电磁离合器性能测试台设计【8张CAD图纸+毕业论文】【答辩优秀】

收藏

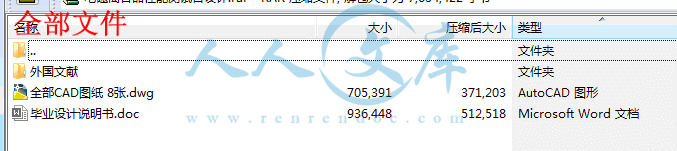

资源目录

压缩包内文档预览:(预览前20页/共36页)

编号:471967

类型:共享资源

大小:3.91MB

格式:RAR

上传时间:2015-08-13

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

45

积分

- 关 键 词:

-

电磁离合器

性能

机能

测试

设计

全套

cad

图纸

毕业论文

答辩

优秀

优良

- 资源描述:

-

目录

第一章 绪论1

1.1电磁离合器概述1

1.2电磁离合器试验台研究的目的和现实意义1

1.3 电磁离合器的结构和工作原理1

1.3.1结构认识(摩擦片式电磁离合器)1

1.3.2动作原理分析2

1.4电磁离合器的作用2

1.4.1 保证机床起步平稳2

1.4.2 方便换档3

1.4.3 防止传动系统过载3

1.5 电磁离合器试验台的研究概况3

1.6 本课题研究的内容4

1.7预计达到的目标4

第二章 电磁离合器性能测试台的总体设计4

2.1 离合器要求4

2.2 一个供研究和考核离合器试验台要求5

2.3 关键理论和技术5

2.4 技术指标5

2.5电磁离合器性能测试台总体方案设计5

2.6 电磁离合器测试台结构特点5

2.7 试验台的工作周期分析6

第三章 电磁离合器性能测试的具体方案7

3.1 温度特性7

3.1.1 电磁离合器温升测量的实现方案7

3.1.2 实验的软件实现方法7

3.1.3系统对环境温度的考虑7

3.2 电磁离合器的转矩特性8

3.2.1静力矩的测定8

3.2.2 测试动力矩8

3.2.3测定空转力矩9

3.3 动作特性9

3.4寿命的测试9

第四章 关键零部件的设计和选取10

4.1 电机的选择10

4.1.1 电机类型选择10

4.1.2 确定电动机的功率和转速10

4.2 轴的设计12

4.2.1轴的材料12

4.2.2 最小轴径的确定13

4.2.3轴的结构设计14

4.3 飞轮的设计15

4.3.1 1飞轮的动力学计算15

4.3.2 飞轮的尺寸设计17

4.4 联轴器17

4.4.1 联轴器类型的选择17

4.4.2 确定联轴器的型号18

4.5 轴承的选择19

4.5.1 滚动轴承的作用19

4.5.2滚动轴承的分类20

4.5.3 滚动轴承类型的选择20

4.6 电磁离合器和制动器的选择20

4.6.1电磁离合器分类20

4.6.2 电磁离合器结构和工作原理21

4.6.3 选择电磁离合器的类型21

4.6.4 电磁离合器的型号及尺寸21

4.6.5 电磁制动器的选择23

4.7 传感器的选择23

4.8 键的选择和校核23

4.8.1 键的类型选择24

4.8.2 键的尺寸选择24

4.8.3 键的校核24

第五章 总结和致谢25

5.1 总结25

5.2 致谢26

第一章 绪论

1.1电磁离合器概述

电磁离合器目前大多是运用于机械的传动系统中,离合器能够实现在机器运转过程中,使主动部分与从动部分随时结合和分离,电磁离合器顾名思义就是通过电磁线圈的驱动实现离合盘的分离与吸和,他有着响应高速,耐久性强,组装维护简单,动作确实,使用操作容易等优点,按工作原理和是否吧离合器浸入润滑油中工作来分,电磁离合器按结构特点来分,可分为磁粉离合器,干式多片电磁离合器,,转差式电磁离合器,湿式多片电磁离合器,转差式电磁离合器。电磁离合器的按工作方式来分又分为通电结合和断电时才结合。

- 内容简介:

-

Materials & Design Materials and Design 28 (2007) 21482153 /locate/matdes Experimental characterization of frictional behaviour of clutch facings using Pin-on-disk machine M. Bezzazi a, A. Khamlichi a,*, A. Jabbouri a, P. Reis b, J.P. Davim b a LMMS, Departement de Physique, F.S.T.T, B.P. 416, Tangier, Morocco b Departamento de Engenharia Mecanica, Universidade do Aveiro, Portugal Received 24 January 2006 Available online 1 September 2006 Abstract During the clutch engagement manoeuvre, sliding contact occurs between the pair of clutch facings mounted on the friction disk and the counter faces belonging to the flywheel and the pressure plate. The transmitted torque is proportional to the overall coecient of friction which depends essentially on temperature, normal pressure load and relative sliding velocity. In this work, performance of the friction coecient is investigated experimentally. Samples of a commercial clutch facings material have been tested using a Pin-on-disk apparatus. When the previous three parameters are preset constant, this machine provides automatic acquisition of friction coef-ficient and wear measurements. The obtained results are compared with the classical SAE J661a standard test. It is found that the actual clutch facings material has good fading resistance and a rather stable coecient of friction once running in phase is achieved. _ 2006 Elsevier Ltd. All rights reserved. Keywords: Composites; Thermal; Mechanical; Friction behaviour; Clutch facings 1. Introduction In a vehicle rotary motion is to be transmitted from the primary shaft (motor) to the secondary shaft (gear box) for intermittent periods only. To achieve that, a clutch is required between these two components. The function of the clutch is to produce a soft gradual increase in the angu-lar velocity of the driven shaft until full coupling between the motor and the gear box is achieved. Then, the clutch must act as a permanent coupling transmitting, from the driving shaft to the vehicle wheels, the entire mechanical power without subsequent slip 1. During dry clutch engagement manoeuvre, a transient sliding contact situation occurs between the pair of clutch facings mounted on the friction disk and the counter faces belonging to the flywheel and the pressure plate. Through- * Corresponding author. Address: 33, Residence Al Ismalia, Avenue des F.A.R., Appt. 15B, Tetouan, Morocco. Tel.: +212 67 79 50 68; fax: +212 39 35 07 02. E-mail address: khamlichi7 (A. Khamlichi). 0261-3069/$ - see front matter _ 2006 Elsevier Ltd. All rights reserved. doi:10.1016/j.matdes.2006.07.001 out this engagement process, heat is generated at the con-tact surface yielding temperature to rise 2. Temperature rise may be very important in case of repetitive engage-ments. Good performances of the clutch facings material such as a stable and suciently high coecient of friction are required in order to operate engagements in an ecient and regular way. Fading phenomenon which is due to a sudden decrease of the friction coecient as function of temperature must be avoided. Variations in time of the fric-tion coecient during the running in phase or due to mate-rial wear must also remain limited. Other factors in addition to temperature might influence the coecient of friction level. They are related to hetero-geneities of the contact surfaces, chemical reactions or physical transformations. But, these mechanisms are both complex and non reproducible. Their eects could be, in practice, globally taken into account through the coe-cient of friction tolerances. To characterize the tribological behaviour of clutch fac-ings, a lot of standard laboratory tests are usually per-formed by the manufacturers: Raybestos tests in case of ntsM. Bezzazi et al. / Materials and Design 28 (2007) 21482153 2149 Europe 3, JIS D-4311 in case of Japan 4 and SAE J661a test in case of USA 5. But, most of these tests are both lengthy and costly. This makes them dicult to use in real research and development operations. So, they should be rather kept to the final stage in order to assess the material commercial specifications. Other basic tests which are more cost eective should be used in order to facilitate more quickly information about fiction and wear behaviours. In case of friction products, the well known FAST test 5 is a quick and inexpensive test. However, it suers from the pathological apparition of glazing eect. This eect is often encountered for polymeric composite materials due to lack of cleaning the friction surface in the FAST test. Apparent glazing has in general nothing to do with real conditions of product working because the friction surface is perma-nently cleaned in real servicing life of friction products. In the special case of metal pairs 6, and PEEK-CF30/ steel 7,8 the Pin-on-disc has proven to be one of the most eective test configurations which allow a reliable and quick determination of coecient of friction and wear. In this work, we have investigated the opportunity to use the Pin-on-disk test in order to study the dry tribolog-ical behaviour of commercial organic clutch facings which are manufactured according to the scatter wound proce-dure. For this purpose, special samples of clutch facings material having the form of disks and special pins made from steel were manufactured. The inverse operating con-figuration in comparison with the habitual technique of using the Pin-on-disk apparatus was chosen in order to per-form the friction and wear tests. These conditions are thought to enable the friction surface cleaning and to avoid artificial glazing. Through this experiment, we have studied the friction coecient behaviour as function of temperature, sliding velocity and sliding distance. Load pressure was kept almost constant. Wear was also measured as function of the previous parameters. The obtained results are presented in the following as charts giving the friction coecient, l, versus the sliding distance when temperature, T, and the sliding velocity, v, are set constant. Qualitative comparison with the classical SAE J661a test is then performed. They show in particular that glazing eect does not occur during testing. The fric-tion product is found to have a stable coecient of friction and does not suer from fading phenomenon. 2. Clutch facing material description 2.1. Clutch facing material formulation and the manufacturing process Organic clutch facings are composites witch are manu-factured in the most common case according to the scatter wound procedure. First a balanced formula is given. This consists of a fibre glass yarn fitted with a copper strip in order to enhance conductivity and to relieve heat evacua-tion from the facing surface during clutch operation. The formula contains also the weight composition of the impregnating mixture which holds in general more than fif-teen raw materials. These materials are bonded by means of a phenolic resin which is put in the impregnant mixture with a proportion of about 30% by weight. The manufacturing steps as described in 5 are as follows: (1) Impregnation. A yarn is placed into an impregnating tank which is filled with the impregnant solution. Vis-cosity is modified by adding organic solvent in order to improve the mixture absorption by yarn. (2) Drain and preliminary bake. Rack of impregnated yarn is lifted from impregnant and allowed to drain in an air circulating oven to remove the extra solvent and to produce a relatively sti yarn. (3) Preforming. This needs an automatic preforming machine and special platens. The dry yarn is forced to form a tracing which enables even distribution of matter over the preform surface. (4) Flat press and final bake. The preform is put into a heated mould and highly pressed during a short cur-ing cycle. Then, rings are stacked in piles on a flat sur-face and under weights to keep flat and placed into an oven during a long and smooth curing cycle. (5) Grinding to thickness and turn and bore. Grinding is done on a double disc grinder. Then the rings are placed on the boring bar in order to have the desired diameters. After all these operations, anti corrosion surface treat-ment of clutch facings is achieved and drilling in accord with a specified drawing can be performed. The clutch fac-ings are then ready to fit a friction disk. 2.2. Clutch facing morphology The clutch facing morphology is in general very hetero-geneous. But it could roughly be defined by the three dimensional tracing achieved by the impregnated yarn dur-ing the preforming operation. Some irregularities may aect the overall yarn tracing due to certain deformations occurring during moulding or because of material removal needed in grinding operations. Yarn tracing results in the actual preforming machine from superposing two basic movements of the pipe: a radial sinusoidal translation with angular frequency x1 and a uniform circular rotation with speed x2, a = x1/x2 defines the preforming ratio. This parameter controls to a large extent the clutch facing morphology. For some given material formulation and for some com-mercial reference application of the clutch facing which corresponds to outer radius Ro, inner radius Ri and thick-ness e, the facing texture depends on how the preform is outfitted. Using polar coordinates (r, h), the location of an arbi-trary point of the yarn tracing is given, as studied in 2, nts2150 M. Bezzazi et al. / Materials and Design 28 (2007) 21482153 Fig. 1. Clutch facing morphology for a = 4.27. by r(t) = Rm + h sin(x1t) and h(t) = x2t, where Rm = (Ro + Ri)/2 is the mean radius of the clutch facing and h = (Ro Ri)/2. Fig. 1 gives the clutch facing morphology where Ro = 100 mm, Ri = 67 mm, e = 3.35 mm, x2 = 180 rpm and a = 4.27. The chosen value of a enables optimal mate-rial distribution over the clutch facing surface, 2. 3. Tribological tests 3.1. Tribometer Pin-on-disk Friction and wear tests, on polymeric composite clutch facings material under unlubricated conditions, were per-formed on a Pin-on-disk tribometer PLINT TE67HT_. The objective was to evaluate the behaviour of the compos-ite material/steel pair under the eect of sliding distance, sliding velocity, normal load and temperature. The tribometer, as shown in Fig. 2, consists of a loading stationary pin sliding against a rotating disk with its axis Fig. 2. Tribometer PLINT TE67HT_. perpendicular to the disk. The test disk is mounted on the disk carrier spindle and secured by a central bolt. The pins specimens were clamped in the collet chuck and fixed in a loading arm. The pins stayed over the disks with two freedom degrees: a vertical one, which allows normal load application by direct contact with the surface of the disk, and a horizontal one, for friction measurement. The nor-mal load applied on the pin is provided by a pneumatic sys-tem with a compression load cell. A motor with a tachogenerator feedback ensured the stable running speeds. An indication of wear process in the pin/disk contact was given by a linear potentiometer mounted in the pneumatic pin-loading piston. 3.2. Tribological conditions DIN Ck45K steel pins (flat-ended) with a diameter of 8 mm and a length of 67.8 mm were machined. All pins have the following chemical composition (wt.%): 0.45%C, 0.25%Si, 0.65%Mn and present a hardness value of 230 HB. Before testing the pins were ultrasonically cleaned in an acetone bath. Organic friction material discs with 8 mm thickness and 76 mm of diameter were manufactured and used as counter face. Table 1 shows the tribological conditions used on tests to evaluate the behaviour of composite material/steel pair. These conditions were chosen so that the load pressure P remains almost constant during the tests. Two test temper-atures were chosen: ambient temperature and 100 LC. Tem-perature is stabilized by a controlled heating system. All the experiments were performed under dry sliding condi-tions with a relative humidity of about 50%. 3.3. Chase machine and standard SAE J661a The Chase machine is well established as a means of determining friction levels for clutch facings material. A sample for Chase testing has the dimensions 25.4 mm 25.4 mm 6 mm. The test procedure is accord-ing to SAE standard J661a. It begins with a bedding in (running in) of 20 applications, 10 s on, 20 s o, with fric-tion readings at every fifth application. This is followed by a drag test where the test drum temperature is allowed to rise to 550 LF (288 LC). During the recovery part of the test the drum is allowed to cool, and the brake is applied, and friction readings taken, at 100 LF (37.8 LC) intervals. The wear portion of the test consists of 100 applications at 400 LF (204.4 LC), 20 s on, 10 s o. This is followed by a second fade and recovery test. Similar to the first, but with Table 1 Tribological conditions used on tests Sliding velocity (m/s) Sliding distance (m) 3 1000 1 1000 ntsM. Bezzazi et al. / Materials and Design 28 (2007) 21482153 2151 temperatures going up to 650 LF (343.3 LC). Finally a base-line like the one at the beginning is performed. Test sam-ples are weighed and thickness is measured before and after testing to get some idea of wear. 4. Experimental friction charts obtained by Pin-on-disk machine The obtained experimental results with the Pin-on-disk machine are depicted in the following figures as curves giv-ing the friction coecient l versus the sliding distance. Fig. 4(a) and (b) are associated with almost the same experimental conditions but the sample disk was returned in case of Fig. 4(a), so the friction surface material in con-tact with the pin is the backward surface in the first case and the forward surface in the second case. This surface was used also for the subsequent tests. One can notice that the friction coecient becomes stable in Fig. 4(a) and (b) for high sliding distances. But the reached levels are slightly dierent: 0.27 for Fig. 4(a) and 0.33 for Fig. 4(b). However, during the running in phase (estimated at 200 m) the fric-tion coecient behaviour is quite dierent from one face to the other. This is mainly due to the manufacturing pro-cess and to the heterogeneous texture of the friction mate-rial surface as depicted in Fig. 1. These variations are considered here as defining tolerances of the friction coe-cient. After the running in phase they are found to be lim-ited to 0.06. The same remarks about the stable behaviour of the fric-tion coecient can be formulated in case of Fig. 4(c)(e). The running in phase is found in these last cases to be shorter. Explanation of this could be related to the amount of the frictional work which is here higher, so only a smal-ler sliding distance is required. It should be noticed also that temperature measure-ments were performed during Pin-on-disk testing on the disk lateral side. This temperature is not equal to that of the friction surface between the pin and the disk. More-over, this last temperature is always higher than the lateral disk temperature due to heating resulting from the fric-tional work. Since the generated heat increases with increasing sliding velocity, the spot temperature at the con-tact surface between the pin and the friction material will increase if sliding velocity is increased. Organic polymeric friction materials sliding against steel or cast iron are known to have a friction coecient which decreases with temperature after reaching a maximum 9. This is in agreement with Table 2 results since the friction coecient is in all cases decreasing with increasing sliding velocity or temperature. Eect of sliding velocity variations is found also to be higher than that associated with temper-ature variations. Finally, one can notice that in all the previous tests the friction coecient behaviour is rather stable and does not show huge fluctuations from the mean level. The friction coecient level remains also high even for the hard condi-tions corresponding to v = 3 m/s. For the special clutch Table 2 Computed average coecient of friction Sliding velocity Temperature Pressure Friction (m/s) (LC) (N) coecient 1 100 51 0.27 1 100 53 0.33 3 100 56 0.19 1 200 58 0.32 3 200 51 0.17 facing material having been tested, fading is found to be outside the range of parameters investigated in the present study. 5. Comparison with other testing results Fig. 5 gives the friction coecient versus temperature during the seven phases of the SAE J661a test. The pres-sure load acting on the clutch facing sample is almost the same than that used in the Pin-on-disk testing. Tempera-ture is measured on the drum, Fig. 3. So, one could expect to find a significant dierence between temperature used in the Pin-on-disk test and temperature given in Fig. 5. Another dierence between these two tests is due to the counter friction surface used in the SAE J661a which is made from cast iron, whereas for the Pin-on-disk it is made from steel. Also, samples used in the SAE J661a are only 4 mm thick and are taken from daily life production whereas the tested disks on the Pin-on-disk machine are 8 mm thick. Dierences between these two tests regarding the coecient of friction level are expected to exceed the above mentioned tolerance of 0.06. From the previous discussion it results that only a qual-itative comparison could be done between Figs. 4(a)(e) and 5. This however shows that the coecient of friction behaviour as function of temperature is well characterized b

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号