摘 要

本次毕业设计的题目为无轴搅拌机传动部件的设计。首先对传统的几种常见的搅拌机构进行分析、总结其工作原理及其存在的常见问题。了解目前对其存在的问题的常用解决方案。熟悉“无轴”搅拌理念,掌握无轴搅拌机的工作原理,然后将其与传统的搅拌机进行比较,分析其主要优点及可能存在的问题以及解决方案。

其次,这次设计的重点是对其传动部件的设计计算,我采用的是带轮加锥齿轮的减速机构,即利用了带轮的传动远距离传动、大传动比,又利用了锥齿轮传动可改变传动方向的优点。通过设计计算达到了即提高工作效率又能有效地节约能源的目的。

关键词: 无轴搅拌机 ;传动部件 ;搅拌机构

Abstract

The graduation project is the subject of non-transmission parts mixer shaft design. First of all, the traditional institutions in several common mixing analysis, concluding its work principle and the existence of the frequently asked questions. Understand the current problems of its common solutions. Familiar with the "non-axis" mixing the concept of master-axis mixer without the working principle, and the mixer with the traditional comparison, analysis of their main advantages and potential problems and solutions.

Secondly, this is designed to focus on the design of its drive components, I used the bevel gear pulley increases the speed, namely the use of long-distance transmission of drive pulley, the transmission ratio and the use of a bevel gear transmission can change the direction of the advantages of transmission. Achieved through the design of computing that can effectively improve the efficiency and energy savings.

Key words: No shaft mixer;Transmission parts ;Stir agencies

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 无轴式搅拌机研究发展现状 1

1.2 搅拌机的各种类型及特点 2

1.3 无轴式搅拌机特点 3

1.4 搅拌机的分析及设计任务 3

1.4.1 搅拌机常见问题的原因分析 3

1.4.2 无轴搅拌的理念 4

1.4.3 基本设计任务 5

1.4.4 毕业设计的目的 5

1.5 课题研究背景及意义 5

1.5.1 课题研究背景 5

1.5.2 课题研究意义 5

2 传动方案及电动机的选择 7

2.1 传动方案的选择 7

2.2 电动机选择 8

3 传动比的计算与分配 9

3.1 计算总传动比 9

3.2 传动比的分配 9

4 传动运动参数的计算 11

4.1 各级转速 11

4.2 各级的输入功率 11

4.3 各级转矩 11

5 V带轮传动的设计计算 13

5.1 设计准则 13

5.2 原始数据及设计内容 13

5.2.1 原始数据: 13

5.2.2 设计内容: 13

5.3 设计步骤和方法 13

5.3.1 确定计算功率 13

5.3.2 选择带型 13

5.3.3 确定带轮的基准直径和 13

5.3.4 确定中心距和带轮的基准长度 14

5.3.5 验算主动轮上的包角 14

5.3.6 单根V带传递的额定功率 15

5.3.7 确定带的根数Z 15

5.3.8 确定带的预紧力 15

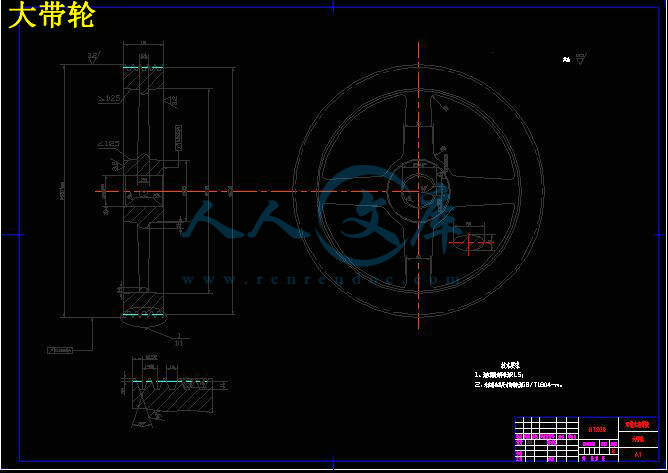

6 V带轮设计 17

6.1 V带轮的设计内容 17

6.2 设计要求 17

6.3 带轮材料的选择及结构形式 17

6.3.1 材料的选择 17

6.3.2 结构形式 17

6.4 V带轮的轮槽 17

6.5 V带轮传动的张紧 18

7 锥齿轮传动的设计计算 19

7.1. 选定精度等级,材料及齿数 19

7.1.1齿轮精度等级的选择 19

7.1.2 材料选择 19

7.1.3 齿数选择 19

7.2 按齿面接触强度设计 19

7.2.1 确定公式内的各计算数值 20

7.2.2 计算 20

7.3 按齿根弯曲强度设计 21

7.3.1 确定公式内的各计算数值 21

7.4 几何尺寸计算 22

7.4.1 计算分度圆直径 22

7.4.2 锥距 22

7.4.3 计算齿轮宽度 22

7.4.4 锥齿轮的结构设计 22

8 轴的设计计算 25

8.1 I轴的设计计算(锥齿轮轴) 25

8.1.1 材料 25

8.1.2 初定轴的最小直径 25

8.1.3 根据轴定位的要求确定轴的各段直径和长度 25

8.1.4 小锥齿轮的受力分析 26

8.1.5 键的校核 26

8.1.6 I轴轴承的校核 26

8.1.7 轴上载荷的计算 28

8.1.8 按弯扭合成应力校核轴的强度 29

8.2 II轴的设计计算 29

8.2.1 材料 29

8.2.2 初定最小直径 29

8.2.3 联轴器的选择 29

8.2.4 根据轴的定位要求,确定各段直径和长度 30

8.2.5 大锥齿轮轴的受力分析 30

8.2.6 键的校核 30

8.2.7 轴承的校核 30

8.2.8 轴上载荷的计算 32

8.2.9 按弯扭合成应力校核轴的强度 33

9 结论与展望 35

致谢 37

参考文献 39

1 绪论

1.1 无轴式搅拌机研究发展现状

改革开放35年以来,中国混凝土搅拌机市场从无到有、从小到大。目前,我国年产水泥混凝土约为15亿,搅拌机的年产量也居世界前列。相比较而言,我国具有的自主知识产权技术也很少。但随着商品混凝土的大力推广、工程建设施工的高效率化、高质量化和高效益化,推动了混凝土搅拌设备向高效率、高质量的方向不断发展,一些传统设备己经无法满足施工要求。

在现有的搅拌机的基础上,对新型搅拌设备的研究和开发,提高混凝土搅拌机的设计水平,同时带动相关技术的发展,创造一个良好的生产空间;对高效混凝土搅拌机的开发,推动搅拌及机事业性能的快速发展,生产出适应市场要求、具有高可靠性和较强竞争力的搅拌机。依据新的搅拌原理,采用理论探讨和试验分析相结合的办法,能方便解决大型双卧轴搅拌机存在的低效率问题,如果生产工业化成功应用,一定为研制具有自主知识产权的高效搅拌机做出重大贡献。

长期以来,国内外搅拌设备虽然种类很多,但他们的共同特点:有一根轴贯穿整个搅拌空间。“双螺旋轴搅拌机”是一种新型的“无轴”搅拌机,它具有双倍的径向进给料流,双倍的轴向进给料流,双倍的剪切力,使搅拌效率达到普通搅拌机的两倍,能耗更小。“双螺旋轴搅拌机”无水平的主轴,不会产生混凝土黏合中心轴并产生结块形成抱轴的现象,更适合于加工粘性强和添加有纤维的混凝土材料。

20世纪70年代未至80年代初,我国为了适应建筑业有关方面混凝土发展的需要,在引进国外搅拌机的基础上,研制出了10多种混凝土搅拌楼(站)。经过引进研究、自主开发生产等几个阶段,到本世纪初,我国搅拌机技术得到更大的发展,在产品型号和生产数量上,都达到了一定规模,出现了一批更具有自主知识产权的新产品,并开始形成了一个具有一定规模和竞争能力的产业。2006年,我国生产装机容量0.5~6的搅拌站2100多台,已成为搅拌设备的研究和生产大国。

自上世纪八十年代初已经开始研制JS系列双卧轴混凝土搅拌机,一直到现在,已研制出从JS35~JS6000系列搅拌机,一直处于国际领先水平,尤其从2000年开始采用UG等三维软件,对搅拌机研究进行优化设计,对搅拌设备进行了动力分析和受力分析,大大提高产品的可靠性,达到国际先进水平。这些搅拌机的研制,基本满足了我国混凝土发展的需求,但随着主机市场的不断发展,新型主机的需求越来越多。无轴式搅拌机在国外也处在研究发展阶段。

1.2搅拌机的各种类型及特点

目前使用的搅拌机就其原理而言,其基本上可分为自落式和强制式两大类。

自落式搅拌机有较长的历史,早在20世纪初,混凝土搅拌设备开始不断出现。50年代后,人们研发出反转出料式和倾翻出料式的双锥形搅拌机,同时,其他一些搅拌机,如裂筒式搅拌机等相继问世。运作时,拌筒绕着水平轴线旋转,加入搅拌筒内的物料,叶片将物料提升至一定高度,然后借助自重下落,这样不断的循环运动,达到搅拌的理想效果。自落式混凝土搅拌机的结构简单,一般以搅拌塑性混凝土为主。但自落式搅拌机已不符合国家的有关标准,属于淘汰产品,所以本文不作研究。

强制式搅拌机从20世纪50年代初兴起后,得到了迅速的发展和生产推广。最先出现的是圆盘立轴式强制混凝土搅拌机。这种搅拌机分为涡桨式和行星式两种。19世纪70年代后,随着轻骨料的出现,研制出了圆槽卧轴式强制搅拌机。

实践证明,在上述混凝土搅拌设备的搅拌主机在工作中经常出现混凝土 “抱轴”现象。如果不及时停机清除,“抱轴”的混凝土会越来越多,将会引发搅拌机电机因过载而堵转,造成电机烧毁。

川公网安备: 51019002004831号

川公网安备: 51019002004831号