专用机床铣削头ZX32的设计

ZX32专用机床铣削头的设计【优秀含8张CAD图纸+专用机床全套课程毕业设计】

【带任务书+开题报告+中期检查表+文献综述+外文翻译】【33页@正文11800字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

专用机床铣削头ZX32的设计任务书.doc

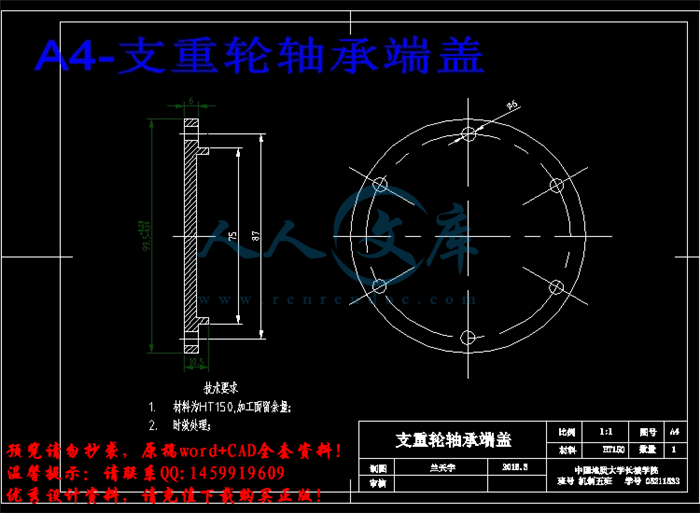

图纸

外文翻译300字符.docx

中期检查.doc

开题报告.doc

摘要.doc

文献综述.docx

正文.doc

摘 要

任务书

毕业设计题目专用机床铣削头ZX32的设计

毕业设计主要内容和要求:

综合运用所学工程图学、理论力学、材料力学、机械原理、机械设计、金属工艺学、公差与测量、金属材料、机械制造基础、AutoCAD等课程的知识,设计组合机床铣床所用ZX32铣削头。

所设计ZX32铣削头可与大一规格的HJ40机械滑台或HY40液压滑台配套使用,完成对铸铁、钢及有色金属的平面铣削。铣削精度达到表面不平度0.03/500,表面粗糙度为;为了调整对刀,主轴滑套调整量为70毫米;滑套夹紧机构为手动;切削满负荷时刀盘直径为Ф200mm,主轴与铣刀盘联接尺寸为Ф128.57mm;该铣削头ZX32能与其相应的齿轮传动装置ZX32A-F41、皮带传动装置ZX32A-F42配套使用。

设计并绘制铣削头的总图及重要零件的工作图。

毕业设计主要参考资料:

[1]、孙小平.机械制造基础.北京 国防工业出版社,1998

[2]、符炜.切削加工手册.湖南 湖南科学技术出版社,2003

[3]、陈璧光.金属切削理论与实践(中册、下册).北京:北京出版社,1985

[4]、清华大学工程图学及计算机辅助设计教研室.机械制图(第四版).北京:高等教育出版社,2000

[5]、梁熙正.工业机械及设备(第二版).北京:中国轻工业出版社,2000

[6]、李建功.机械设计(第四版).北京:机械工业出版社,2007

[7]、西北工业大学机械原理及机械零件教研室.机械原理(第七版).北京:高等教育出版社,2006

[8]、于永泗、齐民.机械工程材料(第七版).北京:大连理工大学出版社,2007

[9]、刘鸿文.材料力学(第四版).北京:高等教育出版社,2003

[10]、哈尔滨工业大学理论力学教研室.理论力学.北京:高等教育出版社,2002

[11]、王先逵.机械制造工艺学(第二版).北京:机械工业出版社,1995

[12]、唐增宝、常建娥.机械设计课程设计(第三版).武汉:华中科技大学出版社,2006

[13]、汪星桥.机床设计手册.北京:机械工业出版社,1986

[14]、冯之敬.机械制造工程原理.北京:清华大学出版社,1999

[15]、王知行.机械原理.北京:高等教育出版社,2000

[16]、吴宗泽.机械设计课程设计手册.北京:高等教育出版社,1992

[17]、胡凤兰.互换性与技术测量基础.北京:高等教育出版社,2005

[18]、Zhu Y, Zhang S, Rong Y.Experimental Study on Stiffness of T-Slot Based Modular Fixure. Transaction of NAMRI/SME, Volumn X XI,1993

[19]、Gere J M, Timoshenko S P. Mechanics of materials.Second SI Edition.New York: Van Nostrand Reinhold,1984

毕业设计应完成的主要工作:

设计并绘制专用机床铣削头ZX32的总图及重要零件的工作图;编写其设计说明书。

毕业设计进度安排:

序号毕业设计各阶段内容时间安排备注

1查阅资料,完成开题报告;2014.12.10—2015.1.20

2外文资料阅读,完成英文翻译; 2015.1.21—2015.2.10

3熟悉有关的资料,完成文献综述;20105.2.11—2015.2.25

4拟定总体方案2015.2.26—2015.3.10

5设计并绘制铣削头总图2015.3.11—2015.3.25

6设计并绘制铣削头重要的零件图2015.3.26—2015.4.20

7整理资料,编写设计说明书;准备答辩。 2015.4.21—2015.5.11

专用机床铣削头ZX32的设计

社会在不断发展的过程中对各种行业的发展需求也有了新的认识若要满足机械制造业下现在发展那么快的情况下,一些新型机床的品种也变得越来越多;其中就包括效率比较高的自动化机床和适应性比较强的特种加工机床;各大新型的难加工的材料无疑离不开机床,其中机床上的零部件所使用的铣削头是专用机床的相对比较复杂和重要的我们通过研究铣削头的结构设计对我们对未来的学习很有帮助,与此同时也会有很大的积极意义。

这篇文章再通过专用机床铣削头ZX32传动系统的结构设计的过程中,计算出了设计所需的传动比,结构式相对比较简单,对完成铣削头齿轮传动设计及轴的结构设计有了一个初步的了解和认识,通过大量的计算说明来分析齿轮的模数;并以此确定铣削头尺寸及设计传动路线。完事之后必须进行一系列的检验,验算传动轴的直径,齿轮模数,如果可以的话,也把刚度求出来。文章很顺利的完成了铣削头结构设计,通过软件的辅助制了完整的图纸。我们研究的课题在很大程度上对铣削加工有了新的理解和突破。

关键词:专用机床; 铣削头; 齿轮传动; 结构设计

ABSTRACT

Special Machine Milling Head?ZX32 Design

Society in the process of growing demand for the development of various industries and a new understanding to meet the mechanical manufacturing industry developing so fast, now under some new machine varieties also become more and more; Including high efficiency automated machine tools and adaptability is strong special machine tools; The new type of difficult-to-machine materials will surely leave the machine tool, the machine tool are the components of the milling head used on the dedicated machine tools is relatively complex and important we through the research of the structure of milling head design of our study is very helpful for the future, at the same time also can have a lot of positive significance.

This article through design of special-purpose machine tools milling head ZX32 transmission system in the process of the required transmission ratio, calculated the design formula is relatively simple, to complete the milling head and shaft structure design of gear transmission design have a preliminary understanding and the understanding, to analyze gear modulus is illustrated through a lot of computation; And to determine the milling head size and design of transmission line. Done to carry out a series of inspection, check the diameter of the shaft, gear modulus, if you can, and the stiffness out. The article very smoothly completed the milling head structure design, through software of auxiliary system, a full set of drawings. Our research topic in the very great degree of milling has a new understanding and breakthrough.

Keywords:Design of special?milling; machine?head; gear?transmission structure

目 录

摘 要II

ABSTRACT0

1 绪论1

1.1 机床的地位及发展1

1.2组合机床的重要性2

1.3 本课题的目的、内容3

1.3.1设计的目的3

1.3.2设计内容3

2 组合机床铣削头主传动设计3

2.1确定结构型式3

2.2 确定传动比4

2.3 确定各齿轮的齿数4

2.4 传动系统图的拟定5

3铣削头电动机的选择6

3.1 电动机的功率计算6

3.2 电动机参数的选择7

4.铣削头齿轮传动的设计计算7

4.1 模数的估算7

4.2齿轮分度圆直径的计算9

4.3齿轮宽度的确定9

4.4齿轮其他参数的计算9

4.5齿轮结构的设计9

4.6齿轮的校核10

5 铣削头轴的设计计算10

5.1各传动轴轴径的估算10

5.2 各轴段长度值的确定12

5.3 轴的强度校核与刚度12

5.3.1轴的强度校核12

5.3.2主轴材料的选择17

5.3.3主轴结构的确定17

5.3.4主轴的刚度验算17

6专用机床铣削头的总体结构设计25

7 结 论27

致 谢29

1 绪论

1.1 机床的地位及发展

在现在的社会发展中,各种机械装备都有了新的变化,人们对经济、高效的生产有了新的要求,从而哎后续的生产中我们会对工具的使用和高新技术的使用有了新的看法,为了研究和创造出更好的技术设备和加工设备,我们进行了大量的更新,例如我们必须具备各种金属加工零件设备,这些设备在使用的过程中都是很重要的,在锻造、铸造、冲压、焊接等加工方式中有了最大的改进,因为机械零件的尺寸精度、形状精度和表面粗糙度,都是一个严重的指标;这些都是金属切削加工所要求的,特别是形状相对比较复杂、精度比较高和零件表面粗糙度的要求并不是很高的一些加工零件,某些加工工艺不能再一步工部中就能完成,也可能需要很多步;因此在现代机械制造业中机床相对于其他的来说是最重要的加工机械设备了。在比较普通的机械加工厂里,我们通过对机床的机床加工工作量进行分析,大约承担了约为总工作量的百分之五十左右,这些在某种程度上会直接影响机械产品的加工质量和技术要求;毫不夸张的说:假如我们国家的机床没有多好的发展,将很可能不具有今天这样结构那么多的、种类那么多的改变。

国家的繁荣发展离不开机械的大发展,实现工业、农业、国防和科学技术的现代化才是国家的发展指标,这也是社会进步所必须的。在无形中我们对正在发展的制造业不得不加以重视,保证新型的加工设备和技术要求,通过对各种机器、仪器和工具的大力使用。我们清楚的发现了一些重要问题那就是一个现代化的机械制造业必须要有一个现代化的机床制造业做强大的支撑。所以,越来越多的国家也都相当重视本国机床工业的发展,只有这样才能使机床的用途有所提高,从而使我们的国家国民经济的发展进行最大的宏观调控;这些都是建立在坚实可靠的技术提高上的。

机床是进行社会生产和社会实践的必需品,人类在长期生产实践中,越来越发现生产工具在不断的更新;在社会的不断发展中科学技术的进步也慢慢地完善了起来。最原始的好像是木制的,再那个时候一般都是由人力或畜力驱动来所有运动,也可以分为好几种了例如陶瓷制品的泥坯、石料和加工木料,从某种方面来分析看它们并不是一种完整机器。通过研究发现金属机械零件的加工大概是从18世纪中期才开始慢慢发展起来的。在那个时候一些工业最发达的欧美国家也迅速的开始证明自己,开始了从工场手工业向机器大工业生产方式大力涌进,这就需要更多的时间和精力来进行研究,逐渐的推动了机床的快速发展。在以前的那个时候我们发明了车床,在其中带有刀架,这在无意之中开创了由机械代替人手控制刀具运动的最开端,人们用双手的时代过去了,这是一个飞跃的突变,同时也是机床的加工精度和工效的有力保证,在目前现代机床的发展模型也慢慢的有了新的形成。在车床进行大幅度的发展之后,随着机械制造业的发展,慢慢的也陆续被创制出来了其他各种机床。至19世纪快要结束的时候,相继形成了铣床、钻床、拉床、车床、镗床、刨床、磨床、这些机床的相继使用让我们在制造业上有了新的自信心。

参考文献

[1] 《机械设计手册》 机械工业出版社

[2]《实用机床设计手册》 辽宁科技出版社

[3]《机床设计图册》 上海科技出版社

[4]《TTL集成电路手册》

[5]《存储器手册》

[6]《机床主轴变速箱设计指导书》 机械工业出版社

[7]《机床数控系统设计设计指导书》 中国科技出版社

[8]《机电综合设计指导书》 中国人民大学出版社

[9] 原ZJK-7532数控立式钻铣床说明书一套

[10]《数控机床与编程实用教程》 化学工业出版社

[11]《数控铣床设计》 机械工业出版社

[12]《金属切削机床概论》 机械工业出版社

[13]《机械设计课程设计手册》 高等教育出版社

[14]《机电一体化系统设计手册》 国防工业出版社

[15]《金属切削机床设计手册》 机械工业出版社

[16]《机械零件设计手册》 (第二版)(上册) 冶金工业出版社

[17]《机械设计》 濮良贵 主编 (第七版) 高等教育出版社

[18]《数控技术》 王永章、杜君文主编 高等教育出版社

[19]《机床设计手册》 (1-3册) 机械工业出版社 1980年

[20]《单片机原理及应用》 杨恢先主编 国防科技大学出版社

[21]《异步电动机变频调速系统及其应用》邓想珍主编 华中理工大学出版社

[22]《几何量公差与检测》 甘永立主编 (第七版)上海科学技术出版社

川公网安备: 51019002004831号

川公网安备: 51019002004831号