摘 要

近年来,我国企业的数控机床占有率逐渐上升,而现有的大多数机床切削加工不能满足复杂型面得加工要求。电解加工机床以其加工速度快,可加工难切削的、表面复杂的零件,具有工具阴极无损耗,加工质量好,生产效率高,加工范围广等优点,在生产中起了越来越重要的作用。

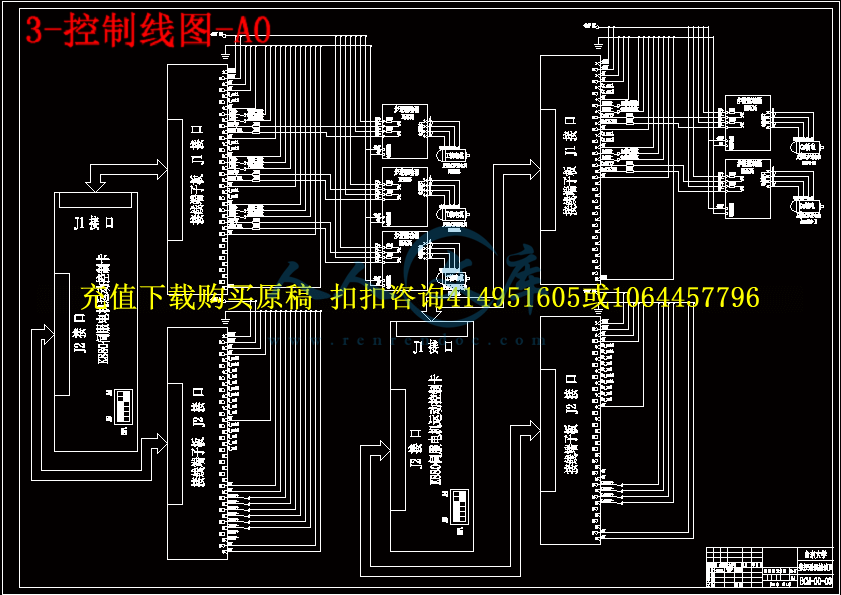

本次设计的内容就是五坐标数控点解加工机床的X, Y, 向传动机构和计算机数控系统。X, Y, 向的传动系统与数控铣床相似,参考了典型数控铣床的结构来设计,在局部放入设计上综合考虑了电解加工的特殊性。在考虑机床的工作性能放的同时也考虑了机床的安全性能和环保性能。在材料的选用上选用了不易腐蚀放入不锈钢等材质,在结构设计上考虑电解液的密封性,从而达到生产的目的。

在参考典型机构的基础上,结合电解加工机床的工作条件,设计完成的数控电解机床可以加工几何形状比较复杂的零件,并能达到较好的精度要求。生产中可以节约更多的时间,人力和物力。

关键词: 电解加工;数控系统;数控机床

ABSTRACT

In recent years, the share of CNC machine tool in Chinese enterprises increased year by year, but most of the existing machine tool cutting processing can not meet the processing requirements of the complex surface. Electro-chemical machine tools play an increasingly important role in the production with the high processing speed, processing the parts of hard-to-cut and the complex surface, cathode without loss, good quality processing, high productivity, processing of wide range and other advantages.

The design elements include the X, Y, CW transmission structure and the computer numerical control system of five coordinates electrolytic NC machine. Because X, Y, CW to the transmission system is similar to the NC milling machine, we can design it referring to the typical structure of the CNC milling machine with the design of partial consideration to the special nature of electrochemical machining for the necessary changes. In considering the machine performance of the machine we should also consider the safety performance and environmental-friendliness. In order to achieve the production goal, the stainless steel and other materials which are difficult to corrode can be chose easily in the selection of materials, and the sealing of electrolyte should be considered in the selection of structural design.

NC electrochemical machine can process more complex geometry of parts, and can achieve better accuracy in the working conditions. The electrolytic processing machine tools are combined with the typical structure. Production can save more time, manpower and resources.

Keywords: Electrochemical machining; Numerical control system; Numerical- control machine tool

目 录

第一章 绪论1

第二章 机床总体方案设4

2.1 课题国内外发展现状4

2.2 机床总体结构形式4

2.3 机床的传动方案确定6

2.3.1 X、Y轴向传动方案6

2.3.2 轴传动方案7

2.3.3 导轨形式8

2.3.4 齿轮副的选择8

第三章 X,Y,向传动机构及工作台设计9

3.1 X轴向滚珠丝杠设计9

3.1.1 强度计算10

3.1.2 滚珠丝杠静态设计11

3.1.3 丝杠螺母的动态设计15

3.2 Y轴向滚珠丝杠设计17

3.2.1 强度计算18

3.2.2 滚珠丝杠静态设计19

3.2.3 丝杠螺母的动态设计22

3.3电动机选择与齿轮传动设计24

3.3.1 电动机的选择24

3.3.2 齿轮传动设计与选用25

3.4 导轨的选择26

3.4.1 导轨类型的选择26

3.4.2 导轨的材料27

3.4.3 滚动导轨的结构形式28

3.4.4 滚动导轨的设计计算28

3.4.5 确定导轨的参数29

3.5 向传动机构及回转工作台的设计29

3.5.1 蜗轮蜗杆传动的设计30

第四章 数控系统硬件设计34

4.1 数控系统设计方案34

4.2 数控系统硬件结构设计34

4.3 数控系统接口设计35

第五章 数控系统控制软件设计38

5.1 CNC系统软件的构成38

5.2 CNC系统软件的功能38

5.3 CNC系统软件的实现39

5.3.1 CNC系统软件开发工具39

5.3.2 CNC系统软件界面设计和编程40

5.3.3 CNC系统软件功能调试49

第六章 结论50

致 谢52

参考文献53

附 录54

川公网安备: 51019002004831号

川公网安备: 51019002004831号