目录

中文摘要………………………………………………………………………………Ⅰ

AbstractⅡ

第1章 绪论1

1.1 我国蔬菜的生产现状1

1.2 大葱生物特性与加工标准2

1.3 国内外的研究现状3

1.4 研究内容3

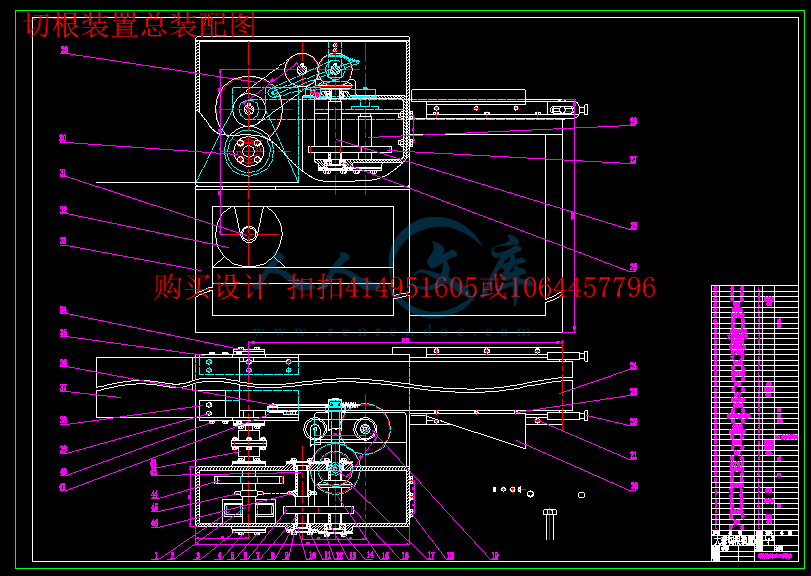

第2章 大葱切根装置的设计5

2.1 动力部分5

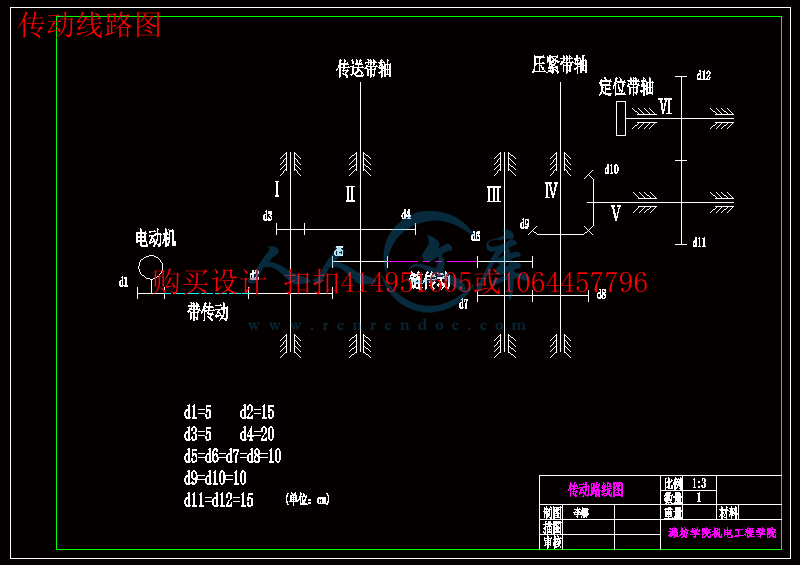

2.2 传动部分的设计5

2.3 传送部分的设计9

2.4 定位部分的设计10

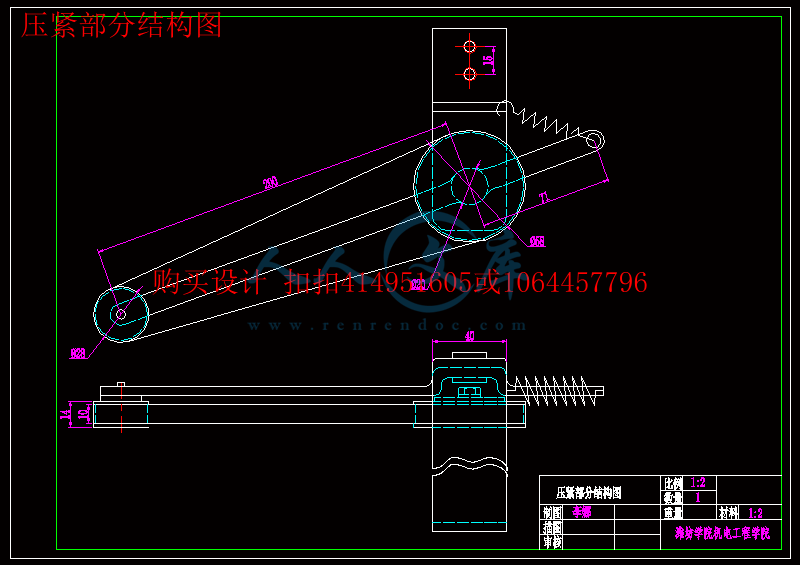

2.5 压紧部分的设计10

2.6 切割部分的设计11

2.7 成品大葱的放置以及残根的处理12

2.8 支架12

第3章 结论13

参考文献14

致谢15

摘要

大葱是我国的主要出口蔬菜之一。本文在总结国内外相关资料的基础上,对大葱切根装置的工作原理及各部分结构进行了详细地设计。该装置采用针定位,成功解决了切割过程中大葱容易跑偏的问题,设计合理,结构简单,对提高大葱的附加值,促进大葱的出口,提高我国大葱产后加工的机械化水平具有重要意义。

关键词:大葱 大葱切根装置 针定位 切割

ABSTRACT

The scallion is one of main export vegetables in our country. Based on the summary of references, the principles and structure of the cutting roots equipment of scallion are thoroughly designed in this paper. The cutting roots equipment of scallion has solved the problem of scallion’s removing irregularly while it is being cut by using the needle-locating implement .The design is reasonable and the structure is simple. The cutting roots implement of scallion plays an important role to increase the mechanization level of scallion’s after-production processing and expand export.

Key words: scallion;the cutting roots equipment of scallion; needle-location;cutting

第1章 绪论

1.1 我国蔬菜的生产现状

我国是农业大国,有着几千年的农业发展历史。历史上,我国曾在各项农业生产技术上处于领先地位,勤劳的中国民发明了各种各样的农具。但是到了近代,由于社会发展滞后,导致我国农业技术发展停滞不前,闭关锁国政策又使我们未能及时引进国外的先进技术,在国外已经普遍使用机械时,我国农民依然进行着繁重的体力劳动。新中国成立后,我国的领导人提出要尽快实现农业机械化,但是由于种种原因,中国只有、黑龙江等地的大农场基本实现了机械化生产,而其它大部分地区由于受各种因素的制约,仍未能实现农业生产的机械化。

众所周知,我国用占世界7%的耕地养活着占世界22%的人口,人多地少,而且我国有相当多地方仍然依靠人畜力劳动,劳动生产率低,不能形成大规模生产。因此,我国要想在农业方面获得更大的成就,必须根据自己的国情,发展有自己特色的农业生产。

近年来,我国的蔬菜和水果的生产逐渐展现出广阔的发展前景。目前,我国蔬菜生产发展迅速,尤其是沿海地区,依托有利的地理条件,大规模发展蔬菜生产,不但满足我国居民消费外,还大量出口国外,是目前出口增长最为迅速的农产品这之一。在一些地区,蔬菜的生产加工和出口贸易已经成为支柱产业,实现了专业化、规范化、优质化经营发展,形成了种加销、贸工农于一体的新的生产格局,除了满足我国居民消费外,出口蔬菜已经成为重要的创汇农产品。而且我国生产的蔬菜在国际市场上有一定的竞争优势,出口蔬菜已成为一些地区增加农民收入、出口创汇和发展农村经济的一条重要途径,越来越显示出它强大的生命力。

但是,目前我国蔬菜生产加工依然主要依靠人力,机械化程度极低,在国际上的竞争优势主要源自于低廉的劳动力。这种优势将随着中国加入WTO以及中国人民生活质量的提高化为乌有。这不符合长久发展的利益,要使我国蔬菜继续在国际市场上保持竞争优势,一是要提高本身的品质,二是要降低生产成本。提高蔬菜生产加工的机械化水平是解决问题的最佳途径。

由于我国蔬菜生产在以前很长的时间里,都是小规模生产,主要是自产自销,所以蔬菜的加工几乎全部是手工完成。现在,随着改革开放的深入,一些地区逐渐出现了大规模的蔬菜生产基地,而且大部分蔬菜将出口国外。以前完全依靠人工的作业方法已经不能适应现在的生产了。这就要求我们必须发展适合于我国生产力状况的蔬菜生产加工机械。尤其是蔬菜的加工机械,因为要想在国际市场上取得竞争优势,必须采用统一规范的加工,创品牌,开拓市场。

大葱在我国出口创汇蔬菜中,占有很重要的位置。大葱原产于我国西部及中亚、西亚地区。约在公元1000多年即成为我国栽培食用蔬菜。在世界上,我国是栽培大葱的主要国家之一。大葱可以周年供应,产量高,栽培容易,病虫害少,既耐贮藏又耐运输。它在一般气候、土壤条件下均能生长良好,它是一种很受欢迎的蔬菜和重要的调味品,在国内外都很受欢迎。目前,我国大葱主要销往日本和欧美国家,部分销往港澳地区,日本国内年产54万吨,近年来从中国进中数量剧增。大葱由外贸加工企业收购后,进行保鲜或加工后运销海外。

川公网安备: 51019002004831号

川公网安备: 51019002004831号