目录

摘要.........................................................I

Abstract....................................................II

第1章 绪论.................................................4

1.1 课题研究目的及意义....................................4

1.2分选机分选方式研究....................................6

1.3课题国内外现状.........................................6

1.3.1国外分选机研究现状..................................6

1.3.2国内分选机研究现状.................................. 7

1.4存在问题...............................................7

第2章 方案的选择与设计..................................9

2.1本课题的设计任务.......................................9

2.2圆柱螺旋弹簧分选机的设计思路..........................9

2.3送料机构..............................................10

2.4加力与检测机构........................................11

2.5落料分选机构..........................................12

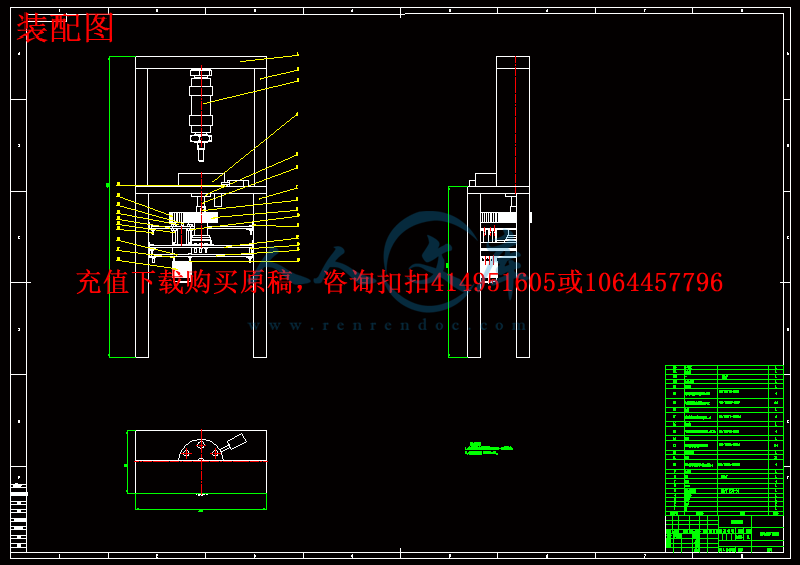

第3章 总体的机构设计...................................14

第4章 弹簧分选机零件结构设计.........................16

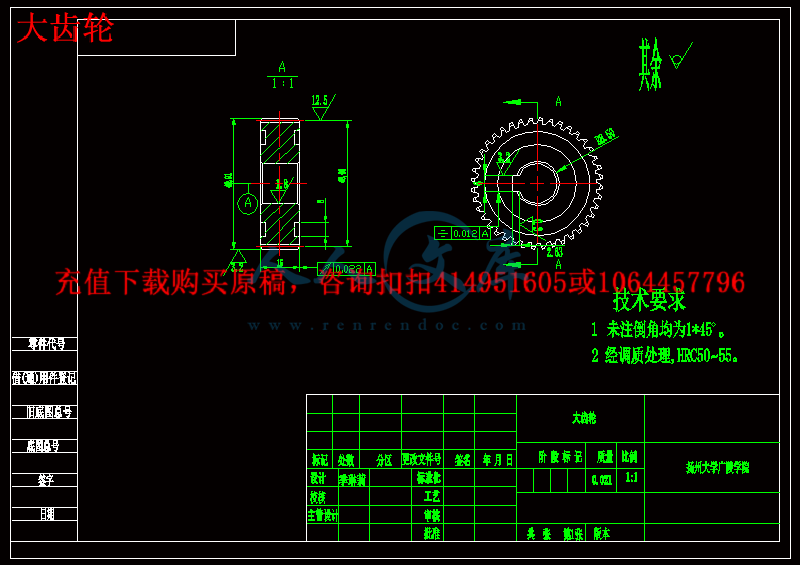

4.1齿轮的选择设计........................................16

4.2夹持轴承与轴的连接的夹具的选择.......................17

4.2.1上夹具的设计.......................................17

4.2.2下夹具的设计.......................................19

4.3气缸的设计选择........................................20

4.4传动轴的选择设计......................................22

4.5轴承的选择设计........................................24

4.5.1原动部分装配所选用的轴承...........................24

4.5.2 执行部分装配所选用的轴承..........................26

4.6其他主要零部件的设计.................................28

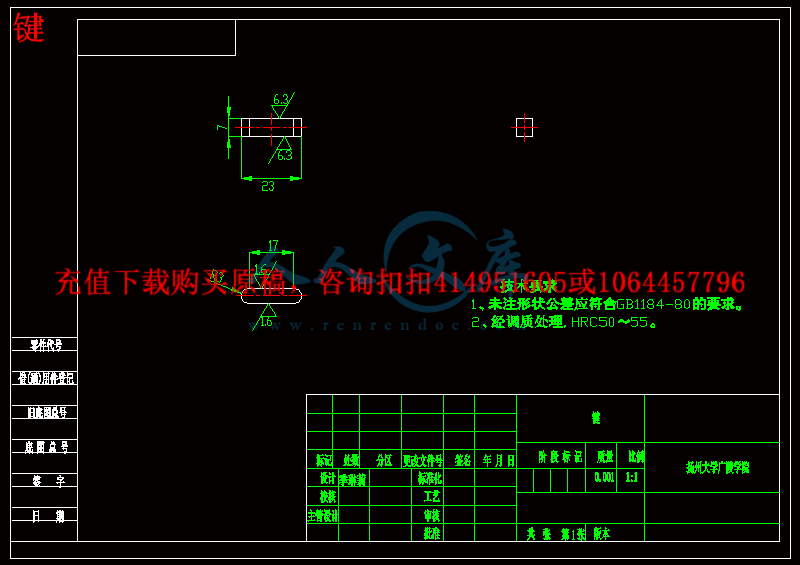

4.6.1键的选择设计.......................................28

4.6.2轴套的选择设计......................................28

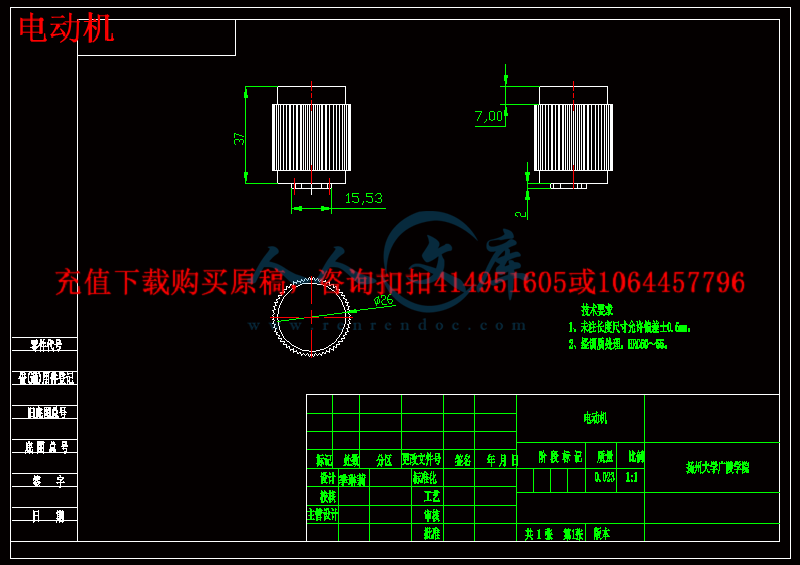

4.6.3电动机的选择设计...................................29

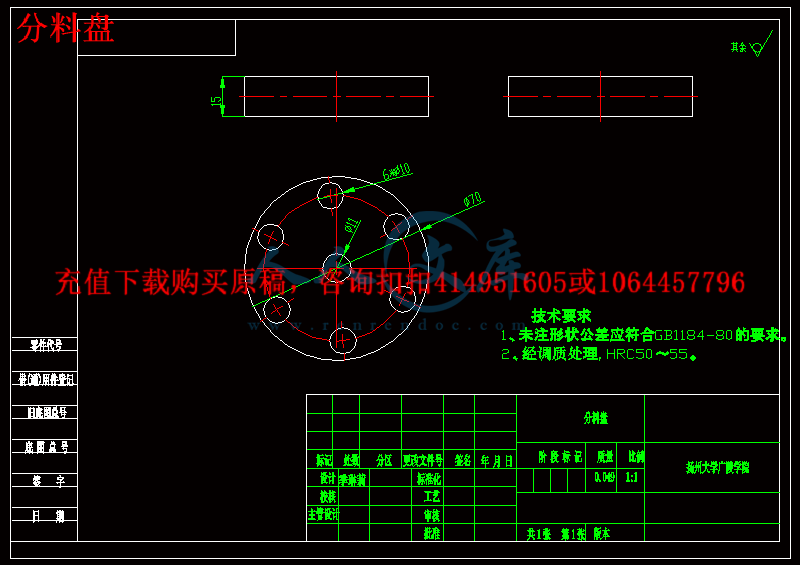

4.6.4分料盘的设计.......................................31

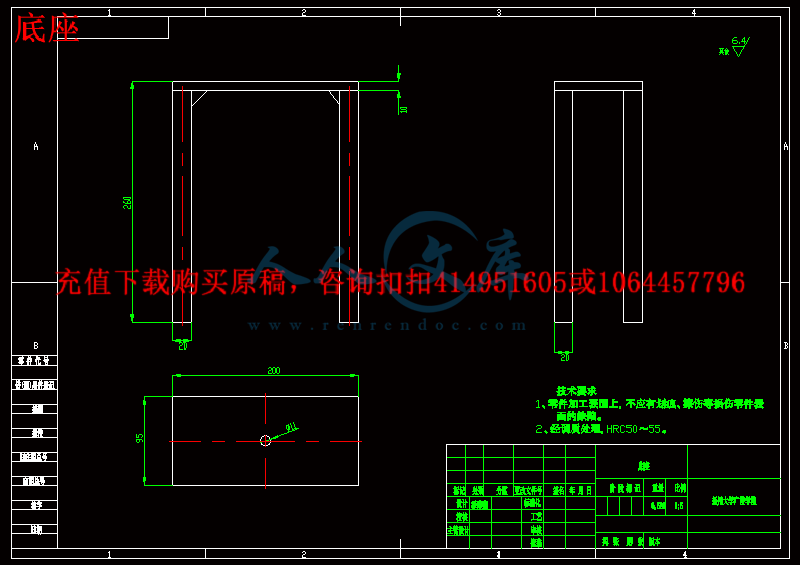

4.6.5底座的设计................................ 32

第5章 校核计算..................................34

5.1底座上板的受力分析与弯曲应力计算...................34

5.2 轴受力分析与应力计算.............................. 36

总结............................................39

致谢............................................41

参考文献........................................42

附录............................................43

摘 要

弹簧的应用十分广泛可以说是各种机械、电器 、化工等产品的关键零件。凡是承受变载荷的弹簧,在企业内部质量控制、用户交验、新产品定型鉴定、认证,行业抽检和工艺调整环节中,必须进行性能检测。所以弹簧检测是其生产过程必不可少的工序,测力是检测的主要内容之一。弹簧测力分选机是在基于工业进程高速发展的今天,结合圆柱螺旋弹簧的需求量和生产企业需求的前提下所应运而生的。本论文主要是对分选机的机械结构进行研究,设计,实验与制造。

此弹簧分选机是针对大批量生产的弹簧依据其弹性系数不同,按照预先规定的指标进行测试自动筛选出合格与不合格产品,并在不合格产品范围内依据是否可以修复将弹簧进一步细分,自动流入不同料箱,以此应用与不同场合。这种弹簧分选机是安装在弹簧加工过程中的检测工艺工段线上,针对汽车、摩托车离合器弹簧生产制造工艺设计的,适用于各种类型的圆柱螺旋弹簧的分选。

本论文首先论述螺旋弹簧分选机的分选方式以及国内外分选机的研究现状和设备的性能优缺点,结合课题背景,提出本论文的主要研究内容。在对弹簧特点与控制需求进行分析的基础上,提出了分选机机械结构的方案设计。

在论文中所研究和设计的圆柱螺旋弹簧分选机,满足功能要求,解决了弹簧生产过程中的实际问题,提高了生产与检测效率,为以后此类设备的设计提供了借鉴作用。

关键词:圆柱螺旋弹簧; 分选机; 弹性系数

Abstract

Spring testing is the phase of the production process essential working procedure, load is one of the main content of detection. Spring load separator is in today's rapid development based on industrial process, in combination with the demand and production of cylindrical helical spring under the premise of enterprise requirements arises at the historic moment. This thesis mainly is the study of mechanical structure of the separator, the design, the experiments and manufacture.

This spring sorting machine is for mass production according to the elastic coefficient of the spring, in accordance with the prescribed index test automatically select the qualified and unqualified products, and within the scope of the unqualified products according to whether can repair will spring further subdivided, automatic into the different material box, with different situations in application. The spring separator is installed in the spring section of online detection technology, in the process of machining for automobile, motorcycle clutch spring manufacturing process design, suitable for various types of cylindrical helical spring sorting.

This paper first expounds the separation method of helical spring sorting machine and the performance of the domestic and foreign research situation of the separator and equipment advantages and disadvantages, combined with the project background, puts forward the main research content of this paper. On the analysis of the demand and control characteristics of the spring, on the basis of sorting machine mechanical structure design are put forward.

In the thesis the research and design of cylindrical helical spring sorting machine, meet the functional requirements, solved the practical problems in the process of producing spring, improve the efficiency of the production and testing, design provides a reference for such a facility.

Keywords: Cylindrical helical spring; separator; Modulus of elasticity

第1章 绪论

1.1 课题研究目的及意义

弹簧的应用十分广泛,可以说是各种机械,电器,化工等产品的关键零件。近几年来,国内弹簧工业的设计制造及材料方面有了新的发展,对弹簧的要求也越来越高,在各种螺旋弹簧中,内燃机的气门簧是其中较为重要的弹簧之一,它是国家质监部门要求负荷值全检的产品,装入内燃机的每一只气门簧,都必须经过数字检测设备的严格检测,这样才能保证内燃机工作的可靠性与寿命。由于内燃机气门弹簧种类繁多,数量巨大。因此,用普通的手动检测设备进行检测,由人进行分类的方法,容易产生许多误操作使得供,需双方发生许多的摩擦与误会并且工作量也是十分巨大的。因此,各弹簧生产厂及主机厂均希望能拥有一种能在线进行检测并能自动进行分类的设备——弹簧分选机,但是,目前国内市场上能见到的弹簧分选机均为国外厂家生产的,这些分选机不但分组单一,且价格昂贵。国内各弹簧生产设备及检测设备生产厂均未研制出高效实用的弹簧分选机。国外市场上能见的分选机类型为两种——高精度型和高速度型;高精度型弹簧分选机主要用来分选那些精度要求很高的弹簧,但这种分选机的分选速度很低,不适合大批量弹簧生产的需要。高速度型弹簧分选机在速度上能达到较高的要求但价格非常昂贵。国内很多弹簧生产机检测设备生产厂针对各自的需求研发了一些弹簧分选机设备,如基于重力的弹簧分选机,基于尺寸的弹簧分选机,基于压力的弹簧分选机,这些设备在功能和性价比上都还和国外同类产品有一定差距。

川公网安备: 51019002004831号

川公网安备: 51019002004831号