目 录

概述3

第一章 概述5

1.1物流知识5

1.1.1物流的定义5

1.1.2物流系统的组成5

1.1.3常用输送机构及功能6

1.2托盘烟垛升降移栽机7

1.2.1升降移载机的分类与特点7

1.2.2 应用情况8

第二章升降移栽机的总体设计方案8

2.1托盘烟垛升降移载机的工作原理8

2.1.1托盘烟垛升降移载机升降机构的工作原理8

2.1.2托盘烟垛升降移载机中转机构的设计和工作原理9

第三章动力系统的设计与计算12

3.1.1电动机功率的选择12

3.1.2移栽机构链轮链条的设计计算13

3.2.1液压缸的选择15

3.2.2推力杆的校核18

第四章轴的设计计算20

4.1.1最小直径20

4.1.2轴上各零件的布置方案20

4.1.3轴的校核21

4.2.1长轴的分布方案23

4.2.2长轴的校核23

第五章轴承的选取与寿命的计算24

链轮轴轴承的校核24

第六章 总结25

参考文献26

概述

物流机械设备不仅是现代化企业的主要作业工具之一,也是合理组织批量生产和机械化流水作业的基础。对第三方物流企业来说,物流设备还是组织物流活动的物质技术基础,它体现着一个企业物流能力的大小。物流设备是物流系统中的物质基础。伴随着物流的发展与进步,物流设备也不断的得到提升与发展。物流设备领域中许多新的设备不断涌现,例如托盘叠盘机、托盘拆盘机、四向托盘、高架叉车、自动分拣机、自动引导搬运车(AGV)、集装箱、升降移栽机等等。它们的出现不但极大的减轻了人们的劳动强度和降低了物流成本,而且提高了物流运作效率和服务质量。因此,它们对物流的快速发展起着重要作用。

关键词: 物流机械 托盘 升降移栽机

ABSTRACT

Logistics equipment is not only the modernization enterprise's main operation tools, and also one of reasonable organization batch production and mechanization flow operation foundation. For the third party logistics enterprise that, logistics equipment or organization logistics activity material and technical basis, it reflects the a enterprise logistics capability of size. Logistics equipment is logistics system of material base. With the development and progress of logistics, logistics equipment also constantly get promoted and development. Logistics equipment in the field of many new equipment constantly emerging, such as tray fold plate machine, tray open offer machine, four to tray, elevated forklift, Automatic sorting machine, Automated guided transport vehicles(AGV), container, Lifting transplanting machine and so on. These appeared not only greatly reduce the labor intensity of the people and reduces the logistics cost, but also improve the logistics operation efficiency and quality. Therefore, the rapid development of their logistics plays an important role.

Key words:Logistics equipment ;Tray Stacked ;Lifting transplanting machine

1.2托盘烟垛升降移栽机

1.2.1升降移载机的分类与特点

升降移栽机机是用于设备及楼层之间的传送装置,广泛用于家电,食品,医药等行业的垂直输送工作。主要型式有托盘式升降机SZ和SC型。在不同的线体之间实现快速而平稳的传递。

SZ托盘式升降移载机是一种自动、连续垂直输送设备,具有输送率高、运行平稳、安全可靠、节能省工的特点。由于托盘式升降机具备自动、连续、垂直输送的特点,在电气控制上要求非常严格。

SC型升降移载机是一种靠齿轮条传动的电梯,主要用于建筑施工的人、货运输。以非常方便的进行安装和拆卸,并可以随着建筑物的增高而增高,及可靠的电器和机械安全系统,是建筑施工中安全高效的垂直运输设备。

1.2.2 应用情况

托盘烟垛升降移载机主要应用于以标准托盘存取的集装化单元货物和货物体积、质量较大的场合。目前广泛应用于烟草行业,烟草行业也是物流系统应用最广泛和技术最成熟的行业。烟草行业货物的转移中转都必须依赖升降移载机。升降移载机的应用不但使货物的存取方便快捷,为烟草行业的迅速发展提供了技术保障。

2.1托盘烟垛升降移载机的工作原理

2.1.1托盘烟垛升降移载机升降机构的工作原理

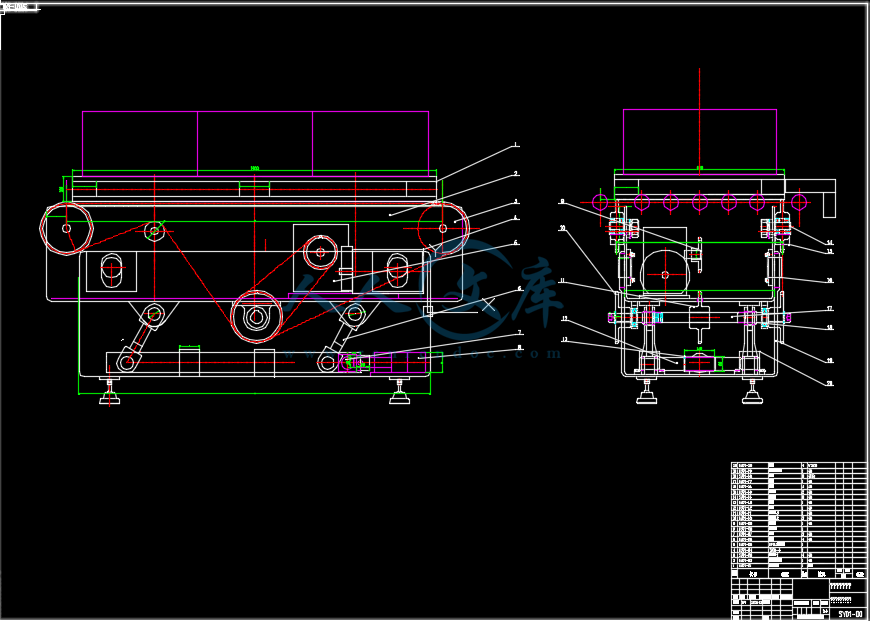

下图所示为有液压缸和杆机构组成的升降机构,如图所示杆机构与上面的移动箱体组成平行四边形在液压缸的带动下左右运动,来实现移动箱体的上下移动,起到货物中转的作用。

图2.1.1

2.1.2托盘烟垛升降移载机中转机构的设计和工作原理

1. 链传动的合理布置

在链传动中,两链轮的转动平面应在同一平面内,两轴线必须平行,最好成水平布置如图 a ,如需倾斜布置时,两链轮中心连线与水平线的夹角 j应小于 45 ° ,如图 b 。同时链传动应使紧边(即主动边)在上,松边在下,以便链节和链轮轮齿可以顺利地进入和退出啮合。如果松边在上,可能会因松边垂度过大而出现链条与轮齿的干扰,甚至会引起松边与紧边的碰撞。

图2.1.2

2. 链传动的张紧

为防止链条垂度过大造成啮合不良和松边的颤动,需用张紧装置。如中心距可以调节时,可用调节中心距来控制张紧程度;如中心距不可调节时,可用张紧轮。张紧轮应安装在链条松边靠近小链轮处,放在链条内、外侧均可,分别如图 c 、 d 所示。张紧轮可以是链轮,也可以是无齿的滚轮

川公网安备: 51019002004831号

川公网安备: 51019002004831号