轻型载货汽车设计(底盘设计)

轻型载货汽车底盘设计【优秀汽车底盘全套课程毕业设计含2张CAD图纸】

【带开题报告+外文翻译】【40页@正文11700字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

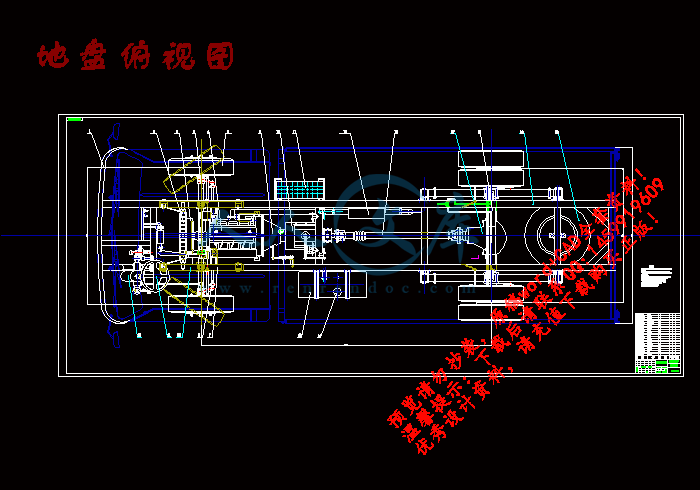

地盘俯视图.dwg

外文原文.doc

底盘总体主视图.dwg

开题报告.doc

拖拉机的分类--中英文翻译.doc

轻型载货汽车底盘设计.doc

轻型载货汽车设计(底盘设计)

摘 要

本次设计的对象是轻型卡车的总体设计,要求该车有良好的动力性和经济性。总体设计的目的是将各分总成协调地组装在一起,避免各总成之间出现干涉现象,从而实现汽车总成的运动准确性及行驶平顺性。驾驶室总成设计要满足客户对舒适性的要求;货厢总成要有足够的尺寸来保证额定装载质量,但也要考虑汽车的最小转弯半径及机动性;底盘总成要避免转向纵拉杆和前悬架钢板弹簧的干涉,保证各总成固定的刚度,使之在行驶中不产生共振。

设计中做了以下工作:总体布置,其中包括汽车主要技术参数的确定,发动机和轮胎的选择等;稳定性的计算,涉及纵向、横向行驶稳定性的计算,最小转向半径的计算等;汽车的动力性计算,包括各挡车速的计算,爬坡度的计算,加速性能的计算,驱动力和行驶阻力的平衡,功率的平衡;汽车燃油经济性的计算。

综合分析、计算、验证得知,本次设计基本满足了设计任务书的要求。

关键字:货车,底盘,总体布置,转向纵拉杆,前悬架,驱动力

THE OVERALL DESIGN OF LIGHT TRUCK

ABSTRACT

This light truck must have adequate hauling power and high working efficiency. The purpose of the overall design is to coordinate the subassemblies got together to avoid interfering between them. And then making the truck’s movement is veracity, and to ensure the ride comfort. The design of the cab must make the driver feel comfortable. The pay cube should be big enough to fulfill the rating carrying ability, but we have to consider the tightest turning radius and flexibility as well. There shouldn’t be interfere among steering drag rod and road spring of front suspension in the chassis. The subassemblies must be fixed to the chassis firmly to prevent syntony in the driving.

Main work is as following in this design: the General arrangement, including selecting the main technology parameters, the engine, the tires and so on; the Calculating of Stability , involving portrait stability and landscape orientation stability while driving, the tightest turning radius; the Power performance calculation, including the calculating of speeds on all gear ratios, gradability, acceleration characteristic, the balance between driving force and running resistance, as well as the power; the Calculation of Fuel Economy.

Through the generalized analysis, computation, confirmation, we confirm that this design has on the whole satisfied the description requirements.

KEY WORDS: Truck, Chassis, General arrangement plan, Steering drag rod, Front suspension, Driving force

第一章前言

从1886年德国人卡尔奔驰和戈特利布载姆勒用四冲程汽油机制成汽车以来,已有一百多年的历史。一百多年来,汽车的发展给人类带来了巨大而深刻的变化。汽车以其惊人的产量、卓越的性能和多种用途渗透到人类活动的各个领域,并以它完美的造型艺术和舒适的内部设施而深受人们的喜爱。汽车已成为各国国民经济和社会生活中不可缺少的运输工具,成为二十世纪改造世界的机器和现代文明的标志。

目前,计算机技术在汽车设计、试验和生产制造中被广泛地应用。现在普遍用计算机进行汽车的总体布置方案设计,确定整车性能并进行动态模拟试验。生产用图已用计算机绘制,且只需几个星期或稍长的时间,就能将设计意图加以实现,并提供多种生产用图纸。对汽车车身全盘实现计算机辅助设计和制造,即所谓的CAD/CAM,大大缩短了计算、绘图时间,提高了设计速度和质量。

参考文献

[1]陈家瑞.汽车构造(上、下册).北京:机械工业出版社,1993

[2]蔡春源.机械零件设计手册(3版)上、下册.北京:冶金工业出版社,1996

[3]王望予.汽车设计(3版).北京:机械工业出版社,1995

[4]余志生.汽车理论(3版).北京:机械工业出版社,1981

[5]黄金陵.汽车车身结构与设计.吉林:吉林工业大学,1985

[6]刘鸿文.材料力学(上、下册).北京:高等教育出版社,1998

[7]张义民 闻邦春.汽车技术.1997,第九期,p7-20

[8]刘惟信.汽车设计.北京:清华大学出版社,2000

[9]王昆 何小柏等.机械设计.北京:高等教育出版社,1995

[10]吉林工业大学汽车教研室.汽车设计,北京:机械工业出版社,1981

[11]张洪欣.汽车设计.北京:机械工业出版社,1989

[12]机械设计手册(第3卷). 北京:机械工业出版社,1991

[13]郭竹亭.汽车车身设计.吉林:吉林科学技术出版社,1994

[14]程正,马芳.汽车造型.吉林:吉林科学技术出版社,1992

[15]温吾凡.汽车人体工程学. 吉林:吉林科学技术出版社,1991

[16](德)阿达姆.汽车行驶性能.北京:科学技术出版社,1992

[17]刘惟信.驱动桥.北京:人民交通出版社,1987

[18]黄天泽、黄金陵.汽车车身结构与设计.北京:机械工业出版社,2003

[19]吴宗泽.机械设计使用手册.北京:化学工业出版社,1999

[20]《汽车百科全书》编纂委员会 编.汽车百科全书(上册).北京:机械工业出版社,1992

[21]魏鑫,张迅,田景崎 编.最新国外汽车车型手册.北京:机械工业出版社,1991

川公网安备: 51019002004831号

川公网安备: 51019002004831号