!【详情如下】【注塑塑料模具类】CAD图纸+word设计说明书.doc[19000字,42页]【需要咨询购买全套设计请加QQ97666224】.bat

任务书.doc

设计说明书.doc[19000字,42页]

毕业设计方案论证

毕业设计翻译

侧型芯1A4.dwg

侧型芯2A4.dwg

侧型芯3A4.dwg

侧滑块A1.dwg

凹模板A1.dwg

动模型芯1A4.dwg

动模型芯2A4.dwg

动模型芯3A4.dwg

动模型芯垫板A2.dwg

动模座板A1.dwg

动模拼块A1.dwg

塑件图.dwg

定位圈A4.dwg

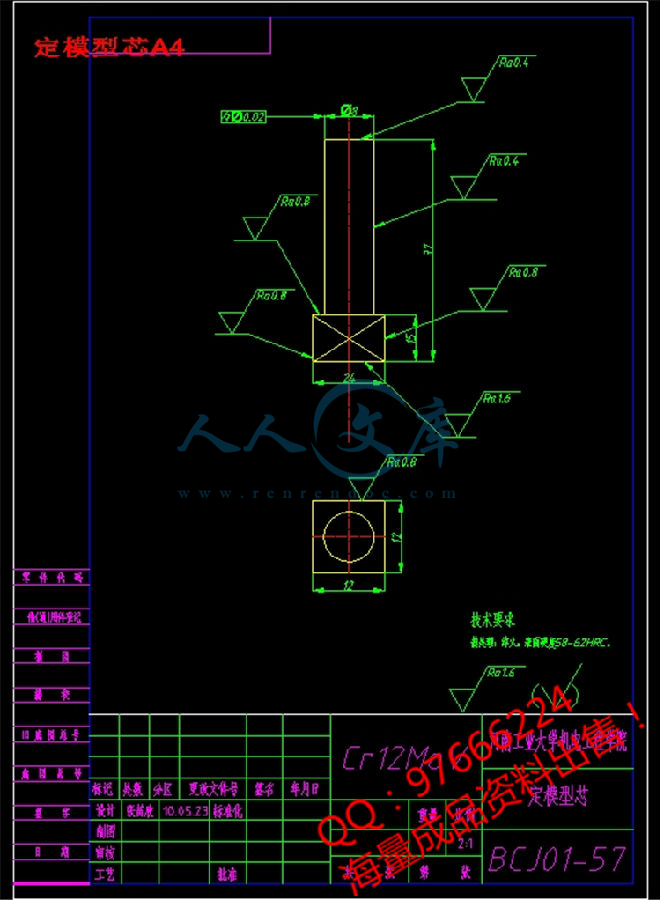

定模型芯A4.dwg

定模型芯垫板A2.dwg

定模座板A1.dwg

定模拼块A1.dwg

定模板A1.dwg

推杆固定板A1.dwg

推板A1.dwg

支撑板A1.dwg

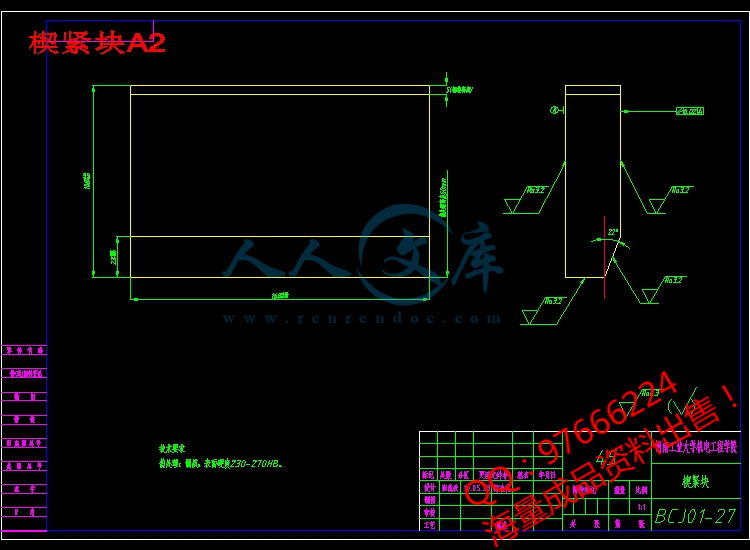

楔紧块A2.dwg

模具总装合模图A0.dwg

模具总装开模图A0.dwg

浇口套A4.dwg

限位挡块A4.dwg

限位片A4.dwg

目 次

1 塑料模具的现状1

2 塑件的成形工艺性分析3

2.1 课题题目介绍3

2.2 制件结构形状3

2.3 塑件材料的选择及其结构分析4

2.4 塑件工艺性分析5

2.5 ABS的主要技术指标5

2.6 ABS的注射成型工艺6

3 模具结构形式的拟定6

3.1 确定型腔数量及排列方式6

3.2 模具结构形式的确定7

4 注塑机型号的确定8

4.1 塑件注塑量的计算:8

4.2 注射机型号的确定9

4.3 注射机及型腔数量的校核9

4.4 注射机及参数量的校核10

4.5 模具与注射机安装部份的校核11

4.6 顶出行程校核11

5 分型面位置的确定11

5.1 分型面的形式11

5.2 分型面的设计原则11

5.3 分型面的确定12

6 浇注系统的形式和浇口的设计12

6.1 浇注系统设计原则12

6.2 主流道的设计13

6.3 分流道的设计14

6.4 冷料井的设计16

6.5 浇口的设计17

6.6 浇注系统的平衡19

6.7 排气系统的设计19

7 成型零件的设计20

7.1 成型零件的结构形式成型零件的选材21

7.2 成型零件的计算21

7.3 成型零件钢材的选用23

7.4 成型零件强度及支撑板厚度的计算25

8 模架的确定和标准件的选用26

8.1 定模座板27

8.2 定模板27

8.3 动模座板27

8.4 动模板27

8.5 支承板27

8.6 垫块27

8.7 推杆固定板28

8.8 推板28

9 导向机构的设计28

9.1 导向机构的作用28

9.2 导向结构的总体设计28

9.3 导柱的设计29

9.4 导套的设计29

10 侧向抽芯机构设计30

10.1 结构形式的确定30

10.2 斜导柱侧向抽芯力的计算30

10.3 斜导柱的设计31

10.4 滑块、倒滑槽及定位装置的设计31

10.5 楔紧块的设计32

11 脱模推出机构的设计33

11.1 推杆推出机构33

11.2 推出机构的导向和复位33

12 排气系统确定335

毕业设计总结37

致 谢39

参考文献40

参考文献

[1]冯晓曾等. 模具材料与热处理. 机械工业出版社,1985

[2]《模具制造手册》编写组. 模具制造手册. 北京:机械工业出版社,2000

[3]罗继相. 浅析我国模具行业现状及发展趋势和对策.模具技术,No.3,2001

[4]张容清. 模具设计与制造. 北京:高等教育出版社,2003.8.

[5]刘品,李哲.互换性与测量技术基础.哈尔滨工业大学出版社,2006

[6]吴生绪.塑料成形模具设计手册.北京:机械工业出版社,2008,1.

[7]杨占尧.塑料模具标准件及设计应用手册.北京:化学工业出版社,2008.

[8]屈华昌.塑料成型工艺与模具设计.北京:高等教育出版社,2008.

[9]吴宗泽,罗圣国.机械设计课程设计手册. 北京:高等教育出版社,2006

[10]孙凤勤.模具制造工艺与设备. 北京:机械工业出版社,2008.

[11]翟秀云.塑料自动成型用模具问题的探讨[J].攀枝花学院学报,2002.

[12]陈万林.实用注塑模具手册[M].机械工业出版社,2000-10.

[13]付丽.螺纹自动脱模的注塑模设计[M].轻工机械,2000.第1期.

[14]申开智,叶淑静.塑料成型模具[M].轻工业出版社,1982.

[15] 崔洪斌,杨海如 等编.AutoCAD2009机械图形设计.清华大学出版社.2008,8.

[16] 詹友刚 编著.Pro/ENGINEER中文野火版2.0基础教程.清华大学出版社.2007,2.

[17] 和庆娣,袁巍,刘昌丽 等编著.Pro/ENGINEER Wildfire 3.0中文版模具设计. 机械工业出版社.2007,1.

[18] 杨占尧 主编.塑料模具标准件及设计应用手册.化学工业出版社.2008,3.

[19] 吴生绪 主编.塑料成型模具设计手册.机械工业出版社。2008,3.

川公网安备: 51019002004831号

川公网安备: 51019002004831号