资源目录

压缩包内文档预览:(预览前20页/共40页)

编号:531203

类型:共享资源

大小:3.93MB

格式:RAR

上传时间:2015-11-25

上传人:郝**

认证信息

个人认证

郝**(实名认证)

浙江

IP属地:浙江

100

积分

- 关 键 词:

-

织机

曲轴

夹具

设计

- 资源描述:

-

毕业设计(论文)题目:

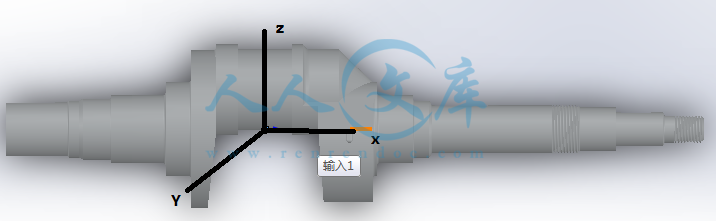

织机曲轴1零件加工工艺及典型夹具设计

毕业设计(论文)要求及原始数据(资料):

要求:曲轴加工是轴类零件中具有一定加工难度的典型的轴类加工,其主要难点在于设计符合加工要求的夹具,确保曲轴弯曲部分与主体部分的偏心距,其加工工艺及典型夹具设计在轴类零件加工中具有特殊意义。本设计要求设计曲轴的一套完整的加工工艺方案及加工曲轴弯曲部分的专用夹具。要求设计能在保证加工质量的前提下,力求技术经济性优秀。

原始数据(资料):见附织机曲轴1零件图及现场实测收集,年生产量为800支。

- 内容简介:

-

xx 学校 毕业设计任务书 2015.01 第 1 页 毕业设计(论文)题目: 织机曲轴 1 零件加工工艺及典型夹具设计 毕业设计(论文)要求及原始数据(资料) : 要求 :曲轴加工是轴类零件中具有一定加工难度的典型的轴类加工,其主要难点在于设计符合加工要求的夹具,确保曲轴弯曲部分与主体部分的偏心距,其加工工艺及典型夹具设计在轴类零件加工中具有特殊意义。本设计要求设计曲轴的一套完整的加工工艺方案及加工曲轴弯曲部分的专用夹具。要求设计能在保证加工质量的前提下,力求技术经济性优秀。 原始数据(资料) :见附织机曲轴 1 零件图及现场实测收集,年生产量为 800支。 nts第 2 页 毕业设计(论文)主要内容 : 1.对织机曲轴 1 进行零件全面分析,画零件图; 2.确定生产类型和工艺特征,选择毛坯种类及制造方法,确定毛坯尺寸,绘制毛坯图; 3.选择加工方法,拟定工艺路线,进行工序设计和工艺计算; 4.画工序简图,填写工艺文件; 5.设计典型工序的专用夹具; 6.结合本课题查阅并翻译 0.5 0.7 万个印刷符号的英文资料; 2.编写不少于 1.5 万字的设计说明书。 学生应交出的设计文件(论文) : 1图纸 ( 1) 典型工序专用夹具装配图 A0 图纸 1 张,主要零件图 A1 或 A2 图纸23 张。 夹具的三维装配图及爆炸图 A0 图纸 1 张。 ( 2) 曲轴 1 零件图、毛坯图各 A1 图纸 1 张。 ( 3)机械加工工艺过程综合卡片 1 张、机械加工工序卡 1 套。 2说明书 ( 1) 曲轴 1 在织机上的作用分析及零件分析、生产类型和工艺特征分析; ( 2) 毛坯种类及制造过程; ( 3) 加工方法选择及工艺路线拟定; ( 4) 工序设计及工艺计算; ( 5)画工序简图,形成工艺文件; ( 6)典型专用夹具的设计过程说明。 (以上内容全部采用计算机制作) nts第 3 页 主要参考文献(资料) : 1 张世昌等 主 编机械制造技术 北京:高等教育 出版社, 2007 2 崇 凯主 编 机械制造技术基础课程设计指南 . 北京:化学 工业出版社,2006 3 梁炳文主编 机械加工工艺与窍门精选 北京: 机械工业出版社, 1997 4 机械工程师手册(第二版)编委会 机械工程师手册(第二版) 北京:机械工业出版社, 2000 5 机械 工程 手册 (第二版)编委会 . 机械 工程 手册 (第二版),第 7 卷 北京: 机械 工业出版社 , 1997 6 机械 工程 手册 (第二版)编委会 . 机械 工程 手册 (第二版),第 8 卷 北京: 机械 工业出版 社 , 1997 7 徐鸿本主编 . 机床夹具设计手册 . 沈阳:辽宁科学技术出版社, 2004 8 卢秉恒主编 .机械制造技术基础(第三版) . 北京 : 机械工业 出版社,2007 9 韩秋实等主编 . 机械制造技术基础(第三版) . 北京: 机械 工业出版社,2009 10 叶伟昌 主编 . 机械工程及自动化简明设计手册(第二版)上册 . 北京:机械工业出版社, 2007 11黄玉美主编 .机械制造装备设计 .北京:高等教育出版社, 2008 专 业 班 级 学 生 设计(论文)工作起止日期 2015.01.122015.05.20 指 导 教 师 签 字 日期 专业(系)主任签 字 日期 nts XX 学校 机械学院 毕业设计(论文)开题报告 毕业设计题目 : 织机曲轴 1 零件加工 工艺及 典型夹具设计 学 生 姓 名 : 指 导 教 师 姓 名 : 专 业: 机械设计制造及其自动化 年 月 日 nts 1.课题名称 : 织机曲轴 1 零件加工工艺及典型夹具设计 2.课题研究背景 : 纺织机械 是 把天然纤维或化学纤维加工成为纺织品所需要的各种机械设备。生产化学纤维的机械虽然包括多种化工机械,现在已被认为是纺织机械的延伸,属广义的纺织机械。 织布机就是纺机的一类。 织布机,织机的俗称,又叫纺机、织机、棉纺机等,早期的织布机都是依靠人力带动的织布机。织机包括原始的有梭织机和新式的无梭织机,无梭织机主要有剑杆织机、喷气织机、喷水织机和片梭织机。曲轴 的作用 是将连杆传来的力转变成为绕其本身轴线旋转的扭矩 ,并将 此 扭矩输出 。 曲轴在工作中既承受转矩又承受弯矩,这就要求曲轴有足够的强度和刚度 ,所以 曲轴是织机中较难保证加工质量的零件。 3.课题研究意义: 毕业设计 是教学计划中最后一个实践教学环节, 不仅是对前面所学知识的一种检验,而且也是对自己能力的一种提高 ,对大学学习的一次总结。 目的是培 养学生 综合运用所学 的基础 理论、 专业知识 、 基本技能研究及 结合生产实际分析和解决工程实际问题的能力,通过 收集素材 、 设计方案 、 工艺制作等过程, 制定设计方案 , 掌握机械零件、机械传动装置的设计过程和方法,巩固、加深和扩展有关机械设计方面的知识,练习 熟悉使用 AutoCad、SolidWorks 等软件 ,加深对制图的理解应用。 为走出学校走向社会工作岗位打下基础。 4.文献查阅、资料收集概况 : 经过大量的搜集相关文献和资料,了解了相关的课题方面的知识和情况,其中主要的参考文献如下: 1 邱宣怀主编 .机械设计 .北京:高等教育出版社, 2012 2 郑文纬 主编 .机械原理 .北京:高等教育出版社, 2012 3 王伯平主编 .互换性与测量技术基础 .北京:机械工业出版社, 2008 4 侯书林 、张建国主编 .机械制造技术基础 .北京:大学出版社, 2012 5 大连理工大学工程图学教研室 . 机械制图(第六版) . 北京:高等教育出版社, 2007 6 机械工程手册(第二版)编委会 .机械工程手册(第二版) .北京:机械工业出版社, 1997 7 徐宏本主编 .机床夹具设计手册 .沈阳:辽宁科学技术出版社, 2004 8 尹成湖 主编 .机械制造技术基础 课程设计 .北京: 高等教育 出版社, 2008 9 韩秋实等主编 .机械制造技术基础(第三版) .北京:机械工业出版社, 2009 5.设计(论文)的主要内容 : (1).对织机曲轴 1 进行零件全面分析,画零件图; nts(2).确定生产类型和工艺特征,选择 毛坯种类及制造方法,确定毛坯尺寸,绘制毛坯图; (3).选择加工方法,拟定工艺路线,进行工序设计和工艺计算; (4).画工序简图,填写工艺文件; (5).设计典型工序的专用夹具; (6).结合本课题查阅并翻译 0.5 0.7 万个印刷符号的英文资料; (7).编写不少于 1.5 万字的设计说明书 ; 6.设计(论文)提交形式 : 1)图纸 (1).典型工序专用夹具装配图 A0 图纸 1 张,主要零件图 A1 或 A2 图纸 23 张。夹具的三维装配图及爆炸图 A0 图纸 1 张。 (2).曲轴 1 零件图、毛坯图各 A1 图纸 1 张。 (3).机械加工工艺过程综合卡片 1 张、机械加 工工序卡 1 套。 2)说明书 (1).曲轴 1 在织机上的作用分析及零件分析、生产类型和工艺特征分析; (2).毛坯种类及制造过程; (3).加工方法选择及工艺路线拟定; (4).工序设计及工艺计算; (5).画工序简图,形成工艺文件; (6).典型专用夹具的设计过程说明。 7.进度安排 : 第 一 周:开题 答辩 、 修改 开题报告 第 二 周: 开题报告答辩 第三周:实习调研 、 完成织机曲轴的分析 、 画零件图 第四周: 选择毛胚 、 设计绘制毛胚图 第五周: 设计,形成工艺路线工艺规程 第六周: 完成曲轴零件工艺规程的设计 第七周: 第八周: 第九周: 第十周: 第十一周: 修改设计 、 完稿 nts 第十二周:准备答辩,毕业答辩 8. 指导教师意见 签名: 年 月 日 nts nts 织机曲轴零件加工工艺 及典型夹具设计 学生姓名: 指导教师: 摘要: 本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。 曲轴零件的工艺规程及其车曲轴弯曲部分的专用夹具设计是包括零件加工的工艺规程、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设 计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并及时修正。 关键词 : 曲轴 工艺规程 专用夹具 设计 nts Loom crack shaft parts processing technology and typical fixture design Authors Name: Tutor: ABSTRACT: This design involves the machinery manufacturing process and fixture design, metal cutting machine tool, tolerance and measurement and other aspects of knowledge.Special fixture process planning and crankshaft bending part of the crank parts design is the design of process design, including the parts processing process design and fixture three. In the process of design should first of all parts for analysis, to understand the parts of the process to design blank structure, and choose the good parts machining datum, design a part of the process route; then the parts of each step of the process dimension calculation, is the key to determine the process equipment and cutting the amount of each working procedure design; then the special fixture fixture design, selection of the various components, such as the connecting part positioning element, clamping elements, guiding elements, fixture and machine tools and other components; the positioning errors calculated fixture positioning, analysis the rationality and shortcoming of the fixture structure, pay attention to improve and design in later. KEYWORDS : crank proc fixture designnts nts 晋 中 学 院 本科毕业设计英文参考资料 题 目 The crank processes specificat -ion and development direction 院 系 机械学院 专 业 机械设计制造及其自动化 姓 名 学 号 学习年限 年 月至 年 月 指导教师 职 称 副教授 申请学位 工学 学士学位 年 月 日 nts 1 The crank processes specification and development direction 1 The crank processes specification The crank specification is very high, its machine-finishing technological process different and the crank complex degree has the very big difference along with the production guiding principle, but includes following several main stages generally: Localization datum processing; Thick, lathe finishing and rough grinding each host neck and other outer annuluses; Che Lianjing; Drills the oil hole; Correct grinding each host neck and other outer annuluses; Correct grinding Lian Jing; Big, capitellum and key slot processing; Journal surface treatment; Transient equilibrium; Super finishing various journals. May see, the main neck or Lian Jing the turning working procedure all separates with the grinding working procedure, is often middle arrangement some different machined surfaces or the heterogeneity working procedure. After the rough machining can have the distortion.Thick, the precision work separates, and arranges the alignment working procedure behind the cutting force big working procedure, guarantees the processing precision. In order to reduce the distortion which the cutting force causes, guaranteed when precision work precision request, correct grinding various journals, uses the single grinding wheel in turn grinding generally. The journal processing requests high, the main neck and the neck uses continually processes many times. 2 Crank machining development direction Along with our country numerical control engine bed unceasing increase, the crank rough machining will be widespread uses in the numerical control lathe, the numerical control the milling machine, the numerical control vehicle broaching machine and so on the advanced equipment to the main journal, the connecting rod journal carries on the numerical control turning, in the milling, the vehicle - broaching nts 2 processing, by will effectively reduce the amount of deformity which the crank will process. The crank precision work will be widespread uses the CNC control the crankshaft grinding to carry on the correct grinding processing to its journal, this kind of grinder will provide grinding wheel automatic function requests and so on transient equilibrium installment, center rest automatic tracking unit, automatic survey, self-compensating system, grinding wheel automatic conditioning, permanent link speed, will guarantee the grinding quality the stability. In order to satisfy the processing request which the crank enhances day by day, set the very high request to the crankshaft grinding. The modern crankshaft grinding except must have the very high static state, the dynamic rigidity and outside the very high processing precision, but also requests to have the very high grinding efficiency and more flexibilities. In recent years, requested the crankshaft grinding to have the stable processing precision, for this, had stipulated to the crankshaft grinding process capability coefficient Cp1.67, this meant requested the crankshaft grinding the actual processing common difference to have the common difference which assigned compared to the crank small one half. Along with the modern actuation and the control technology, the survey control, CBN (cubic boron nitride) the grinding wheel and the advanced engine bed part application, for the crankshaft grinding high accuracy, the highly effective abrasive machining has created the condition. One kind calls it the connecting rod neck follow-up grinding craft. Has manifested these new technical synthesis application concrete achievement. This kind of follow-up grinding craft may obviously enhance the crank connecting rod neck the grinding efficiency, the processing precision and the processing flexibility. When carries on the follow-up grinding to the connecting rod neck, the crank take the main journal as the spool thread carries on revolving, and clamps the grinding all connecting rod neck in an attire. In the grinding process, the wheelhead realization reciprocation swing feed, tracks the biased rotation connecting rod neck to carry on the abrasive machining. Must realize the follow-up grinding, X axis besides must have the high dynamic performance, but also must have the enough tracking accuracy, guarantees the shape common difference which the connecting rod neck requests. The CBN grinding wheel nts 3 application realizes the connecting rod neck follow-up grinding important condition. Because the CBN grinding wheel resistance to wear is high, in the grinding process medium plain emery wheel diameter is nearly invariable, a conditioning may the grinding 600800 cranks. The CBN grinding wheel also may use the very high grinding speed, may use generally on the crankshaft grinding reaches as high as the 120140m/s grinding speed, the grinding efficiency is very high. 3 Connecting rod processing method The connecting rod decomposes (also called connecting rod breaks) the technical principle uses the material break theory, first artificial has the whole forging connecting rod semi finished materials big end of hole the fissure, forms the initial break source, then expands with the specific method control fissure, achieved the connecting rod The decomposition processing process enable the decomposition the connecting rod cap, the pole adjoining plane to have the complete meshing jig-saw patterned structure, guaranteed the adjoining plane precise docking, tallies, does not need to carry on the adjoining plane again the processing, simultaneously simplified the connecting rod bolt hole structural design and the whole processing craft, has the processing working procedure few, the economical precision work equipment, the nodal wood energy conservation, the product quality high, the production cost low status merit. Main body and the connecting rod cap separate goal. 4 Trend of development At present, the drop for and the die casting connecting rod host, the important status, are facing the powder to forge the steel connecting rod and a powder agglutination steel connecting rod forming craft challenge. Speaking of the domestic present situation, although the powder metallurgy forging industry had certain development, but must provide the mass and the high grade powder metallurgy forging is not mature. Moreover involves the equipment to renew, aspect expense questions and so on technical change, in next one, in long time, domestically produced connecting rod production also by drop forging craft primarily. The connecting rod is one of internal combustion engine main spare parts, its nts 4 reducing socket two sizes and the shape position errors have many requests, for example: Diameter, roundness, cylindricity, center distance, parallelism, hole and end surface verticality and so on. How does these erroneous project produce the scene in the workshop to examine, always is in the internal combustion engine profession a quite difficult question. In the connecting rod production, domestic mainly has following several examination method at present: With the spindle survey, namely puts on the spindle in connecting rod two, with the aid of in V shape block, plate, dial guage survey. Because the spindle needs to load and unload, therefore between the hole axis has the gap, the measuring accuracy is very low. 5 Crankshaft design requirements and working conditions Crankshaft is in constant cyclical changes in the gas pressure, reciprocating and rotating motion of the inertial force and the quality of their work under the joint action of the moment, so that both the torsion and bending the crankshaft, resulting in fatigue, stress state; internal imbalance of the engine crankshaft also withstand bending moment and shear force; not taken measures to make the crankshaft torsional vibration damping effect may also be a large amplitude torsional elastic torque. These loads are cross degeneration, may cause fatigue failure of the crankshaft. Practice shows that the bending has a decisive role in bending fatigue failure is the main failure modes. Therefore, the structural strength of the crankshaft bending fatigue strength is the focus, the crankshaft is designed to be committed to improving the fatigue strength of the crankshaft. Crankshaft complex shape, stress concentration is very serious, especially in the connecting rod journal and the crank arm of the fillet and lubricants at the stress concentration near the exit hole is particularly prominent. Common crankshaft fracture, fatigue crack begins with fillet and the hole place. Root bending fatigue cracks in the surface of the fillet from the journal at the development of the crank, the crank is basically broken into 450; torsion fatigue damage is usually bad from the machining start hole edge, about 450 cut into the crank pin. Therefore, in the design nts 5 of the crankshaft, pay special attention to finding ways to ease stress concentration, strengthen the stress concentration. Crankshaft journal at a very high ratio of pressure to a large relative velocity of sliding friction in the bearings in place. The bearings in the actual operation conditions changed conditions does not always guarantee a liquid friction, especially when the oil is not clean, the journal was a strong abrasive wear surface, making the actual life of the crankshaft greatly reduced. Therefore, the design, to wear to the friction surface, and the appropriate material-bearing Crank in the crankshaft is the central link, the stiffness is very important. If the crankshaft bending stiffness, then the possible occurrence of more severe bending, the piston rod and bearing deterioration in working conditions greatly affect the reliability of these parts work and durability, even the crankcase is too large and the local stress cracking. Crankshafts torsional stiffness is poor, the working speed range may be a strong torsional vibration. Ranging from noise, such as transmission gear on the crank to accelerate the wear; while in the crankshaft fracture. Therefore, the design should ensure-highest. As the crankshaft by the power complex, geometric cross-section shape is rather special, in the design, has yet to reflect the objective reality of a theoretical formula for Universal. Therefore, the current design of the crankshaft design relies mainly on experience. nts 1 曲轴加工的技术要求及发展方向 1 曲轴加工的技术要求 曲轴的技术要求是很高的,其机械加工工艺过程随生产纲领的不同和曲轴的复杂程度而有很大的区别,但一般均包括以下几个主要阶段:定位基准的加工;粗、精车和粗磨各主 轴 颈及其它外圆;车连 杆轴 颈;钻油孔;精磨各主 轴 颈及其他外圆;精磨连颈;大、小头及键槽加工;轴颈表面处理;动平衡 ;超精加工各轴颈。 可以看出,主 轴 颈或连 杆轴 颈的车削工序都与磨削工序分开,往往中间安排一些不同的加工面或不同性质的工序。粗加工后会发生变形,因此常把粗、精加工分开,并在切削力较大的工序后面安排校直工序,以保证加工精度。 为了减小切削力所引起的变形,保证精加工的精度要求,精磨各轴颈时,一般采用单砂轮依次磨削。 轴颈的加工要求高,主 轴 颈和连 杆轴 颈采用多次加工 。 2 曲轴机加工发展方向 随着我国数控机床的不断增加, 曲轴粗加工将广泛采用数控车床、数控内铣床、数控车拉床等先进设备对主轴颈、连杆轴颈进行数控车削、内铣削、车 -拉削加工,以有效减少曲轴加工的变形量。曲轴精加工将广泛采用 CNC 控制的曲轴磨床对其轴颈进行精磨加工,此种磨床将配备砂轮自动动平衡装置、中心架自动跟踪装置、自动测量、自动补偿装置、砂轮自动修整、恒线速度等功能要求,以保证磨削 质量的稳定。 为满足曲轴日益提高的加工要求,对曲轴磨床提出了很高的要求。现代曲轴磨床除了要有很高的静态、动态刚度和很高的加工精度外,还要求有很高的磨削效率和更多的柔性。近年来,更要求曲轴磨床具有稳定的加工精度,为此,对曲轴

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号