目 录

1 概述

2 物料破碎及其意义

2.1 物料破碎及其意义 3

2.2 破碎物料的性能及破碎比 5

3 工作原理和构造

3.1 工作原理 10

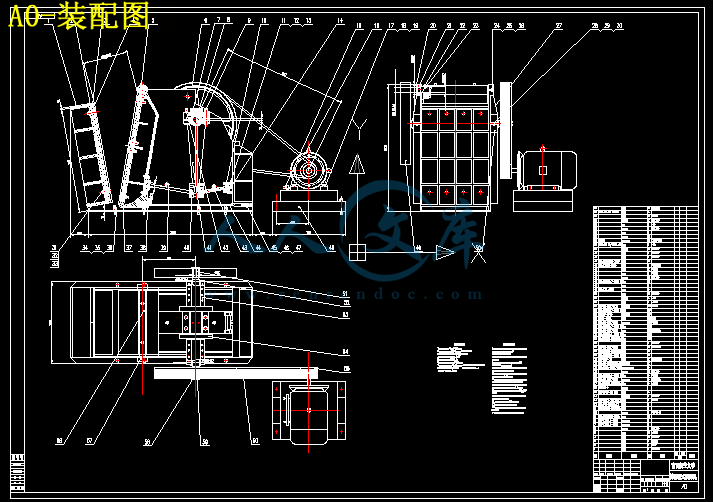

3.2简摆腭式破碎机的结构 11

4 主要零部件的结构分析

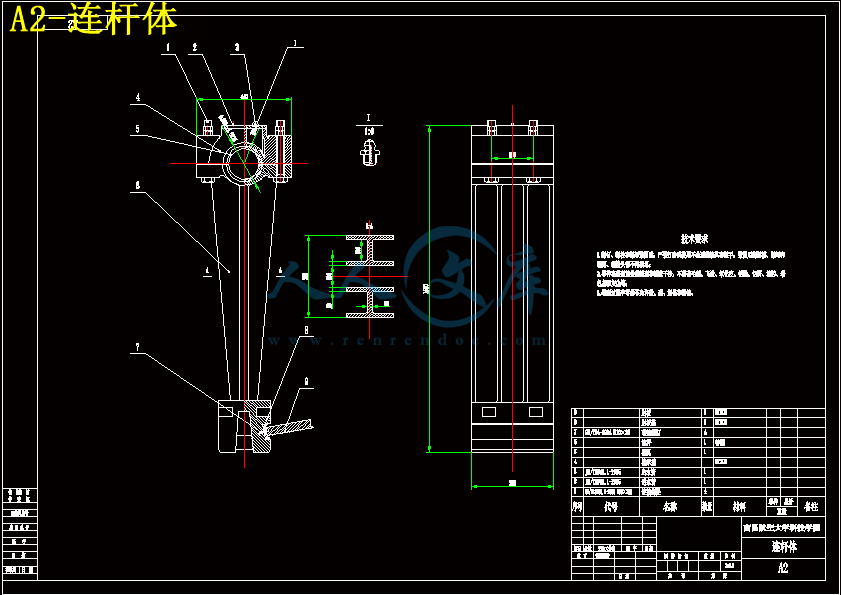

4.1连杆 14

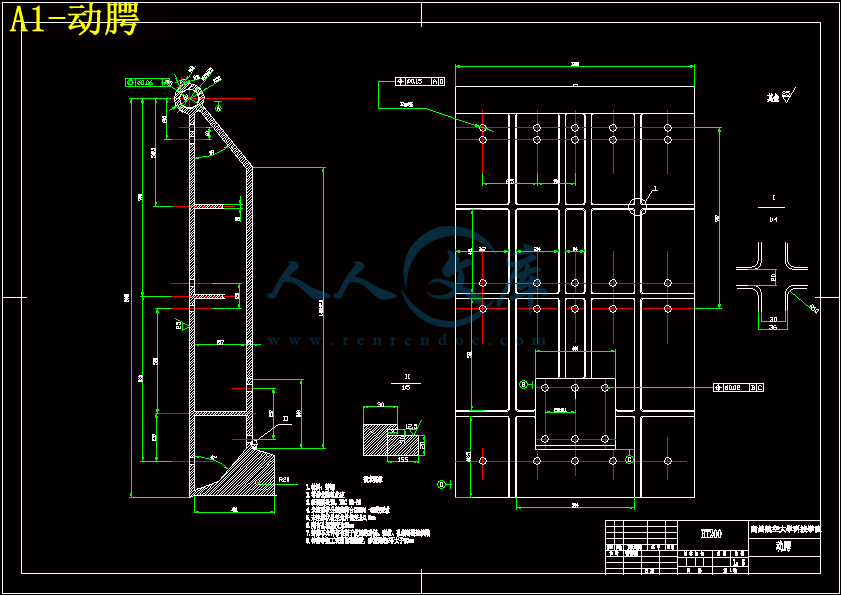

4.2动腭 15

4.3齿板的结构 16

4.4肘板 17

4.5调整装置 17

4.6保险装置 18

4.7机架结构 19

4.8传动件 20

4.9飞轮 20

4.10润滑装置 20

5 简摆腭式破碎机的主参数设计计算

5.1 机构参数 21

5.2 破碎力 25

5.3 功率的计算 27

5.4 主要零件受力计算 28

6 重要零件的设计和校核

6.1带轮的设计 30

6.2曲轴的设计计算 32

6.3 滑动轴承的设计计算 36

7 腭式破碎机的饿安装与运转

7.1破碎机的安装 38

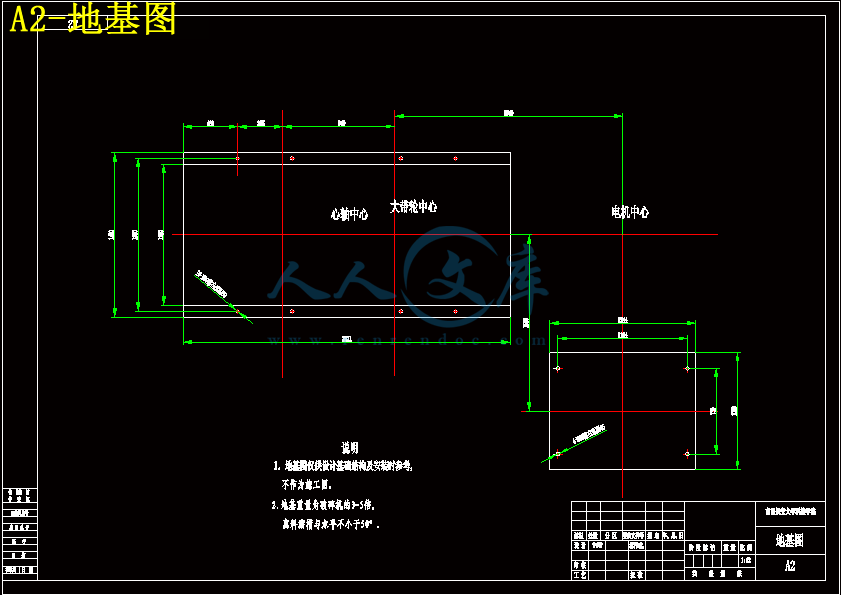

7.2机架的安装 38

7.3连杆的安装 39

7.4肘板的安装 39

7.5动腭的安装 39

7.6齿板的安装 39

7.7破碎机的运转 40

8用对一个主要零件进行有限元分析

8.1solidworks软件介绍 41

8.2CosmosWorks功能和特点 41

8.3对曲轴的有限元分析 42

8.3变形结果 48

参考文献 49

致谢 50

摘要:破碎机械设备,属于矿山机械范畴。这这类机械设备在冶金、建材、化工、能源、交通建设、城市建设和环保等诸多领域有广泛的用途。简摆一般制成大型和中型的,复摆一般制成中型和小型的。简摆破碎机可以产生很大的破碎力,这是复摆破碎机所不能能、低能耗的新型颚式破碎机,从而大大提高了破碎机的性能,缩短了产品开比的,故在大型破碎机中一般用这种结构,复摆腭式破碎机的生产能力高于简摆腭式破碎机约30%,同时也因为过大的垂直行程,使得定、动腭衬板(齿板)磨损很快,大大降低了使用寿命。我国自50年代生产腭式破碎机以来,在破碎机设计方面经历了类比、仿制、图解法设计阶段,目前正向计算机辅助设计阶段过渡。国外从上世纪中后期开始利用计算机仿真技术对颚式破碎机机构、腔型、产量和磨损等进行优化,高性发周期,提高了产品的市场竞争力。

本文中所设计PEJ900X1200简摆颚式破碎机的设计要求为:破碎机偏心轴偏心距为25mm,连杆长度为1325mm左右,破碎腔设计为900×1200mm,破碎腔啮角20度,传动角为45~55度,动颚上端厚度为316mm,肘板长度为300~400mm,破碎机悬挂高度为100~160mm。腭式破碎机动颚水平行破碎腔啮角的大小直接关系到物料的受力状态,机架结构设计和破碎机产量,小的啮角有利于提高破碎机产量,利用先进破碎原理进行物料破碎,但破碎机高度将增加。所以根据经验值,本设计采用的啮角为20度。

关键词:简摆 腭式 破碎腔

1 概述

破碎机械是对固体物料施加机械力,克服物料的内聚力,使之碎裂成小块物料的设备。

破碎机械所施加的机械力,可以是挤压力、劈裂力、弯曲力、剪切力、冲击力等,在一般机械中大多是两种或两种以上机械力的综合。对于坚硬的物料,适宜采用产生弯曲和劈裂作用的破碎机械;对于脆性和塑性的物料,适宜采用产生冲击和劈裂作用的机械;对于粘性和韧性的物料,适宜采用产生挤压和碾磨作用的机械。

在矿山工程和建设上,破碎机械多用来破碎爆破开采所得的天然石料,使这成为规定尺寸的矿石或碎石。在硅酸盐工业中,固体原料、燃料和半成品需要经过各种破碎加工,使其粒度达到各道工序所要求的以便进一步加工操作。

通常的破碎过程,有粗碎、中碎、细碎三种,其入料粒度和出料粒度,如表1——1所示。所采用的破碎机械相应地有粗碎机、中碎机、细碎机三种。

表1—1 物料粗碎、中碎、细碎的划分(mm)

类别 入料粒度 出料粒度

粗碎

中碎

细碎 300~900

100~350

50 ~100 100~350

20~100

5~15

制备水泥、石灰时、细碎后的物料,还需进一步粉磨成粉末。按照粉磨程度,可分为粗磨、细磨、超细磨三种。

所采用的粉磨机相应地有粗磨机、细磨机、超细磨机三种。

在加工过程中,破碎机的效率要比粉磨机高得多,先破碎再粉磨,能显著地提高加工效率,也降低电能消耗。

工业上常用物料破碎前的平均粒度 D刁民破碎后的平均粒度d之比来衡量破碎过程中物料尺寸变化情况,比值i称为破碎比(即平均破碎比)

为了简易地表示物料破碎程度和各种破碎机的方根性能,也可用破碎机的最大进料口尺寸与最大出料口尺寸之比来作为破碎比,称为公称破碎比。

在实际破碎加工时,装入破碎机的最大物料尺寸,一般总是小于容许的最大限度进料口尺寸,所以,平均破碎比只相当于公称破碎比的0.7~0.9。

每各破碎机的破碎比有一定限度,破碎机械的破碎比一般是i=3~30。如果物料破碎的加工要求超过一种破碎机的破碎比,则必须采用两台或多台破碎机械串连加工,称为多级破碎。多级破碎时,原料尺寸与最终成品尺寸之比,称总破碎比,如果各级破碎的破碎比各是 , … 。则总破碎比是

= …

由于破碎机构造和作用的不同,实际选用时,还应根据具体情况考虑下列因素;

1)物料的物理性质,如易碎性、粘性、水分泥沙含量和最大给料尺寸等;

2)成品的总生产量和级配要求、据以选择破碎机类型和生产能力;

3)技术经济指标,做到既合乎质量、数量的要求、操作方便、工作可靠,又最大限度节省费用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号