!【详情如下】【注塑塑料模具课题】CAD图纸+word设计说明书.doc[25000字,59页]【需要咨询购买全套设计请加QQ97666224】.bat

侧型芯.dwg

侧滑块.dwg

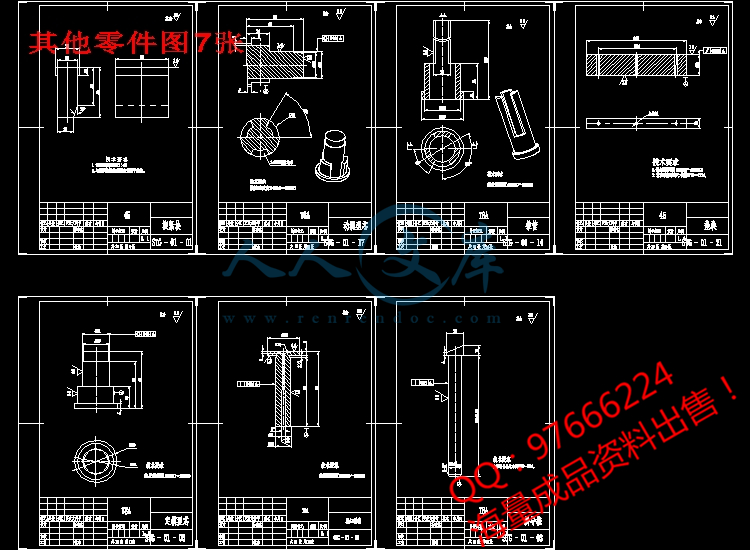

其他零件图7张.dwg

动模座板.dwg

动模板.dwg

塑件图.dwg

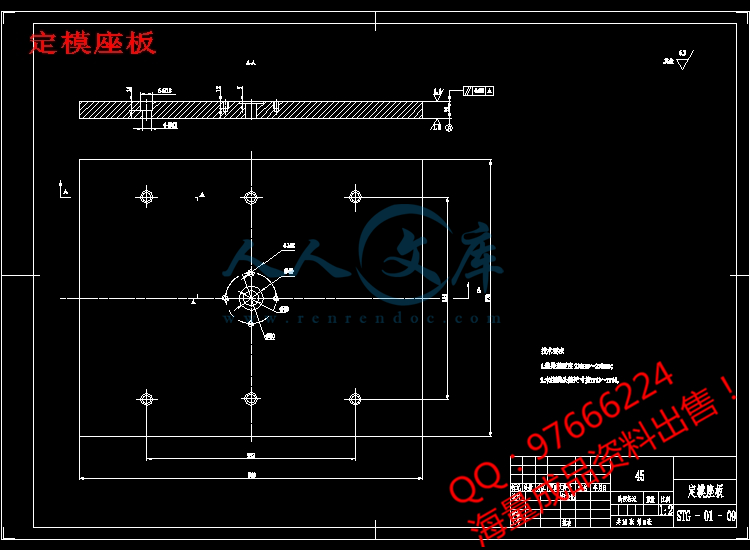

定模座板.dwg

定模板.dwg

推管固定板.dwg

支撑板.dwg

装配图.dwg

任务书.doc

开题报告.doc

设计说明书.doc[25000字,59页]

翻译.doc

摘 要

三通管作为一种连接件在日常生活中应用广泛,本文对塑料模具的设计方法及过程进行了阐述。包括了塑件结构的分析和材料的选择,拟定模具结构形式、注塑机型号的选择,浇注系统的形式和浇口的设计、成型零件的设计、模架的确定和标准件的选用。合模导向机构的确定、脱模推出机构的确定,侧向分型与抽芯机构的设计、排气系统的设计、模具温度调节系统的设计、典型零件制造工艺、模具材料的选用等。

关键词 三通管;注塑模;导向;分型;脱模

ABSTRACT

The Three Links Pipeline as a kind of attachment is widely used in daily life. In the paper, the design method and processes of the plastics mould have been described. including the structural analysis and material selection of the plastic, drawing up the mold structural style, selection of the injection molding machine, the form of feed system and the design of the runner, the design of shaped parts, mold-determination and selection of standards, the oriented institutions to identify for mold clamping, the determination of ejector organization for de-molding, the design of lateral core-pulling organization, the design of the mold pumping system, the design of the system for controlling the mold temperature, the manufacturing processes of typical components, selection of the mold material and so on.

Keywords Three links pipeline; Injection mould; director; joint face; stripping

目 录

1 前言…………………………………………………………………………………………1

1.1 我国塑料模具工业的发展现状……………………………………………………1

1.2 国际塑料模具工业的发展现状…………………………………………………1

1.2.1 网络的CAD/CAE/CAM一体化系统结构初见端倪………………………2

1.2.2 AM软件日益深人人心并发挥越来越重要的作用………………………2

1.2.3 AM软件的智能化程度正在逐渐提高……………………………………2

1.2.4 设计与3D分析的重要性更加明确………………………………………2

1.3 我国塑料模具工业和技术今后的主要发展方向…………………………………3

1.4 本次设计的目的……………………………………………………………………4

2 塑件成型工艺性分析………………………………………………………………………5

2.1 塑件(直三通)分析………………………………………………………………5

2.1.1 塑件图(因使用需要对原式样有所改进…………………………………5

2.1.2 塑件分析…………………………………………………………………5

2.1.3 成型工艺分析如下………………………………………………………5

2.2 ABS的注射成型过程及工艺参数…………………………………………………6

2.2.1 注射成型过程……………………………………………………………6

2.2.2 ABS的注射工艺参数……………………………………………………6

2.2.3 ABS化学和物理特性………………………………………………………7

2.2.4 ABS塑料的主要技术指标…………………………………………………8

3 拟定模具结构形式………………………………………………………………………9

3.1 分型面的选择………………………………………………………………………9

3.1.1 分型面的选择原则…………………………………………………………9

3.1.2 分型面的确定………………………………………………………………9

3.2 型腔数目的确定……………………………………………………………………10

4 注塑机型号的确定………………………………………………………………………11

4.1 所需注射量的计算………………………………………………………………11

4.2 塑件和流道凝料在分型面上的投影面积及所需锁模力的计算………………11

4.3 选择注射机………………………………………………………………………12

4.4 注射机有关参数的校核…………………………………………………………13

4.4.1 型腔数量的校核…………………………………………………………13

4.4.2 注射机工艺参数的校核…………………………………………………13

4.4.3 安装尺寸………………………………………………………………14

4.4.4 开模行程的校核…………………………………………………………14

4.4.5 模架尺寸与注射机拉杆内间距校核……………………………………14

5 浇注系统的形式和浇口的设计…………………………………………………………15

5.1 主流道的设计……………………………………………………………………15

5.1.1 主流道设计要点…………………………………………………………15

5.1.2 主流道尺寸………………………………………………………………15

5.1.3 主流道衬套的形式………………………………………………………16

5.1.4 主流道衬套的固定………………………………………………………17

5.2 冷料穴的设计……………………………………………………………………17

5.3 分流道的设计……………………………………………………………………19

5.3.1 分流道的布置形式………………………………………………………19

5.3.2 分流道的长度……………………………………………………………19

5.3.3 分流道的形状及尺寸……………………………………………………19

5.3.4 分流道的表面粗糙度……………………………………………………20

5.4 浇口的设计………………………………………………………………………20

5.4.1 浇口的形式………………………………………………………………21

5.4.2 浇口类型的选择…………………………………………………………21

5.4.3 浇口位置的选择…………………………………………………………22

5.4.4 浇口的尺寸的确定………………………………………………………22

5.5 浇注系统的平衡…………………………………………………………………22

5.6 浇注系统凝料体积计算…………………………………………………………22

5.7 浇注系统各截面流过熔体的体积计算…………………………………………23

5.8 普通浇注系统截面尺寸的计算与校核…………………………………………23

5.8.1 确定适当的剪切速率…………………………………………………23

5.8.2 确定主流道体积流率…………………………………………………23

5.8.3 注射时间(充模时间)的计算…………………………………………24

5.8.4 校核各处剪切速率……………………………………………………24

6 成型零件的结构设计和计算……………………………………………………………26

6.1 成型零件的结构设计……………………………………………………………26

6.2 成型零件工作尺寸的计算………………………………………………………26

6.3 型腔零件强度、刚度的校核………………………………………………………30

6.3.1 根据侧壁厚度校核强度、刚度…………………………………………30

6.3.2 根据底板厚度校核强度、刚度…………………………………………31

7 模架的确定和标准件的选用……………………………………………………………33

8 合模导向机构的设计……………………………………………………………………35

8.1 导向结构的总体设计……………………………………………………………35

8.2 导柱设计…………………………………………………………………………35

8.3 导套设计…………………………………………………………………………36

9 脱模推出机构的设计……………………………………………………………………37

9.1 脱模力的计算……………………………………………………………………37

9.2 脱模机构的结构设计……………………………………………………………38

10 侧向抽芯机构的设计……………………………………………………………………39

10.1 抽芯距与抽芯力的计算…………………………………………………………39

10.2 斜导柱截面尺寸的确定…………………………………………………………40

10.3 楔紧块的设计……………………………………………………………………41

11 排气系统的设计…………………………………………………………………………43

12 温度调节系统设计………………………………………………………………………44

12.1 冷却时间的计算…………………………………………………………………44

12.2 冷却管道传热面积及管道数目的简易计算……………………………………45

13 典型零件的制造加工工艺………………………………………………………………48

13.1 带头导柱的制造工艺……………………………………………………………48

13.2 编程零件及刀具选择……………………………………………………………49

13.3 切削用量确定……………………………………………………………………49

13.4 编制加工程序……………………………………………………………………49

14 设计小结…………………………………………………………………………………51

参考文献………………………………………………………………………………………52

致谢词…………………………………………………………………………………………53

附录…………………………………………………………………………………………54

川公网安备: 51019002004831号

川公网安备: 51019002004831号