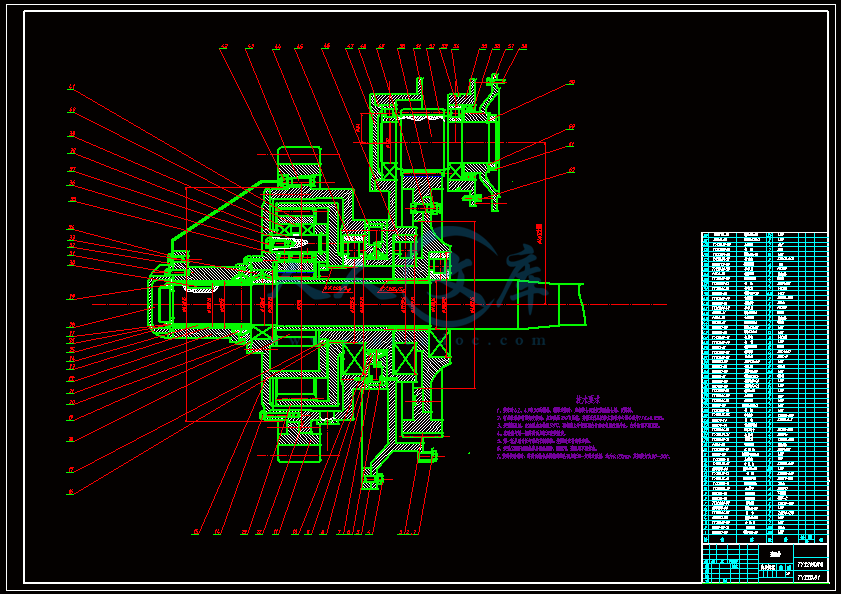

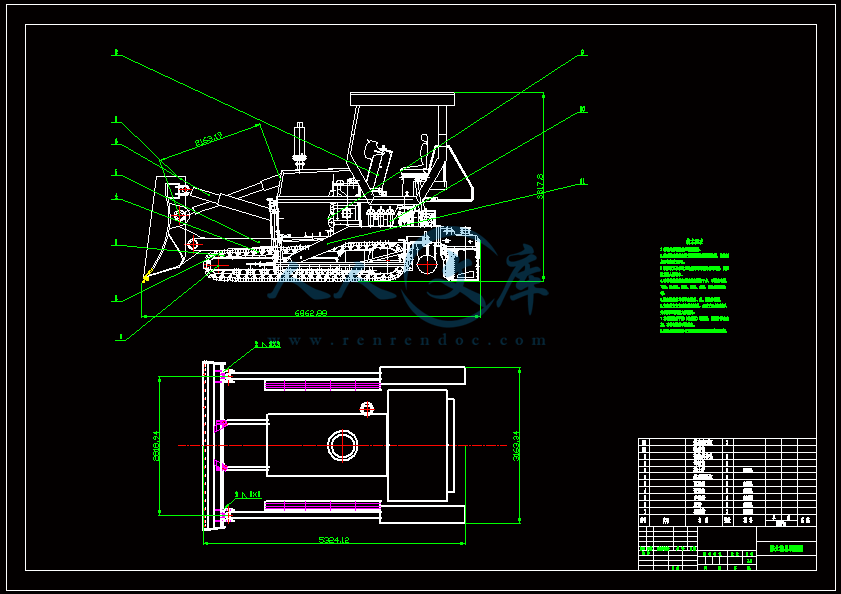

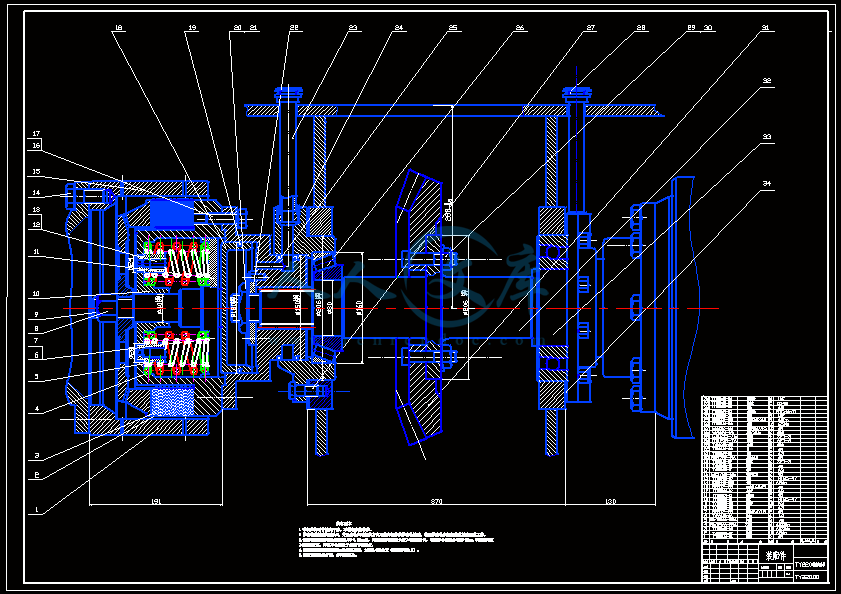

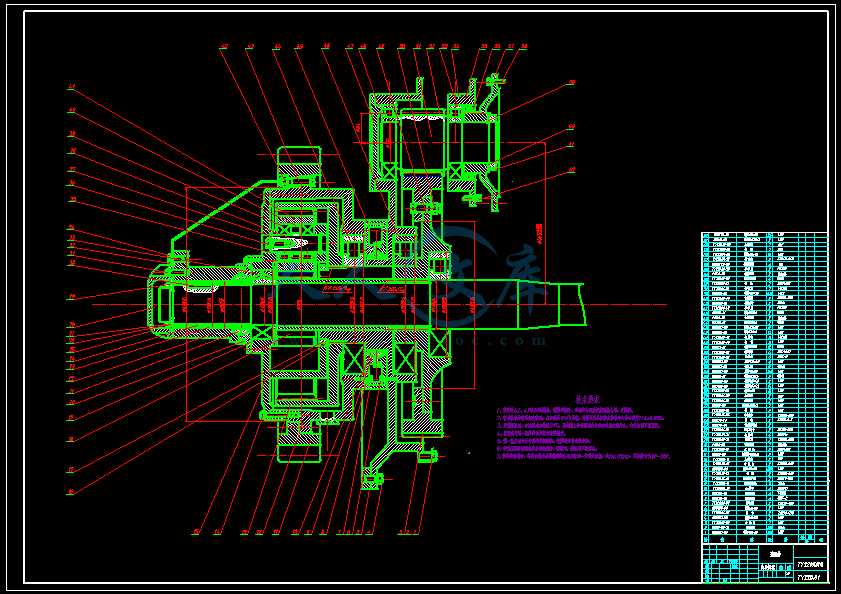

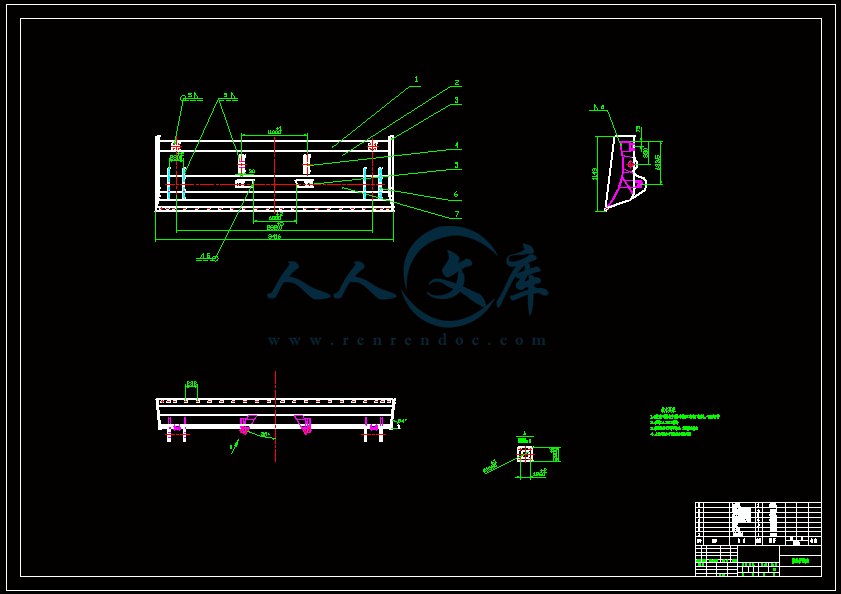

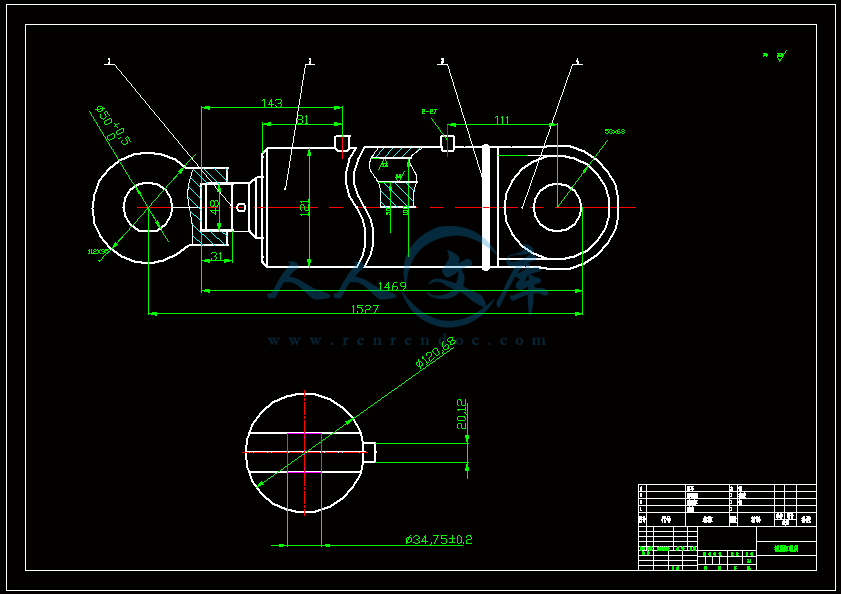

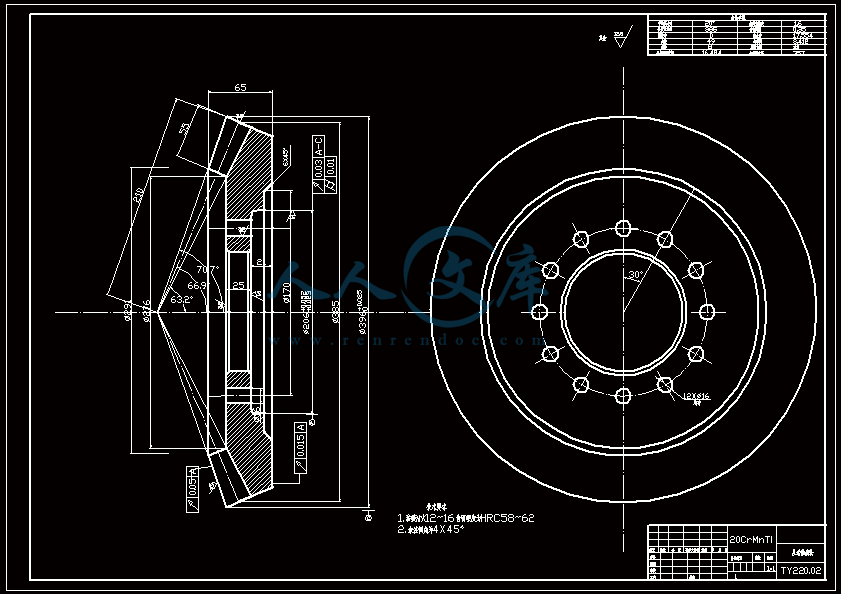

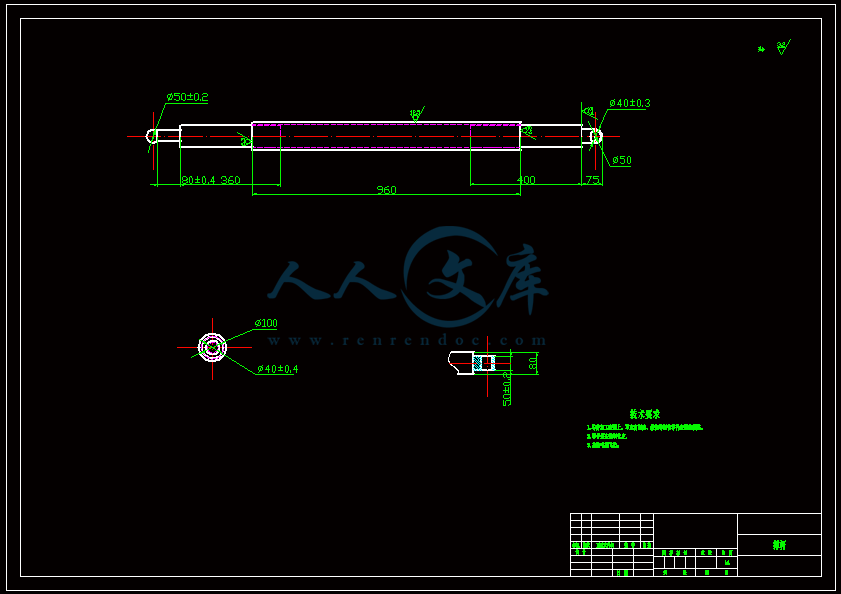

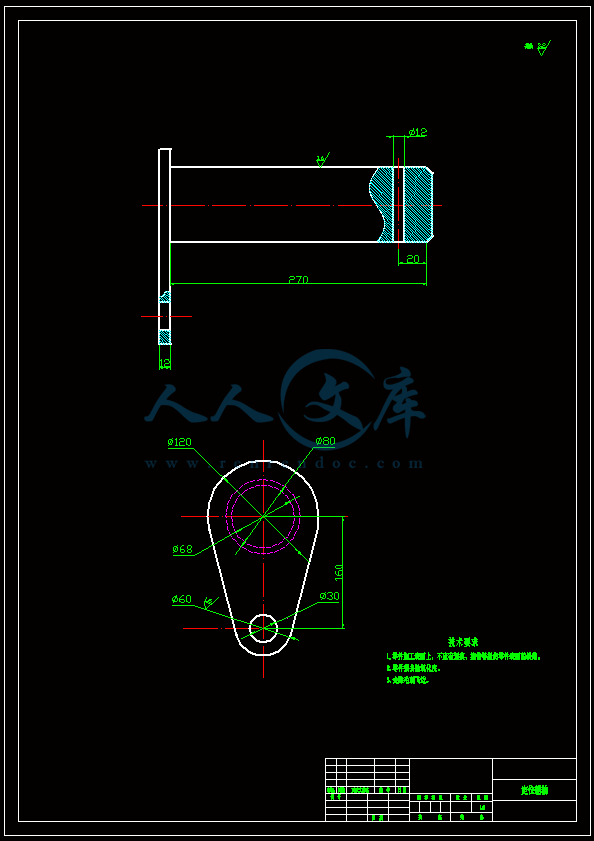

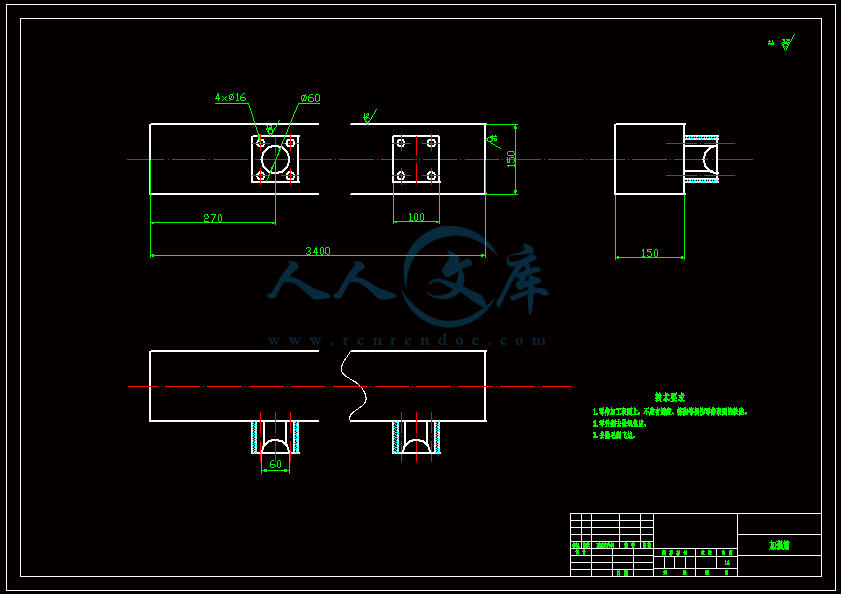

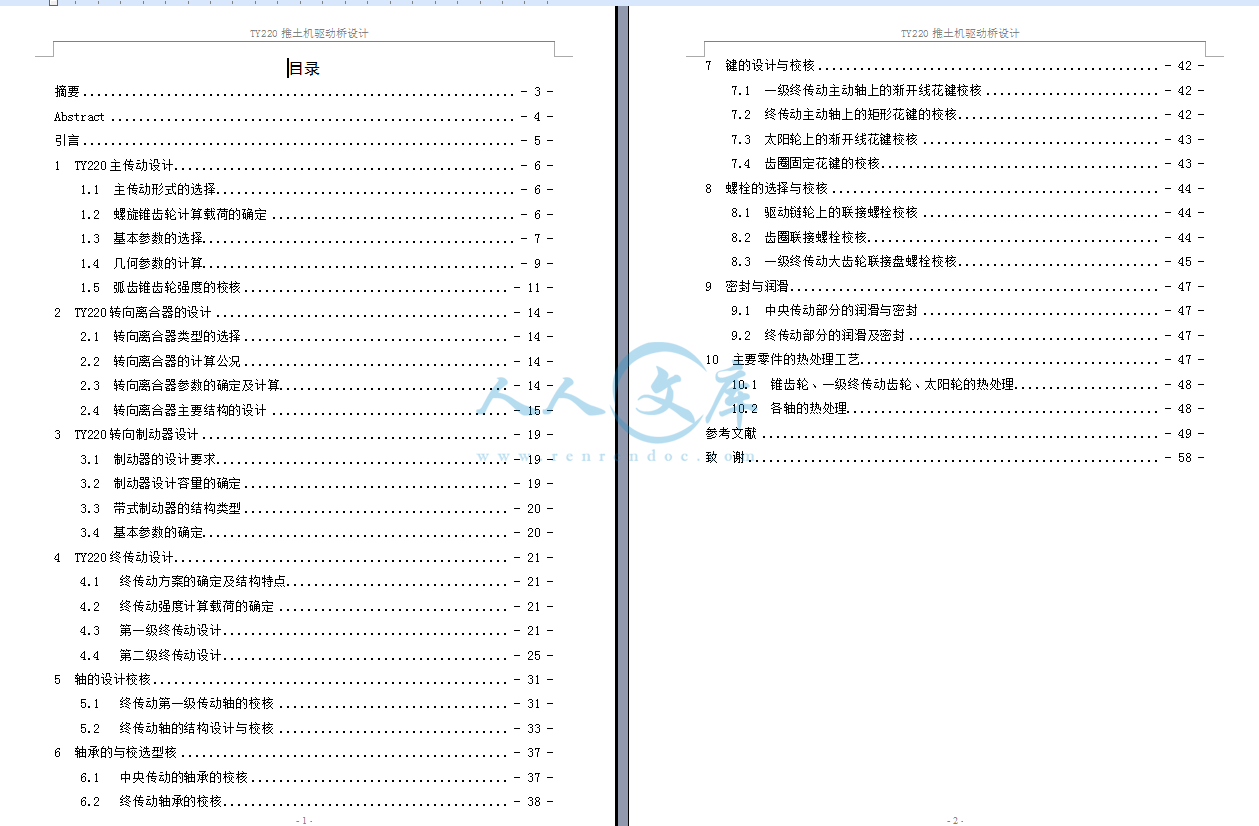

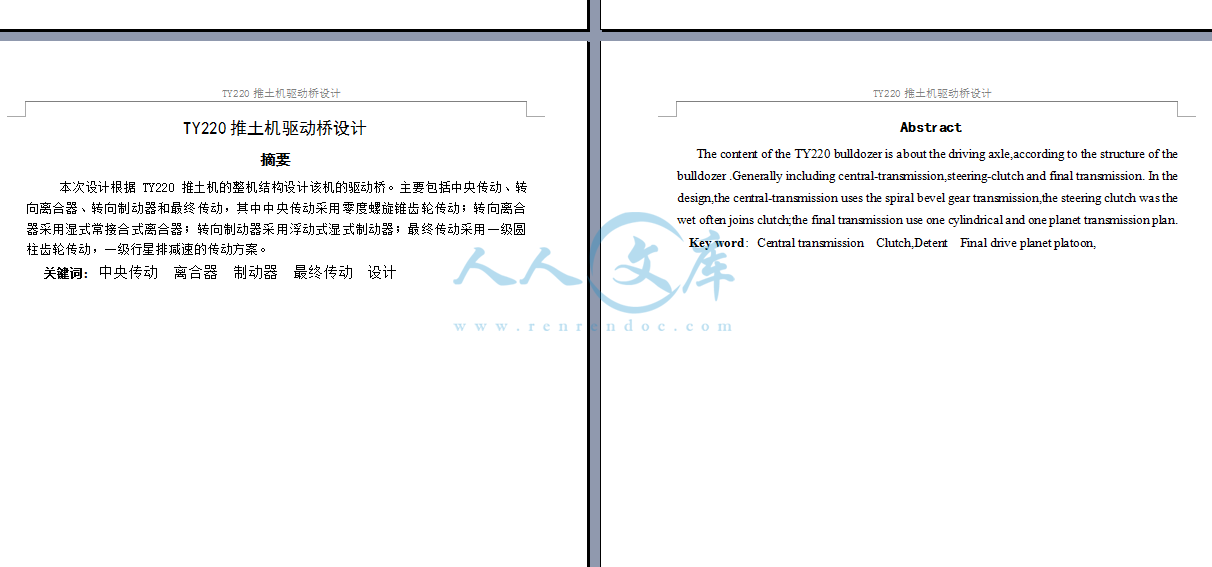

TY220履带式推土机驱动桥的设计【全套含CAD图纸、开题报告、说明书及翻译】

收藏

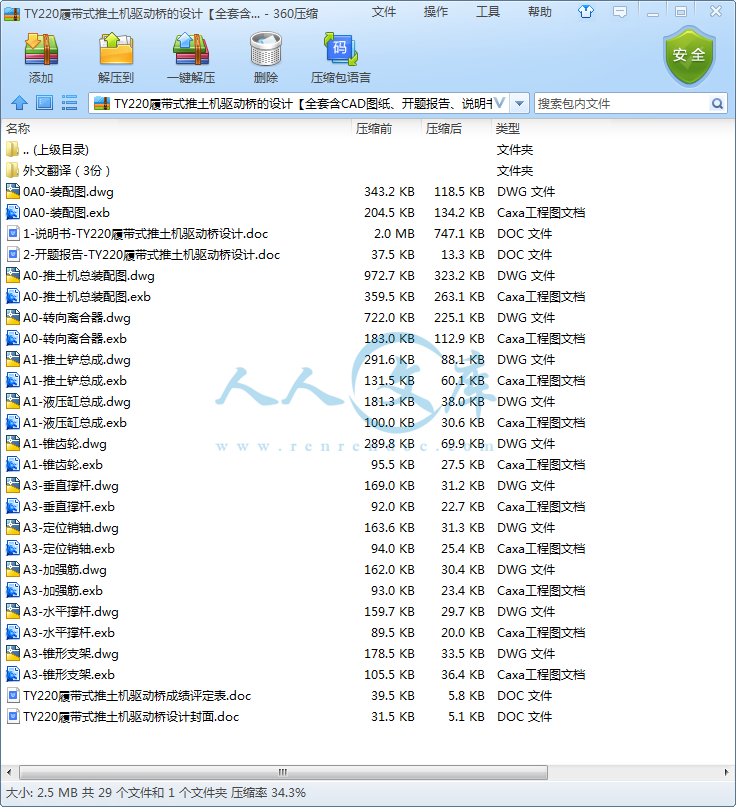

资源目录

压缩包内文档预览:

编号:55093132

类型:共享资源

大小:3.02MB

格式:ZIP

上传时间:2020-03-08

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

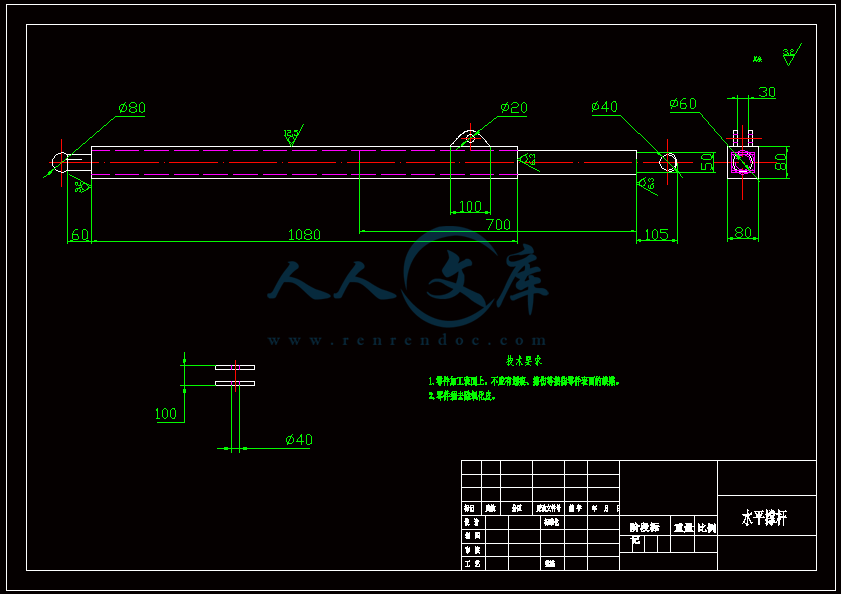

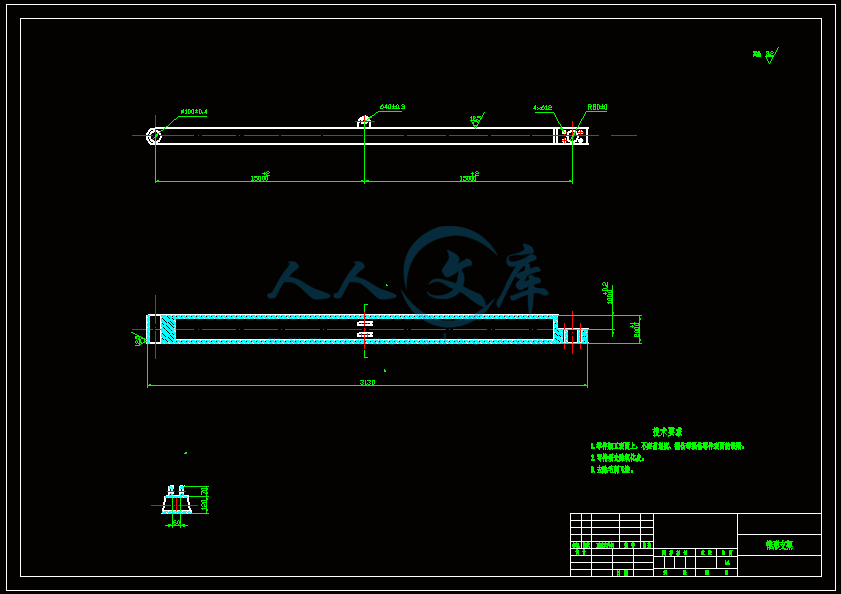

全套含CAD图纸、开题报告、说明书及翻译

TY220

履带式

推土机

驱动

设计

全套

CAD

图纸

开题

报告

说明书

翻译

- 资源描述:

-

- 内容简介:

-

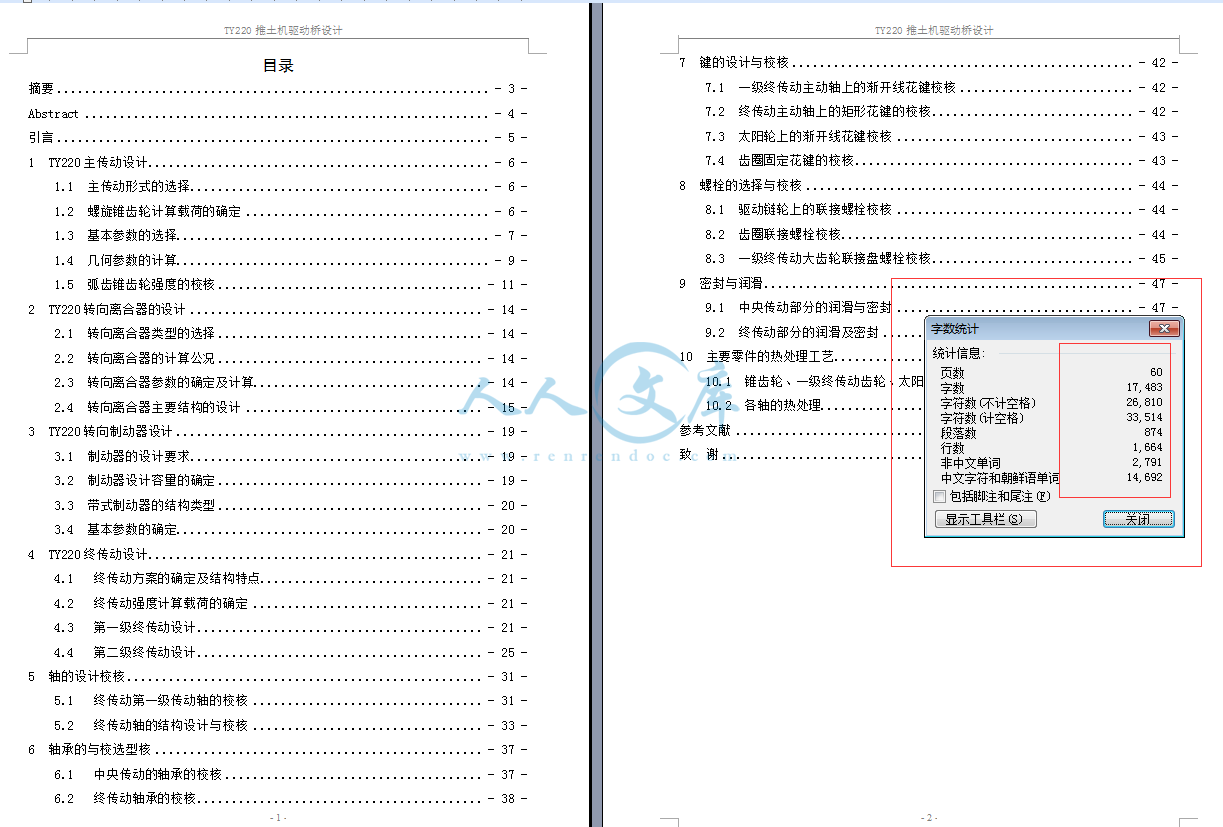

附件1:外文资料翻译译文机械设计摘要: 机器是由机械装置和其它组件组成的。它是一种用来转换或传递能量的装置,例如:发动机、涡轮机、车辆、起重机、印刷机、洗衣机、照相机和摄影机等。许多原则和设计方法不但适用于机器的设计,也适用于非机器的设计。术语中的“机械装置设计” 的含义要比“机械设计”的含义更为广泛一些,机械装置设计包括机械设计。在分析运动及设计结构时,要把产品外型以及以后的保养也要考虑在机械设计中。在机械工程领域中,以及其它工程领域中,所有这些都需要机械设备,比如:开关、凸轮、阀门、船舶以及搅拌机等。关键词: 设计流程 设计规则 机械设计设计流程设计开始之前就要想到机器的实际性,现存的机器需要在耐用性、效率、重量、速度,或者成本上得到改善。新的机器必需具有以前机器所能执行的功能。在设计的初始阶段,应该允许设计人员充分发挥创造性,不要受到任何约束。即使产生了许多不切实际的想法,也会在设计的早期,即在绘制图纸之前被改正掉。只有这样,才不致于阻断创新的思路。通常,还要提出几套设计方案,然后加以比较。很有可能在这个计划最后决定中,使用了某些不在计划之内的一些设想。一般的当外型特点和组件部分的尺寸特点分析得透彻时,就可以全面的设计和分析。接着还要客观的分析机器性能的优越性,以及它的安全、重量、耐用性,并且竞争力的成本也要考虑在分析结果之内。每一个至关重要的部分要优化它的比例和尺寸,同时也要保持与其它组成部分相协调。也要选择原材料和处理原材料的方法。通过力学原理来分析和实现这些重要的特性,如那些静态反应的能量和摩擦力的最佳利用,像动力惯性、加速动力和能量;包括弹性材料的强度、应力和刚度等材料的物理特性,以及流体润滑和驱动器的流体力学。设计的过程是重复和合作的过程,无论是正式或非正式的进行,对设计者来说每个阶段都很重要。最后,以图样为设计的标准,并建立将来的模型。如果它的测试是符合事先要求的,则再将对初步设计进行某些修改,使它能够在制造成本上有所降低。产品的设计需要不断探索和发展。许多方案必须被研究、试验、完善,然后决定使用还是放弃。虽然每个工程学问题的内容是独特的,但是设计师可以按照类似的步骤来解决问题。产品的责任诉讼迫使设计人员和公司在选择材料时,采用最好的程序。在材料过程中,五个最常见的问题为:(a)不了解或者不会使用关于材料应用方面的最新最好的信息资料;(b)未能预见和考虑材料的合理用途(如有可能,设计人员还应进一步预测和考虑由于产品使用方法不当造成的后果。在近年来的许多产品责任诉讼案件中,由于错误地使用产品而受到伤害的原告控告生产厂家,并且赢得判决);(c)所使用的材料的数据不全或是有些数据不确定,尤其是当其性能数据长期不更新;(d)质量控制方法不适当和未经验证;(e)由一些完全不称职的人员选择材料。通过对上述五个问题的分析,可以得出这些问题是没有充分理由而存在的结论。对这些问题的研究分析可以为避免这些问题的出现而指明方向。尽管采用最好的材料选择方法也不能避免发生产品责任诉讼,设计人员和工业界按照适当的程序进行材料选择,可以大大减少诉讼的数量。从以上的讨论可以看出,选择材料的人们应该对材料的性质,特点和加工方法有一个全面而基本的了解。在随后生产和售后服务的几年中,要接受新观念的变化,或者由试验和经验为基础,进一步分析并改进。一些设计规则在本节中,建议要运用创造性的态度来替代和改进。也许会创造出更实用、更经济、更耐用的产品。 为了激发创造性思维,下列是设计和分析的建议规则。前六个规则对设计者来说特别适用。1. 要有创造性的利用所需要的物理性质和控制过程。2. 认识负载产生的影响及其意义。3. 预测没有想到的负载。4. 创造出对载荷更为有利的条件。5. 提供良好的应力分布和最小的刚度条件。6. 运用最简单的方程来优化体积和面积。7. 选择组合材料。8. 仔细选择所备的原料和不可缺少的组件。9. 调整有效的设计方案,以适应生产过程和降低成本。10. 规定好准确的位置条件为了使组件安装时不干涉。机械设计包括一下内容:1. 对设计过程、设计所需要公式以及安全系数进行介绍。2. 回顾材料特性、静态和动态载荷分析,包括梁、振动和冲击载荷。3. 回顾应力的基本规律和失效分析。4. 介绍静态失效理论和静态载荷下机械断裂分析。5. 介绍疲劳失效理论并强调在压力条件下接近高循环的疲劳设计,这通常用在旋转机械的设计中。6. 深入探讨机械磨损机理、表面接触应力和表面疲劳现象。7. 使用疲劳分析技术校核轴的设计。8. 讨论润滑油膜与滚动轴承的理论和应用。9. 深入介绍直齿圆柱齿轮的动力学、设计和应力分析,并简单介绍斜齿轮、锥齿轮和涡轮有关方面的问题。10. 讨论弹簧设计、螺杆等紧固件的设计,包括传动螺杆和预紧固件。11. 介绍盘式和鼓式离合器以及制动器的设计和技术说明。机械设计一台完整机器的设计是一个复杂的过程。机械设计是一项创造性的工作。设计工程师不仅在工作上要有创造性,还必须在机械制图、运动学、工程材料、材料力学和机械制造工艺学等方面具有深厚的基础知识。任何产品在设计时第一步就是选择产品每个部分的构成材料。许多的材料被今天的设计师所使用。对产品的功能,它的外观、材料的成本、制造的成本作出必要的选择是十分重要的。对材料的特性必须事先作出仔细的评估。仔细精确的计算是必要的,以确保设计的有效性。在任何失败的情况下,最好知道在最初设计中有有缺陷的部件。计算(图纸尺寸)检查是非常重要的。一个小数点的位置放错,就可以导致一个本可以完成的项目失败。设计工作的各个方面都应该检查和复查。计算机是一种工具,它能够帮助机械设计师减轻繁琐的计算,并对现有数据提供进一步的分析。互动系统基于计算机的能力,已经使计算机辅助设计(CAD)和计算机辅助制造(CAM)成为了可能。心理学家经常谈论如何使人们适应他们所操作的机器。设计人员的基本职责是努力使机器来适应人们。这并不是一项容易的工作,因为实际上并不存在着一个对所有人来说都是最优的操作范围和操作过程。另一个重要问题,设计工程师必须能够同其他有关人员进行交流和磋商。在开始阶段,设计人员必须就初步设计同管理人员进行交流和磋商,并得到批准。这一般是通过口头讨论,草图和文字材料进行的。如前所诉,机械设计的目的是生产能够满足人类需求的产品。发明、发现和科技知识本身并不一定能给人类带来好处,只有当它们被应用在产品上才能产生效益。因而,应该认识到在一个特定的产品进行设计之前,必须先确定人们是否需要这种产品。应当把机械设计看成是机械设计人员运用创造性的才能进行产品设计、系统分析和制定产品的制造工艺学的一个良机。掌握工程基础知识要比熟记一些数据和公式更为重要。仅仅使用数据和公式是不足以在一个好的设计中做出所需的全部决定的。另一方面,应该认真精确的进行所有运算。例如,即使将一个小数点的位置放错,也会使正确的设计变成错误的。一个好的设计人员应该勇于提出新的想法,而且愿意承担一定的风险,当新的方法不适用时,就使用原来的方法。因此,设计人员必须要有耐心,因为 所花费的时间和努力并不能保证带来成功。一个全新的设计,要求屏弃许多陈旧的,为人们所熟知的方法。由于许多人墨守成规,这样做并不是一件容易的事。一位机械设计师应该不断地探索改进现有的产品的方法,在此过程中应该认真选择原有的、经过验证的设计原理,将其与未经过验证的新观念结合起来。新设计本身会有许多缺陷和未能预料的问题发生,只有当这些缺陷和问题被解决之后,才能体现出新产品的优越性。因此,一个性能优越的产品诞生的同时,也伴随着较高的风险。应该强调的是,如果设计本身不要求采用全新的方法,就没有必要仅仅为了变革的目的而采用新方法。附件2:外文原文(复印件)Mechanical DesignAbstract:A machine is a combination of mechanisms and other components which transforms, transmits. Examples are engines, turbines, vehicles, hoists, printing presses, washing machines, and movie cameras. Many of the principles and methods of design that apply to machines also apply to manufactured articles that are not true machines. The term mechanical design is used in a broader sense than machine design to include their design. the motion and structural aspects and the provisions for retention and enclosure are considerations in mechanical design. Applications occur in the field of mechanical engineering, and in other engineering fields as well, all of which require mechanical devices, such as switches, cams, valves, vessels, and mixers.Keywords: Mechanical Design mechanisms Design ProcessThe Design ProcessDesigning starts with a need real.Existing apparatus may need improvements in durability, efficiency, weight, speed, or cost. New apparatus may be needed to perform a function previouslydone by men, such as computation, assembly, or servicing. With the objective wholly or partlyIn the design preliminary stage, should allow to design the personnel fully to display the creativity, not each kind of restraint. Even if has had many impractical ideas, also can in the design early time, namely in front of the plan blueprint is corrected. Only then, only then does not send to stops up the innovation the mentality. Usually, must propose several sets of design proposals, then perform the comparison. Has the possibility very much in the plan which finally designated, has used certain not in plan some ideas which accepts.When the general shape and a few dimensions of the several components become apparent, analysis can begin in earnest. The analysis will have as its objective satisfactory or superior performance, plus safety and durability with minimum weight, and a competitive cost. Optimum proportions and dimensions will be sought for each critically loaded section, together with a balance between the strengths of the several components. Materials and their treatment will be chosen. These important objectives can be attained only by analysis based upon the principles of mechanics, such as those of static for reaction forces and for the optimum utilization of friction; of dynamics for inertia, acceleration, and energy; of elasticity and strength of materials for stress and deflection; of physical behavior of materials; and of fluid mechanics for lubrication and hydrodynamic drives. The analyses may be made by the same engineer who conceived the arrangement of mechanisms, or, in a large company, they may be made by a separate analysis division or research group. Design is a reiterative and cooperative process, whether done formally or informally, and the analyst can contribute to phases other than his own. Product design requires much research and development. Many Concepts of an idea must be studied, tried, and then either used or discarded. Although the content of each engineering problem is unique, the designers follow the similar process to solve the problems. Product liability suits designers and forced in material selection, using the best program. In the process of material, the most common problems for five (a) dont understand or not use about the latest application materials to the best information, (b) failed to foresee and consider the reasonable use material may (such as possible, designers should further forecast and consider due to improper use products. In recent years, many products liability in litigation, the use of products and hurt the plaintiff accused manufacturer, and won the decision), (c) of the materials used all or some of the data, data, especially when the uncertainty long-term performance data is so, (d) quality control method is not suitable and unproven, (e) by some completely incompetent persons choose materials.Through to the above five questions analysis, may obtain these questions is does not have the sufficient reason existence the conclusion. May for avoid these questions to these questions research analyses the appearance indicating the direction. Although uses the best choice of material method not to be able to avoid having the product responsibility lawsuit, designs the personnel and the industry carries on the choice of material according to the suitable procedure, may greatly reduce the lawsuit the quantity. May see from the above discussion, the choice material people should to the material nature, the characteristic and the processing method have comprehensive and the basic understanding. Finally, a design based upon function, and a prototype may be built. If its tests are satisfactory, the initial design will undergo certain modifications that enable it to be manufactured in quantity at a lower cost. During subsequent years of manufacture and service, the design is likely to undergo changes as new ideas are conceived or as further analyses based upon tests and experience indicate alterations. Sales appeal.Some Rules for DesignIn this section it is suggested that, applied with a creative attitude, analyses can lead to important improvements and to the conception and perfection of alternate, perhaps more functional, economical,and durable products. To stimulate creative thought, the following rules are suggested for the designer and analyst. The first six rules are particularly applicable for the analyst.1. A creative use of need of physical properties and control process.2. Recognize functional loads and their significance.3. Anticipate unintentional loads.4. Devise more favorable loading conditions.5. Provide for favorable stress distribution and stiffness with minimum weight.6. Use basic equations to proportion and optimize dimensions.7. Choose materials for a combination of properties.8. Select carefully, stock and integral components.9. Modify a functional design to fit the manufacturing process and reduce cost.10. Provide for accurate location and noninterference of parts in assembly. Machinery design covers the following contents.1. Provides an introduction to the design process , problem formulation ,safety factors.2. Reviews the material properties and static and dynamic loading analysis ,Including beam , vibration and impact loading. 3. Reviews the fundamentals of stress and defection analysis. 4. Introduces fatigue-failure theory with the emphasis on stress-life approaches to high-cycle fatigue design, which is commonly used in the design of rotation machinery. 5. Discusses thoroughly the phenomena of wear mechanisms, surface contact stresses ,and surface fatigue. 6. Investigates shaft design using the fatigue-analysis techniques. 7. Discusses fluid-film and rolling-element bearing theory and application 8. Gives a thorough introduction to the kinematics, design and stress analysis of spur gears , and a simple introduction to helical ,bevel ,and worm gearing. 9. Discusses spring design including compression ,extension and torsion springs. 10. Deals with screws and fasteners including power screw and preload fasteners. 11. Introduces the design and specification of disk and drum clutches and brakes.Machine DesignThe complete design of a machine is a complex process. The machine design is a creative work. Project engineer not only must have the creativity in the work, but also must in aspect and so on mechanical drawing, kinematics, engineerig material, materials mechanics and machine manufacture technology has the deep elementary knowledge. One of the first steps in the design of any product is to select the material from which each part is to be made. Numerous materials are available to todays designers. The function of the product, its appearance, the cost of the material, and the cost of fabrication are important in making a selection. A careful evaluation of the properties of a. material must be made prior to any calculations. Careful calculations are necessary to ensure the validity of a design. In case of any part failures, it is desirable to know what was done in originally designing the defective components. The checking of calculations (and drawing dimensions) is of utmost importance. The misplacement of one decimal point can ruin an otherwise acceptable project. All aspects of design work should be checked and rechecked. The computer is a tool helpful to mechanical designers to lighten tedious calculations, and provide extended analysis of available data. Interactive systems, based on computer capabilities, have made possible the concepts of computer aided design (CAD) and computer-aided manufacturing (CAM). How does the psychologist frequently discuss causes the machine which the people adapts them to operate. Designs personnels basic responsibility is diligently causes the machine to adapt the people. This certainly is not an easy work, because certainly does not have to all people to say in fact all is the most superior operating area and the operating process. Another important question, project engineer must be able to carry on the exchange and the consultation with other concerned personnel. In the initial stage, designs the personnel to have to carry on the exchange and the consultation on the preliminary design with the administrative personnel, and is approved. This generally is through the oral discussion, the schematic diagram and the writing material carries on. If front sues, the machine design goal is the production can meet the human need the product. The invention, the discovery and technical knowledge itself certainly not necessarily can bring the advantage to the humanity, only has when they are applied can produce on the product the benefit. Thus, should realize to carries on before the design in a specific product, must first determine whether the people do need this kind of productMust regard as the machine design is the machine design personnel carries on using creative ability the product design, the system analysis and a formulation product manufacture technology good opportunity. Grasps the project elementary knowledge to have to memorize some data and the formula is more important than. The merely service data and the formula is insufficient to the completely decision which makes in a good design needs. On the other hand, should be earnest precisely carries on all operations. For example, even if plaA good design personnel should dare to propose the new idea, moreover is willing to undertake the certain risk, when the new method is not suitable, use original method. Therefore, designs the personnel to have to have to have the patience, because spends the time and the endeavor certainly cannot guarantee brings successfully. A brand-new design, the request screen abandons obsoletely many, knows very well the method for the people. Because many person of conservativeness, does this certainly is not an easy matter. A mechanical designer should unceasingly explore the improvement existing product the method, should earnestly choose originally, the process confirmation principle of design in this process, with has not unified it after the confirmation new idea.ces wrong a decimal point position, also can cause the correct design to turn wrongly.附录1 驱动桥桥壳是汽车上的主要零件之一,非断开式驱动桥的桥壳起着支承汽车荷重的作用,并将载荷传给车轮作用在驱动车轮上的牵引力,制动力、侧向力和垂向力也是经过桥壳传到悬挂及车架或车厢上。因此桥壳既是承载件又是传力件,同时它又是主减速器、差速器及驱动车轮传动装置(如半轴)的外壳。在汽车行驶过程中,桥壳承受繁重的载荷,设计时必须考虑在动载荷下桥壳有足够的强度和刚度。为了减小汽车的簧下质量以利于降低动载荷、提高汽车的行驶平顺性,在保证强度和刚度的前提下应力求减小桥壳的质量桥壳还应结构简单、制造方便以利于降低成本。其结构还应保证主减速器的拆装、调整、维修和保养方便。在选择桥壳的结构型式时,还应考虑汽车的类型、使用要求、制造条件、材料供应等。桥壳的结构型式桥壳的结构型式大致分为可分式、整体式。可分式桥壳可分式桥壳的整个桥壳由一个垂直接合面分为左右两部分,每一部分均由一个铸件壳体和一个压入其外端的半轴套管组成。半轴套管与壳体用铆钉联接。在装配主减速器及差速器后左右两半桥壳是通过在中央接合面处的一圈螺栓联成一个整体。其特点是桥壳制造工艺简单、主减速器轴承支承刚度好。但对主减速器的装配、调整及维修都很不方便,桥壳的强度和刚度也比较低。过去这种所谓两段可分式桥壳见于轻型汽车,由于上述缺点现已很少采用。整体式桥壳整体式桥壳的特点是将整个桥壳制成一个整体,桥壳犹如一整体的空心粱,其强度及刚度都比较好。且桥壳与主减速器壳分作两体,主减速器齿轮及差速器均装在独立的主减速壳里,构成单独的总成,调整好以后再由桥壳中部前面装入桥壳内,并与桥壳用螺栓固定在一起。使主减速器和差速器的拆装、调整、维修、保养等都十分方便。整体式桥壳按其制造工艺的不同又可分为铸造整体式、钢板冲压焊接式和钢管扩张成形式三种。驱动桥处于动力传动系的末端,其基本功能是增大由传动轴或变速器传来的转矩,并将动力合理地分配给左、右驱动轮,另外还承受作用于路面和车架或车身之间的垂直力力和横向力。驱动桥一般由主减速器、差速器、车轮传动装置和驱动桥壳等组成。驱动桥设计应当满足如下基本要求:(a)所选择的主减速比应能保证汽车具有最佳的动力性和燃料经济性。(b)外形尺寸要小,保证有必要的离地间隙。(c)齿轮及其它传动件工作平稳,噪声小。(d)在各种转速和载荷下具有高的传动效率。(e)在保证足够的强度、刚度条件下,应力求质量小,尤其是簧下质量应尽量小,以改善汽车平顺性。 (f)与悬架导向机构运动协调,对于转向驱动桥,还应与转向机构运动协调。(g)结构简单,加工工艺性好,制造容易,拆装,调整方便。驱动桥的结构型式按工作特性分,可以归并为两大类,即非断开式驱动桥和断开式驱动桥。当驱动车轮采用非独立悬架时,应该选用非断开式驱动桥;当驱动车轮采用独立悬架时,则应该选用断开式驱动桥。因此,前者又称为非独立悬架驱动桥;后者称为独立悬架驱动桥。独立悬架驱动桥结构叫复杂,但可以大大提高汽车在不平路面上的行驶平顺性。非断开式驱动桥普通非断开式驱动桥,由于结构简单、造价低廉、工作可靠,广泛用在各种载货汽车、客车和公共汽车上,在多数的越野汽车和部分轿车上也采用这种结构。他们的具体结构、特别是桥壳结构虽然各不相同,但是有一个共同特点,即桥壳是一根支承在左右驱动车轮上的刚性空心梁,齿轮及半轴等传动部件安装在其中。这时整个驱动桥、驱动车轮及部分传动轴均属于簧下质量,汽车簧下质量较大,这是它的一个缺点。驱动桥的轮廓尺寸主要取决于主减速器的型式。在汽车轮胎尺寸和驱动桥下的最小离地间隙已经确定的情况下,也就限定了主减速器从动齿轮直径的尺寸。在给定速比的条件下,如果单级主减速器不能满足离地间隙要求,可该用双级结构。在双级主减速器中,通常把两级减速器齿轮放在一个主减速器壳体内,也可以将第二级减速齿轮作为轮边减速器。对于轮边减速器:越野汽车为了提高离地间隙,可以将一对圆柱齿轮构成的轮边减速器的主动齿轮置于其从动齿轮的垂直上方;公共汽车为了降低汽车的质心高度和车厢地板高度,以提高稳定性和乘客上下车的方便,可将轮边减速器的主动齿轮置于其从动齿轮的垂直下方;有些双层公共汽车为了进一步降低车厢地板高度,在采用圆柱齿轮轮边减速器的同时,将主减速器及差速器总成也移到一个驱动车轮的旁边。在少数具有高速发动机的大型公共汽车、多桥驱动汽车和超重型载货汽车上,有时采用蜗轮式主减速器,它不仅具有在质量小、尺寸紧凑的情况下可以得到大的传动比以及工作平滑无声的优点,而且对汽车的总体布置很方便。 断开式驱动桥断开式驱动桥区别于非断开式驱动桥的明显特点在于前者没有一个连接左右驱动车轮的刚性整体外壳或梁。断开式驱动桥的桥壳是分段的,并且彼此之间可以做相对运动,所以这种桥称为断开式的。另外,它又总是与独立悬挂相匹配,故又称为独立悬挂驱动桥。这种桥的中段,主减速器及差速器等是悬置在车架横粱或车厢底板上,或与脊梁式车架相联。主减速器、差速器与传动轴及一部分驱动车轮传动装置的质量均为簧上质量。两侧的驱动车轮由于采用独立悬挂则可以彼此致立地相对于车架或车厢作上下摆动,相应地就要求驱动车轮的传动装置及其外壳或套管作相应摆动。汽车悬挂总成的类型及其弹性元件与减振装置的工作特性是决定汽车行驶平顺性的主要因素,而汽车簧下部分质量的大小,对其平顺性也有显著的影响。断开式驱动桥的簧下质量较小,又与独立悬挂相配合,致使驱动车轮与地面的接触情况及对各种地形的适应性比较好,由此可大大地减小汽车在不平路面上行驶时的振动和车厢倾斜,提高汽车的行驶平顺性和平均行驶速度,减小车轮和车桥上的动载荷及零件的损坏,提高其可靠性及使用寿命。但是,由于断开式驱动桥及与其相配的独立悬挂的结构复杂,故这种结构主要见于对行驶平顺性要求较高的一部分轿车及一些越野汽车上,且后者多属于轻型以下的越野汽车或多桥驱动的重型越野汽车。多桥驱动的布置为了提高装载量和通过性,有些重型汽车及全部中型以上的越野汽车都是采用多桥驱动,常采用的有44、66、88等驱动型式。在多桥驱动的情况下,动力经分动器传给各驱动桥的方式有两种。相应这两种动力传递方式,多桥驱动汽车各驱动桥的布置型式分为非贯通式与贯通式。前者为了把动力经分动器传给各驱动桥,需分别由分动器经各驱动桥自己专用的传动轴传递动力,这样不仅使传动轴的数量增多,且造成各驱动桥的零件特别是桥壳、半轴等主要零件不能通用。而对88汽车来说,这种非贯通式驱动桥就更不适宜,也难于布置了。为了解决上述问题,现代多桥驱动汽车都是采用贯通式驱动桥的布置型式。在贯通式驱动桥的布置中,各桥的传动轴布置在同一纵向铅垂平面内,并且各驱动桥不是分别用自己的传动轴与分动器直接联接,而是位于分动器前面的或后面的各相邻两桥的传动轴,是串联布置的。汽车前后两端的驱动桥的动力,是经分动器并贯通中间桥而传递的。其优点是,不仅减少了传动轴的数量,而且提高了各驱动桥零件的相互通用性,并且简化了结构、减小了体积和质量。这对于汽车的设计(如汽车的变型)、制造和维修,都带来方便。由于非断开式驱动桥结构简单、造价低廉、工作可靠,查阅资料,可参照国内相关货车的设计。附录2Bridge-driven car shell is one of the main parts, non-drive off-shell bridge played a supporting role in the automotive load and load to the wheels. In the role of the drive wheels on the traction, braking force, lateral and vertical forces also spread to fly through the bridge and the shell or inside the frame. Therefore, the bridge carrying both pieces of shell-edge thing is, at the same time it is also the main reducer, and differential wheel drive transmission (such as the axle) of the shell. In the car, the axle housing to bear the heavy load, the design must take into account the dynamic load under the axle housing have enough strength and stiffness. In order to reduce the spring under the car of lower quality in order to facilitate dynamic load, and improve the cars running smoothly, while ensuring the strength and stiffness on the premise of the bridge should seek to reduce the quality of the shell. Shell structure of the bridge should be simple and easy to create the benefit of lower costs. It should also ensure that the structure of the main reducer of disassembly, adjustment, repair and maintenance easy. Bridge in the selection of the shell structure, should also be given to the type of car, asked to use, manufacture, supply materials and so on.A bridge of the shell structureBridge of the shell structure can be roughly divided into typeThere are bridge-shell There are bridge-shell as a whole from the shell of a bridge into the vertical joints around two parts, each part by the casting of a shell into the outside pressure and a side of the axle casing components. Half shell casing and connected with rivets. In the main reducer, and differential assembly after about two half-bridge through the shell in the joints of the Central Office of the bolt circle into a whole. It features a simple bridge shell manufacturing process, the main reducer bearing stiffness well. But the main reducer of the assembly, adjustment and maintenance are inconvenient, the bridge shell strength and stiffness will be lower. In the past the so-called two-axle housing can be found in the car light, as a result of these shortcomings is now rarely used.Whole-axle housin Bridge-shell as a whole is characterized by the entire bridge made of a shell as a whole, the bridge is like a shell of the hollow beam as a whole, its strength and stiffness than good. Bridge and the shell and the shell will be divided into two main reducer, the main reducer, and differential gears are mounted on the main independent slowdown shell, constitute a separate assembly, later adjusted by the bridge in front of the shell in the central bridge into the shell , And with the axle housing fixed together with bolts. It enables a reducer, and differential of disassembly, adjustment, repair, maintenance and so on is very convenient. Bridge-shell as a whole according to their different manufacturing process can be divided into a whole-casting, stamping steel plates welded steel pipe and the expansion into three forms.Bridge drive powertrain in the end, its basic function is to increase the transmission shaft or transmission from the torque and power reasonably allocated to the left and right wheel also bear on the role of road and the frame or body Between vertical and horizontal force strength. Driven by the main bridge in general reducer, and differential, gear wheels and drive axle housing component, and so on.Drive bridge should be designed to meet the basic requirements are as follows:(a) choice of the main reduction ratio should be able to ensure the car has the best power and fuel economy.(b) smaller size, it is necessary to ensure that the ground clearance.(c) transmission gears and other pieces of work in a smooth, small noise.(d) in a variety of speed and load with a high transmission efficiency.(e) to ensure sufficient strength, rigidity conditions, the quality should be as small, especially the quality of the next spring should be small in order to improve the car ride.(f)-oriented suspension and body movement coordination, the drive to the bridge, but also with the agency to coordinate movement.(g) simple structure, good process and create easy disassembly, easy adjustment. Drive bridge structure in accordance with characteristics of the work, can be grouped into two broad categories, namely non-drive off the bridge and drive off the bridge. When the drive wheel of a non-independent suspension, the non-selection should be off-drive axle; when the drive wheel independent suspension, the choice should be off-drive axle. As a result, the former driver, also known as non-independent suspension bridge; the latter known as the independent suspension bridge driver. Independent suspension bridge structure called complex drive, but will be much more uneven in the car traveling on the road ride comfort.Non-drive axle disconnect General non-drive off the bridge, because it is simple, low-cost, reliable, widely used in a variety of truck, bus and a bus, in most of the off-road cars and car parts is also using this structure. Details of their structure, in particular, the shell structure of the bridge although different, but there is a common feature of the bridge is a shell around the drive wheel bearing on the rigid hollow beams, such as transmission gears and axle components to install it. At this time the entire drive axle, wheel and drive shaft are part of the quality of the next spring, next spring the quality of the larger car, which is one of its shortcomings. Bridge drive size depends largely on the outline of the main type of reducer. In the tire size and drive under the bridge minimum ground clearance have been identified, will be limited to the main driven gear reducer diameter size. In a given ratio of the conditions, if the single-stage main reducer not meet the requirements of ground clearance, with the two-level structure. In the main two-stage reducer, usually two-stage gear reducer in a shell of the main reducer, can also slow down in the second grade as a round edge gear reducer. The round side reducer: off-road vehicle in order to improve the ground clearance, can constitute a pair of cylindrical gear wheel of the gear reducer at the top of the vertical driven gear; bus in order to reduce the vehicles center of mass and a high degree of deck A high degree of order to enhance the stability and convenience of the passengers get off, can be round edge of the gear reducer at the bottom of the vertical driven gear; some double-decker bus in order to further reduce the deck height, cylinder gear used in the round edge Reducer, the main reducer, and differential assembly also moved to a wheel next to the driver. In a small number of high-speed engine with a large bus, Bridge Multi-drive cars and super-heavy-duty truck, sometimes using the main worm-reducer, which not only has the quality in a small, compact size of the case could be a big transmission ratio, as well as the work of Smooth silent advantages, but also to the overall layout of the car easily.Drive-off bridge Off-drive off the bridge from the non-drive axle of the obvious characteristics is that the former do not have a connection about the drive wheels or beam rigid shell as a whole. Drive off-shell bridge is a section, and each other can do relative motion, such as the bridge-off. In addition, it is always with the independent match suspension, it is also known as the independent suspension bridge driver. This bridge in the middle of the main reducer, and differential, and so is mounting in the frame beams inside or on the floor or backbone frame-linked. The main reducer, and differential part of the drive shaft and the quality of the gear wheels are on the quality of the spring. Both sides of the drive wheel independent suspension as a result can be caused by site as opposed to one another or inside the frame for swinging up and down, and accordingly on the request of the gear wheel drive and its shell casing or swing accordingly. Flying car assembly and its flexibility in the type of device components and vibration characteristics of the work is to determine a car ride a major factor, and the spring under the car the size of some of the qualit

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号