HKD260混合动力自卸汽车设计(离合器设计)

HKD260混合动力自卸汽车离合器设计【优秀汽车离合器全套课程毕业设计含4张CAD图纸】

【带外文翻译】【53页@正文20900字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

HKD260混合动力自卸汽车离合器设计.doc

传动轴.dwg

摘要及目录.doc

操纵机构.dwg

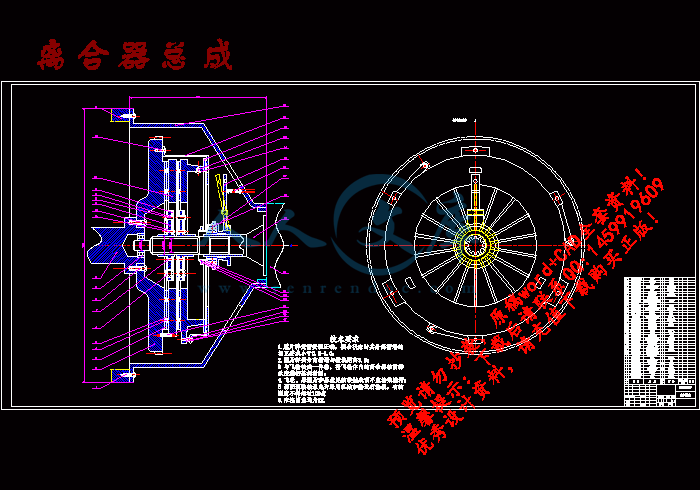

离合器总成.dwg

翻译中文.doc

翻译中文.wps

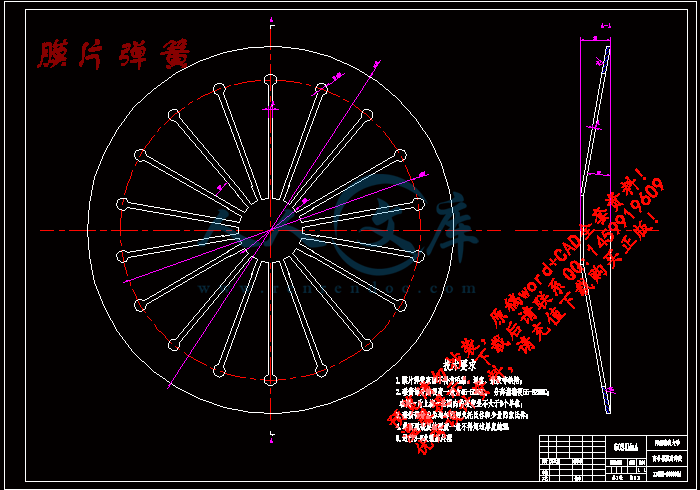

膜片弹簧.dwg

HKD260混合动力自卸汽车设计(离合器设计)

摘 要

本离合器的设计与整车中底盘、变速器、驱动桥的设计密切相关,在设计中尽量做到与车辆其它部位的最佳匹配,力求整车结构更加合理。

在本方案中,离合器被布置在发动机的后面,用来切断和实现动力总成对传动系的动力传递,确保汽车平稳起步:在换档时将动力总成与传动系分离, 减少变速器中换挡齿轮的冲击;防止传动系各零件过载损坏;降低传动系的震动和噪声等。混合动力轿车可采用传统的内燃机的传动系。

离合器是汽车传动系的重要组成部分,对于汽车的动力性、燃油经济性和舒适性等性有很大影响。本设计主要介绍了混合动力轿车离合器的总体设计,包括离合器的设计要求,离合器形式,如从动盘数、压紧弹簧和布置形式的选择、扭转减振器与操纵机构的选择;选择离合器主要参数,对参数进行优化设计,使其尽量满足约束条件。并详细介绍三大总成的结构方案和其设计要求,包括从动盘总成、离合器盖总成和分离轴承总成。

关键词:混合动力,重型自卸,离合器形式,操纵机构,结构性能计算

HKD260 HYBRID DUMP TRUCK DESIGN

(CLUTCH DESIGN)

ABSTRACT

In this design,the design of clutch is closely relevant to the designs of the car chassis, transmission and driving draft. The clutch is designed to be perfectly matching those parts which can make the car structure more reasonable.

In my design, the clutch is installed in the rear of the engine and the motor (ISG) to continue or disengage the power from the engine. And this can start the car smoothly. When shifting the gears, the clutch petal has to be depressed for the disengagement the transmission from the engine which could minimize the shock on the gears of transmission. It can also prevent damages caused by the shock and bring down the vibration and shock of transmission system. PHEV could adopt the traditional transmission of internal combustion engine.

The clutch is one of the most important sections in the transmission system and has great impact on the energy efficiency, fuel efficiency and comfort of a car. This is a design about clutch of the HEV car. It includes the requirements for clutch, choosing the form of a clutch, such as how to choose clutch disc, pressure spring, diaphragm spring and torsion damper. Then choose the parameters of clutch and optimize them to meet the limit condition requirements. The design concludes specification of the main three assemblies and the requirements for them (clutch disc assemblies, release bearing assemblies, cover assemblies).

KEY WORDS: Hybrid, Heavy Dump Truck, the form of clutch, the disengagement mechanism, the calculation of structure and performance

目 录

第一章 前言1

第二章 动力性计算3

§2.1最小传动比的选取3

§2.2 最大传动比的选取3

§2.3 车速的计算4

§2.4驱动力与阻力的计算5

§2.4.1 空气阻力6

§2.4.2 滚动阻力6

§2.5 动力特性图8

§2.6 汽车的功率平衡8

第三章 离合器主要参数的选择10

§3.1 离合器转矩容量10

§3.2 离合器的转矩容量与发动机最大转矩的基本性能关系10

§3.3 离合器基本结构尺寸和参数的选择11

§3.3.1 离合器后备系数β的确定11

§3.3.2 摩檫系数的确定12

§3.3.3 摩檫片外径D的确定13

§3.3.4 单位压力的确定15

§3.3.5 摩檫片的约束条件16

第四章 离合器的结构选型与设计计算18

§4.1 从动盘总成18

§4.2 从动盘总成设计18

§4.2.1 从动盘钢片19

§4.2.2 从动盘毂21

§4.2.3 从动盘摩檫片25

§4.3 压盘和离合器盖26

§4.3.1 压盘设计26

§4.3.2 压盘传力结构设计29

§4.4 离合器盖设计31

§4.5 离合器的分离装置设计32

§4.5.1分离杆结构型式的选择32

§4.6 膜片弹簧设计32

§4.6.1膜片弹簧基本参数的选择33

§4.7扭转减振器的设计34

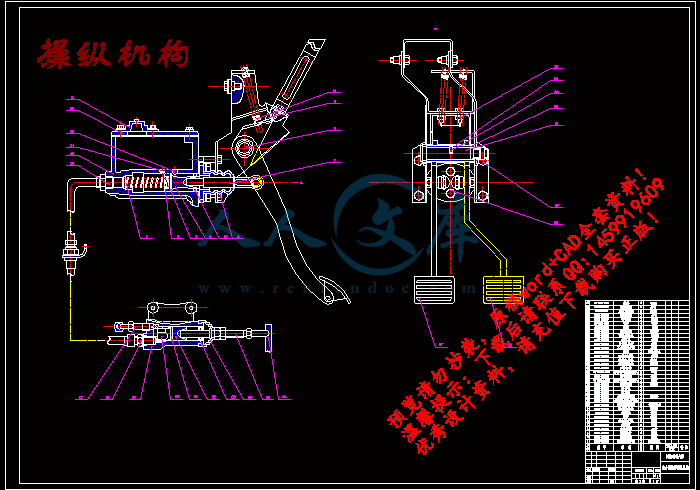

第五章 操纵机构设计计算38

§5.1离合器操纵机构的基本要求与常用结构类型38

§5.1.1对离合器操纵机构的基本要求38

§5.1.2常用离合器操纵机构的类型38

§5.2离合器操纵机构主要参数的确定与计算38

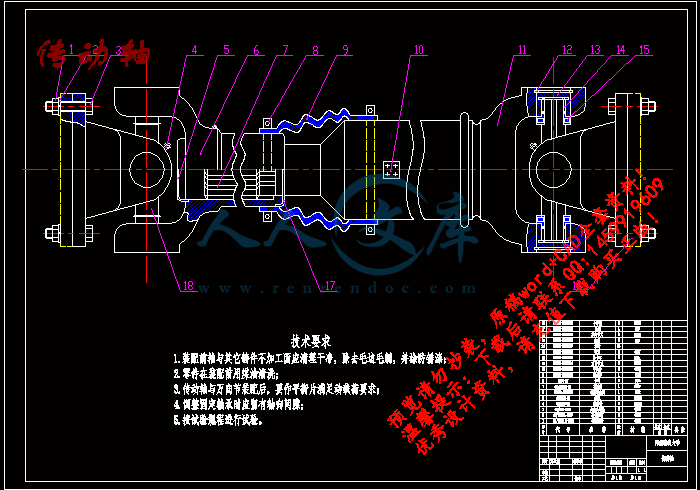

第六章 传动轴的设计与计算41

§6.1 概 述41

§6.2 万向节结构方案分析42

§6.3 万向节的设计计算42

§6.3.1 万向节设计42

§6.3.2 传动轴的设计44

§6.3.3 中间支承结构46

§6.3.4 十字轴万向节传动实验47

参考文献48

致 谢49

第一章 前 言

汽车诞生之前马车是人类最好的陆上交通工具。1770年法国人尼古拉斯古诺(1725-1804)将蒸汽机装在板车上,制造出第一辆蒸汽板车,这是世界上第一辆利用机器为动力的车辆。1769年,瑞士军官普兰捷尔也造出一辆以蒸汽机为动力的额自由行驶的板车,于是有人将普兰捷尔也认定为汽车的始祖之一。1860年,法国人艾蒂勒努瓦发明了一种内部燃烧的汽油发动机。1885年德国工程师卡尔奔驰(1844-1929)在曼海姆制成一部装有0.85马力汽油机的三轮车。德国另一位工程师戈特利布戴姆勒(1834-1900)也同时造出了一辆用1.1马力汽油机作动力的三轮车。他们俩被公认为以内燃机为动力的现代汽车的发明者,1886年1月29日也被公认为汽车的诞生日。

汽车从无到有并迅猛发展。从20世纪初至20世纪50年代,汽车产量大幅增加,汽车技术也有很大进步,相继出现了高速汽油机、柴油机;弧齿锥齿轮和准双面锥齿轮传动、带同步器的齿轮变速器;化油器;差速器;摩擦片式离合器;等速万向节;荻第安后桥半独立悬架;液压减振器;艾克曼式转向结构;石棉制动片;充气式橡胶轮胎等。

参考文献

1.汽车离合器设计 徐石安 江发潮 编著 清华大学出版社 2005

2.联轴器、离合器设计与选用指南 阮忠唐 编著 化学工业出版社 2006

3.离合器及机械变速器 张 毅 编著 化学工业出版社 2005

4.离合器、制动器选用手册 周明衡 编著 化学工业出版社 2003

5.离合器结构图册 段广汉 编著 国防工业出版社 1985

6. 朱冬梅,胥兆澜主编 画法几何及机械制图第5版 高等教育出版社 2000年12月

7. 刘鸿文主编 简明材料力学 高等教育出版社 1997年7月

8. 孙恒,陈作模主编 机械原理第六版 高等教育出版社 2004年3月

9. 濮良贵,纪名刚主编 机械设计第7版 高等教育出版社 2001年6月

10. 徐谨主编 机械设计手册 机械工业出版社 2000年6月

11. 吴宗泽主编 机械设计使用手册 化学工业出版社 2001年5月

12. 蔡春源主编 机械零件设计手册第3版 冶金工业出版社 1995年10月

13. 王予望主编 汽车设计第4版 机械工业出版社 2004年8月

14. 陈家瑞主编 汽车构造第2版 机械工业出版社 2005年1月

15. 张则曹主编 汽车构造图册 人民交通出版社 1998年2月

16. 林清福主编 国外汽车构造最新构造图册 机械工业出版社 1996年5月

川公网安备: 51019002004831号

川公网安备: 51019002004831号