摘要

本文的研究对象,螺杆型干式真空泵,吸入腔没有任何工作液,保证了空间用泵无污染;没有油蒸汽排放,保证清洁的外部环境。由于转子齿面之间有间隙,因而可以抽除含有灰尘或腐蚀性的有毒气体。本课题主要集中在以下几个方面:基本原理的干式螺杆真空泵,阴阳转子螺杆型线的研究,螺旋型面线是单边等螺距型线,演绎数学的计算,建立几何模型面型线方程推导,然后螺旋齿面方程推导。几何特征研究等。

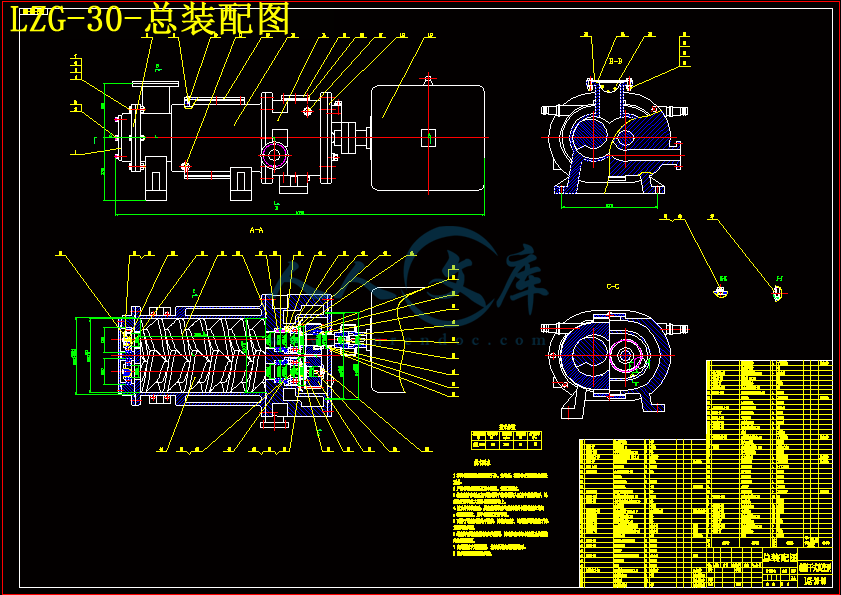

设计完成后应用solidworks软件做运动仿真对真空泵转子做三维建模,并且模拟转子运动展示其工作过程.

关键词:干式螺杆真空泵 转子 型线 三维建模 运动仿真

Modeling?and?Simulation?of? LGZ-30?single?screw?dry?vacuum?pump

Abstract

The research object of this paper, Dry screw vacuum pump, The suction chamber with no working fluid, ensure the space is pumped from pollution; No oil vapor emissions, guarantee the clean of the external environment. Due to the gaps between the rotor tooth surface of Yin and Yang, thus it can be pumped in addition to containing dust, or corrosive, poisonous gases. The author studies mainly focus on the following aspects: the basic principles of dry screw vacuum pump. Yin and Yang screw type line of research. Screw type face line made bilateral symmetric circular arc line, deduce the mathematical expressions of meshing principle, establish geometric model face type line equation is deduced, and then screw tooth surface equation is deduced. Geometric characteristics research, etc.

After the design is completed using SolidWorks software to do motion simulation to do 3D modeling of vacuum pump rotor. And the simulation of rotor motion display their works.

Keywords: dry screw vacuum pump rotor type line Three-dimensional modeling

Motion simulation

目 录

绪 论 1

1 螺杆型干式真空泵的概述 2

1.1 课题背景及研究意义 2

1.2 螺杆真空泵在国内外的研究现状与发展方向 4

1.3 论文包括的主要内容 5

1.4 论文的组织结构 6

2 螺杆干式真空泵转子型线的研究 7

2.1 常见转子型线比较 7

2.2 单头等螺距矩形螺纹转子型线 8

2.2.1转子型线要素 8

2.2.2转子型线设计原则 9

2.2.3转子螺旋齿面方程 10

3 螺杆干式真空泵工作原理 12

3.1 吸气过程 12

3.2 压缩过程 12

3.3 排气过程 13

4 螺杆干式真空泵设计计算 14

4.1螺杆基本尺寸 14

4.2排气量 16

4.2.1理论排气量 16

4.2.2实际排气量 17

4.3进排气孔口 18

4.3.1轴向进气口 18

4.3.2轴向排气口 19

4.4极限真空度、功率及冷却水量 19

4.5轴的强度计算 20

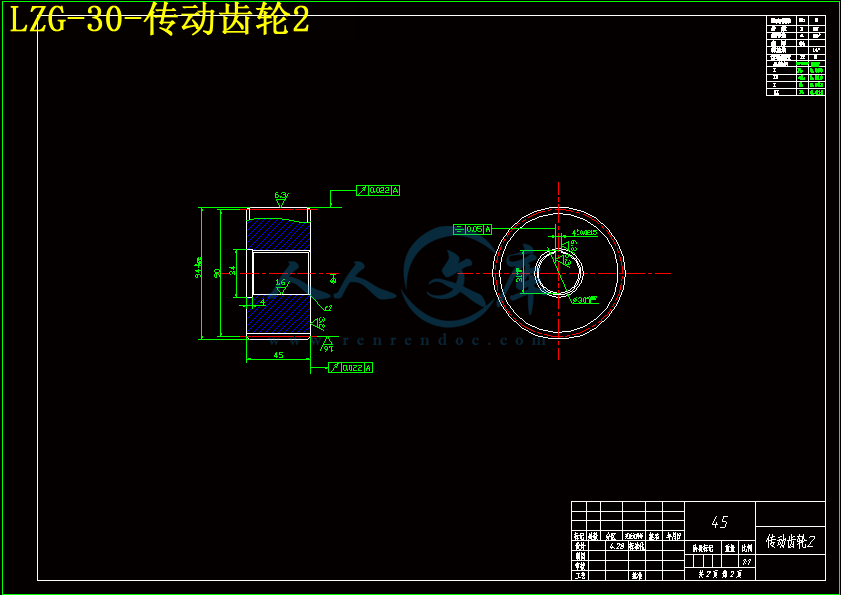

4.6同步齿轮的设计计算 20

4.6.1齿轮尺寸计算 21

4.6.2齿轮强度校核 21

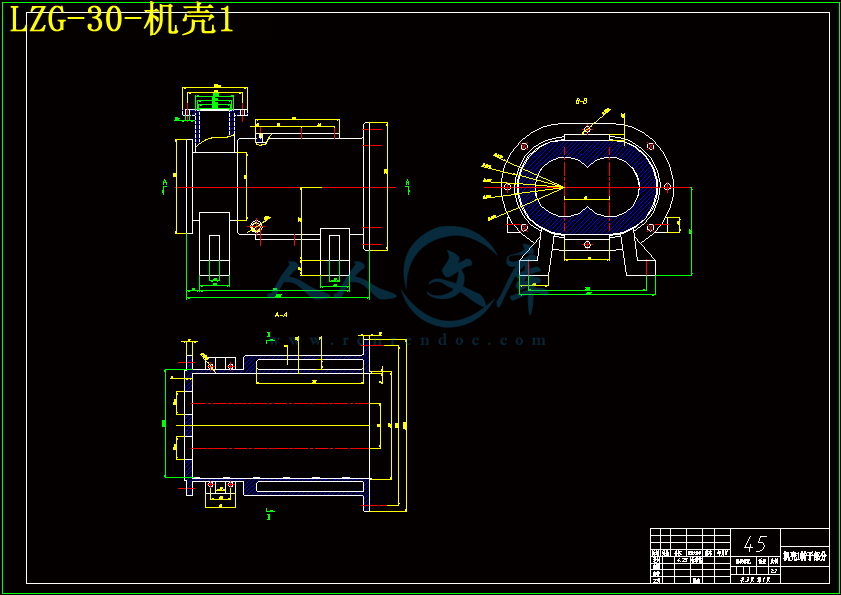

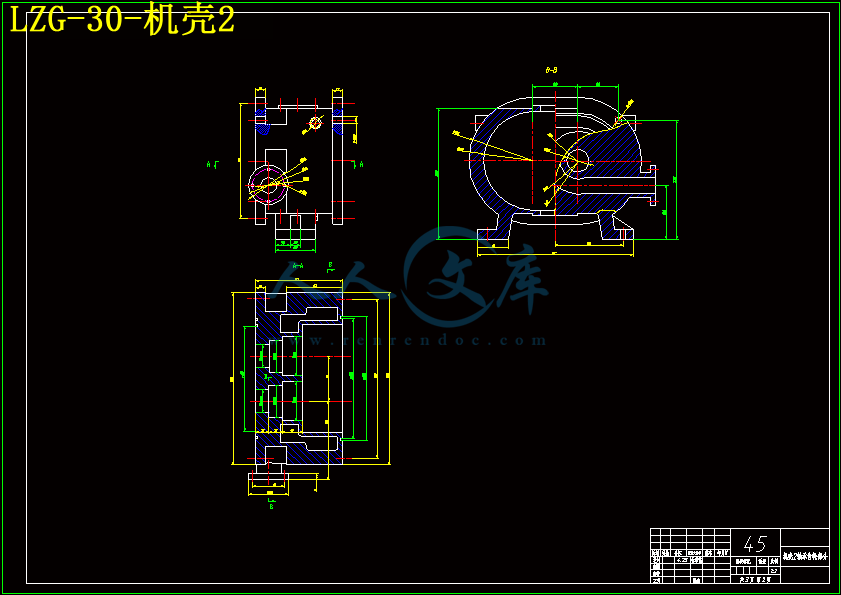

5 单头螺杆干式真空泵的应用 22

5.1 应用范围 22

5.2 抽气原理与结构 22

6 三维建模与运动仿真 23

6.1 SolidWorks介绍 23

6.2 转子三维建模 24

6.3 转子运动仿真 26

结 论 27

参考文献 28

致 谢 29

绪 论

1905年德国人沃尔夫岗.盖德发明了油封式旋片泵,从此各种以油为工作液、润滑剂、密封液的真空泵如雨后春笋般迅速普及,统治了真空设备市场近百年。从真空工业的视角来看,如果说20世纪是有油真空泵的世纪,那么21世纪将是干式真空泵的世纪。因为,各种形式的有油真空泵在工作过程中不可避免的随同排出的气体一起排出了大量的油污,这些油污能够严重的污染环境。随着利学技术的发展,要求提供比较清洁真空环境的真空工艺越来越多,甚至近于达到苛刻的要求,如微电子、化学、冶金、医疗、核聚变领域以及宇航、新材料的开发等技术领域.都要求提供比较洁的内真空环境。传统的有油泵很难满足这些要求,无油泵的概念便自然而然的在此基础上提出。有些工业过程,如低压气相沉积,会产生一些微小颗粒,这些颗粒在工作液中难以排除,它们可以使泵油污染,同样也会影响泵的抽气系统性能及使用寿命。而有些工业过程在运转中可能会使工作液冷凝成粘状物质,这样可能使泵卡住,甚至导致运转失效。又如对于食品工业为代表的一些特殊行业,这种污染更是非常不可取的。对于这些少数有着特殊需要的工业来说,就只能采用无油污的无油泵或水环式泵类(湿式泵),但这类泵的真空度不高,耗水耗能严重,而且相应的工作时带有大量的水汽,因此对于有干式要求的,又不得不采用繁琐的物理、化学吸附,冷凝低温手段,从而使成本变得极其昂贵。如:膜式泵,真空度不高,抽速小;吸附泵,不仅抽速小,液氮的费用也很大。所以可以这样说,在当时能直接排入大气和高真空机绍相连接的泵类各有其缺憾,因此导致了干式泵不适宜大工业的应用。

1 螺杆型干式真空泵的概述

1.1 课题背景及研究意义

干式螺杆真空泵是干式泵家族中的一员。所谓干式真空泵,一般认为是能在大气压到10Pa的压力范围内工作;在泵的抽气流道中,不能使用任何油类和液体,排气口与大气相通,能直接连续向大气中排气的泵,也称无油真空泵。

干式真空泵在抽气流道内无任何液态工作介质或密封介质,从根本上解决了油封式真空泵引发的各种问题。总的来说是两种不同的需求推动开发出两种类型的干泵。

川公网安备: 51019002004831号

川公网安备: 51019002004831号