液压两工位加紧装置的分析与计算【6张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:

编号:6044192

类型:共享资源

大小:1.07MB

格式:ZIP

上传时间:2017-10-30

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

液压

两工位

加紧

抓紧

装置

分析

计算

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

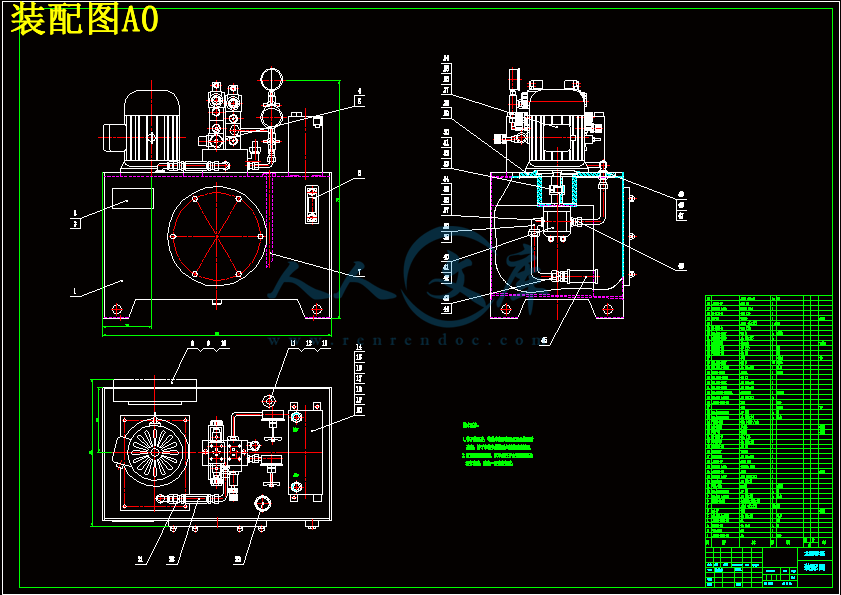

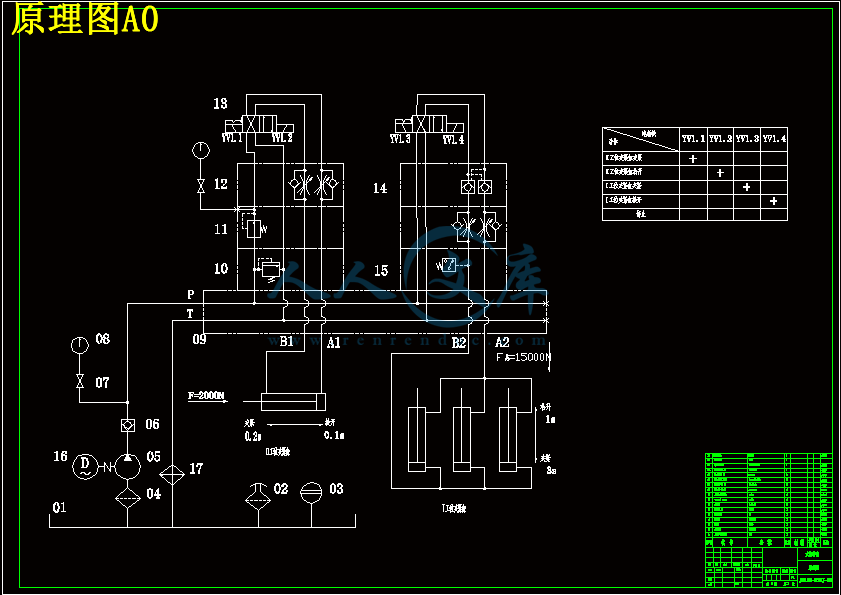

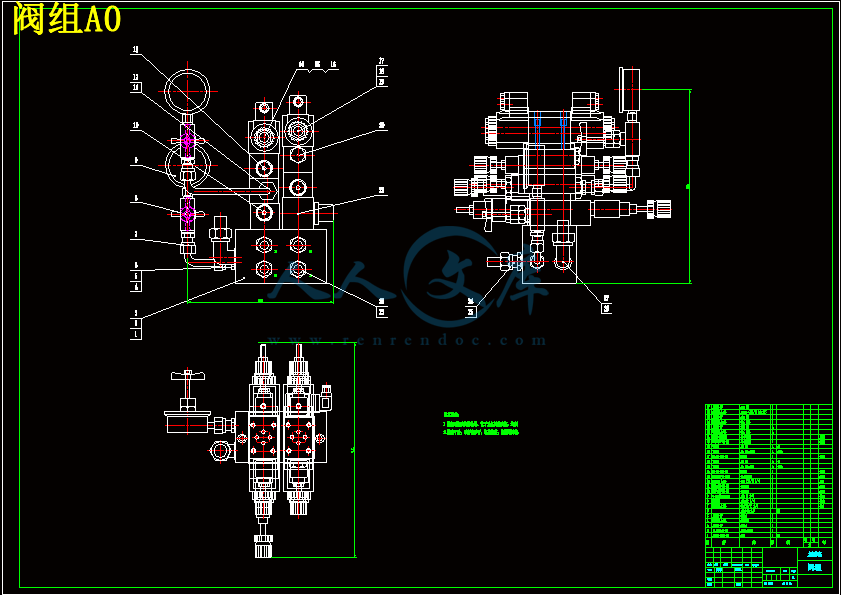

编 号无锡太湖学院毕 业 设 计 ( 论 文 )相 关 资 料题目: 液压两工位夹紧装置的分析与计算 信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923050学生姓名: 张佳睿 指导教师: 陈伟明(职称:教授 )(职称: )2013 年 5 月 25 日目 录一、毕业设计(论文)开题报告二、毕业设计(论文)外文资料翻译及原文三、学生“毕业论文(论文)计划、进度、检查及落实表”四、实习鉴定表无锡太湖学院毕 业 设 计 ( 论 文 )开 题 报 告题目: 液压两工位加紧装置的分析与计算 信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923050 学生姓名: 张佳睿 指导教师: 陈伟明 (职称:教授 )(职称: )2013 年 05 月 25 日 课题来源工厂科学依据(包括课题的科学意义;国内外研究概况、水平和发展趋势;应用前景等) 随着科学技术的发展,机电产品日趋精密复杂。产品的精度要求越来越高、更新换代的周期也越来越短,从而促进了现代制造业的发展。用普通的机床加工精度低,效率低,劳动度大,已经无法满足生产要求,从而一种新型的数字程序控制的机床应运而生。这种机床是一种综合应用了计算机技术、自动控制技术、精密测量和机械设计等新技术的机电一体化的产品。数控机床是一种装有程序控制系统的自动化机床,它对加工精度和自动化都有严格的要求。数控车床上的工位夹紧装置对于加工的精度有着直接的关系,以往的机床的工位夹紧装置使用简单的机械装置,在加工时容易产生大的加工误差。随着数控车床自动化程度的提高,使用液压系统控制这一过程已经大大提高了自动化和加工精度。液压传动在机械设备中的应用非常广泛。有的设备是利用其能传递大的动力,且结构简单、体积小、重量轻的优点,如工程机械、矿山机械、冶金机械等;有的设备是利用它操纵控制方便,能较容易地实现较复杂工作循环的优点,如各类金属切削机床、轻工机械、运输机械、军工机械、各类装载机等。所以研究液压系统有很好的应用价值和广阔的前景。我国进入世界贸易组织之后,对我国的机械行业是个机遇,更是一个艰难的挑战。因此作为二十一世纪的主人,我们更应该通过作大量的设计制造和广泛地使用各种先进的机器,以便能加快我国国民经济的增长速度,加快我国现代化建设。 研究内容液压系统的设计拟采取的研究方法、技术路线、实验方案及可行性分析1. 分析 本文根据液压系统的技术指标对数控铣床两工位夹紧装置液压系统进行整体方案设计,对其功能和工作原理进行动力分析和运动分析,初步确定了系统各回路的基本结构及主要元件。2. 计算 按照所给机构性能参数和液压性能参数进行元件的选择计算。3. 设计 对两工位夹紧装置液压系统整体设计。4. 作图 元件设计完毕,根据尺寸进行 CAXA 作图,尺寸精确,布局合理,作出总图及原理图。5. 验证 对系统性能的进行验算和发热校核,以满足该铣床所要达到的要求。研究计划及预期成果20012 年 11 月 12 日-2013 年 12 月 25 日:按照任务书要求查阅论文相关参考资料,填写毕业设计开题报告书。2013 年 1 月 11 日-2013 年 3 月 5 日:填写毕业实习报告。2013 年 3 月 8 日-2013 年 3 月 14 日:按照要求修改毕业设计开题报告。2013 年 3 月 15 日-2013 年 3 月 21 日:学习并翻译一篇与毕业设计相关的英文材料。2013 年 3 月 22 日-2013 年 4 月 11 日:液压系统图的设计。2013 年 4 月 12 日-2013 年 4 月 25 日:液压站的设计。2013 年 4 月 26 日-2013 年 5 月 20 日:毕业论文撰写和修改工作。预期成果:能够顺利的设计出数控铣床两工位夹紧装置液压系统,并且能够成功的应用于实际工作当中,起到相应的作用,提高生产率和产品质量,减轻工人劳动强度,为公司降低生产成本。特色或创新之处 设计过程中要重视设计方法和设计工具的现代化,积极推广应用价值工程。 通过阅读大量的资料,参考一系列液压传动,设计出尽量使液压传动的可靠性,加工精度,变速范围,操作宜人性,工作效率及防护结构适合实际使用已具备的条件和尚需解决的问题 尚需解决的问题:液压系统的设计、液压系统原理图的拟定和方案论证、液压装置的总体配置等。指导教师意见指导教师签名:年 月 日教研室(学科组、研究所)意见教研室主任签名:年 月 日系意见主管领导签名:年 月 日英文原文Machinery, Machina Mechine derived from the Greek and Latin,Mechanical gear (figure 1) means clever design, as a general mechanical concept, can be traced back to the Roman period, main is to distinguish and hand tools. Of modern Chinese language the word Machine is organization is (Mechanism) of the English and the floorboard of the Machine (the Machine). Mechanical characteristics are: machinery is a combination of physical components. To determine the relative motion of mechanical parts. So the Machine can convert mechanical energy or accomplish useful mechanical work, is the most basic concept in modern mechanical principle, the modern concept of Chinese machinery more derived from the word Machine of the Japanese, Japanese machinery should supplies to do the following definition (that is, in accordance with the following three characteristics is called mechanical Machine) :1, the machinery is a collection of objects, concentration to the various parts are also difficult to deformation.2, the object must implement the mutual movement, single, regulations.3, to exert energy into a useful form, or converted into mechanical work effectively.Mechanism and machine definition is derived from the mechanical engineering, belongs to the most basic concept of modern mechanical principles, mechanical more modern concepts derived from Chinese of the word machine in Japanese.All have certain sports machine and the floorboard of the system. Such as machine tools, tractors, etc.Mechanical engineering is related to the theoretical basis of natural science and technology,Mechanical gear (figure 2) combined with the accumulation of technical experience in the production practice, study and solve in the development, design, manufacture, installation, use and repair of all kinds of machinery an applied subject of theoretical and practical problems.Every development in the field of engineering requirements in mechanical engineering has adapted to the development, need mechanical engineering provides the necessary machinery. Some mechanical invention and improvement, and could lead to new engineering technology and the emergence and development of new industry. Large machinery manufacturing success, for example, led to the establishment of electric power system; The invention of the locomotive led to the rise of railway engineering and railway undertakings; The invention of the internal combustion engines, gas turbines, rocket engines, etc and progress, as well as the successful development of aircraft and spacecraft has led to the rise of aviation and aerospace business; The development of high voltage equipment lead to the success of many new synthetic chemical engineering and so on.Mechanical engineering is in all respects under the pressure of rising demand for development, at the same time from different disciplines and the advancement of the technology improved and innovative ability.Machinery is a simple device, it can transfer energy, force from one place to another place.Mechanical gear (FIG. 3) it can change the shape of the object structures to create new objects. In life, all around us there are thousands of different kinds of machinery in the work for us.Everyday understanding of mechanical is a mechanical device, which is all kinds of machines and equipment.From the point of view of mechanical professional: machinery has a very important basic position.Machinery is a modern society the five factors of production and service (that is, people, money, energy, materials and machinery).When Marx to industrial society, industrial society, especially in big industrial society, which is machine production machine age.Whether from life in contact with all kinds of physical devices, such as telephones, electric lights, television, refrigerator, elevator and so on contains the machine, or included in the general machinery, and from the point of production, all kinds of machine tools, automation equipment, aircraft, ships, god five, six, and so on, are short of machinery.So, machinery is one of the foundations of modern society. If someone say agriculture is the foundation, also understandable, but in modern society, mechanical serve as the basis for the rest of the industry and engineering, it is no exaggeration to think is the big pillar in society.Any modern industrial and engineering applications require machinery, is the Peoples Daily life, are increasingly used all kinds of machinery, such as cars, bicycles, watches and clocks, cameras, washing machine, refrigerator, air conditioner, vacuum cleaners, etc.The first machine is defined as the Roman architect vitruvius pollio (Vitruvii) in itMechanical gear (figure 4) for building ten book mainly for carrying heavy things work machinery and tools: the difference between mechanical (machane) and tools (organon) seem to have the following differences between. The machine is most artificial and very big power and effect, such as heavy ballista and grapes press. While the tool is a manipulation of the staff carefully processing, to achieve the purpose of such as were the shape of light range ballista or circular spiral device. Thus, tools and machinery are used in the indispensable thing. The ancient Greek for cylindrical gears. Alexandria, Mr Hiro (Heron of Alexandria) in the 1st century first discussed the basic elements of machinery, mechanical elements considered to be five classes: wheel and shaft, lever, pulley, wedge, spiral. Hiros discourse reflects the classical mechanical characteristics. BC China has guidelines on the application of complex gear system, the incense burner in the application of the permanent control level of the bogie and other parts of a cross. Annotations, said: the machine, the crossbow tooth; enclosed, the arrow around. Said wen jie zi explanation of machine is machine, the main mover , refers to the crossbow.Mechanical in leipzig, Germany in 1724 and liao poulter (Leopold) is defined as machines or tools is a kind of artificial device, use it to produce favorable movement; at the same time cant use other ways to save time and power, it can save. British mechanics, Willis (truly illis) in its agency theory (The Principle of Mechanism, 1841) give The definition of:Machinery gear speed reducer any machine (machine) are made in a variety of different ways of connecting a set of artifacts that make it a component, the component will happen in a certain sport, these artifacts and the initial movement of the components of relative motion relationship depends on the nature of the connections between them. German machinery at le loro (F.R euleaux) in the theory of kinematics (Theoretische Kinematik, Grundzuge einer TheorieChina is the worlds first national machinery development. Chinese mechanical engineering technology not only has a long history and splendid achievements in Chinese is not only the material culture and social economic development plays an important role in the world, and to promote the progress of civilization, technology has made great contribution to Chinese traditional machine. And in a long period ahead in the world. In modern times, especially from the early 18th century, due to the nineteen forties, due to the economic and social reasons, such as the China machinery industry, stagnation, in the 100 years is western bourgeois political revolution and industrial revolution, mechanical science and technology is developing rapidly, and far more than the level of China. So, China mechanical development level and the western gap widens, sharply to the 19th century middle behind western one hundred years.After the founding of new China, especially in the past 30 years, our countrys mechanical science and technology development speed. To the mechanical product large-scale, precision, automation and discusses the trend of development. In some aspects has reached or exceeded the world advanced level. Generally speaking, currently China mechanical science and technology achievement is huge, developing fast, high level of unprecedented. In this period, China has no end of mechanical science and technology will develop to a higher level. As long as we can adopt the correct policy, with good technology development and innovation, our machinery industry and mechanical technology can revitalize, leading to the development trend of mechanical industry.Just small ramming machinery:In the 1960s, China mechanical very small tamp lack, many small venues ramming basically USES artificial ramming.Early 1960s, changsha construction machinery institute and Beijing architectural engineering institute, etc., the technical innovation achievements in mass on the basis of summing up Chinese characteristic invented the breaststroke ramming machine, 1962 exceeded national science and technology. The breaststroke ramming machine structure is simple, easy to use and maintenance in 1960s, soon became the dominant products to consolidate machinery. According to not complete count breaststroke tamp cumulative yield reached more than 50,000 machine, in the economic development of our country has played an important role. Since 1970s, the breaststroke ramming machine was gradually more advanced performance of vibration shock ram and vibrating plate ram, now replaced by laying machine has rarely breaststroke, basically be eliminated. In 1964, changsha construction machinery institute HB120 developed movable type, type of Shanghai began laying machine, engineering machine production mainly by tianjin municipal later, annual production engineering machinery dongting about 200. In the 1980s, movable type ramming machine product quality has increased greatly, have exported to southeast Asia and Africa. Since 1990s, internal-combustion type ramming machine production sales, and gradually decreased in only a few small private enterprise production.In 1977, changsha construction machinery factory buildings and developed in liuzhou HZR250 type and the HZR70 type vibrating plate ram, these two kinds of products in 1979 and 1982 passed by the ministry of construction of the organization. Then yiwu building construction machinery factory, siping, anyang vibrators factory, tianjin municipal engineering machinery dongting and other enterprises have started producing vibrating plate ram. In 1986, changsha construction machinery research and develop a larger HZR450 type of vibrating plate ram. Since 1990s, vibrating plate ram in our country has developed very quickly, varieties of products, specifications and increase production enterprises, foreign vibrating plate ram gradually to enter the Chinese market.In 1983, changsha construction machinery institute and the joint development of hubei vibration in the first HZR70 type vibration shock ramming, 1984, passed by the ministry of construction, organization construction technology progress in 1985 won prizes. Due to the vibration impact compaction result has good ramming, productivity, high volume and weight of small, lightweight flexible outstanding characteristics, deeply user etc, obtained a rapid promotion, and soon ZiJiang development to the factory, xinxiang municipal engineering machine tool plant and tianjin dozens of dongting production factory etc. Vibration shock ramming although than vibrating plate ram, but later development speed of development, production and use of extensive than vibrating plate ram, has become the largest in China in the ramming machinery products. Since 1990s, foreign vibrating plate ram gradually to enter the Chinese market.Vibration shock ramming and vibrating plate ram the successful development in our country, not only for our construction department provides advanced performance of mechanical, laying have achieved good economic benefit and social benefit, and make our ramming mechanical technology into a big step forward, shorten the gap with the advanced world level, promoting the development of compaction machine.The mechanical processing:According to the archaeological discovery, hot-working casting in Beijing pinggu, changping and so have proved that the 16th century BC shang dynasty (bronze objects. Ming yongle (1403-1424 years), Beijing produce world-renowned Ming yongle great 3-ton bell made (46.5 tons) and tower (63 tons of great 3-ton bell made of iron clock (25) and the furnace of melting, pit TaoFan model and method of casting. In the 1950s, Beijing based on clay sand castings in manual. In 1955, Beijing first machine tool plant began using leakage mould modelling, double-sided model and iron plate type plate and standard sand box modelling. In 1965, start using plastic model. In 1980, the institute and Beijing municipal electrical factory has successfully developed line frequency coreless bathroom plug stem bottom note type electric insulation casting. In 1982, hospital and Beijing the casting machine research cupola tuyere oxygen blowing technology. 1985-1988, Beijing institute of machine of floating end face seal ring by die successful test pressure casting process.In 1959, Beijing second metalforming machinery general factory changed (Beijing) built 2500 ton heavy-duty hydraulic press. In 1971, the factory produced 6,000 tons, which is then Beijing hydrtesting biggest metalforming equipment. 1968-1979, Beijing hoisting machine factory has 300 tons of using hydraulic press 2000 tons and create crane and large panel. In the 1980s, Beijing institute of electrical and developed a series of Beijing mould centre high-precision cutting die, the multistage close to or to import mould level, changed Beijing precision punching moulds dependence on imports.Before 1949, Beijing has heat treatment furnace, salt dissolved by thermocouples means furnace, quenching and tempering, parts of annealing, normalizing, quenching and tempering, carburizing and etc. In 1956, Beijing first began using high-frequency quenching machine tool plant. In 1961, the Beijing second machine tool plant began using gas nitriding quenching. In 1969, the following enterprise by Beijing gage start light quenching. In 1978, the complete machine tool research institute of Beijing guide surface contact quenching process and equipment, quenching condition of quality inspection. In 1979, scientific research institute of China academy of railway and mechanical institute of high-power diesel engine cylinder collaboration of surface modification of laser. In 1979, Beijing institute of electrical carbon dioxide laser is developed, and the kilowatt in early 1980s respectively applied in cylinder and stamp printing equipments of laser treatment. Among them, tsinghua university, Beijing, Beijing institute of electrical YouPiaoChang jointly completed YouPiaoChang seven color machine DaKongQi laser surface strengthening research. From 1984 to 1990, Beijing institute of vacuum heat treatment research, gas carburizing microcomputer control technology (Beijing university of aeronautics &astronautics and cooperation), rare earth soft nitriding, powder metallurgy products surface strengthening, kerosene and methanol small drops of microcomputer control method of carburizing, solid boriding and carburizing process computer aided process planning and tracking control system, and the application of new technology heat in production. Welding and cutting in 1949, Beijing has geo-drilling, electric welding and cutting etc oxyacetylene flame manual operation. In 1963, Beijing metal structure and YiJiBu mechanical science research cooperation to develop tungsten argon arc welding, and realize the nitrogen plasma cutting stainless steel. In 1964, the use of dc argon arc welding and tungsten wire alloying technology solved by tilting electrolysis industry worse pure nickel welding. In 1966, Beijing metal structure factory developed by rotating sphere of the submerged arc welding automatic welding. In 1968, the plant began to liquef

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号