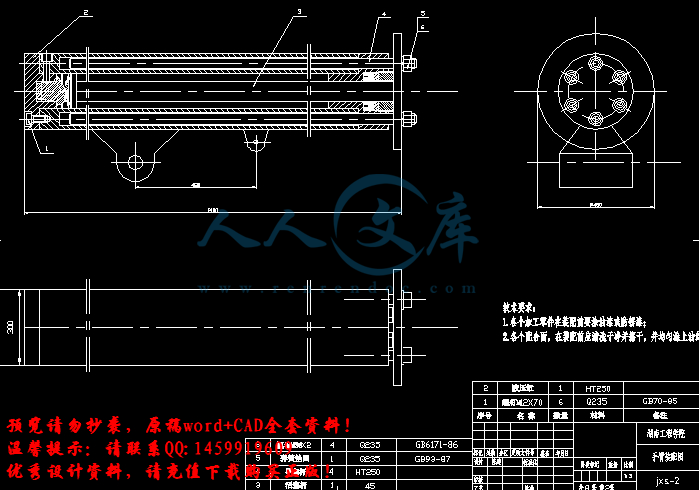

手臂机构图.fdwg.dwg

机械手总装图.dwg

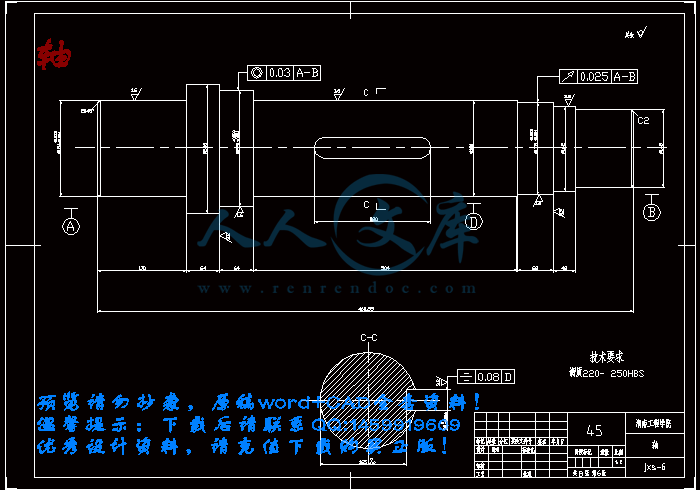

轴.dwg

(A3)活塞杆零件图.fdwg.dwg

任务书.doc

外文文献翻译.doc

实习报告.doc

封面.doc

开题报告.doc

摘要.doc

目 录.doc

说明书.doc

目 录

摘要………………………………………………………………………………Ⅰ

Abstract……………………………………………………………………………Ⅱ

第1章 引言…………………………………………………………………………1

1.1 工业机械手的发展史…………………………………………………1

1.2工业机械手的用途………………………………………………2

1.3 工业机械手的发展趋势………………………………………………3

1.4 机械手的组成…………………………………………………………4

1.5 应有机械手的意义……………………………………………………………6

第2章 总体设计方案及系统组成………………………………………………………7

2.1液压机械手的组成及各部分关系概述………………………………7

2.2 液压力机械手的设计分析……………………………………………7

2.2.1设计要求…………………………………………………………7

2.2.2 总体设计任务分析………………………………………………8

2.2.3 总体方案拟定……………………………………………………8

2.2.4 自动搬运机械手的设计方案论证………………………………9

第3章 机身设计……………………………………………………………………12

3.1机身设计要点…………………………………………………………12

3.2驱动力计算……………………………………………………………12

第4 章 手臂设计…………………………………………………………………14

4.1 手臂设计要点…………………………………………………………14

4.1.1应使手臂刚度大、重量轻………………………………………14

4.1.2应使手臂运动速度 、惯性小…………………………………15

4.1.3手臂动作应灵活………………………………………………16

4.1.4应使手臂传动准确、导向性好…………………………………16

4.1.5 位置精度要求高………………………………………………16

4.2手臂机构的选择与设计………………………………………………17

4.2.1手臂直线运动机构……………………………………………17

4.2.1.1直线运动机构…………………………………………17

4.2.1.2导向装置………………………………………………17

4.2.1.3手臂驱动力计算………………………………………19

4.2.1.4手臂伸缩油伸缩油缸的设计计算……………………19

4.2.2手臂回转运动机构……………………………………………19

4.2.2.1只含回转缸一种缸体的机身机构……………………19

4.2.2.2回转缸置于升降之下的机身结构……………………19

4.2.2.3臂部回转运动驱动力矩的计算……………………19

4.2.3手臂俯仰运动机构……………………………………………20

4.2.3.1驱动力矩的计算……………………………………20

4.2.3.2俯仰摆动缸驱动力计算……………………………21

第 5章 手腕设计………………………………………………………………22

5.1手腕回转结构…………………………………………………………22

5.2 手腕驱动力矩的计算…………………………………………………22

第 6 章 手部的设计计算 …………………………………………………………24

6.1手指夹紧缸驱动力计算………………………………………………24

第 7章 主要液压元件的设计计算 ………………………………………………26

7.1 液压缸的计算…………………………………………………………26

7.2 油泵的选择论证………………………………………………………26

7.2.1 油泵的工作压力计算…………………………………………27

7.2.2 油泵流量计算…………………………………………………27

7.2.3 油泵电机功率计算……………………………………………27

第 8章 液压缸的设计计算………………………………………………… 29

8.1 液压缸内径的设计计算……………………………………………29

8.1.1 液压缸主要尺寸的计算…………………………………………29

8.1.2 液压缸筒壁厚的设计计算………………………………………31

8.2 液压缸主要零件的结构材料及技术要求……………………………32

8.3 液压缸活塞缸的校核…………………………………………………33

8.3.1 活塞缸的强度校核………………………………………………33

8.3.2 活塞缸的弯曲稳定性校核………………………………………34

第 9章 液压系统的设计…………………………………………………………36

9.1 液压系统设计…………………………………………………………36

9.2 拟定液压系统原理图…………………………………………………36

9.2.1 基本回路的选择………………………………………………36

9.2.2液压阀的选择…………………………………………………37

9.3机械手液压系统图及特点……………………………………………38

9.4 液压系统电磁铁动作表………………………………………………39

9.5 液压系统的特点………………………………………………………41

第 10章 控制系统的设计…………………………………………………………42

10.1 PLC的工作原理………………………………………………………42

10.2控制面板设计………………………………………………………42

10.3硬件选择……………………………………………………………43

10.3公用程序编写………………………………………………………42

10.4手动程序和自动程序………………………………………………43

10.5自动控制程序的输出电路……………………………………………44

小结…………………………………………………………………………………47

参考文献……………………………………………………………………………48

致谢…………………………………………………………………………………49

附录 …………………………………………………………………………………50

摘要

本文将设计一台五自由度的曲轴搬运上线机械手,目的是为了提高曲轴加工过程中的劳动生产率,实现机械加工的自动化。根据机械手的工作要求和结构特点,进行了机械手的总体设计,确定了机械手的外形尺寸和工作空间,拟定了机械手各关节的总体传动方案,采用可编程控制器( PLC) 对其液压驱动装置进行顺序控制,实现了系统的自动化。该设计提高了加工的自动化程度,全部机械设计采用了等强度、可靠性设计方法,初步达到了高效低成本生产加工的目标。

关键词:机械手;曲轴; 顺序控制

ABSTRACT

In this paper, the design of a crankshaft of the five degrees of freedom manipulator handling on-line in order to improve the process of the crankshaft labor productivity, to achieve the automation of machining. According to the work manipulator and structural characteristics of the requirements for the design of the mechanical hand, determine the size of the robot and work space, the development of a manipulator of the overall transmission of the joint program, the use of programmable logic controller (PLC) of its hydraulic-driven sequential control devices to achieve automation of the system. The design increased the degree of automation for processing all the mechanical design, such as intensity of use, reliability design method, the initial reach of a highly efficient production and processing of low-cost objectives.

Keywords: Manipulator; Crankshaft; sequence control

第1章 引 言

机械手(mechanical hand)也被称为自动手(auto hand)。工业机械手(简称机械手)是近代自动控制领域中出现的一项新技术,并已渐成为现代机械制造系统中的一个重要组成部分。这种新技术发展很快,逐渐形成一门新兴的学科——机械手工程。

机械手之所以迅速发展还因为它的积极作用日益为人们所认识:其一、它能部分的代替人工操作;其二、它能按照生产工艺的要求,遵循一定的程序、时间和位置来完成工作的传送和装卸;起三、它能操作必要的机具进行焊接和装配。从而大大地改善工人的劳动条件,显著提高劳动生产率,加快实现工业生产机械化和自动化的步伐。因而,受到各先进工业国家的重视,投入大量的人力物力加以研究和应用

工业机械手是在自动线上搬运物料的一种自动化装置。其工作对象是将物料从生产线上转运到下道工序或存放位置。 主要完成以下几个动作:下降一旋转一抓取并夹持物料一旋转一上升一松开并放置物料。

1.1 工业机械手的发展史

早在三国时代,诸葛亮发明的木牛流马即是古代中国人的智能结晶。随着近代的工业革命,机器产业的不断发展成为近代工业的主要支柱。由于科学幻想所系的“永动机”、太空探险以及梦想解决人的机能所无法达致境界的求新意念,推动科学家想研究创造出种种能够代替人的机械。上世纪六、七十年代的自动化机器、无人操纵的飞行器等等,即是此产业发展链条上的一个大胆的尝试与突破。

机械手首先是从美国开始研制的。1958年美国联合控制公司研制出第一台机械手。它的结构是:机体上安装一回转长臂,端部装有电磁铁的工件抓放机构,控制系统是示教型的。

参 考 文 献

[1] 天津大学工业机械手编写组.工业机械手设计基础.天津:天津科学技术出版社,1980.8.

[2] 梁利华.液压传动与电液伺服系统.哈尔滨:哈尔滨工程大学出版社,2005.

[3] 李慧勇,张竺英.水下机械手运动学逆解的一种优化解法[J].机床与液压,2003.

[4] 杜志俊.工业机器人的应用及发展趋势.机械工业出版社,2002.

[5] 张效祖.工业机器人的现状与发展趋势.世界制造技术与装备市场,2004.

[6] 朱浩翔.工业机器人及其应用.装备机械,2003.

[7] 杨化书,曲新峰.工业机器人技术的应用及发展黄河水利职业技术学院.学报,2004.

[8] 刘庆潭.材料力学.北京:机械工业出版社,2003.2.

[9] 孔庆华,刘传绍.极限配合与测量技术基础.上海:同济大学出版社,2002.2.

[10] 濮良贵,纪名刚.机械设计.北京:高等教育出版社,2001.6.

[11] 方昌林.液压、气压传动与控制.北京:机械工业出版社,2000.

[12] 何存兴.液压传动与气压传动.武汉:华中科技大学出版社,2000.

[13] 章宏甲,黄谊,王积伟.液压与气压传动.北京:机械工业出版社,2000.

[14] 张铁,谢存禧.机器人学.广州:华南理工大学出版社,2001.4.

[15] 张福学.机器人技术及其应用.北京:电子工业出版社,1999.

[16] 朱世强,王宣银.机器人技术及其应用.杭州:浙江大学出版社,2006.

[17] 王知行,刘延荣.机械原理.北京:高等教育出版社,2000.

[18] 钟约先.机械系统计算机控制.北京:清华大学出版社,2001.4.

[19] 宗光华 等.机器人的创意设计与实践.北京:北京航空航天大学出版社,2004.2.

[20] 大连组合机床研究所.组合机床设计.北京:机械工业出版社,1978.2.

川公网安备: 51019002004831号

川公网安备: 51019002004831号