工程陶瓷珩磨加工珩磨头的设计

摘要

本设计是对加工工程陶瓷材料的珩磨头的结构设计,我首先通过查阅有关的视频,了解了珩磨加工的特点,再查阅相关资料认识了解珩磨机的工作原理,清楚其结构组成,然后重点观察现有珩磨头的结构,对我国的珩磨机掌握其运动参数的选择原则、油石个数的选择油石的形状和密度及分布原理、涨锥的设计技术要求以及进给机构的运动装置等;然后通过和老师不断的沟通与交流,确定了设计方向。最后分析了现有珩磨头结构的缺点,确定了对工程陶瓷加工所用珩磨头的总体方案。

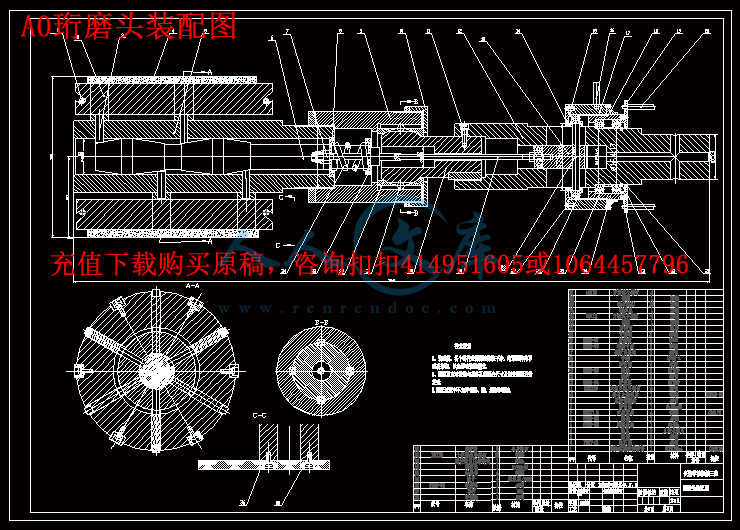

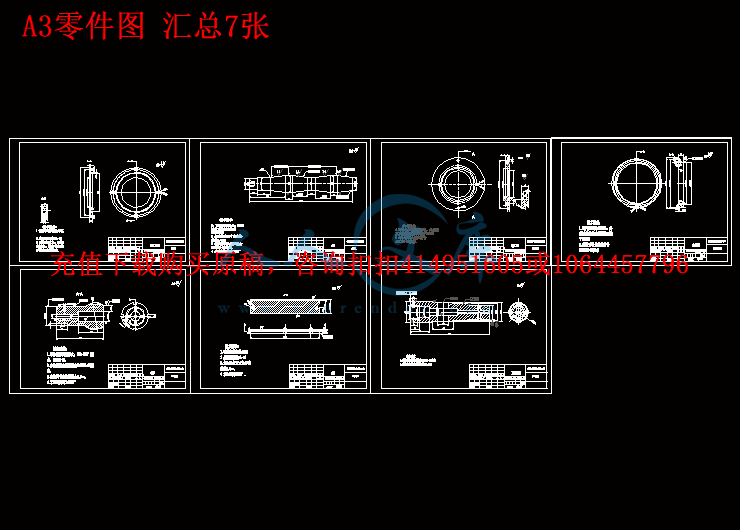

在确认方案后通过对珩磨头结构的设计对各个具体零件进行相应的设计,然后对一些有强度要求和扭矩要求的零件进行校核,使设计出的结构确保磨削可靠运行,最后绘制整套的珩磨头结构的装配图和零件图。

在通过对珩磨头的结构设计,使书本知识和理论与实际生产相结合,加强了对机械设计,工程材料,理论力学,机械原理等相关专业知识的理解,让自己能运用书本知识设计出基本符合生产要求的零部件。而且在论文中我充分地运用了大学期间所学到的知识进行了复习,巩固和深化,达到了预期的设计意图。

关键词:油石;涨锥;珩磨头。

The design of the honing machining engineering ceramics honing head

Abstract

This design is the structure of the honing head of machining engineering ceramics material design, I first by looking at the video, understanding of the features of the honing process, and then understand the working principle of honing machine to consult the relevant information, know its structure, and then focus on observation of the structure of existing honing head, to our country of honing machine to master the principle of choosing the motion parameters, the number of the choice of sharpening stone shape and density, and distribution principle, design and technical requirements as well as the rise of cone motion device of can feed mechanism, etc: Then through constant communication and communication and the teacher, determine the design direction. In the final analysis the shortcoming of the existing structure of honing head, used for machining engineering ceramics was determined the overall scheme of the honing head.

After confirm scheme using the set of honing head structure design principle to each specific parts of the corresponding design, and then some, the strength and torque requirements of parts of the structure of the designed to ensure reliable operation of grinding, finally draw a complete set of the honing head structure of the assembly drawing and part drawing.

In through the structure of honing head design, make the book knowledge and theory combined with the actual production, strengthens the of mechanical design, engineering material, theoretical mechanics, mechanical principle and so on the understanding of the relevant professional knowledge, let oneself can apply book knowledge to design basic meet the requirements of the production parts. And in the thesis I fully apply the knowledge learned during the period of university has carried on the review, consolidate and deepen, achieved the desired design intent.

Key words: oil stone; Cone up; Honing head.

目录

前言························10

3.课题研究的目的及意义··············11

4.国内外珩磨头的研究情况·············11

1).国外研究情况·····················12

2).国内研究情况····················12

第一章、光整加工·····················12

1.1光整加工与珩磨加工的关系················13

1.2什么是光整加工·····················13

1.3光整加工的原理·····················13

1.4光整加工的特点·····················14

第二章、一般珩磨·················15

2.1 珩磨加工原理·····················16

2.2珩磨的工艺特点及应用范围················18

2.3珩磨的切削过程·····················20

2.4珩磨技术在汽车制造中的应用···············24

2.5珩磨头的结构形式····················26

2.6珩磨机有哪几种,选用原则···············27

2.7 珩磨工件常见有哪些缺陷和消除措施···········28

第三章 珩磨头的结构设计·············29

3.1珩磨油石的选择·····················29

3.2珩磨油石怎样与油石座固定················29

3.3怎样修整珩磨用的油石··················35

3.4. 涨锥的设计:······················36

3.5导向装置的设计·····················37

第四章 珩磨用量的选择···············38

4.1.怎样选择珩磨速度与切削交叉角··············38

4.2.珩磨头油石扩张进给方式对珩磨过程有哪些影响·······41

4.3.怎样选择珩磨油石的工作压力············43

4.4.珩磨时怎样选择定量进给的进给进度·········43

4.5.珩磨时怎样调整工作行程··············44

4.6怎样选择工件孔的珩磨余量·············44

4.7珩磨前对工件有哪些要求·················45

4.8珩磨不同形状孔时有哪些工作要点···········45

4.9珩磨头的工作行程的计算和调整············46

4.10.珩磨前工序要求·················47

4.11.珩磨液的选择·················47

4.12.手动进给机构的设计··················49

第五章 珩磨头结构薄弱零件的校核 ·········51

5.1 零件 3 圆柱销扭转强度的校核 ··············51

5.2 零件 11 六角头沉头螺钉强度的校核 ···········56

结束语······················57

致谢·······················57

参考文献·························58

前言

1.课题研究的目的及意义:

随着我国教育的普及和科技的迅猛发展,国民经济等各行业对高精度、高品质、多品种、多功能、高度自动化的技术装备的需求不断增大,这促使了科技的极大发展,磨削加工技术是先进制造技术中的重要领域,是现代机械制造业实现精密加工、超精密加工最有效的基本技术。具有关资料表明,磨削加工占整个机械加工的40%左右,在金属切削机床的11各大类中,磨床的品种是最为繁多的一种。利用珩磨头珩磨工件精加工表面,主要用于汽车、航空、液压件、轴承等行业中珩磨工件的孔加工。随着我国交通运输、航天、军事、工业的飞速发展,高级铁路、公路、神州系列的建设步伐的加快,国家安全的日益重要,对零件的精密度要求越来越高,产品质量要求也逐步提高,所以发展珩磨业是必要的。

长期以来,由于国外的垄断,国内技术的落后,以及我国各行业发展的相对落后,对于精密度要求一直很低,甚至大部分标准是沿用国外的标准。但随着改革开放和政策的改变,大量人才回国、政府和本土企业等各方面的重视,我国珩磨业发展迅速。在20世纪70年代我国开始采用金属结合剂的金刚石油石和立方氮化硼油石,在用它们以加工淬火钢或铸铁时,磨耗量仅为普通油石的1/150~1/250左右,同时油石对工件的压力也可提高大约2~3倍,从而使珩磨的效率和表面质量进一步得到提高。

《2014-2018年中国人造金刚石珩磨条行业调查及发展前景分析报告》从行业市场份额、行业需求增长率、竞争者数量、行业产量、利润、企业规模、技术、进入退出壁垒等几个方面,综合分析,定性判断人造金刚石珩磨条行业所处的行业将进入快速发展期。综合国家统计局、国家信息中心、海关总署、行业协会等权威部门发布的统计信息和统计数据,糅合各类年鉴信息数据、财经媒体信息数据、商用数据库信息数据,从行业发展现状,当前产业政策,行业所处生命周期,行业市场竞争程度,市场稳定性几个方面分析,我国目前对珩磨加工的要求高,需求大。

为了早日实现我国尽快发展我国珩磨业,也是我校领导和教授对行业的远瞻性,本次毕业设计的课题“工程陶瓷珩磨加工珩磨头的设计”在对国家技术开发和科技发展支持的同时,让我们充分融合书本知识,对设计和开发新产品有解。

川公网安备: 51019002004831号

川公网安备: 51019002004831号